Belt cutting machine

A tape cutting machine and cutting knife technology, applied in the field of cutting machines, can solve the problems of easy computer problems, high work efficiency, low work efficiency, etc., and achieve the effects of not easy to slip, ensure the consistency of feeding length, and increase the transmission force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

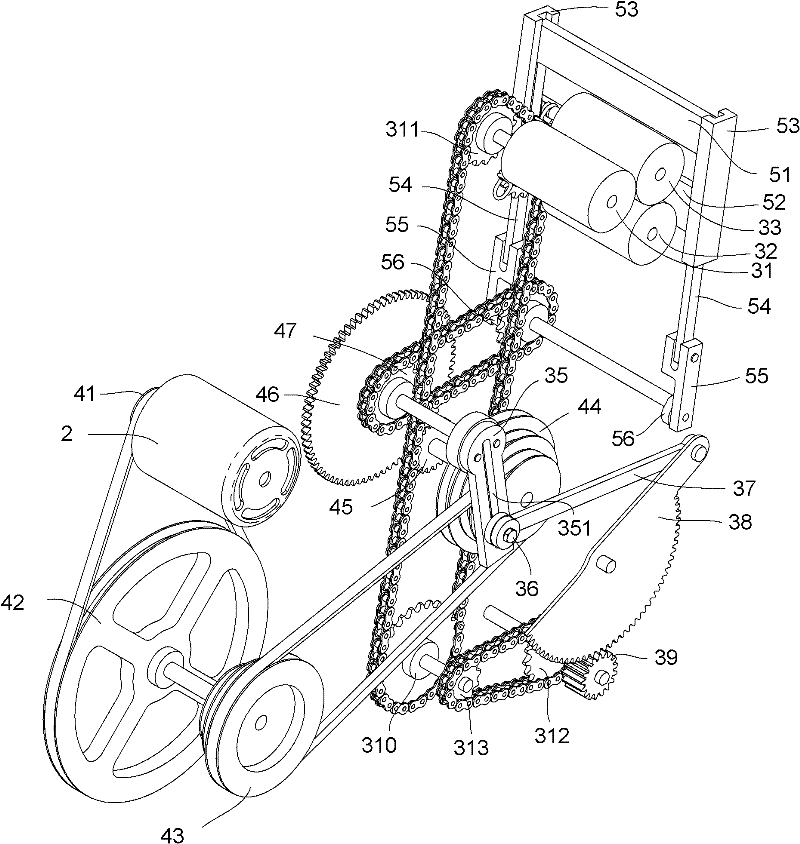

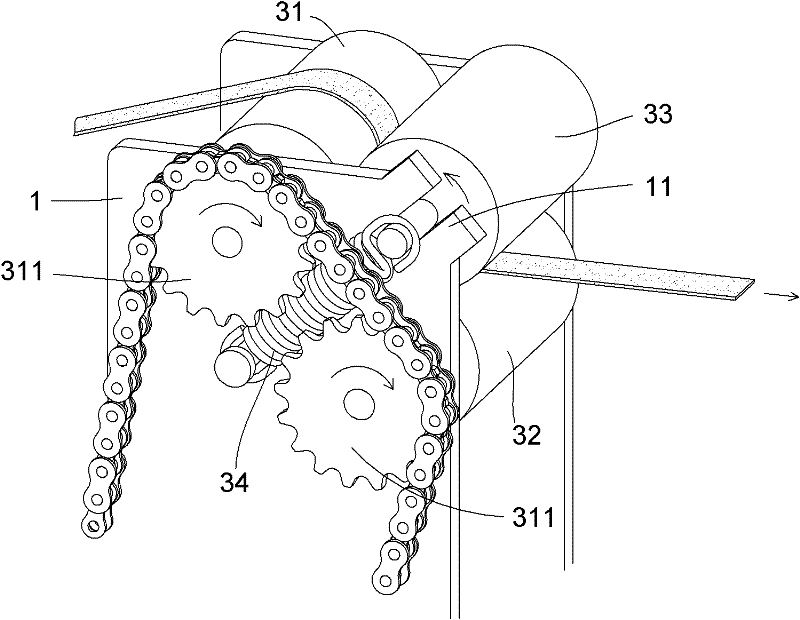

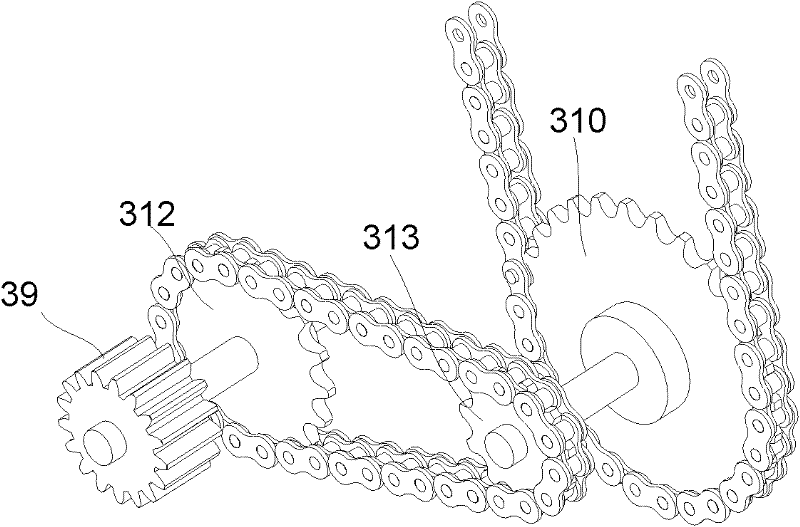

[0023] As an embodiment of the tape cutting machine of the present invention, please refer to Figure 1 to Figure 3 , comprising a frame 1, a drive motor 2, a transmission mechanism 4, a cutter device 5, and a feed device 3, the drive motor 2 drives the cutter device 5 and the feed device 3 to work through the transmission mechanism 4, and the feed device 3 Including elastic member 34, feeding eccentric wheel 35, feeding length adjustment assembly 36, feeding connecting rod 37, semicircular gear 38, feeding one-way gear 39, feeding length conversion gear 310, active feeding wheel drive gear 311, mutually parallel and At least one is the first feeding wheel 31, the second feeding wheel 32 and the third feeding wheel 33 which are active feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com