Pilot control overflowing system for airplane pressure fuel filling

A technology of pilot control and pressure control, which is applied in the direction of liquid delivery devices, etc., can solve problems such as large diameter, heavy weight, and influence on aircraft flight attitude, and achieve the effects of safe refueling, simple control, and reliable flight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

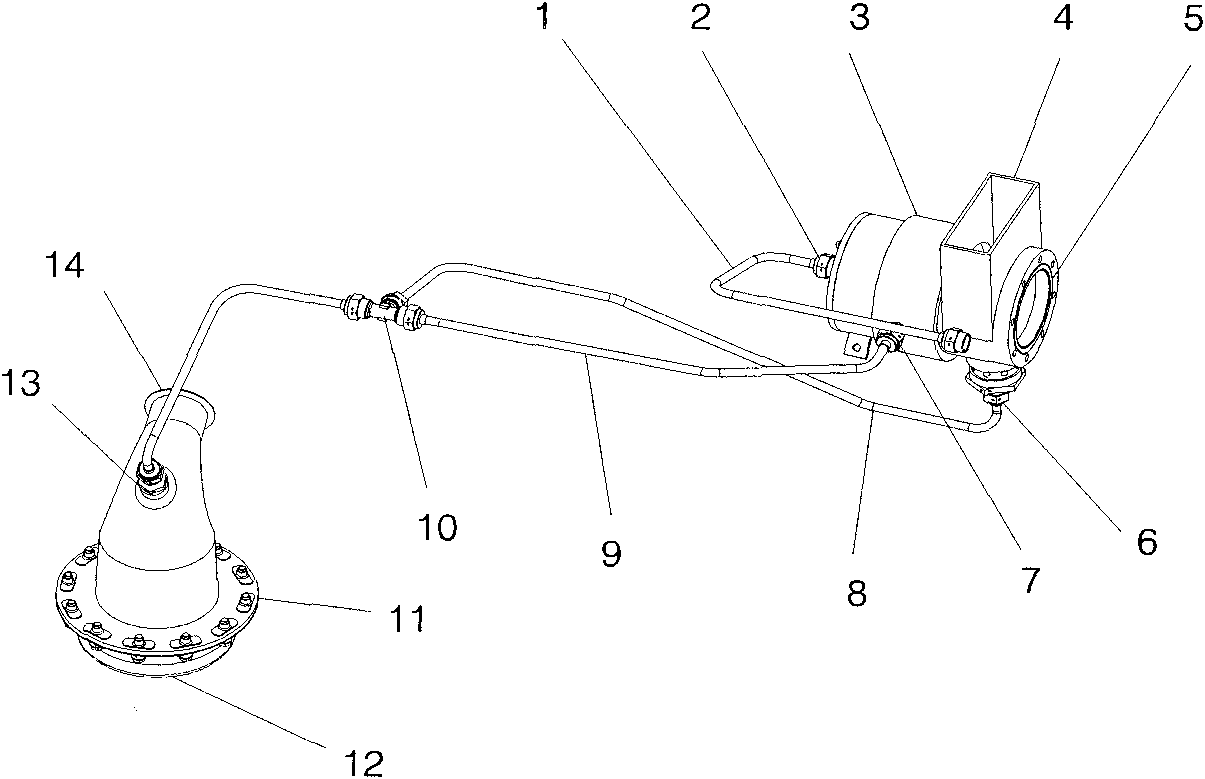

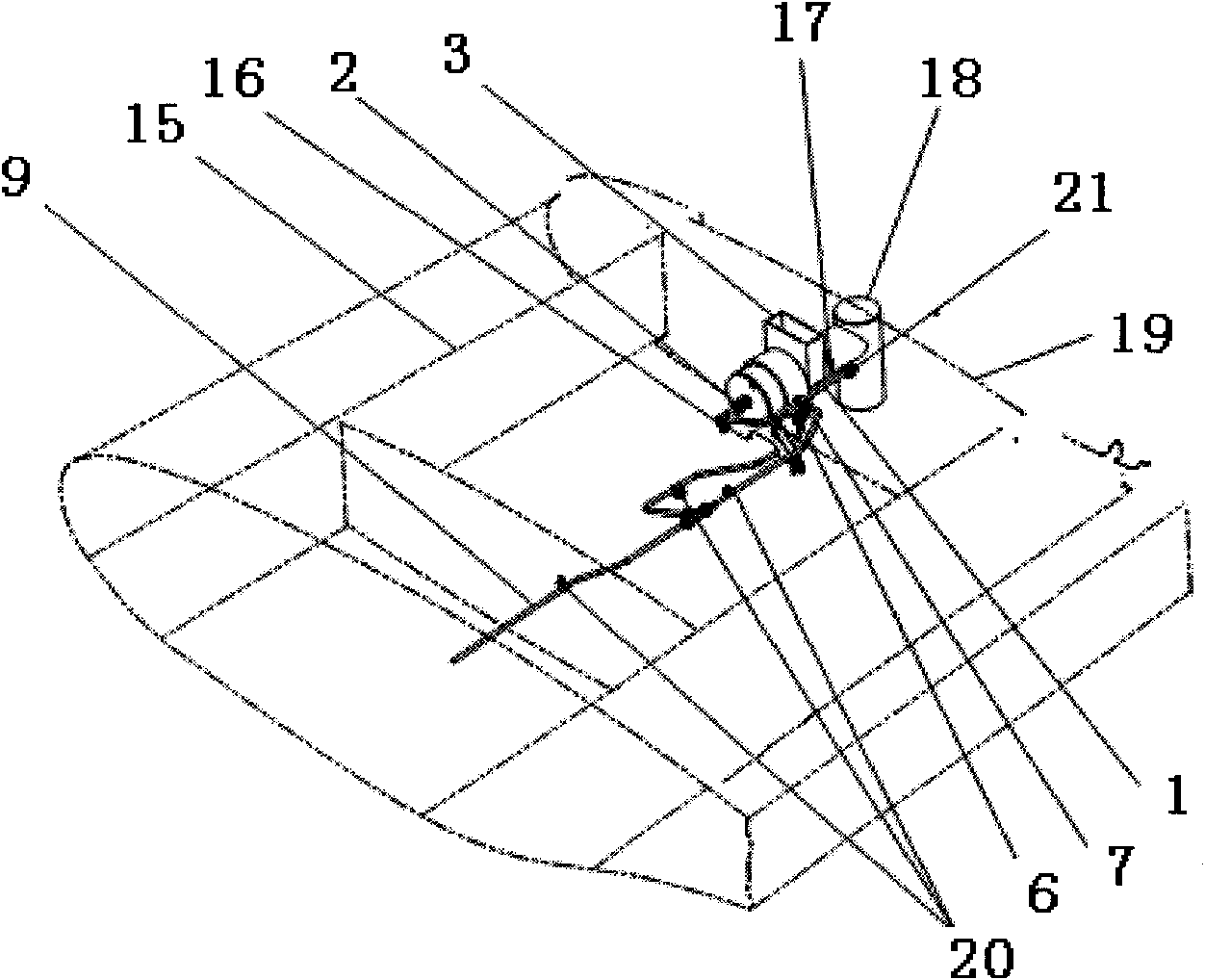

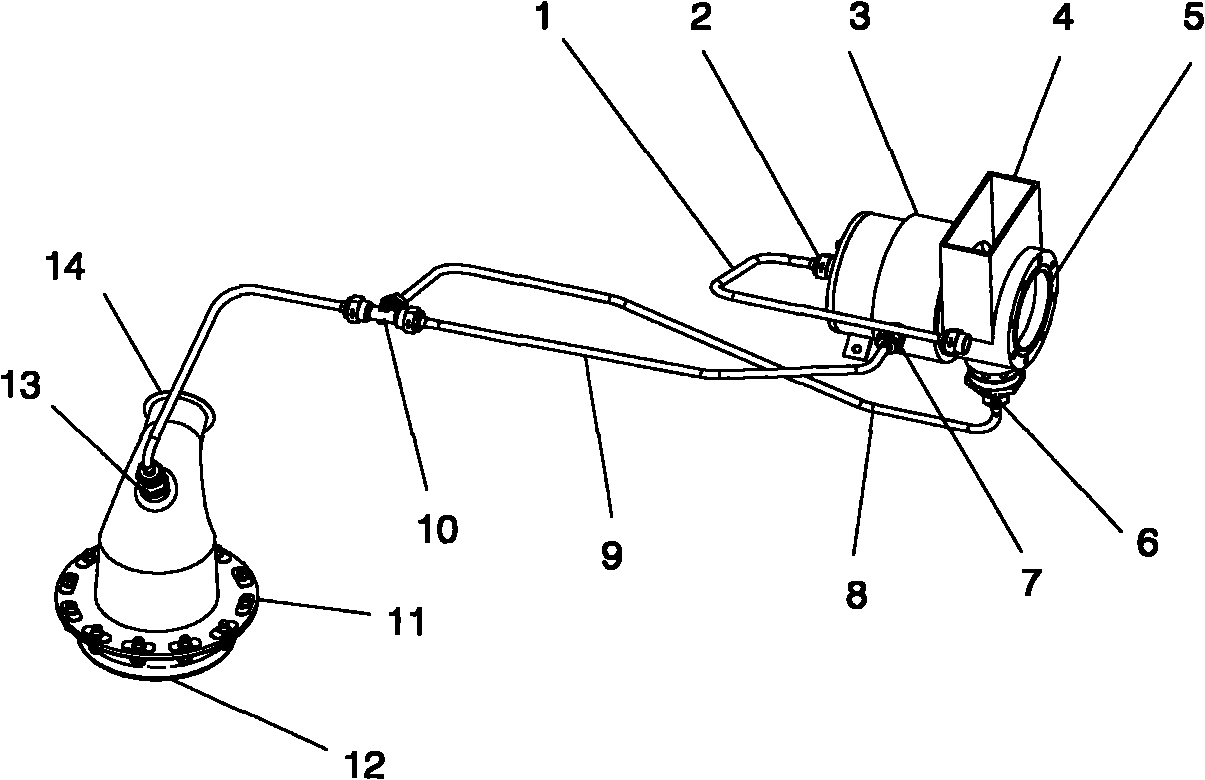

[0015] See attached figure 1 As shown, this kind of aircraft pressure refueling pilot control overflow system is characterized in that: the manifold 13 of the aircraft pressure refueling joint 11 passes through the three-way joint 10 and then divides into two ways to transmit pressure, and one way passes through the remaining oil control pipe 8 and the overflow The remaining oil discharge control joint 6 on the valve 3 is connected, and the other is connected to the pressure control joint 7 on the relief valve 3 through the pressure control pipe 9, and the ventilation balance joint 2 on the relief valve 3 is connected to the atmosphere through the ventilation balance pipe 1 .

[0016] When the aircraft is refueling, the pressure refueling vehicle generates pressure at the inlet 12 of the aircraft pressure refueling joint 11 and the manifold 13, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com