Backlight module and rubber frame unit structure thereof

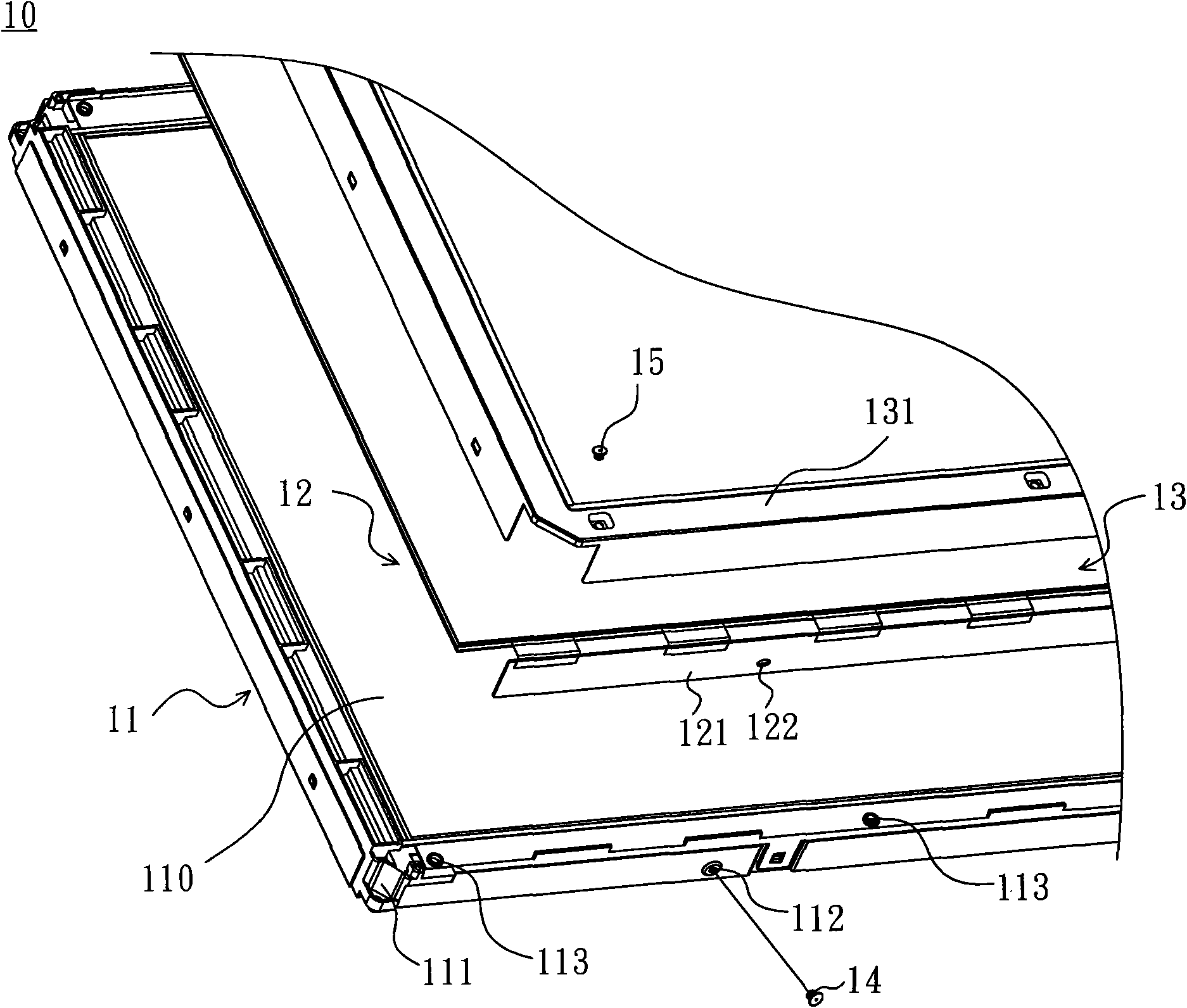

A backlight module and plastic frame technology, which is applied in the field of backlight module and its plastic frame unit construction, and can solve the problems of increased materials used for the plastic frame 111, increased material management complexity of the plastic frame 111, increased development costs and time of the backlight module 10, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention will be specifically cited below, together with the accompanying drawings, for a detailed description as follows:

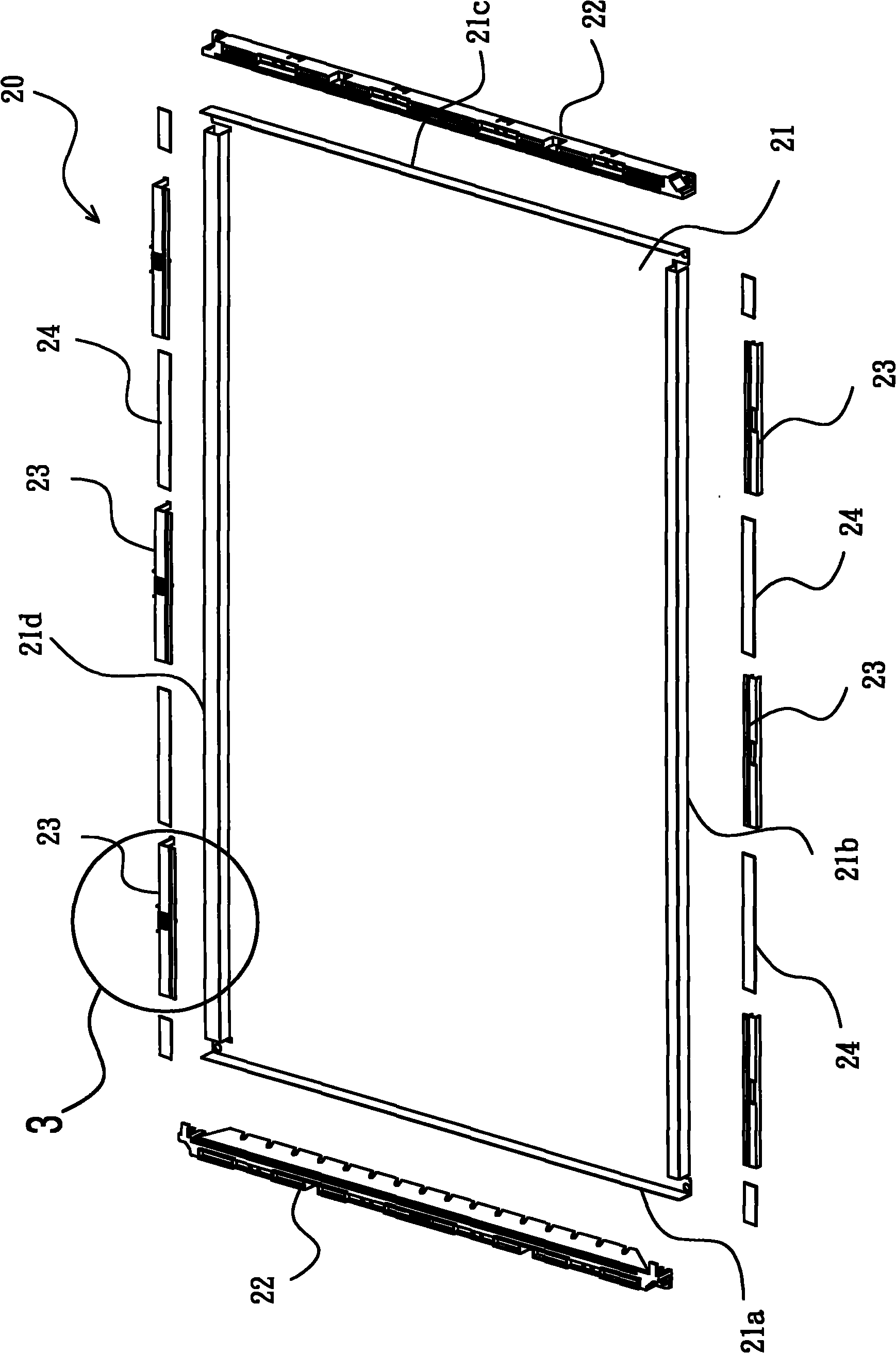

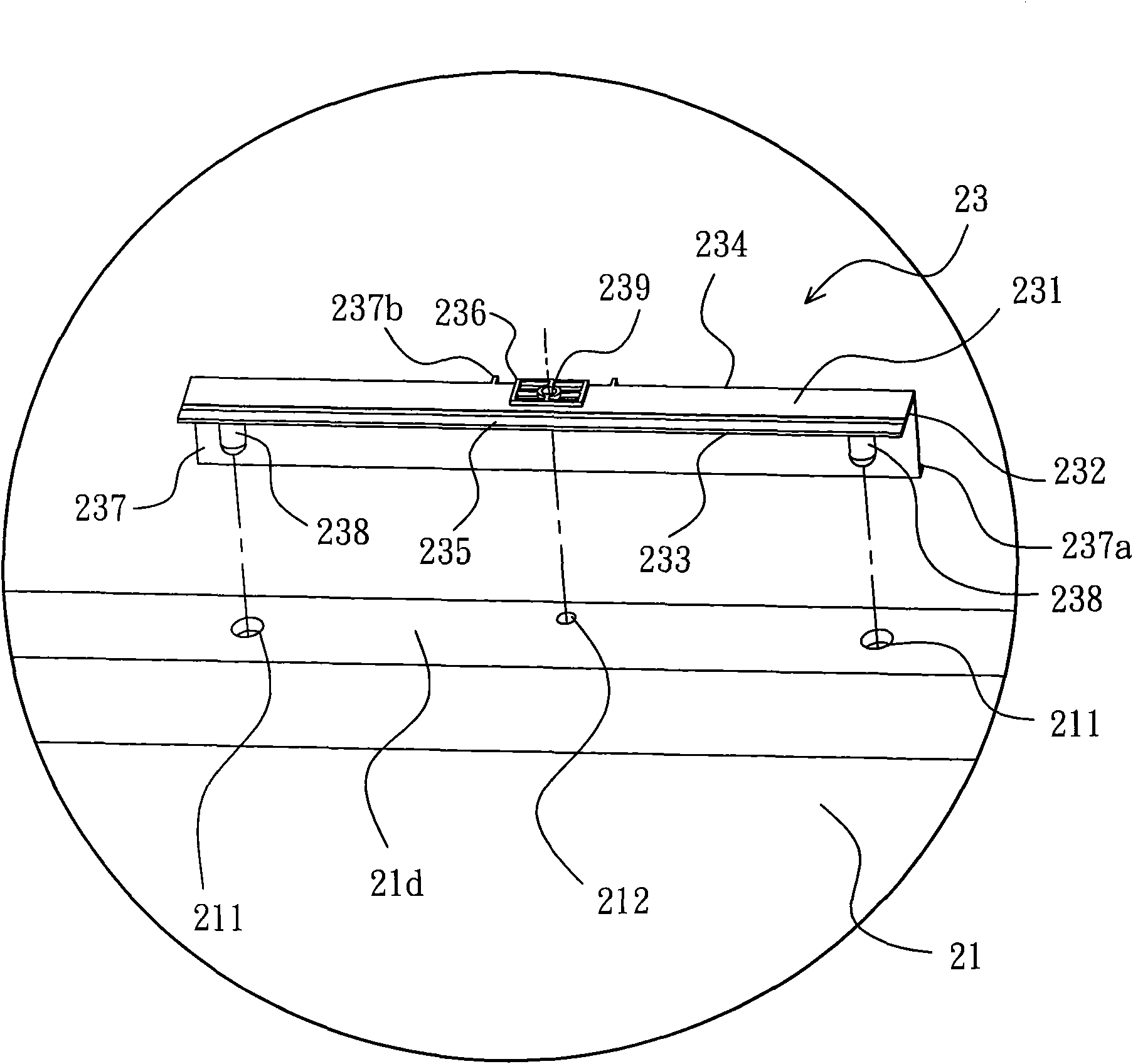

[0038] Please refer to figure 2 as shown, figure 2 It is a three-dimensional exploded view of a backlight module in a preferred embodiment of the present invention. A backlight module 20 mainly includes a backplane 21, two plastic frame strips 22, a plurality of plastic frame unit structures 23 and a plurality of buffer strips 24, wherein the backplane 21 has a first edge 21a, a second edge 21b, a second Three edges 21c and a fourth edge 21d, wherein the first edge 21a corresponds to the third edge 21c; the second edge 21b corresponds to the fourth edge 21d. The four edges 21 a - d of the backboard 21 further include the two plastic frame strips 22 , a plurality of plastic fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com