Aerosol inhaling system

An aerosol and aspirator technology, applied in the direction of inhalers, spray devices, nebulizers for treatment, etc., can solve the problems of loss of solution, aerosol response delay, etc., to prevent waste loss, shorten response time, and easy suction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

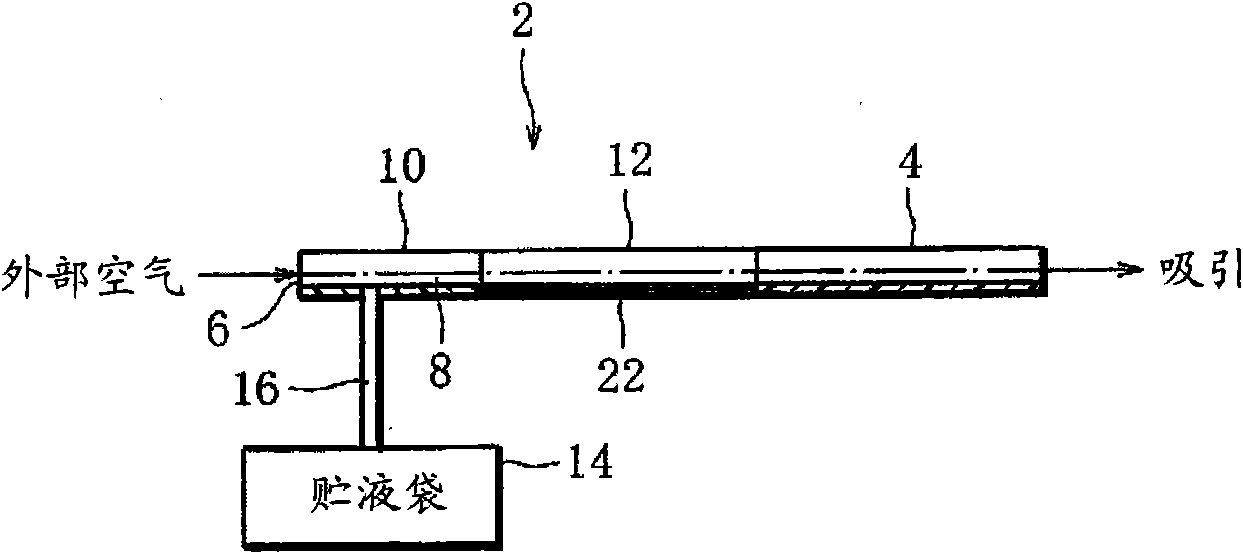

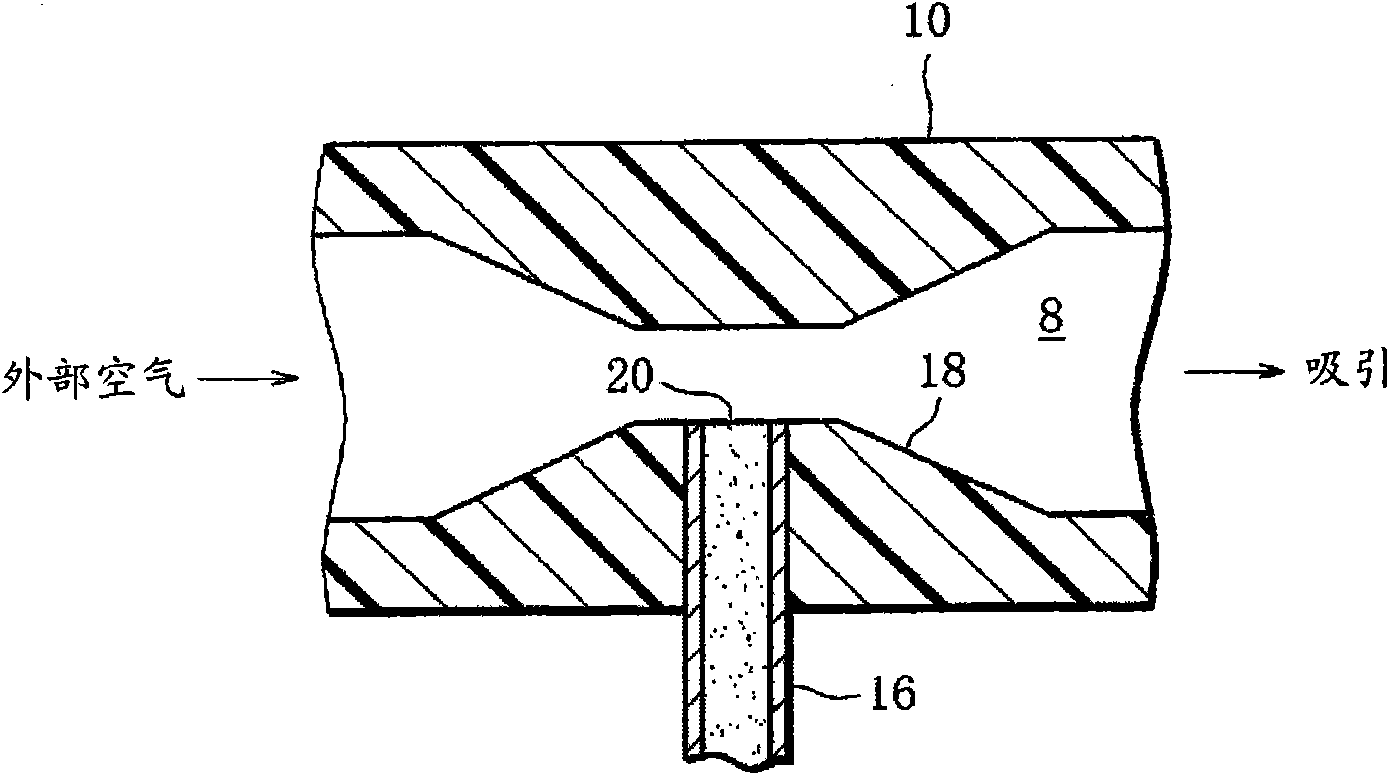

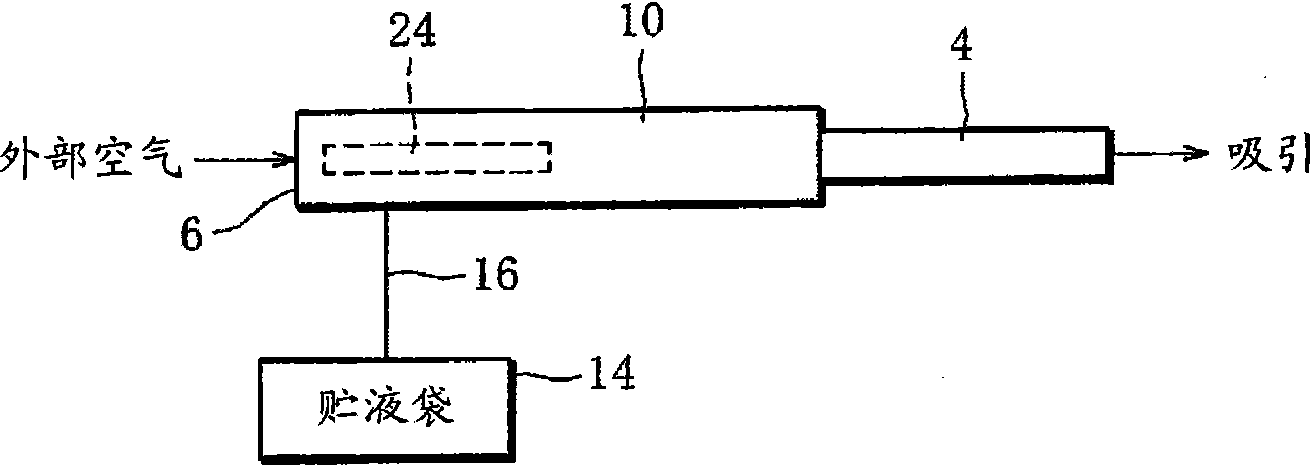

[0040] figure 1 and figure 2 The aerosol suction system (hereinafter simply referred to as the system) of the first embodiment is shown.

[0041] The system includes an aspirator 2 which has a rod shape as a whole. The aspirator 2 has a front end portion, a middle portion, and a rear end portion, and the rear end portion is formed as a nozzle opening 4 . The aspirator 2 has an external air inlet 6 at its front end, and the front end and the middle portion define an aerosol generating flow path 8 extending from the external air inlet 6 to the mouthpiece 4 .

[0042]More specifically, the front end and the middle portion of the aspirator 2 are respectively formed by an air introduction pipe 10 provided with an external air introduction port 6 and a tubular electric heater 12 which is a tubular heating element. The passage is formed as an aerosol generating channel 8 .

[0043] On the other hand, a flexible liquid storage bag 14 is prepared outside the aspirator 2, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com