Method for preparing sample for low-carbon steel EBSD analysis

A low-carbon steel and sample technology, which is applied in the field of low-carbon steel EBSD sample preparation, can solve the problems of difficulty in mastering the success rate and heavy workload, and achieve the effect of simple operation and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

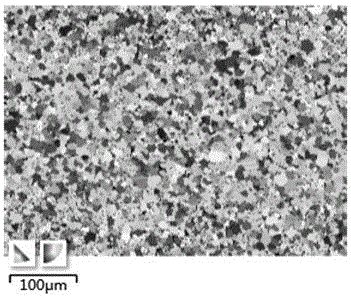

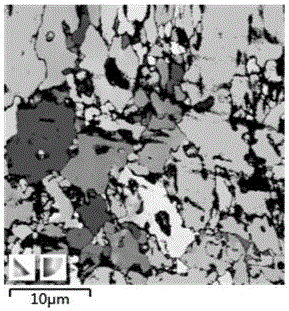

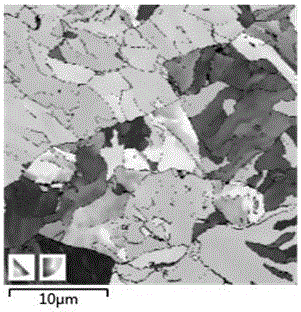

Image

Examples

Embodiment 1

[0030] A kind of preparation method of low carbon steel EBSD analysis sample, comprises the following steps:

[0031] (1) Sample interception: Use a wire cutting machine to process the low-carbon steel into a sample with a size of 6mm×8mm×8mm, and use a grinder to grind the surface of the sample to be tested;

[0032] (2) Grinding: Polish the sample with 400#, 800#, 1200# silicon carbide water sandpaper. The grinding time is 2 minutes each time with different numbers of sandpaper. The sample should be rotated in the same direction every time the sandpaper is changed. 90 degrees, to grind off the scratches left by the previous grade of sandpaper, and use water as a lubricant and coolant during the polishing process;

[0033] (3) Cleaning: Clean the ground sample with absolute ethanol, and dry it with the cold air of a hair dryer;

[0034] (4) Argon ion beam polishing: Use a high-energy argon ion beam to polish the surface of the sample to be tested. The energy of the argon ion...

Embodiment 2

[0038] The invention provides a kind of preparation method of low carbon steel EBSD sample, comprises the following steps:

[0039] (1) Sample interception: Use a wire cutting machine to process a low-carbon steel sample with a size of 8mm×8mm×8mm, and use a grinder to grind the surface of the sample to be tested;

[0040] (2) Polishing: Polish the sample with 400#, 800#, 1200# silicon carbide water sandpaper, each time with different numbers of sandpaper for 4 minutes, and rotate the sample in the same direction every time the sandpaper is changed 90 degrees, to grind off the scratches left by the previous grade of sandpaper, and use water as a lubricant and coolant during the polishing process;

[0041] (3) Cleaning: Clean the ground sample with absolute ethanol, and dry it with the cold air of a hair dryer;

[0042] (4) Argon ion beam polishing: Polish the surface of the sample to be tested with a high-energy argon ion beam. The energy of the argon ion beam is 4.1KeV. The...

Embodiment 3

[0046] The invention provides a kind of preparation method of low carbon steel EBSD sample, comprises the following steps:

[0047] (1) Sample interception: Use a wire cutting machine to process a low-carbon steel sample with a size of 7mm×8mm×8mm, and use a grinder to grind the surface of the sample to be tested;

[0048] (2) Polishing: Polish the sample with 400#, 800#, 1200# silicon carbide water sandpaper. The grinding time is 3 minutes each time with different numbers of sandpaper, and each time the sandpaper is changed, the sample should be rotated 90 degrees in the same direction to remove the scratches left by the previous number of sandpaper, and use water as a lubricant during the polishing process and coolant;

[0049] (3) Cleaning: Clean the ground sample with absolute ethanol, and dry it with the cold air of a hair dryer;

[0050] (4) Argon ion beam polishing: Use a high-energy argon ion beam to polish the surface of the sample to be tested. The energy of the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com