Rod position processing device of nuclear power station control rod based on PLC (Programmable Logic Controller) platform

A processing device and control rod technology, applied in nuclear power generation, nuclear engineering, nuclear reactor monitoring, etc., can solve problems such as difficulty in circuit upgrade and modification, low integration of components, and many signal lines, so as to reduce the risk of reactor shutdown, Guarantee stability and diversity, improve the effect of stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A kind of PLC platform-based nuclear power plant control rod position processing device of the present invention is introduced below in conjunction with accompanying drawing and embodiment:

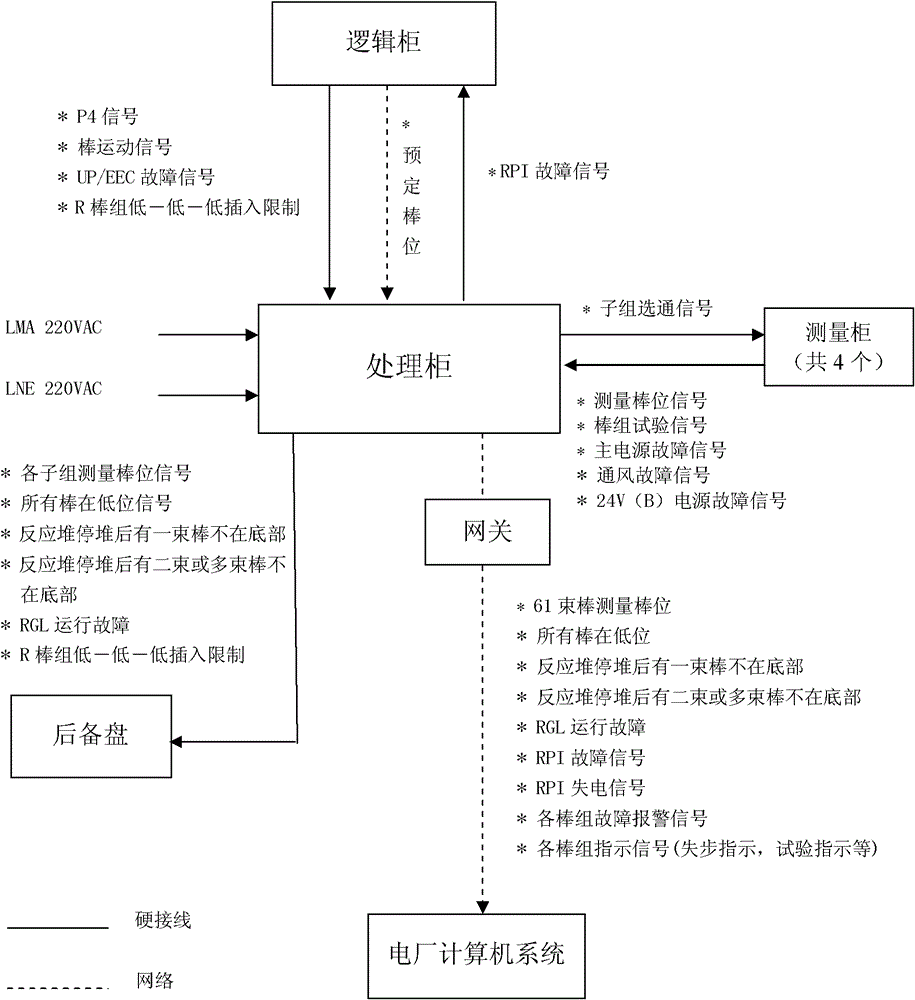

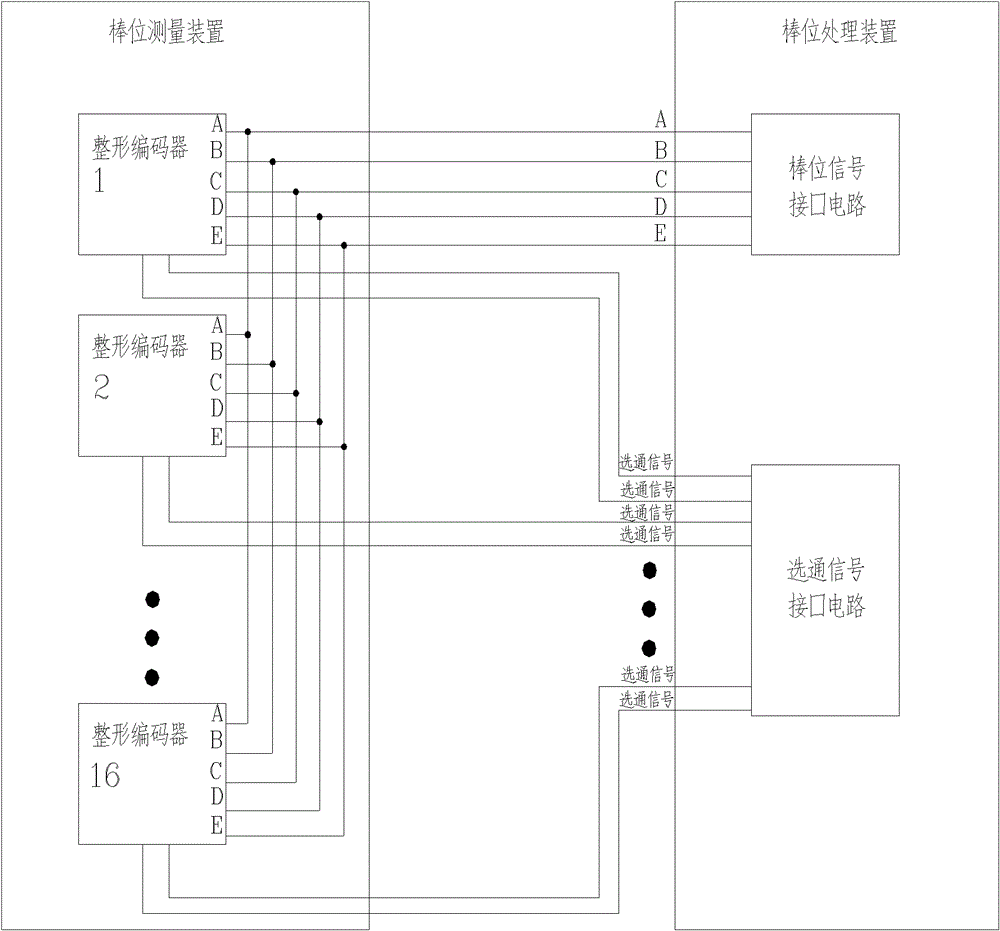

[0042] 1. The structure of a control rod position processing device for nuclear power plants based on the PLC platform

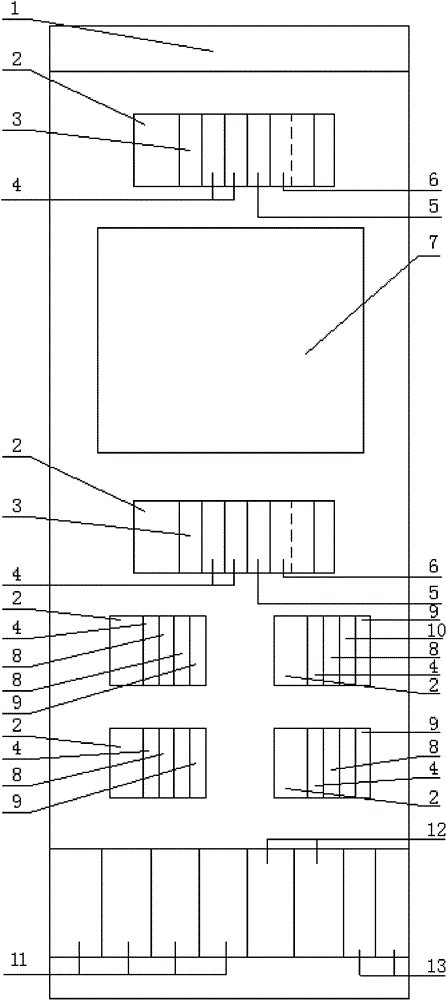

[0043] Such as figure 1 As shown, a PLC platform-based nuclear power plant control rod position processing device (referred to as processing cabinet) includes:

[0044] Two controllers 3, the controllers are also called ControlLogix controllers, which are logic control modules based on programmable controllers, and perform control rod measurement rod position signal processing, rod position and equipment fault monitoring, display, and online programming. One of the controllers is the main controller, and the other is the slave controller, which constitutes a controller hot backup redundant system; the master controller and the slave controller are consistent, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com