Warping machine blowing device

A warping machine and pre-warping technology, which is applied in the field of warping machines, can solve the problems of affecting weaving efficiency and product quality rate, increasing the number of stoppages in the weaving process, and the inability to effectively improve the sizing process, etc., so as to improve weaving efficiency and Product quality rate, the effect of solving weaving difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

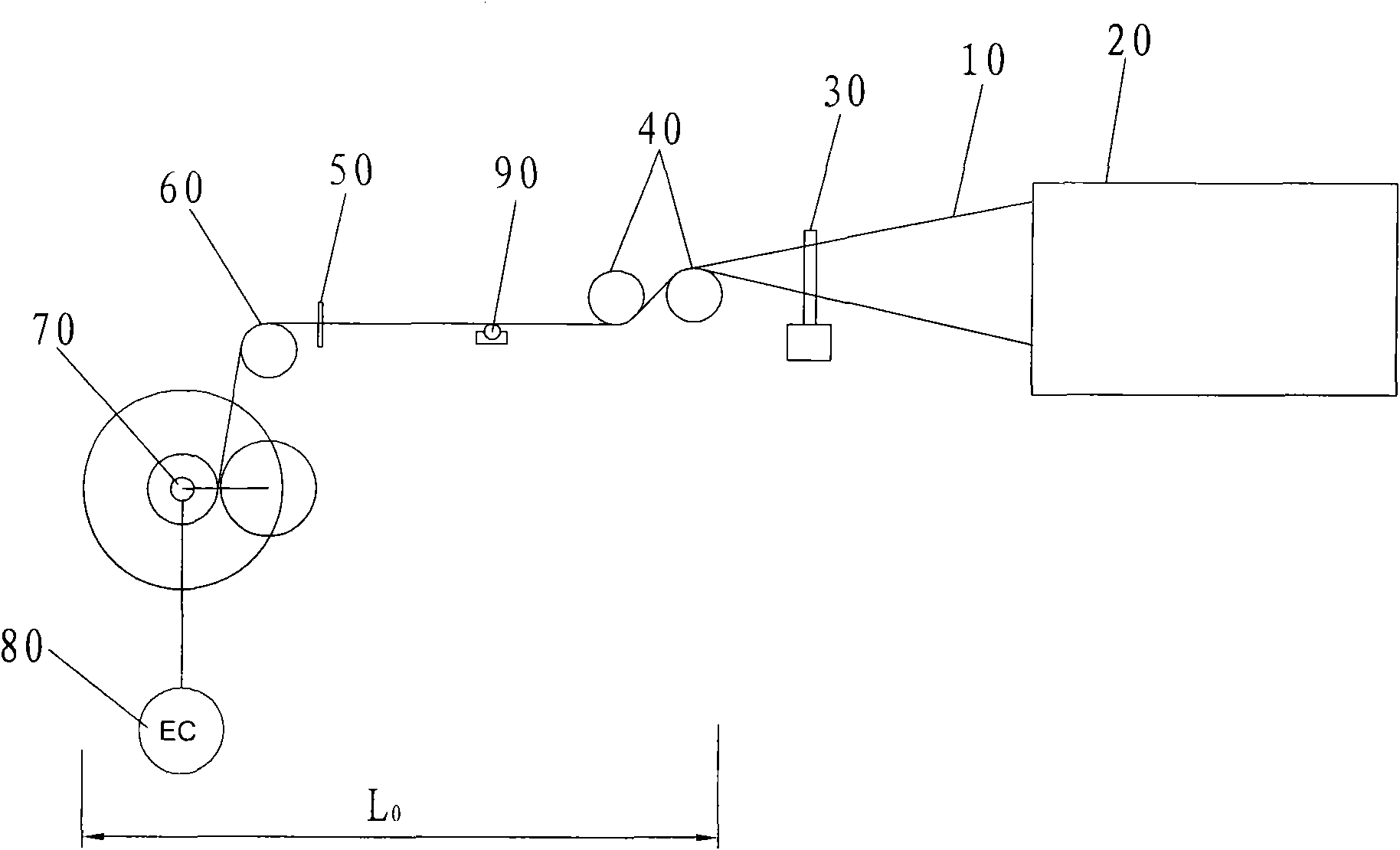

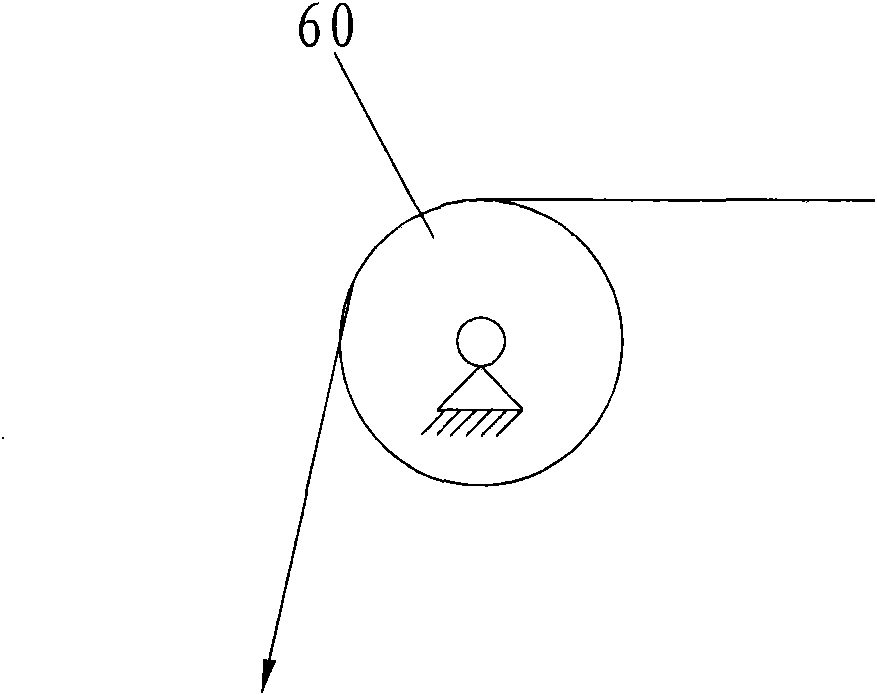

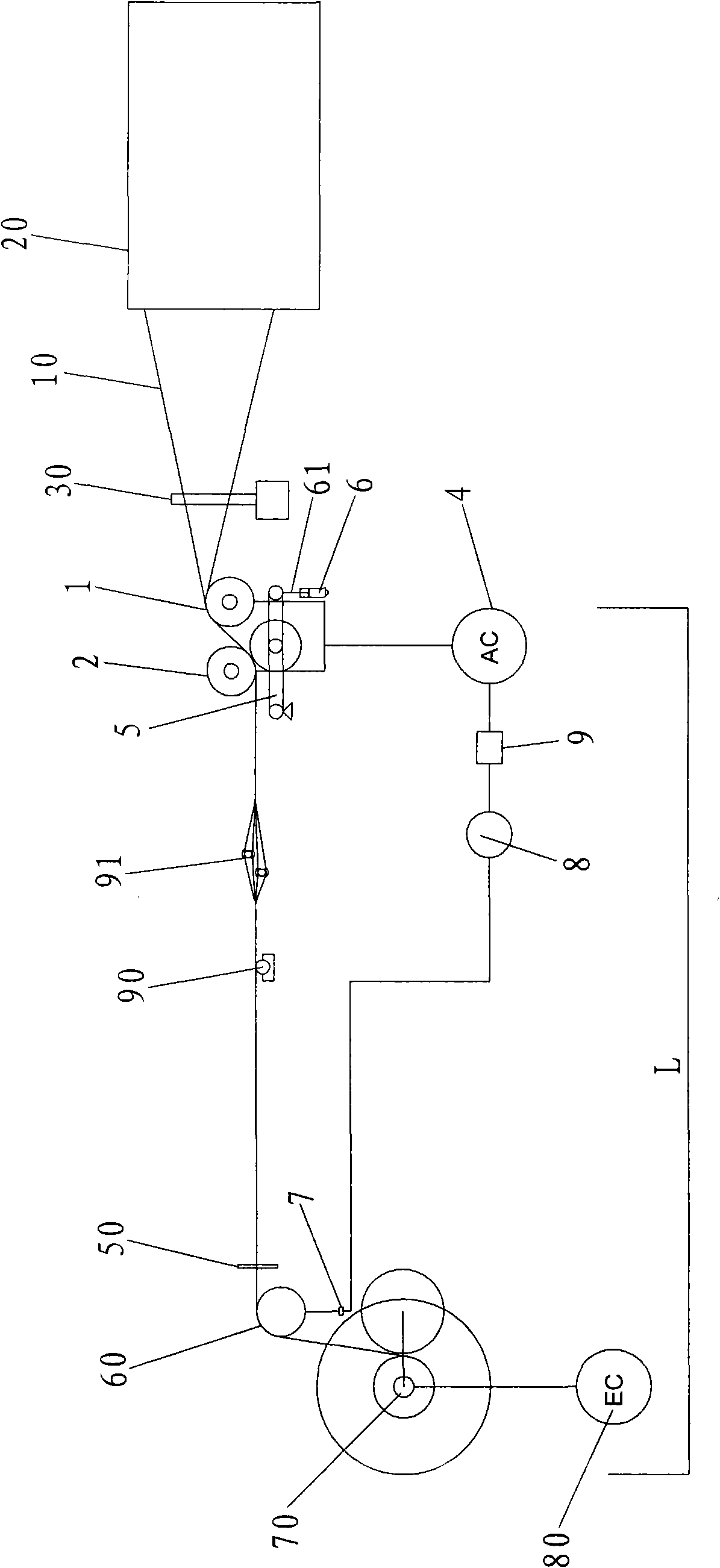

[0038] like image 3 and Figure 4 As shown, the warping machine blowing device disclosed in the present invention includes a guide roller group and a blowing machine 91 installed between the front reed 30 and the oil roller 90, and the silk yarn 10 bundled by the front reed 30 bypasses the guide yarn Roll group, pass through blower 91 again (see Figure 8 ) is transported to the oil roller 90, and the blown silk thread 10 is as Figure 9 shown. In the warping process, the present invention can effectively solve the problem of difficult weaving by installing a blower and adjusting the number of knots of the silk thread.

[0039] like image 3 As shown, the guide roller set in Embodiment 1 of the present invention specifically includes a guide roller 1 , a tension roller 2 and a pinch roller 3 . The guide roller 1 and the tension roller 2 are active rollers driven by the vector motor 4, the guide roller 1 and the tension roller 2 are arranged horizontally, the clamp roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com