Strapping unit and method

A technology of binding device and working position, which is applied in the direction of binding materials, parts of binding machinery, paper/cardboard containers, etc., to achieve the effect of compact design and reduced quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

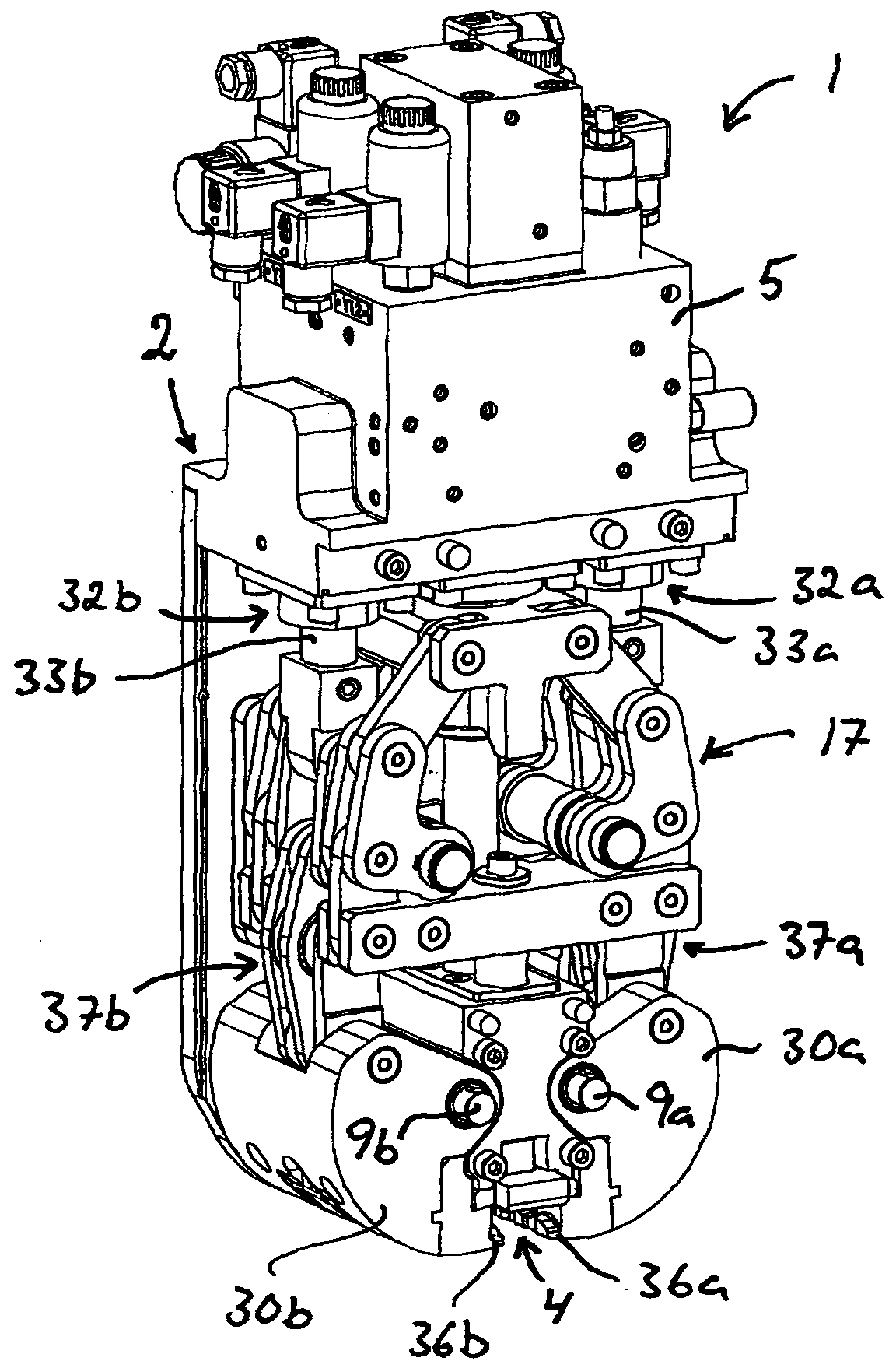

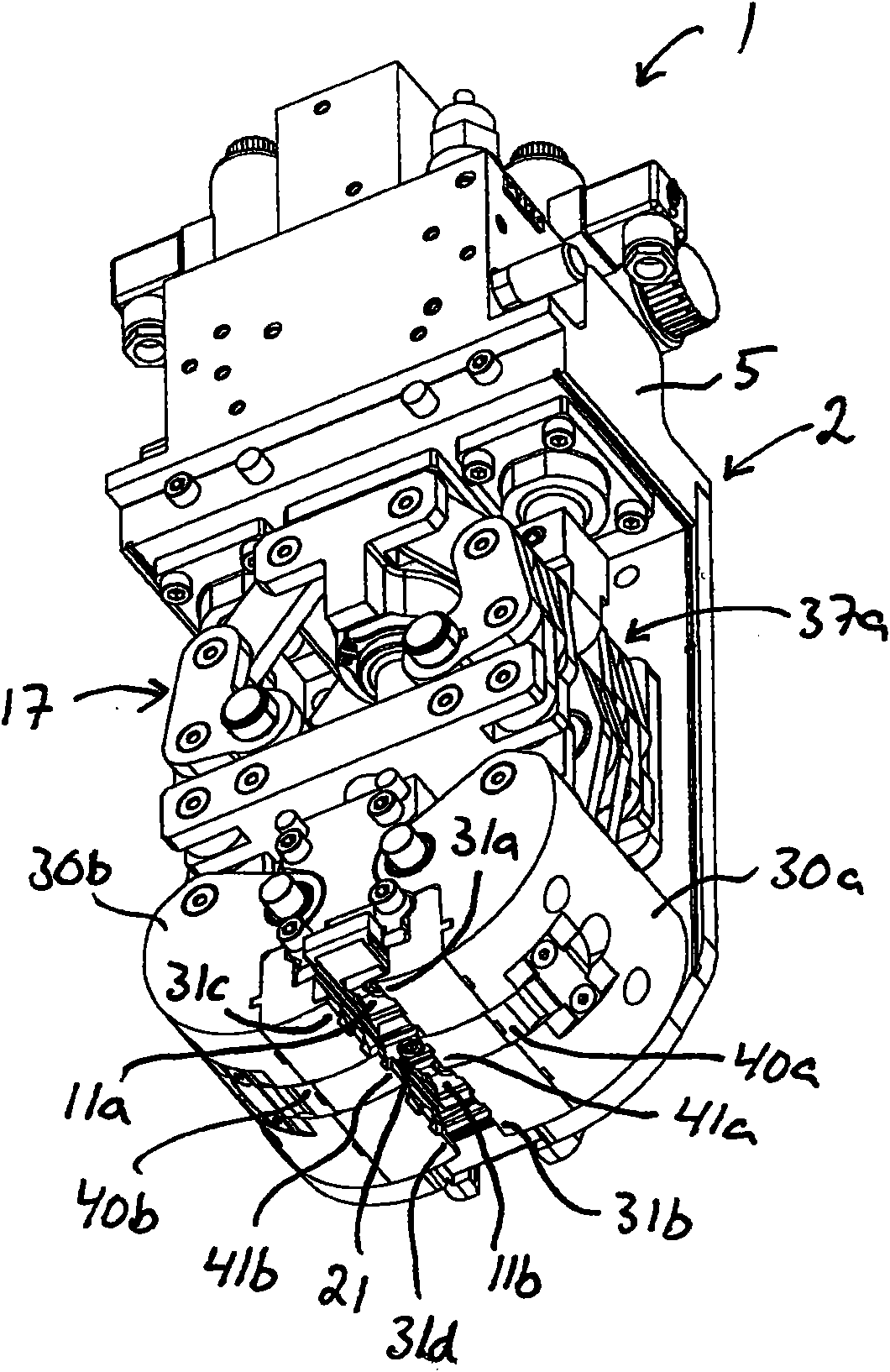

[0043] figure 1 and 2 A strapping device for forming a sealless joint in an overlap at the ends of a loop of metal strap is shown in accordance with an embodiment of the invention. The strapping device is shown here without a protective cover that would cover the central portion of the strapping device to protect the mechanisms contained therein.

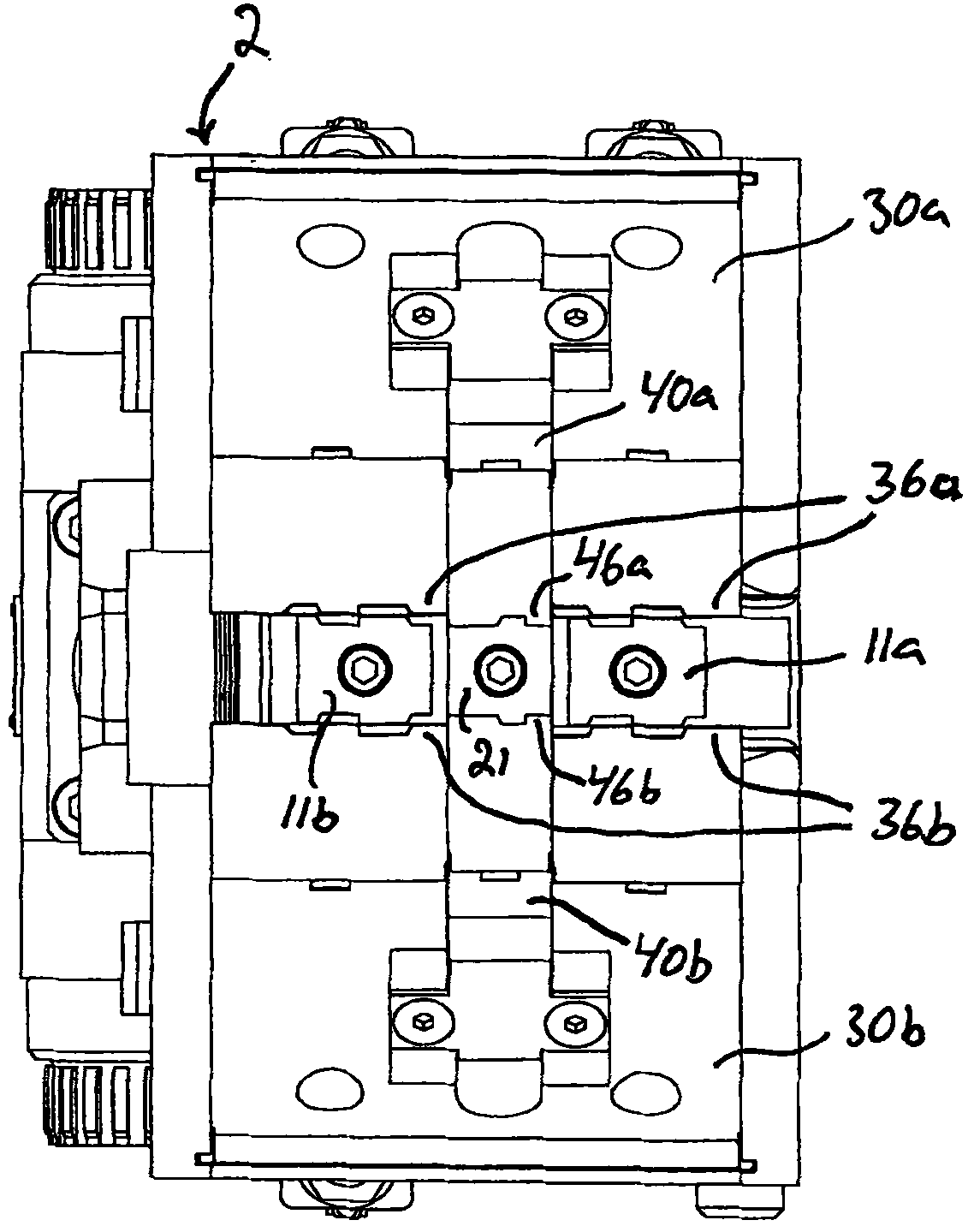

[0044] The strapping device 1 comprises a housing 2 . Main punch seat 10 (see Figure 3c ) is movably mounted in the housing 2 and carries a number of stamped parts 11a, 11b. In the illustrated embodiment, the two main stamping parts 11a, 11b are detachably mounted on the main punch holder 10 by means of screws or similar fastening elements, so that the corresponding main stamping parts can be replaced. By means of the first punch actuator, the main punching parts 11a, 11b can be brought together with the main punch holder 10 in the retracted position (see Figure 3c ) and feed stamping position (see Figure 5c ) to move back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com