Washing machine inner tub and washing machine

A washing machine and inner tub bottom technology, which is applied in the field of washing machines, can solve the problems of increasing energy consumption, secondary pollution of clothes, affecting the cleaning of the inner tub of the washing machine, etc., and achieves the effect of maintaining cleanliness and avoiding secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

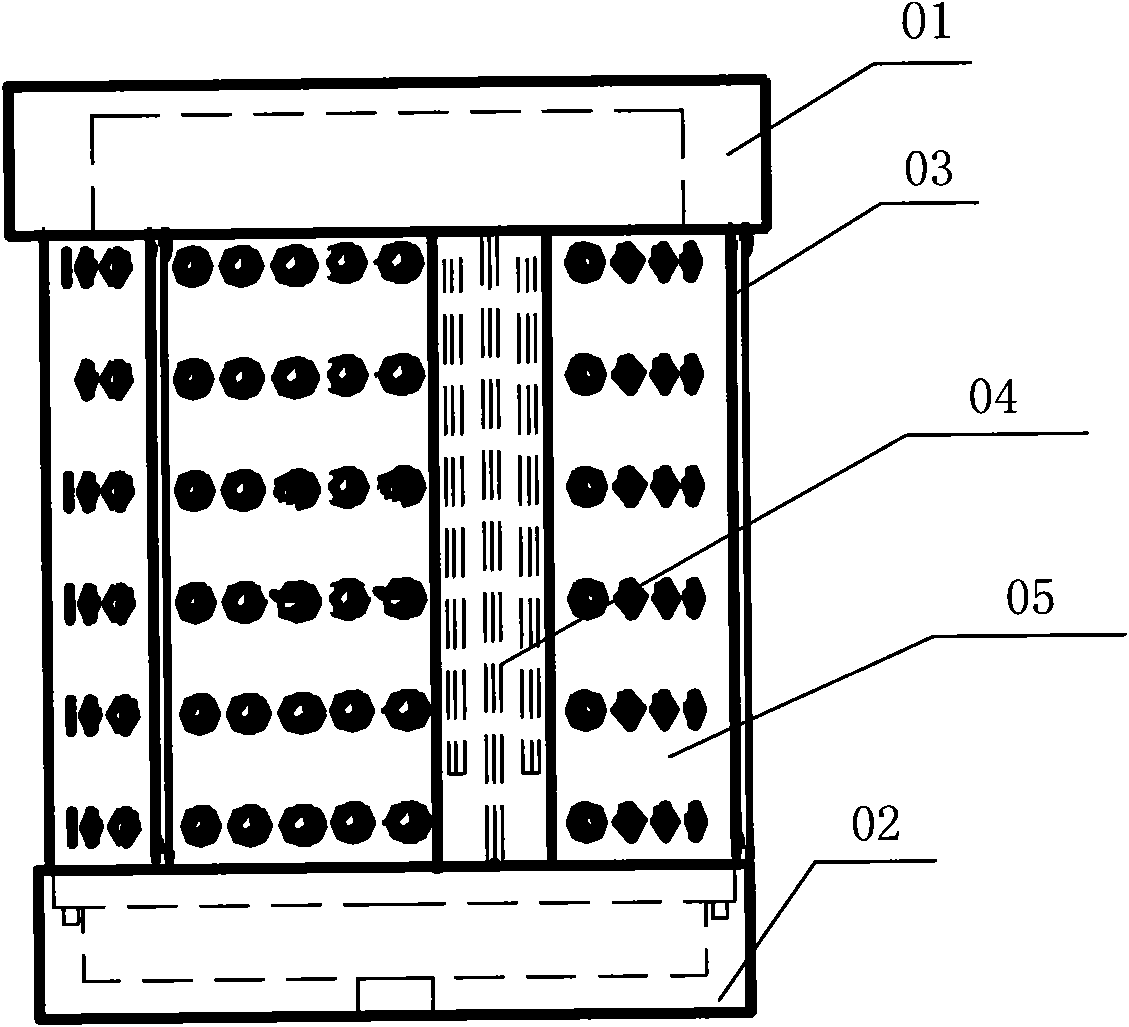

[0023] see figure 1 The inner tub of the washing machine provided in this embodiment includes: a balance ring 01 at the top and an inner tub bottom 02 at the bottom, and more than one cylindrical rod 03 and more than one support rib 04 are vertically arranged between the balance ring 01 and the inner tub bottom 02 alternately, The number of cylindrical rods 03 and supporting ribs 04 is equal, and an openable door body 05 is arranged between adjacent cylindrical rods 03 and supporting ribs 04 .

[0024] Wherein, after the door body 05 is closed, one end thereof is connected with the cylindrical rod 03 , and the other end is connected with the support rib 04 . When only one cylindrical rod 03 and one supporting rib 04 are arranged between the balance ring 01 and the inner barrel bottom 02, two door bodies 05 can be arranged between the cylindrical rod 03 and the supporting rib 04, but in this case, in order to ensure To successfully open the door 05 in the inner tub space of th...

Embodiment 2

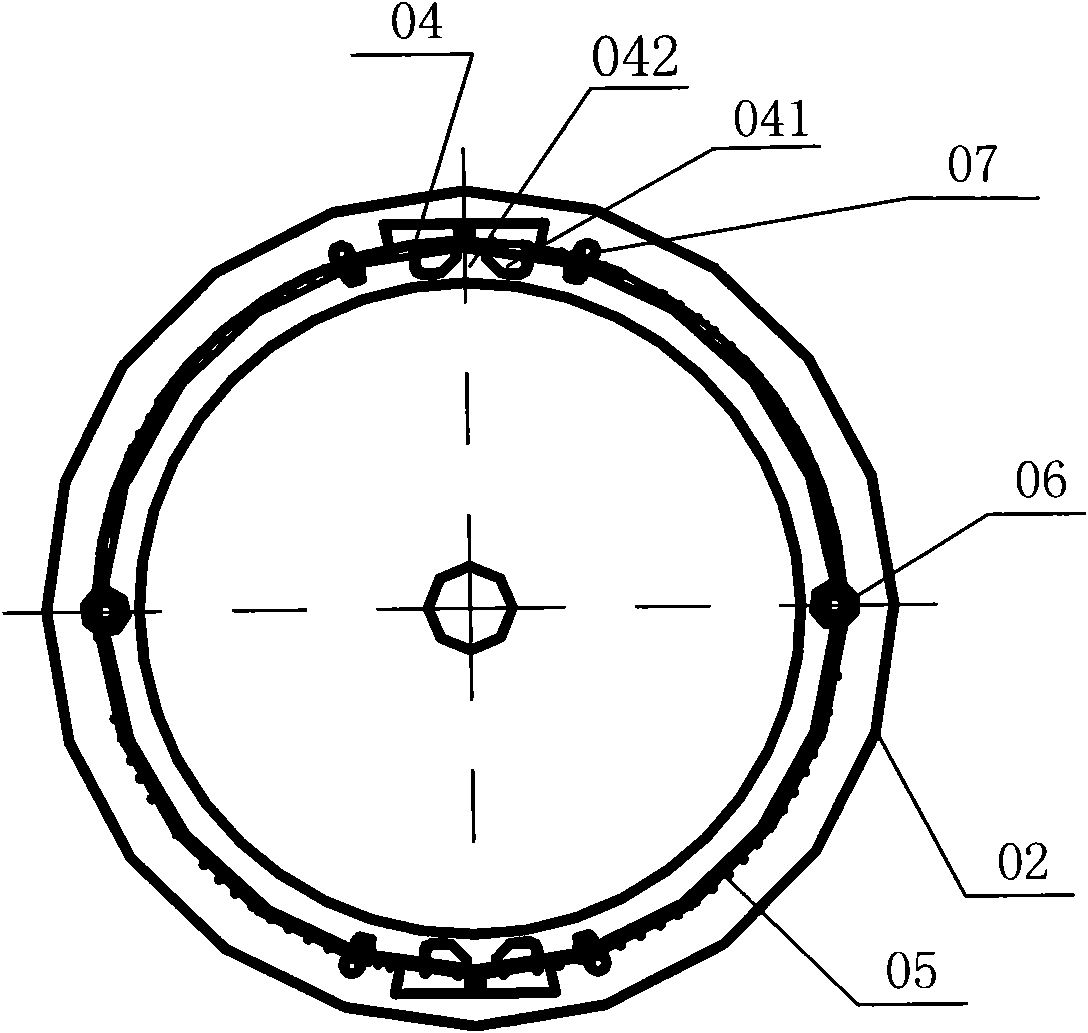

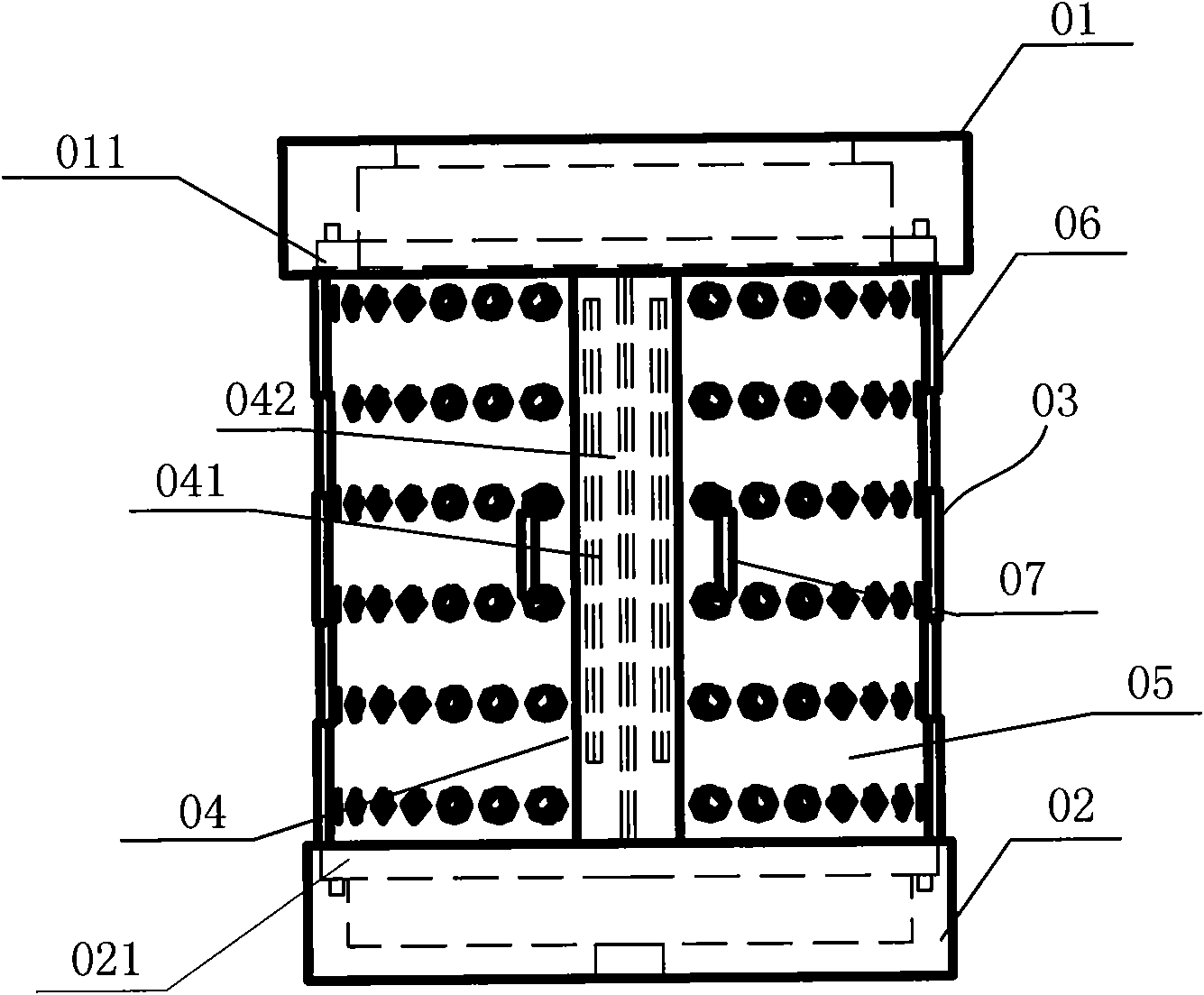

[0028] see figure 2 and image 3 The inner tub of the washing machine provided in this embodiment includes: a balance ring 01 at the top and an inner tub bottom 02 at the bottom, and more than one cylindrical rod 03 and more than one support rib 04 are vertically arranged between the balance ring 01 and the inner tub bottom 02 alternately, The number of cylindrical rods 03 and supporting ribs 04 is equal, and an openable door body 05 is arranged between adjacent cylindrical rods 03 and supporting ribs 04 .

[0029] Wherein, after the door body 05 is closed, one end thereof is connected with the cylindrical rod 03 , and the other end is connected with the support rib 04 . The number of cylindrical rods 03 and supporting ribs 04 can be determined according to the size of the circumference of the inner tub. Each door 05 is in the shape of an arc, and all the doors 05 on the circumference of the inner tub become cylindrical after being closed to form the inner tub of the washing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com