Electrical connector and method for making the same

An electrical connector and connecting part technology, which is applied in the direction of connection, two-part connecting device, and components of the connecting device, etc., can solve the problems of unreliable coordination, complicated assembly of the electrical connector, and increased production cost of the electrical connector, etc. Achieve the effect of saving production cost, good contact and ensuring coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

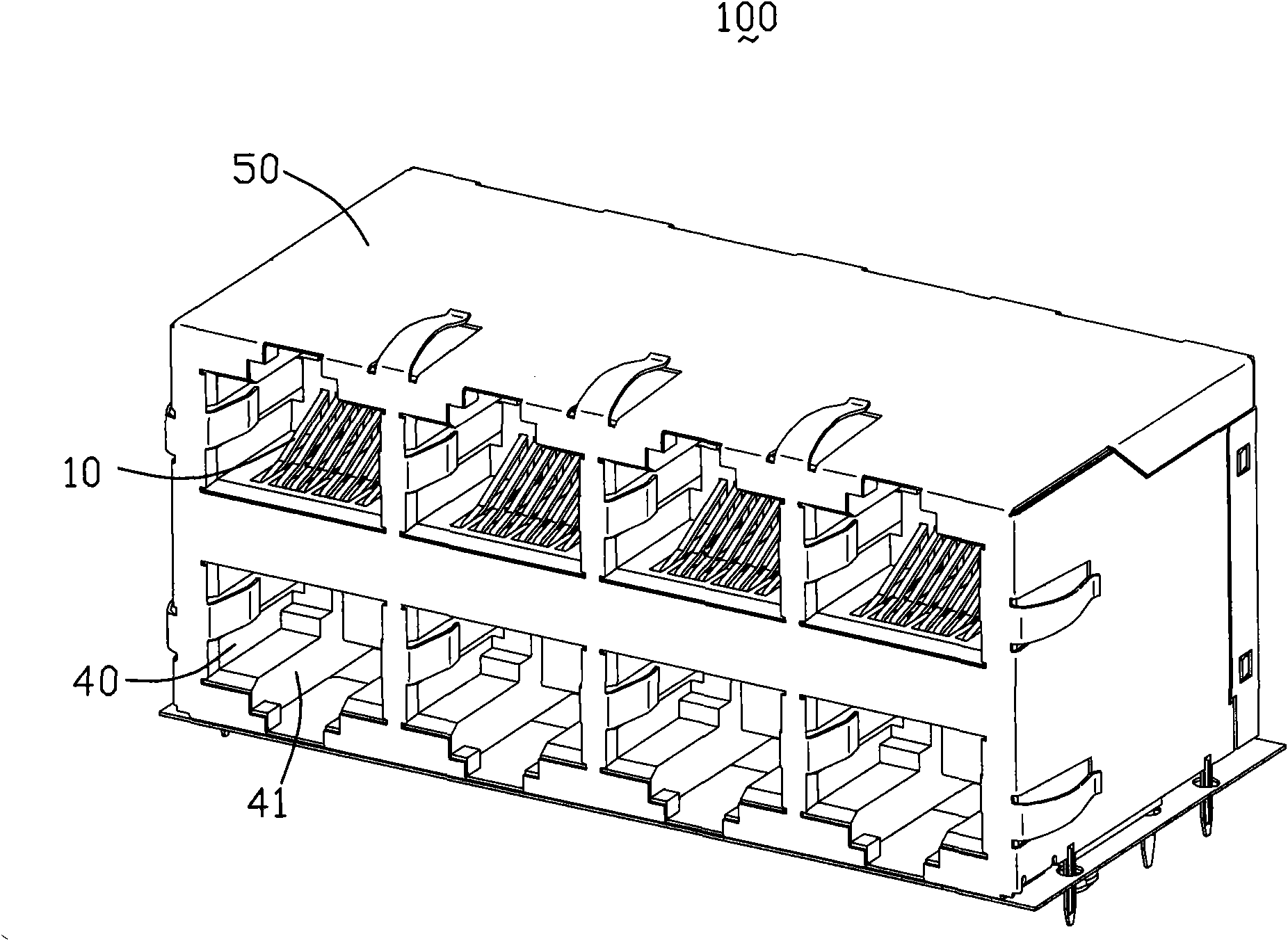

[0018] Such as figure 1 As shown, the electrical connector 100 according to the first embodiment of the present invention includes an insulating body 40 with a plurality of receiving cavities 41, a plurality of terminal modules 10 accommodated in the receiving cavities 41, and a shield covering the insulating body 40. Body 50. In other embodiments, the insulating body 40 can also be configured as a single interface.

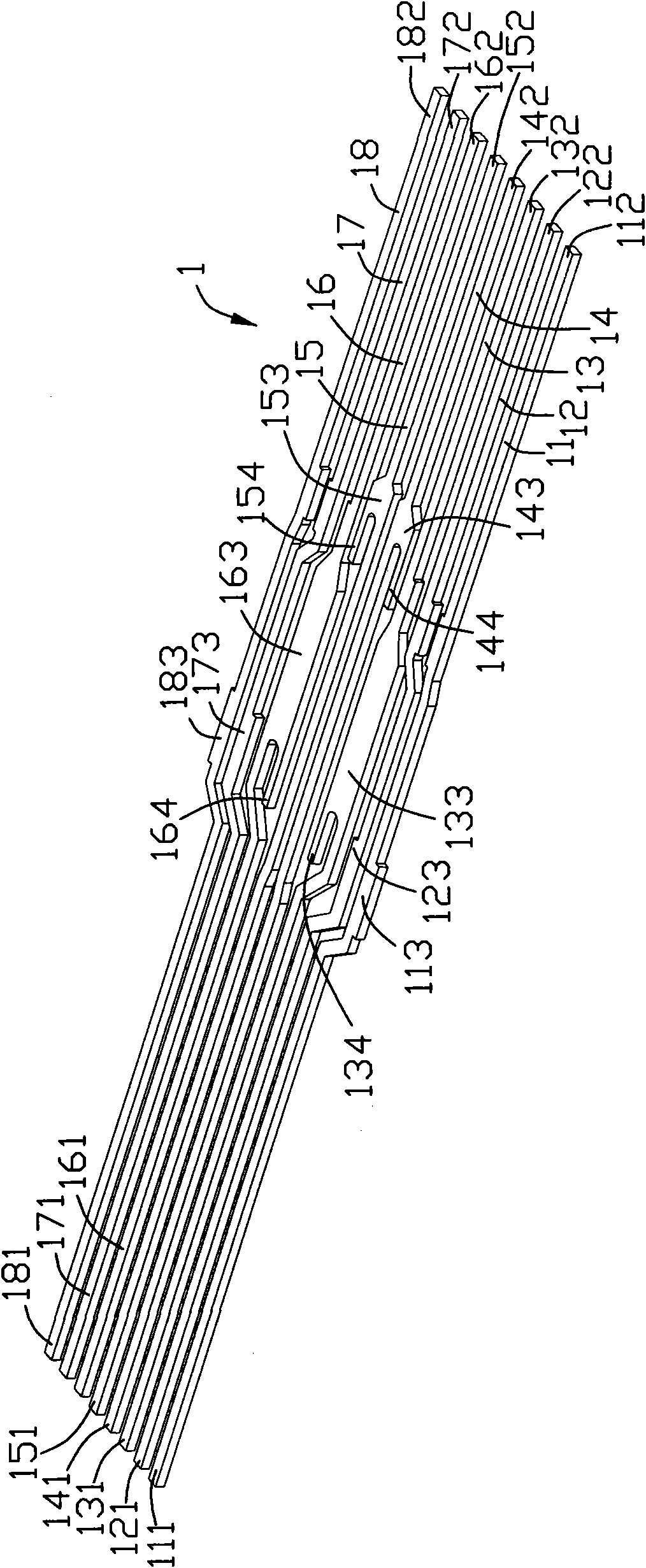

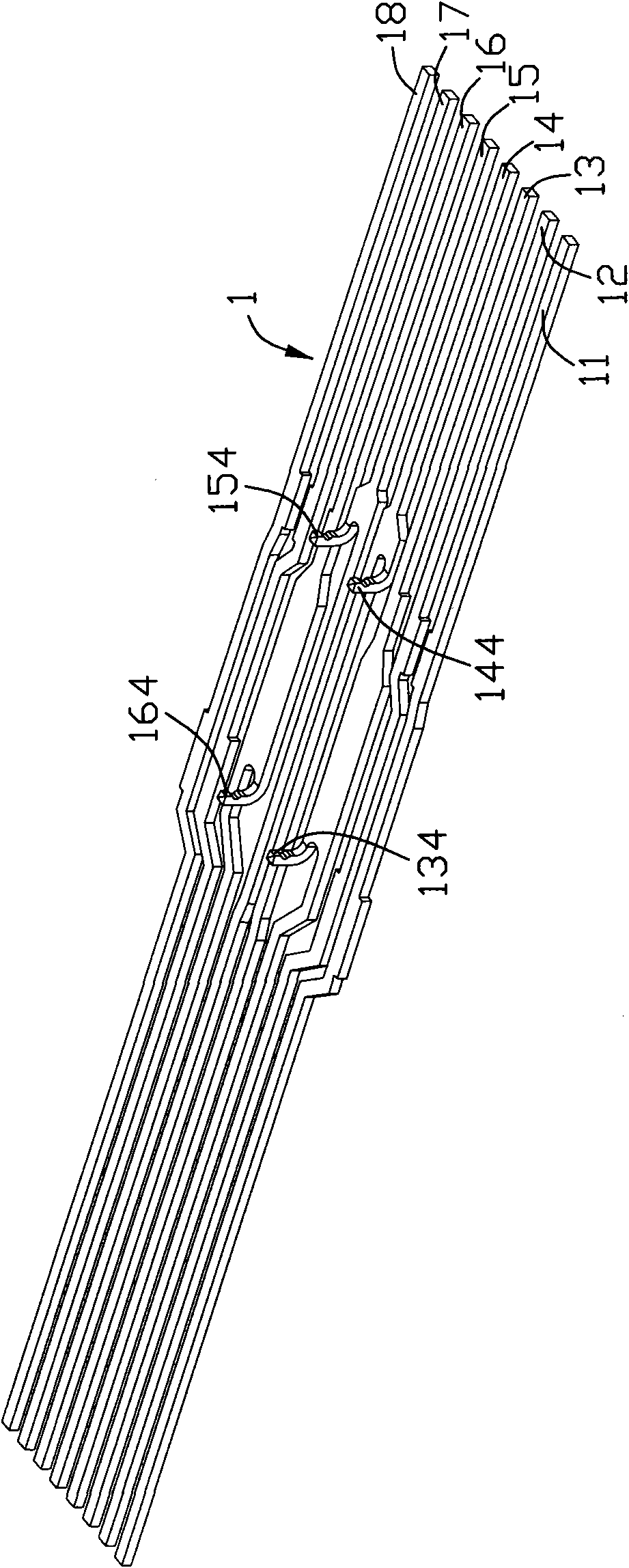

[0019] refer to Figure 4 to Figure 6 , each terminal module 10 includes an insulating sheet 2 , a plurality of terminals 1 and a metal sheet 3 . The terminals 1 are the first to eighth terminals 11-18 in this embodiment. The first to eighth terminals 11 - 18 are configured in the insulating sheet 2 by insert molding. Among them, the first and second terminals 11 and 12 are differential signal terminal pairs; the third and sixth terminals 13 and 16 are differential signal terminal pairs; the fourth and fifth terminals 14 and 15 are differential signal termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com