Self-locking method for nut and compression pitch deformation type self-locking nut

A self-locking nut and nut technology, applied in nuts, screws, bolts, etc., can solve the problems of unsatisfactory use effect of self-locking nut production process, large difference between locking torque and locking torque, and difficulty in tooling manufacturing. Achieve the effect of low production cost, slow decay of self-locking torque, and high reliability of self-locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

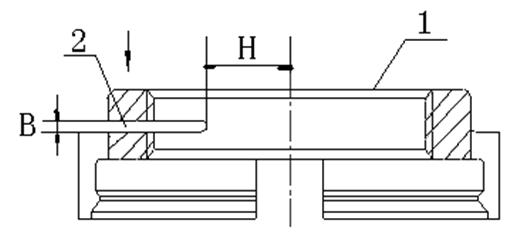

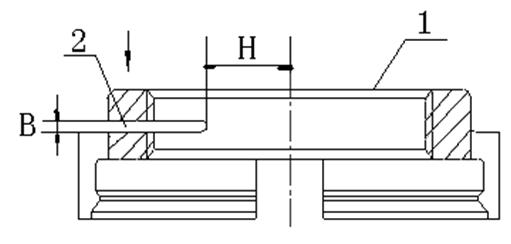

[0012] Embodiments of the present invention: when making self-locking nuts, preferably adopt a kind of self-locking method of nut of the present invention to design self-locking nuts, promptly on the surface of nut 1 with threaded holes, perpendicular to the central axis of nut 1 and Make at least one opening groove 2 communicating with the threaded hole along the radial direction of the threaded hole of the nut 1 (such as figure 1 shown), and then squeeze the nut 1 in the axial direction (such as figure 1 The direction indicated by the middle arrow), so that the width of the opening groove 2 is compressed and reduced, so that the pitch of the internal thread at the edge of the opening groove 2 of the nut 1 is locally deformed, and the pitch of the internal thread of the nut 1 is partially deformed. The nut 1 can be self-locked when it is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com