Construction method of raft foundation

A raft foundation and construction method technology, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problems of different settlement and stress distributions of raft foundations, reduce electroosmosis costs, improve structural performance, reduce The effect of differential settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

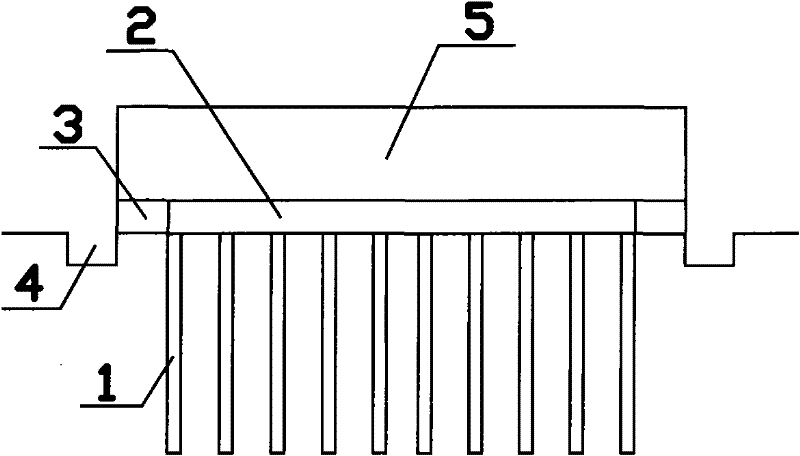

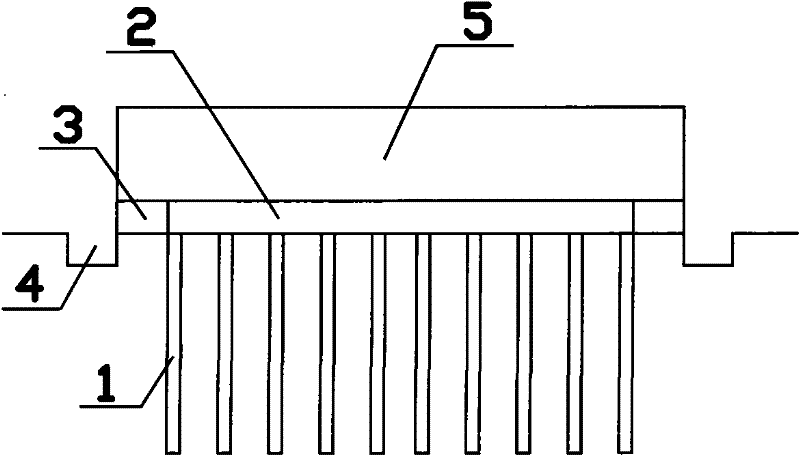

[0013] Describe in detail below in conjunction with accompanying drawing.

[0014] A building is a nine-story frame structure with a building area of 3240m 2 , using a frame structure, the raft thickness of the project is 60cm, and the pile foundation adopts bored piles.

[0015] In this embodiment, a cushion layer is arranged under the raft foundation, and the cushion layer is made of sand and gravel mixture with a thickness of 35 cm. The lower part of the cushion layer is rigid piles and foundation soil, and a 10 cm polystyrene board is arranged between the rigid piles and the cushion layer. , the surrounding beams are made around the cushion layer. The height of the surrounding beams is 35cm and the width is 30cm. The distance between the edge of the plate is 30cm, the distance between the four rows of electroosmotic wells at the edge is 2.5m, and the distance between the middle electroosmotic wells is 3m. A drainage ditch is arranged around the raft, and the drainage d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com