Rigid fixture suitable for ultrasonic guided wave detection of various pipe diameters and using method

An ultrasonic guided wave and rigid technology, which is applied in the direction of material analysis, measuring devices, and piping systems using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as poor applicability of rigid fixtures, and achieve improved reliability, guaranteed coupling, and large contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The given examples are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

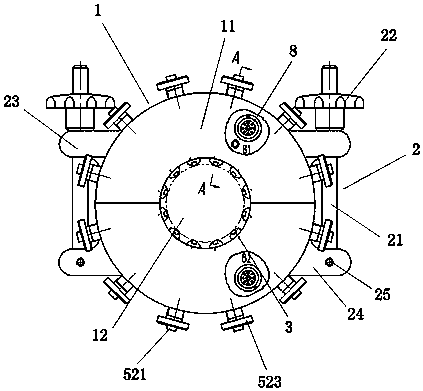

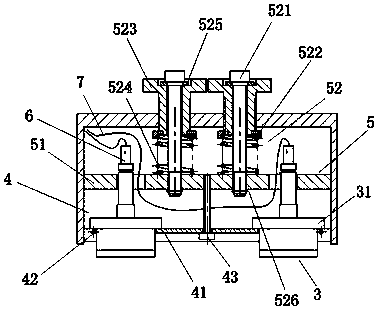

[0025] Such as figure 1 and figure 2 As shown, this embodiment is a rigid fixture suitable for industrial pipelines with an outer diameter of Φ57mm-Φ108mm ultrasonic guided wave detection, including an annular groove body 1 with both ends closed, and the annular groove body 1 is composed of two semicircular groove bodies 11 passing through it. The locking devices 2 arranged symmetrically on both sides of the radial direction are combined, and the annular tank body 1 is made of carbon steel. Two sets of probes 3 are arranged side by side along the axial direction of the inner hole 12 of the annular groove, and multiple groups of probes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com