Table-top cutter

A desktop cutting machine and rotary table technology, applied in sawing equipment, metal sawing equipment, sawing machine devices, etc., can solve the problems of increasing wall thickness, large supporting span, inability to accurately position, and reduce space. , to ensure the support rigidity, reduce the effect of deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

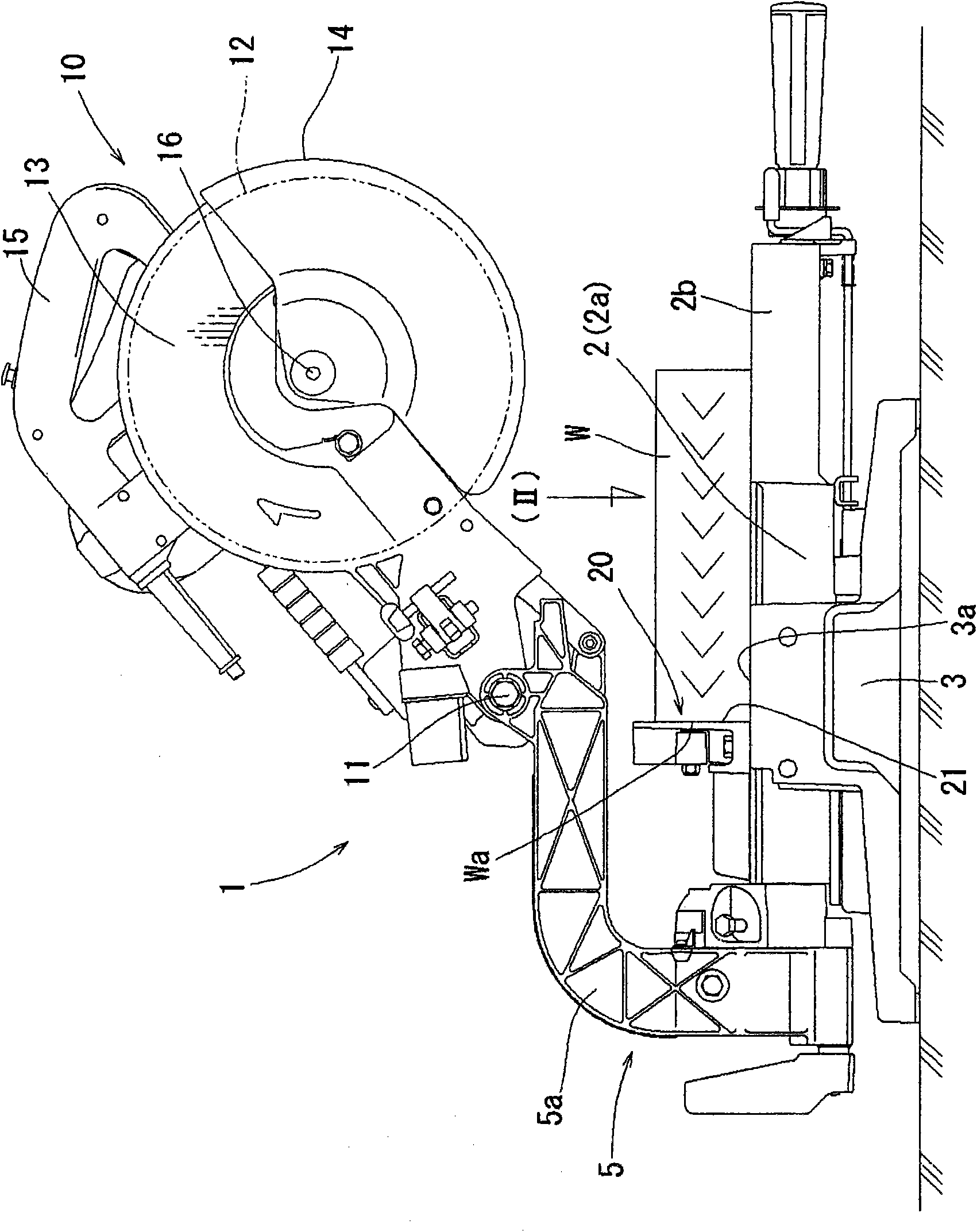

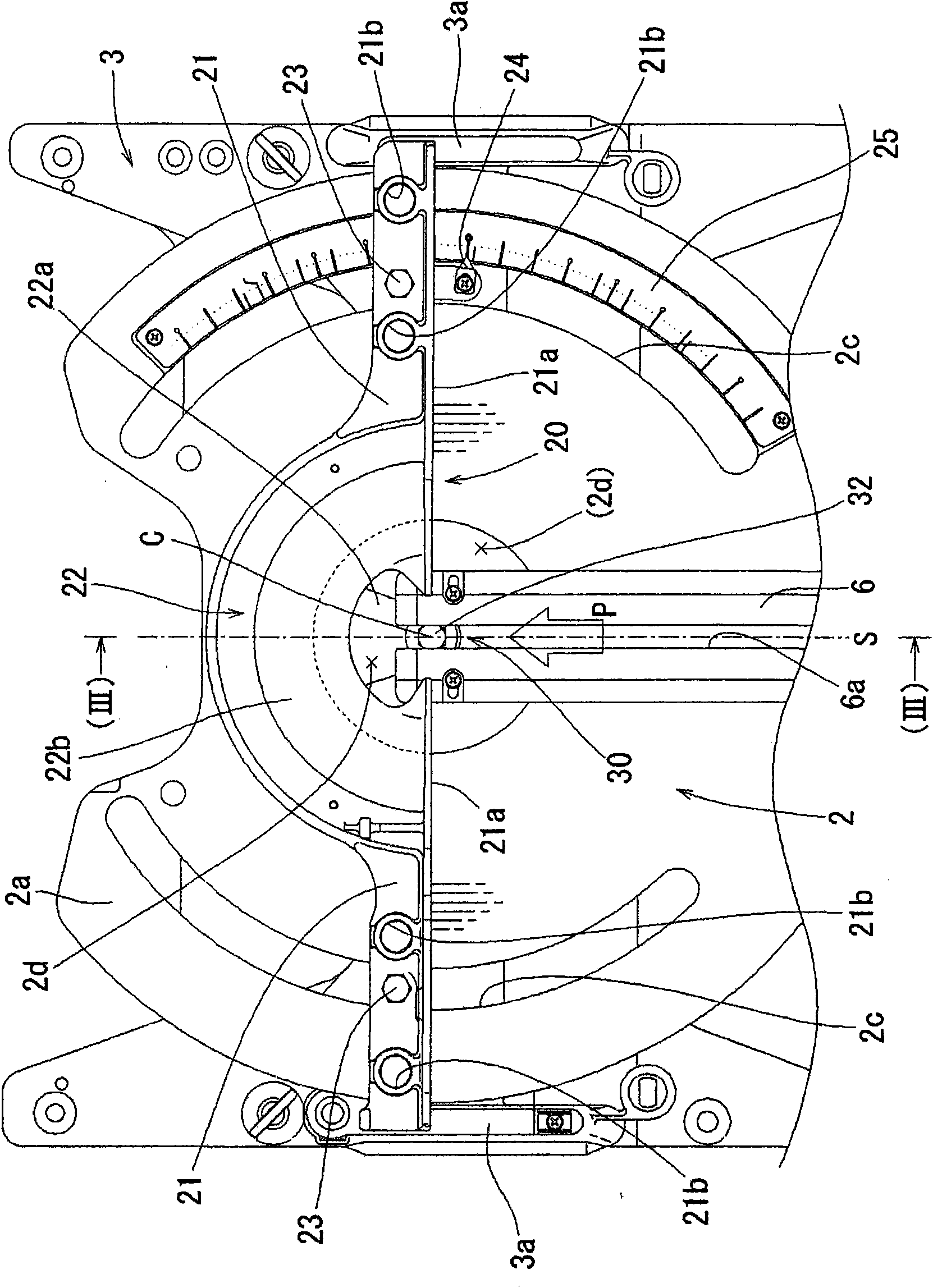

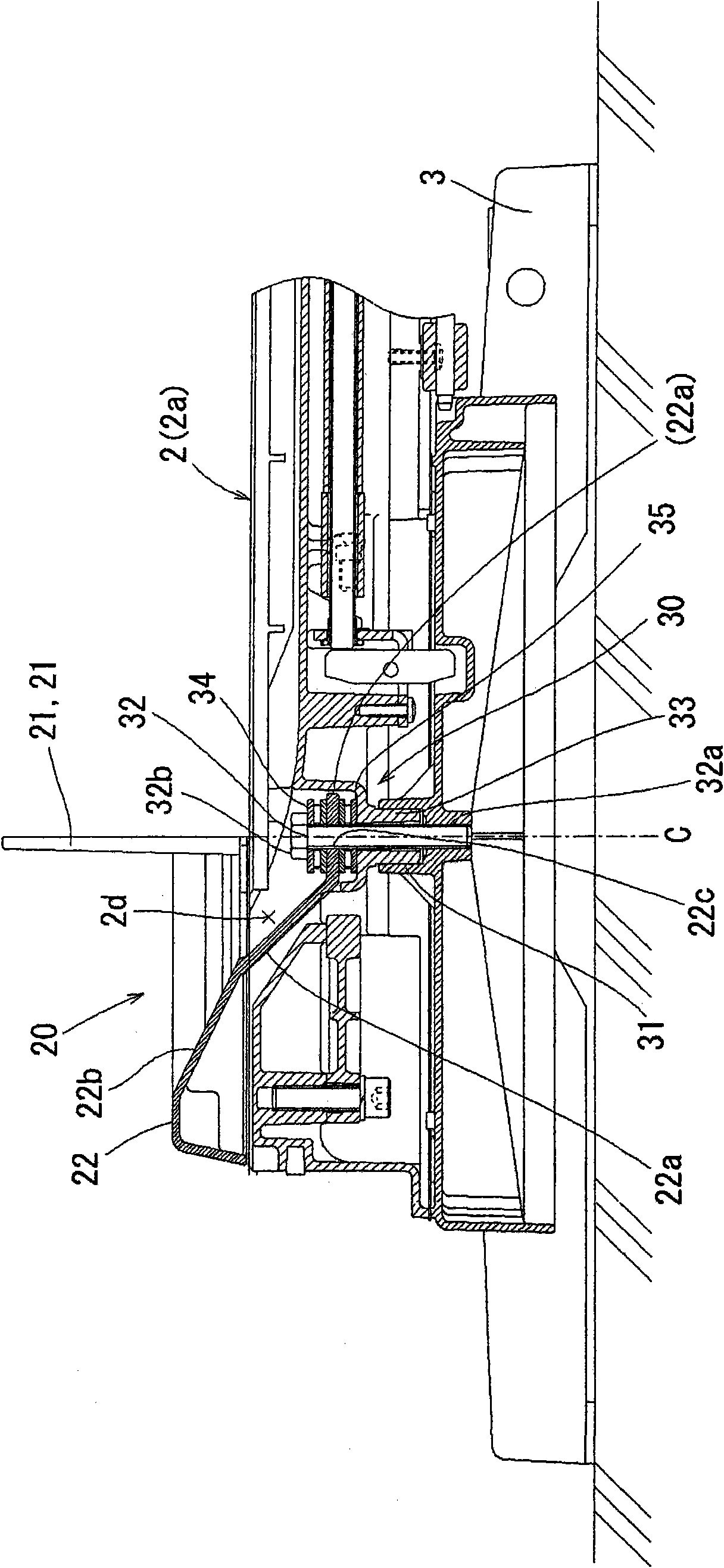

[0035] The following is based on Figure 1-Figure 12 Embodiments of the present invention will be described. figure 1 The whole table cutting machine 1 provided with the stopper 20 of this embodiment is shown. The desktop cutting machine 1 of this embodiment is characterized by the supporting structure of the limit stopper 20, which is used to position the position of the material W to be cut on the rotary table 2, and serves as the other part of the cutting machine. The basic structure and the like are the same as those of the prior art, and there is no need to change this part in this embodiment, so detailed description thereof will be omitted.

[0036] The desktop cutting machine 1 has: a rotary table 2 for resting the material W to be cut on the upper surface; a base 3 supporting the rotary table 2 in a manner that the rotary table 2 can rotate in a horizontal plane; Cutting machine body 10, at the rear portion of rotary table 2 ( figure 1 The middle left part) is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com