Thin coal bed fully-mechanized mining scraper conveyor

A scraper conveyor, thin coal seam technology, used in conveyors, earth-moving drilling, slitting machinery, etc., can solve the problems of pulling back the coal and the shearer can not cut, etc., to increase the chain spacing and improve the adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the drawings and embodiments.

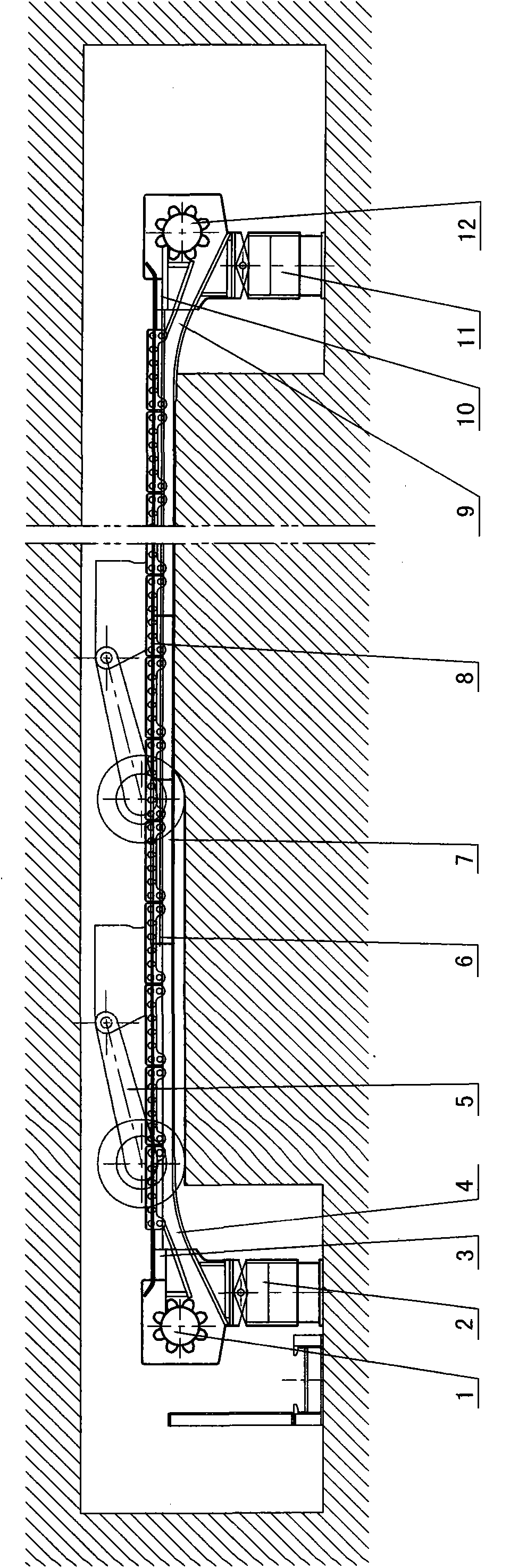

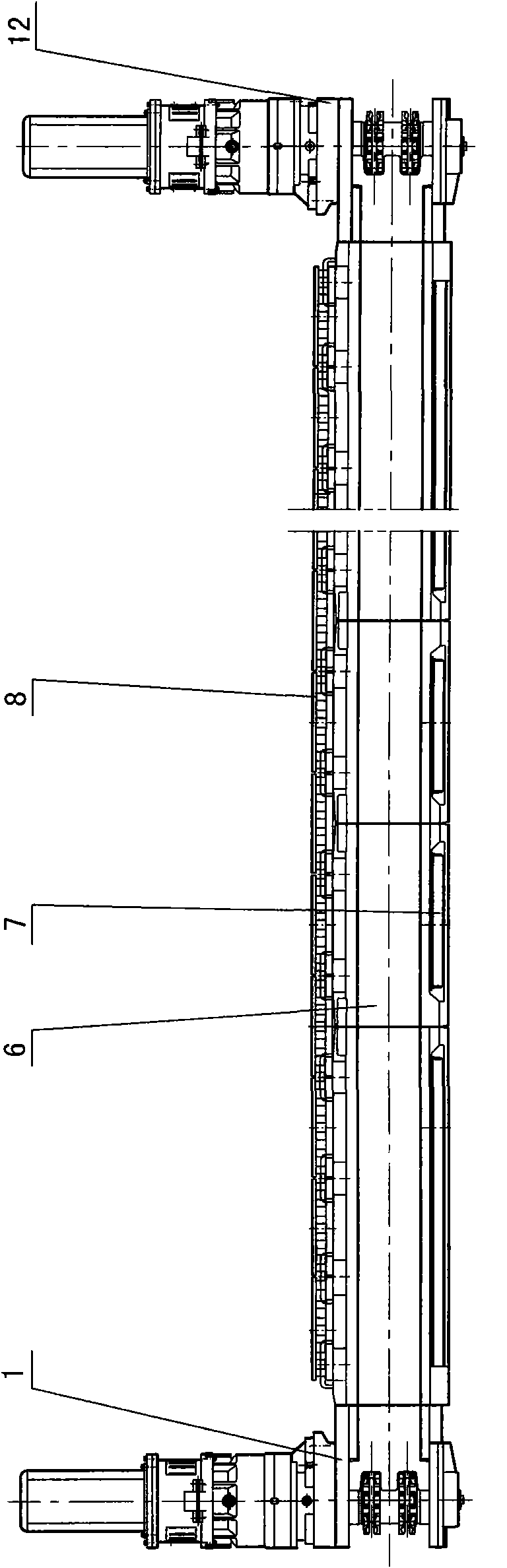

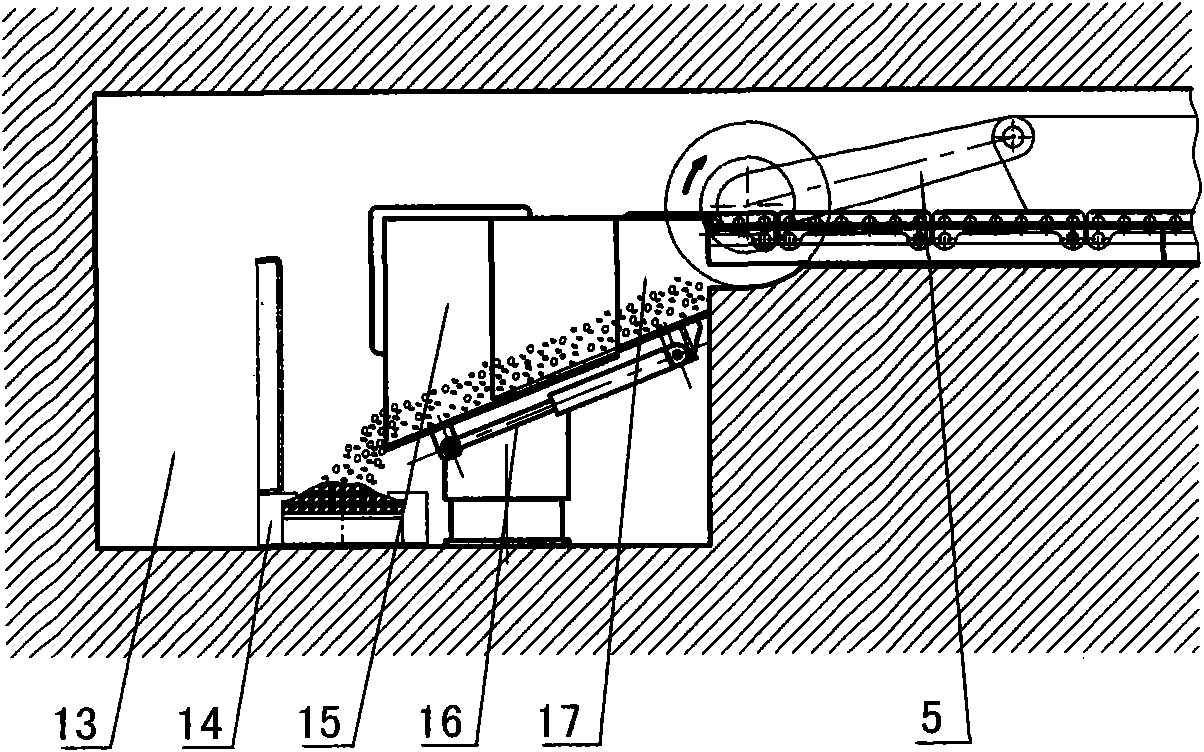

[0022] in figure 1 , 2 Shows the composition of the scraper conveyor for thin coal seams of the present invention. It is a scraper conveyor with a straight head and a tail plate, which is mainly composed of a head 1, a tail 12, a middle groove 6, a scraper chain, etc.

[0023] 1. The middle plate of the head and tail of the scraper conveyor are arranged straight:

[0024] ①In the entire laying length of the scraper conveyor, the middle plate of the head 1, tail 12 and the middle plate of the middle trough 6 are arranged horizontally, at the same height, and always kept consistent. The angle between the middle plate of the nose 1 and the tail 12 and the middle plate of the middle groove 6 is preferably about zero degrees, and can have an upward tilt angle of +6 degrees to a downward angle of -20 degrees. The upturn angle is smaller than the general-purpose scraper conveyor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com