Method for detecting impurities in corrosive gas

A technology for corrosive gases and impurities, which is applied in the field of devices for analyzing and detecting impurities in corrosive gases, can solve the problems of inability to meet detection requirements, different analysis and detection elements, etc., and achieves a simple structure, good separation effect, and simple and fast analysis process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

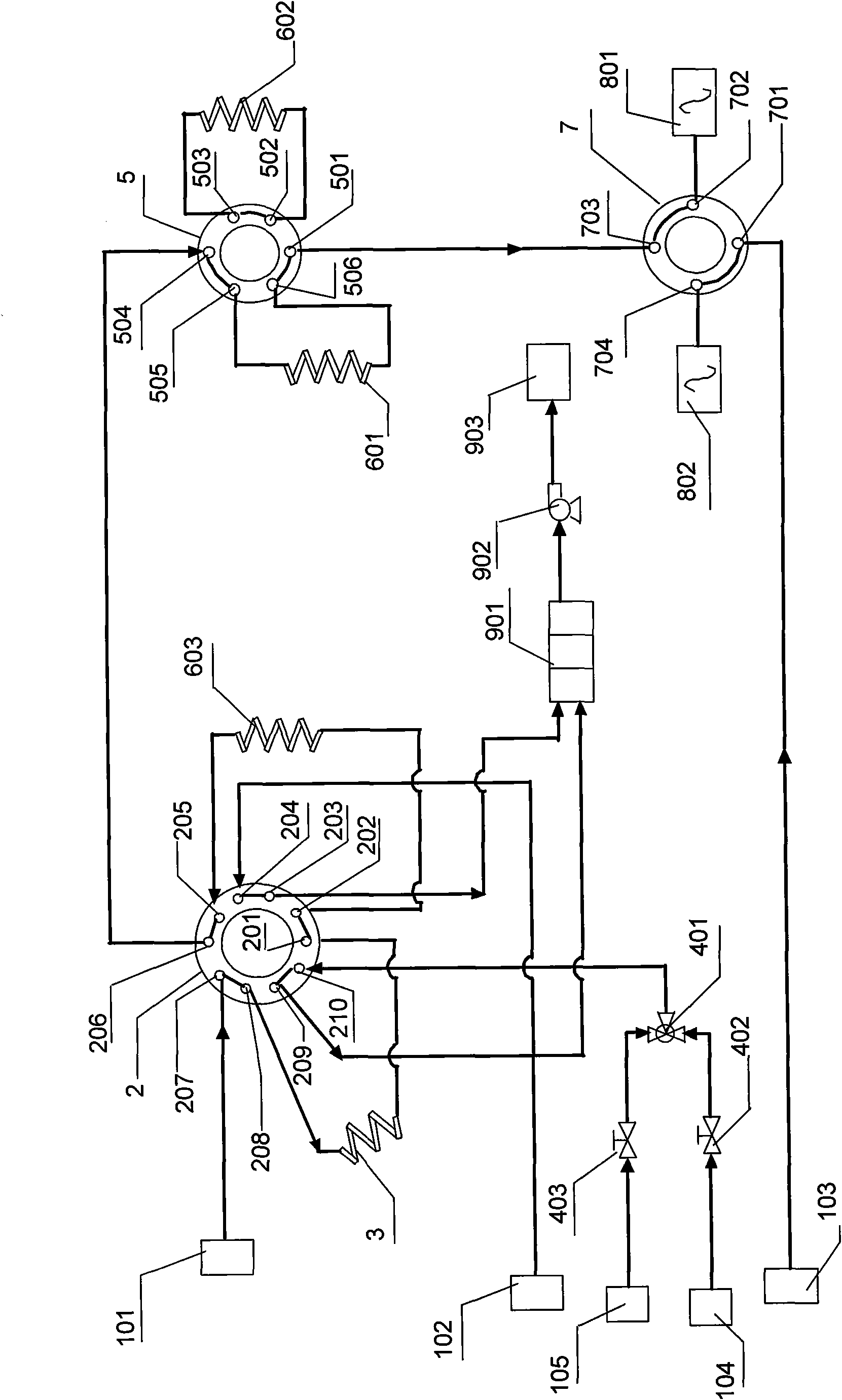

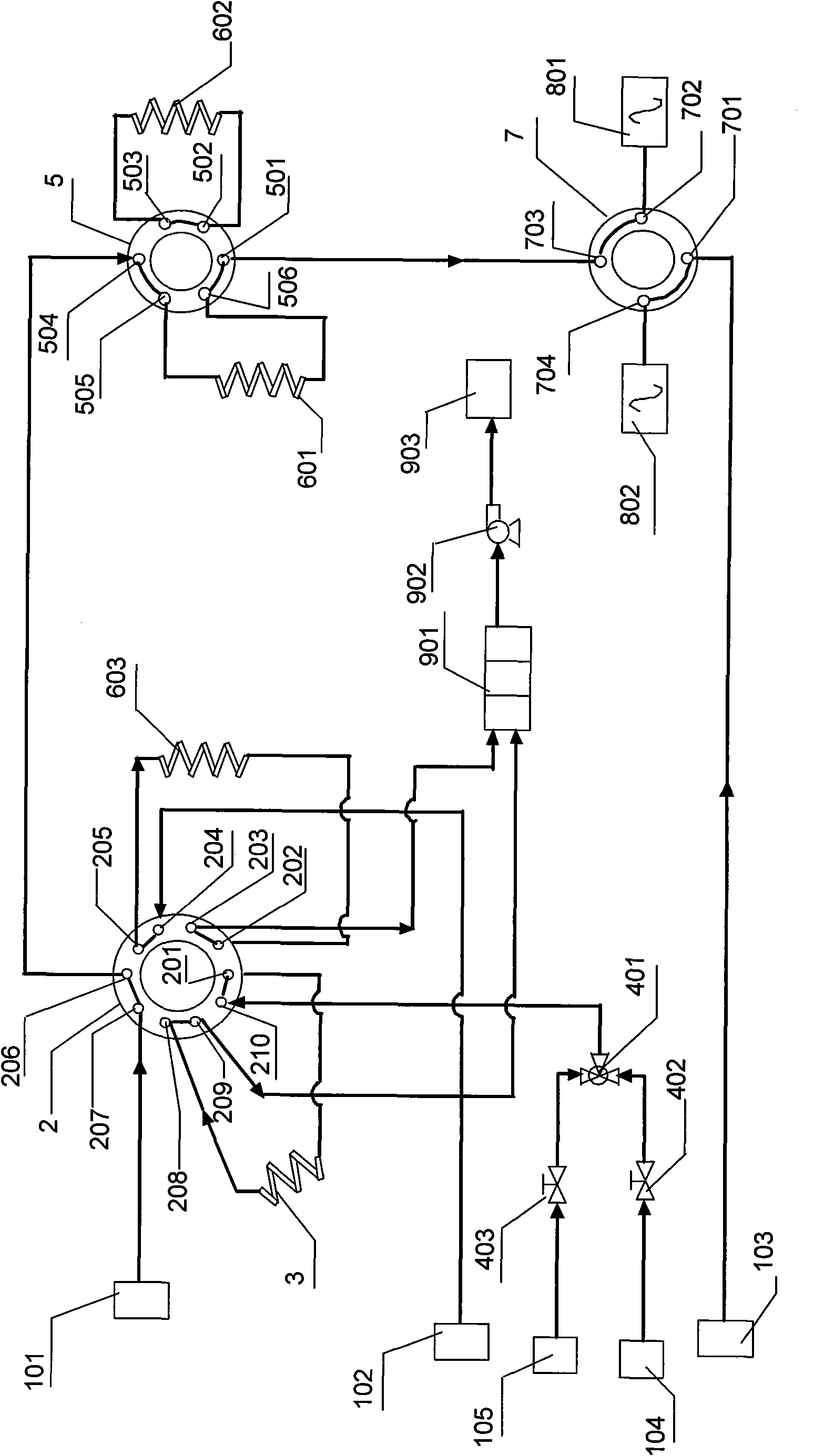

[0026] Such as figure 1 and figure 2 As shown, a device for analyzing impurities in corrosive gases, its structure includes a three-way auxiliary carrier gas flow stabilization system, corrosive gas base gas passage 104, helium passage 105, corrosion-resistant belt purging ten-way valve 2, Sampling column 3, corrosion-resistant belt purge six-way valve 5 and corrosion-resistant belt purge four-way valve 7, pre-separation column 603, analytical chromatographic column A601, and analytical chromatographic column B602.

[0027] Corrosion-resistant ten-way valve with purge 2 has ten channels, the first auxiliary carrier gas flow stabilization system 101 is connected to the seventh channel 207 of corrosion-resistant ten-way valve 2 with purge, the second auxiliary carrier gas flow stabilization system The system 102 is connected to the fourth channel 204 of the corrosion-resistant belt purging ten-way valve 2, and the two ends of the sampling column 3 are respectively connected to...

Embodiment 2

[0042] For low-purity corrosive gases, the content of impurity components is relatively high. The sampling process is the same as in Example 1. The third channel of the corrosion-resistant belt purging four-way valve is connected to the fourth channel, and the first channel is connected to the second channel. . The auxiliary carrier gas I flows out of the analytical chromatographic column A or analytical chromatographic column B with impurity components and then enters the thermal conductivity detector 802 for analysis and detection. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com