A device that can evenly distribute copper wires in the cable shielding layer by using magnetic suction to fit the cable

A technology of cable shielding layer and magnetic attraction, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of low pressure, inability, and difficult to adjust quickly, and achieve the effect of preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

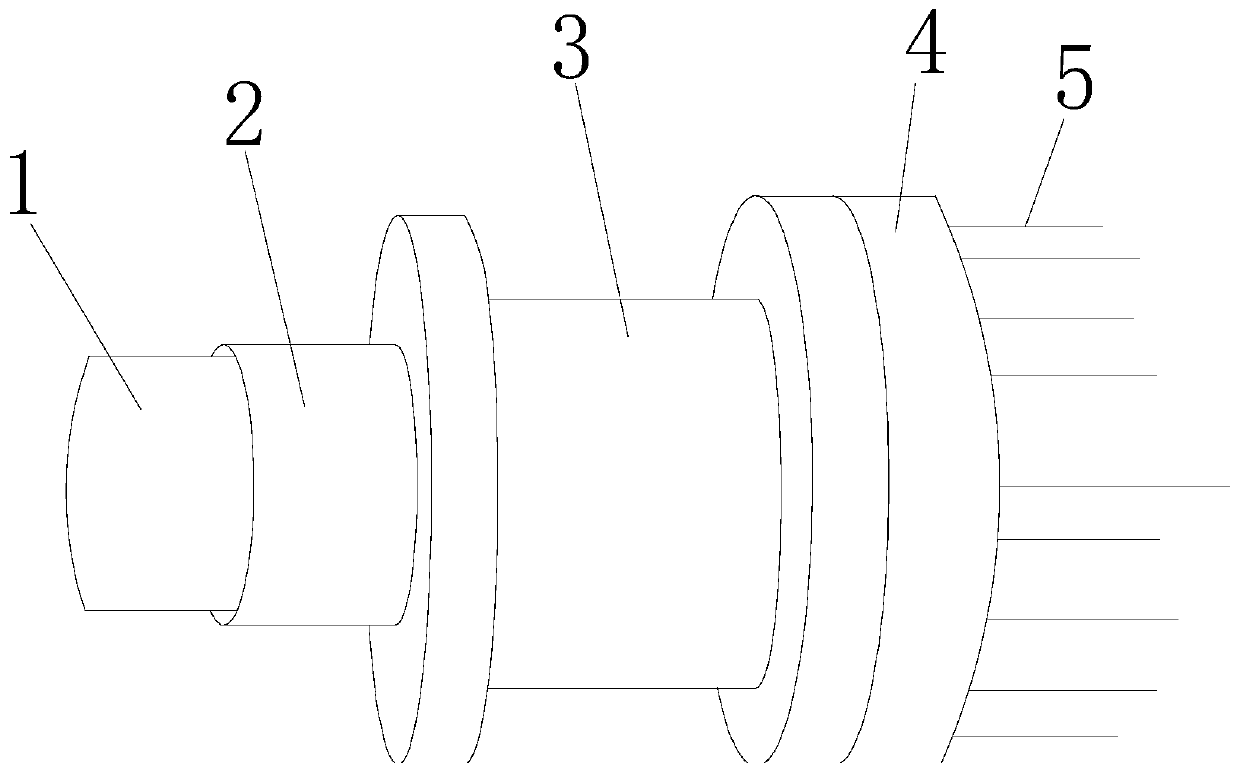

[0027] see figure 1 , the present invention provides a device that uses magnetic attraction to fit the cable so that the copper wires in the cable shielding layer can be evenly distributed, and its structure includes: 5. The protective frame 2 is set on the left end face of the movable wire covering device 3, and the copper wire is fixedly connected with the movable wire covering device 3, and the wire straightener 4 is set on the right end face of the movable wire covering device 3, and both are fixedly connected , the cable strip 1 is embedded in the protective frame 2 and is movably connected with the movable wire covering device 3 at the same time. The inside of device 4 is provided with a plurality of guide balls, and guides the whole line work for the inner copper wire through the guide balls.

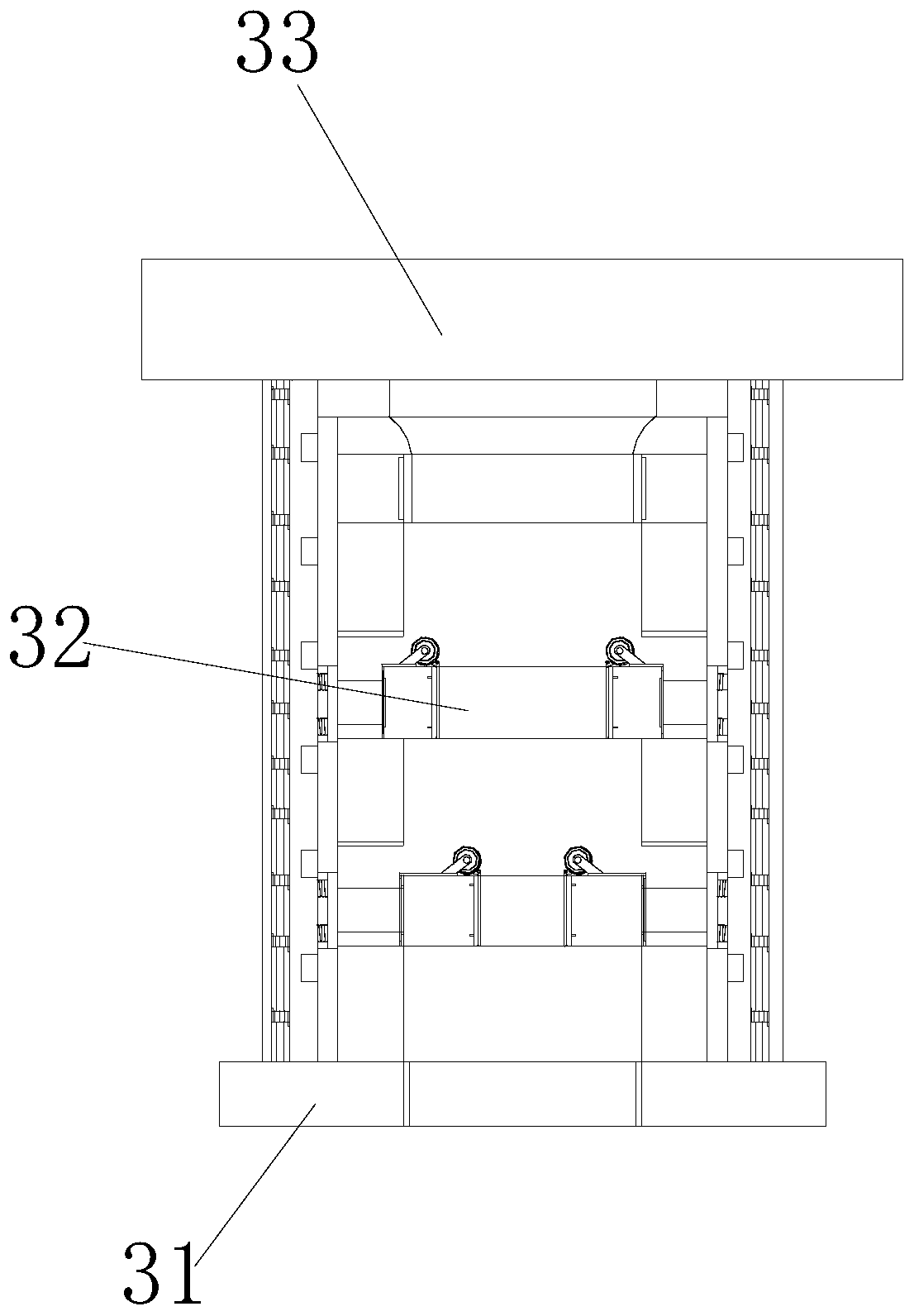

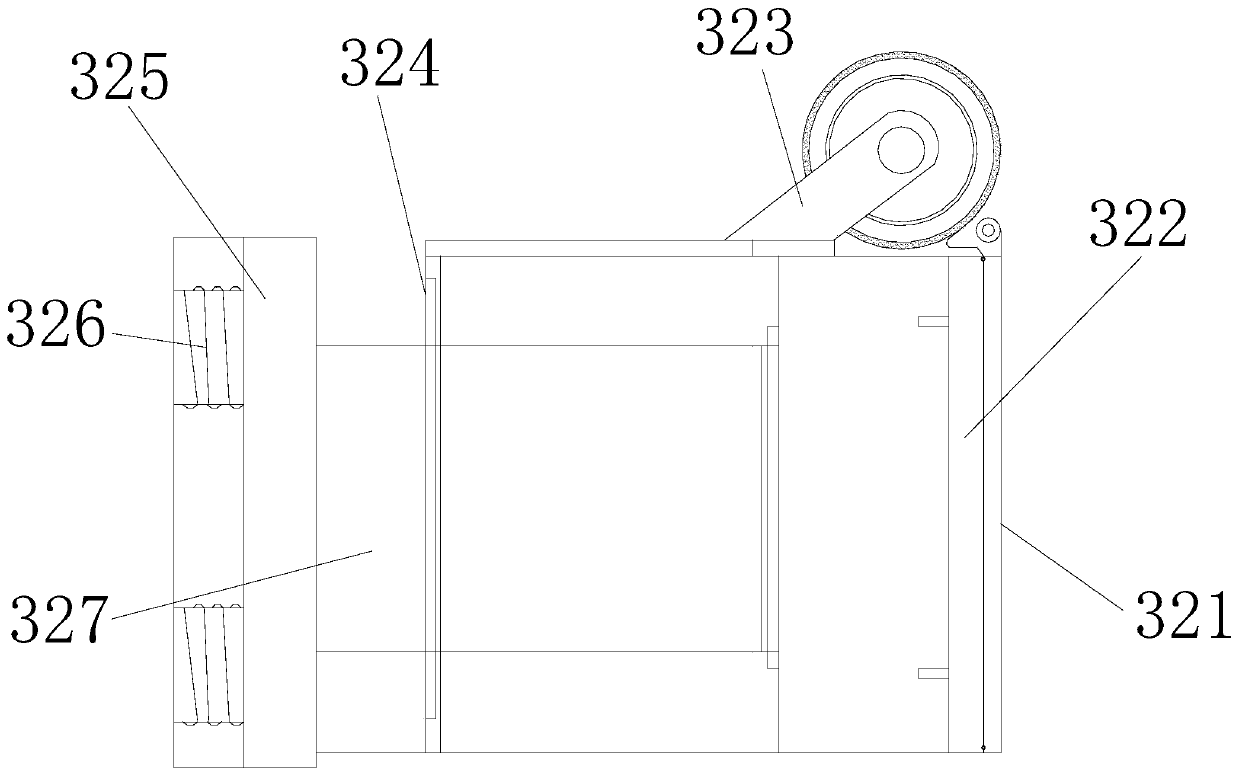

[0028] see figure 2 , the present invention provides a device that utilizes magnetic attraction to fit the cable so that the copper wires in the cable shielding layer can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com