Probe for three-dimensional shape measuring apparatus and three-dimensional shape measuring apparatus

A measuring device and three-dimensional shape technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problem of reducing the measurement error of the vertical plane of the pressing force, and achieve the effect of high-precision measurement and reduction of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0133] Hereinafter, a probe for a three-dimensional shape measuring device (hereinafter referred to as a probe) and a three-dimensional shape measuring device (hereinafter referred to as a shape measuring device) according to embodiments of the present invention will be described in detail with reference to the drawings.

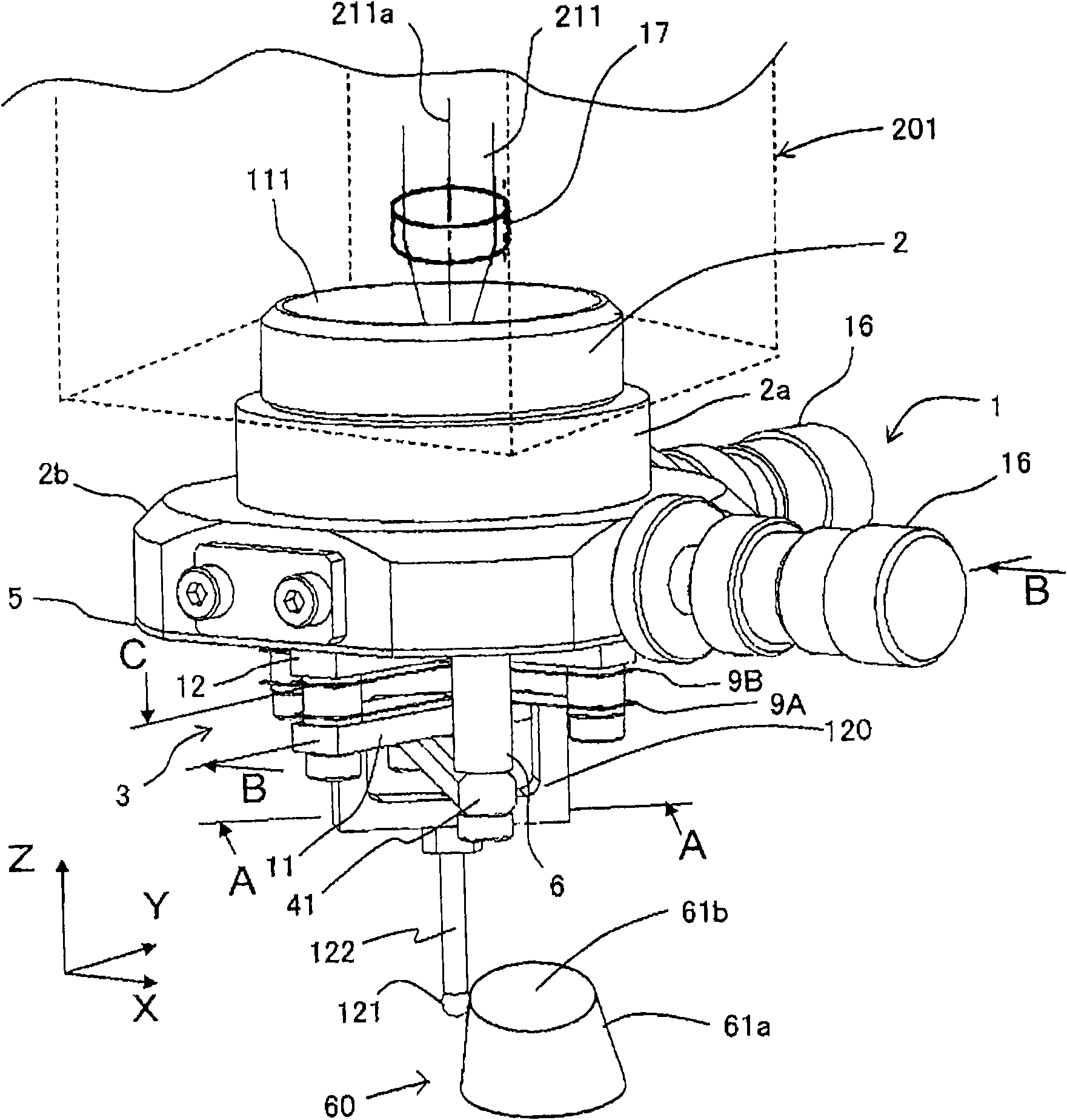

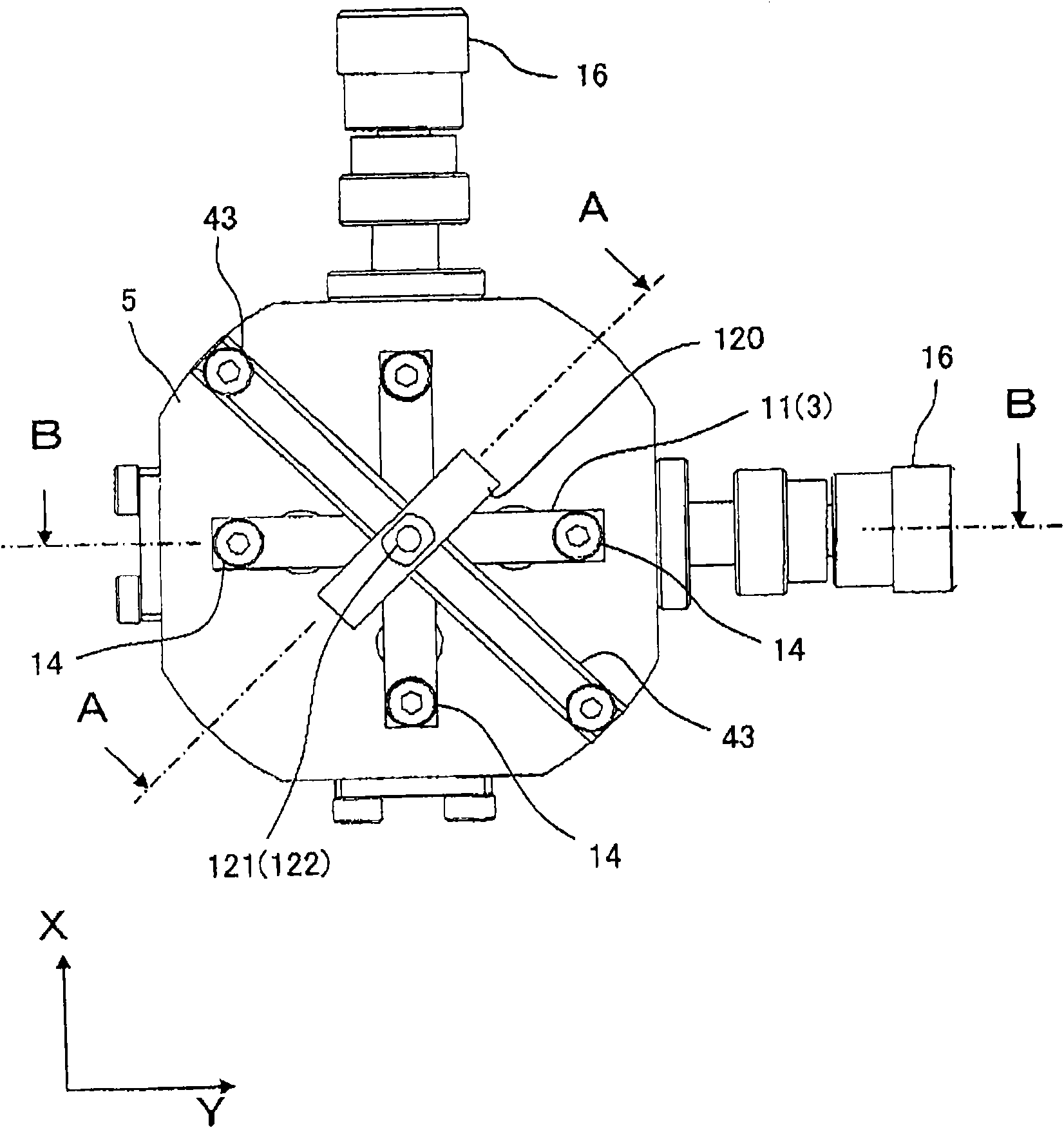

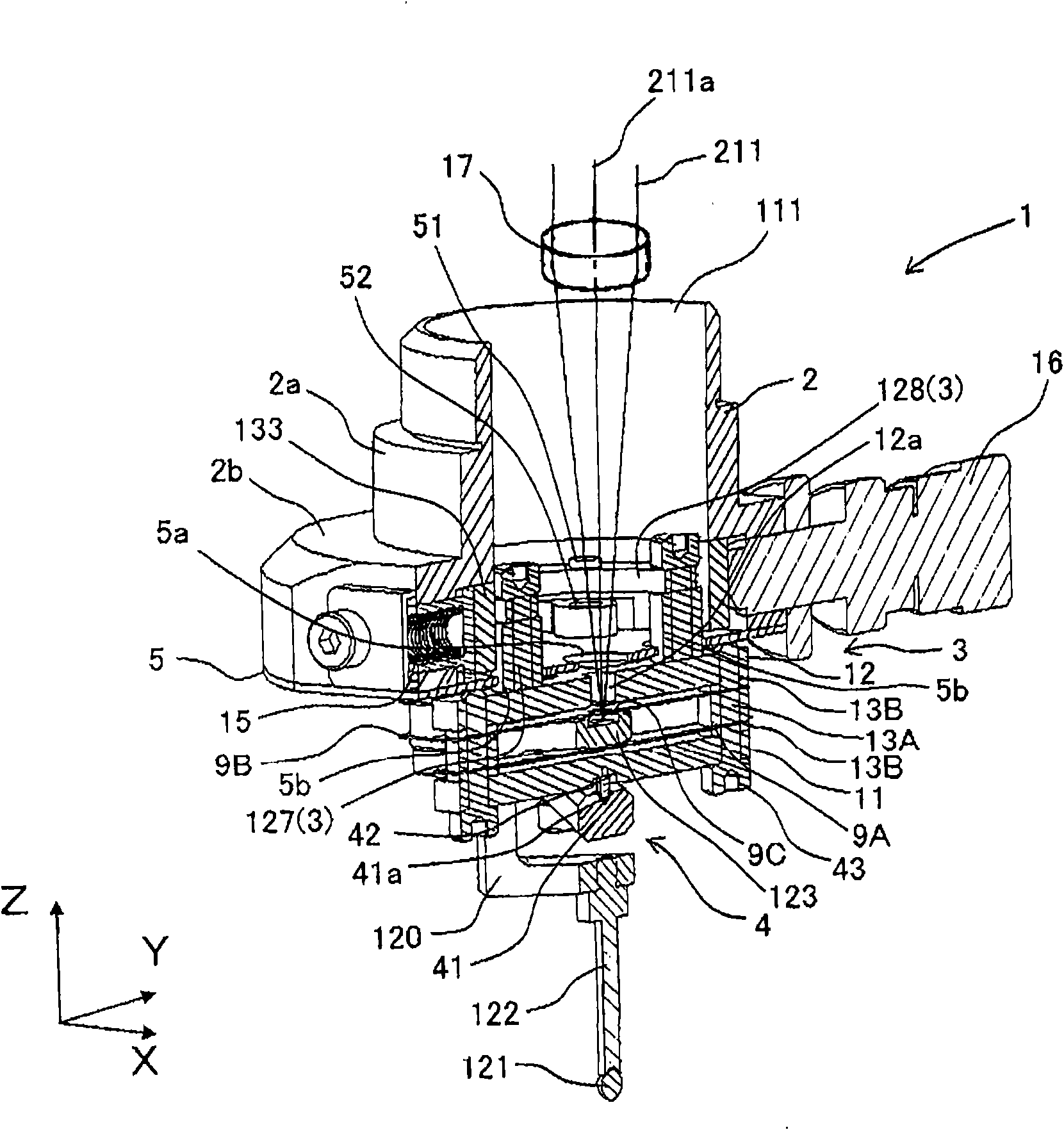

[0134] First, refer to Figure 1 to Figure 8 , indicating detector 1. figure 1 It is a perspective view showing the appearance of the probe 1 . figure 2 viewed from the vertical figure 1 diagram. image 3 yes figure 1 The perspective view when the detector 1 is cut in B-B plane. Figure 4 yes figure 1 is a perspective view of the detector 1 cut by plane A-A. Figure 5 viewed from above figure 1 diagram. Figure 6 to Figure 8 It is a diagram showing details of a part of the probe 1 .

[0135] The shape measurement device 201 includes a probe 1 having a portion in contact with the measured surfaces 61 a and 61 b of the measuring object 60 to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com