Planetary screw mixing integral injection molding machine

A planetary screw, injection molding machine technology, applied in the field of injection molding machines, medium and large injection molding machines, can solve the problems of difficult to solve the sealing and heating of the storage cavity, the length of the whole machine is large, the structure is complex, etc., to ensure injection and pressure retention. Effect, high shearing times, compact structure of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

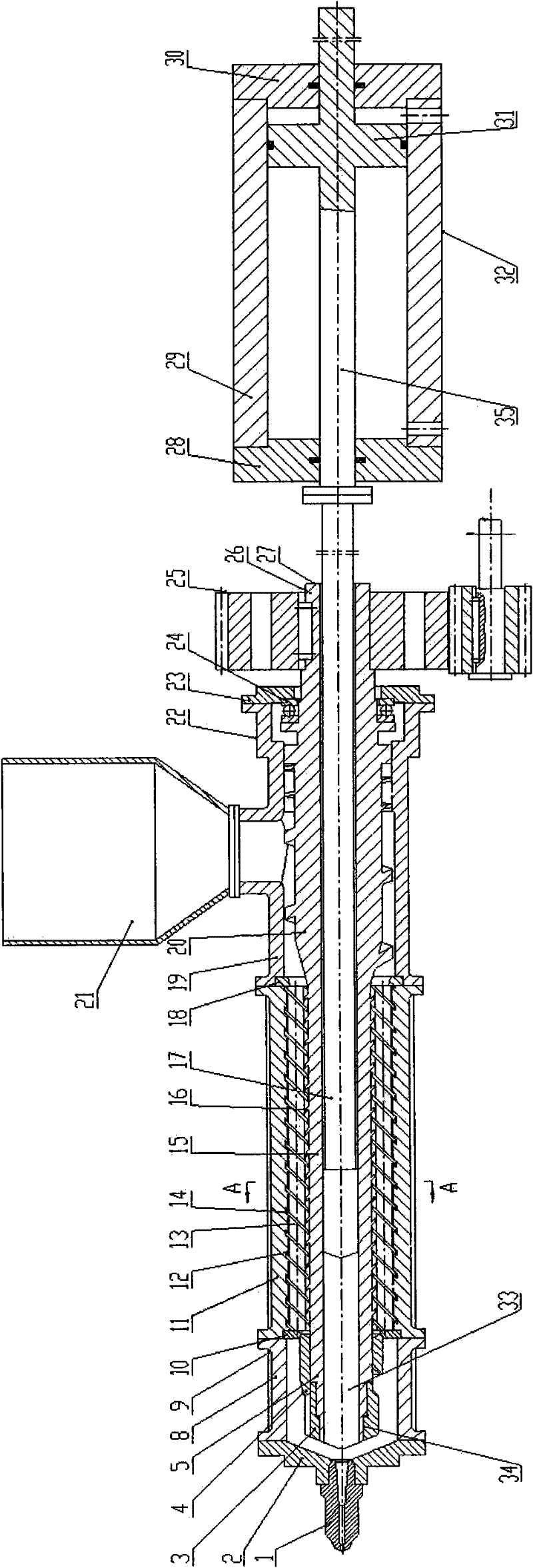

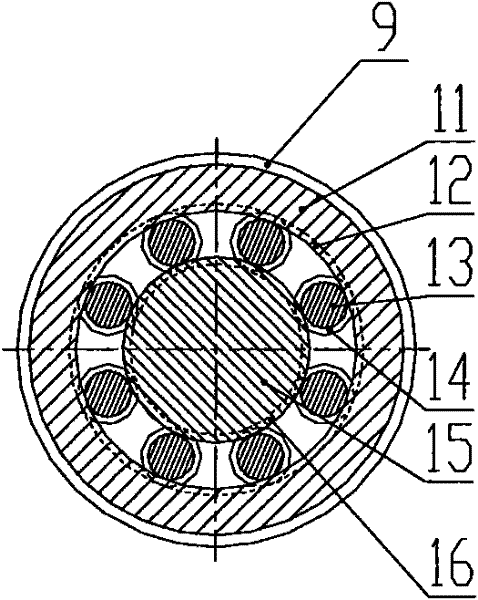

[0029] Such as figure 1 and figure 2As shown, a planetary screw mixing integral injection molding machine of the present invention is mainly composed of a nozzle 1, a barrel 22, a heating device 9, a hopper 21, a screw head 3, a check ring 4, a main screw 27, and an integral planetary screw 13. , front stop ring 10, rear stop ring 18, plunger 17, thrust bearing 24, bearing cover 23, transmission device 25 and injection cylinder 32, main screw 27 is composed of screw front section 5, screw planetary section 15, screw The feeding section 20 and the screw drive section 26 are composed of a through hole (storage cavity) 33 at the center of the main screw 27, and the barrel 22 is sequentially composed of the front barrel 2, the first section 8 of the barrel, the second section 11 of the barrel, and the barrel feeding section 19, the injection cylinder 32 is composed of an injection piston 31, an injection piston rod 35, an injection cylinder barrel 29, an injection cylinder front...

Embodiment 2

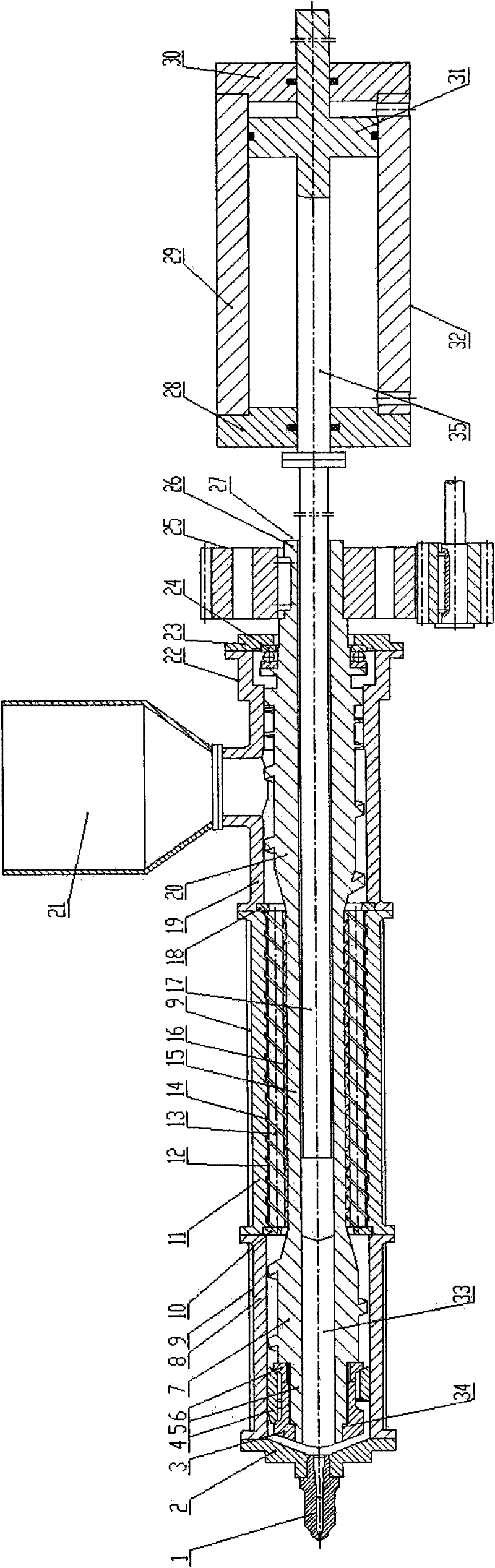

[0036] see image 3 , the structure, working principle and effect of this embodiment and embodiment 1 are basically the same. The difference is that the main screw 27 can also be composed of the front section 5 of the screw, the homogenizing section 7 of the screw, the planetary section 15 of the screw, the feeding section 20 of the screw and the transmission section 26 of the screw in turn, and the center of the main screw 27 has a through hole (storage chamber ) 33, adding a thrust ring 6 set on the front section 5 of the screw, the screw head 3 is connected with the front section 5 of the screw through threads, the screw head 3 is in contact with the end surface of the thrust ring 6; the anti-reverse ring 4 is set on the screw head 3, the anti-reverse ring 4 cooperates with a section 8 of the machine barrel and can slide relative to the axial direction; the non-return ring 4 can be in contact with the thrust ring 6 . During injection, under the action of injection pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com