Left/right adjustable plastic-steel window hinge

An adjustable, plastic-steel window technology, applied to hinges, door/window accessories, pin hinges, etc., can solve the problems of inconvenient installation and processing, increased friction, complex structure, etc., and achieve easy installation and processing The effect of making, reducing the friction force of the switch, and overcoming the deformation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

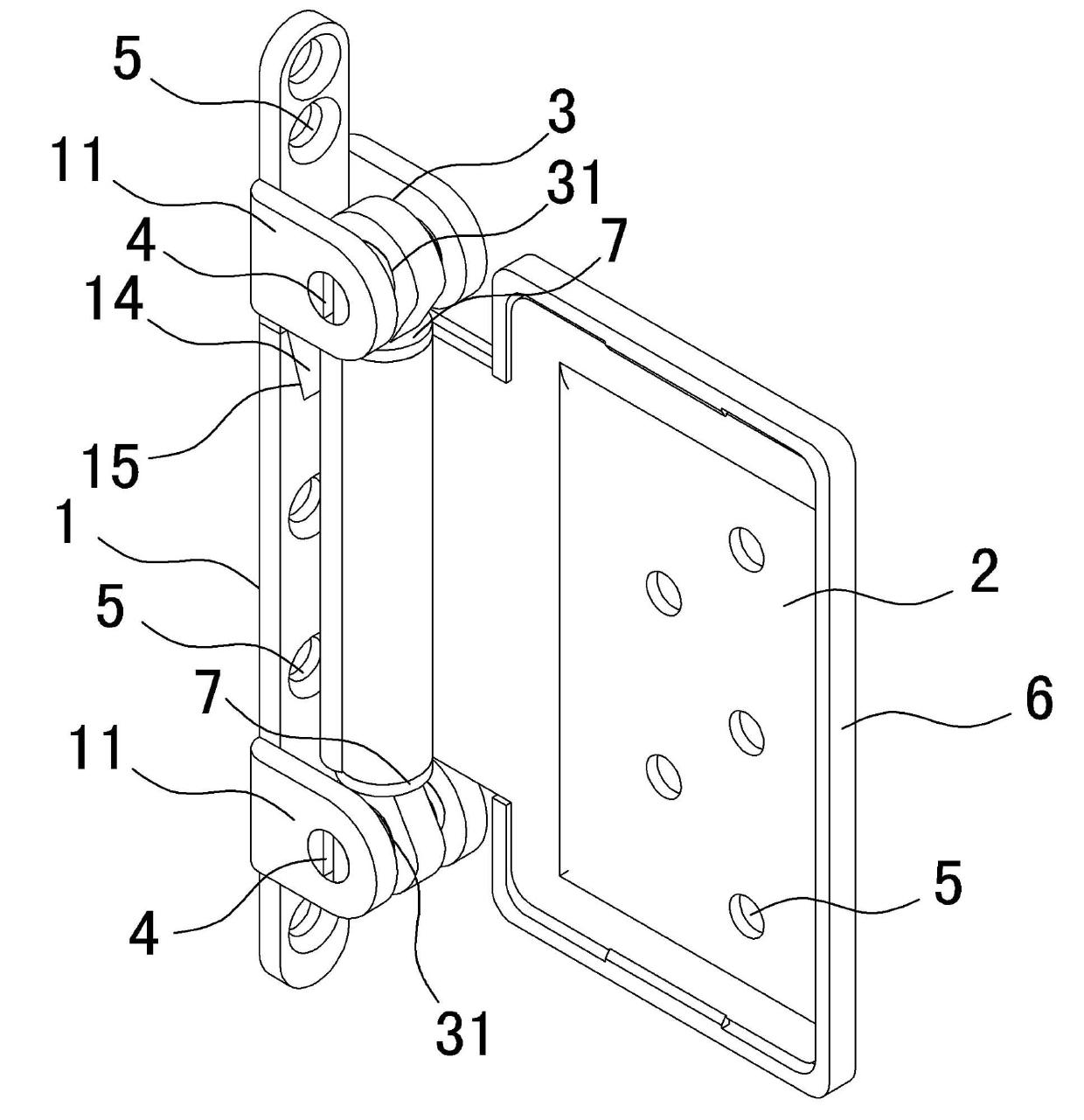

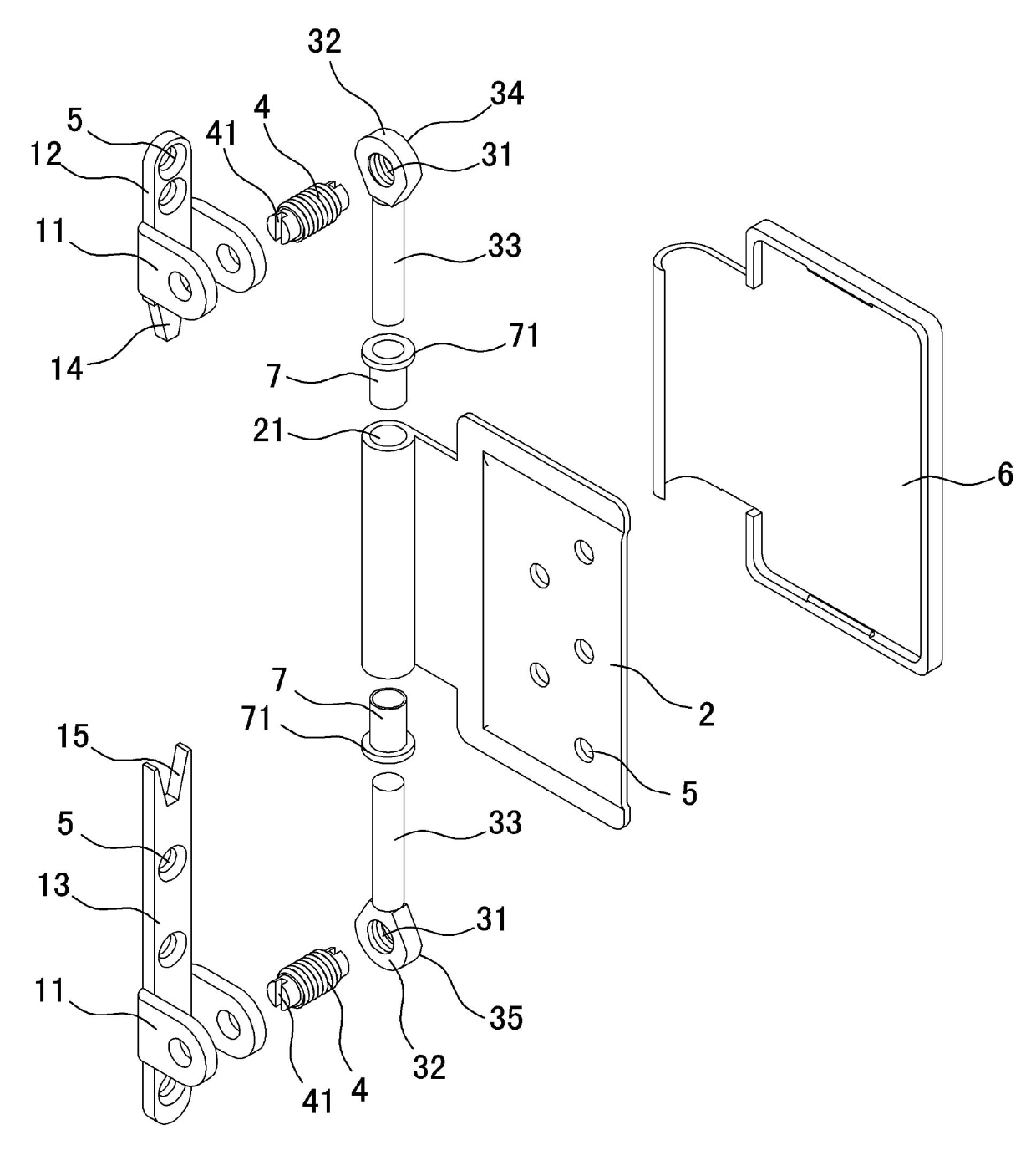

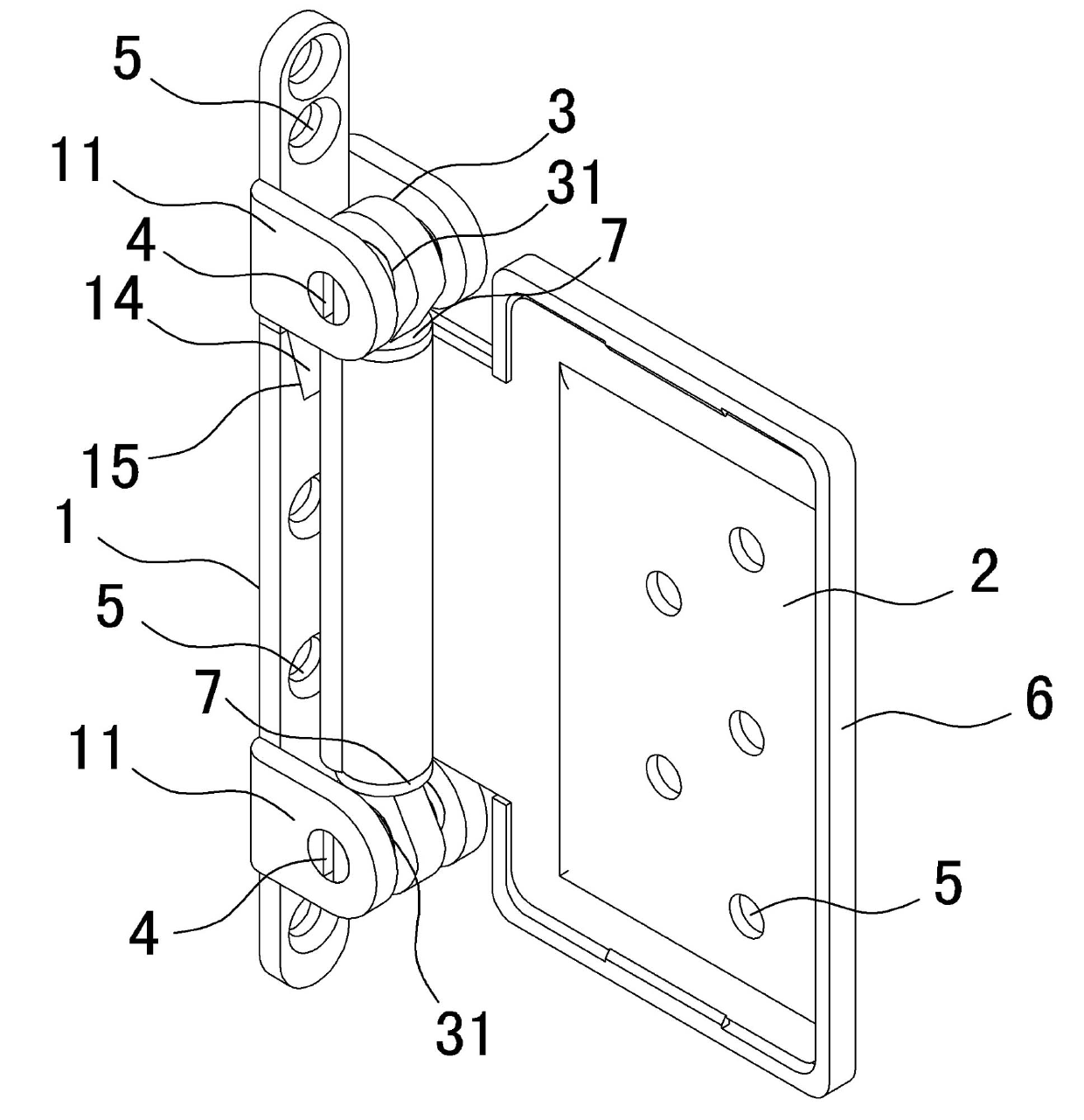

[0009] The window frame mounting body 1 is composed of an upper section 12 and a lower section 13, and two hinge seats 11 of the window frame mounting body 1 are respectively arranged on the upper section 12 and the lower section 13. The upper section 12 and the lower section 13 of the window frame mounting body 1 are respectively provided with matching positioning clips 14 and positioning slots 15 to prevent the upper section 12 and the lower section 13 from moving laterally and shifting when they are mounted on the window frame. The upper section 12 and the lower section 13 of the window frame mounting body 1 are respectively provided with several mounting screw holes 5 .

[0010] The sash installation body 2 is composed of two parts, the left and right parts, which are fixed vertically by one side with a hinge shaft installation hole 21 and with several installation screw holes 5 on the other side. The sash mounting body 2 is provided with a plastic cover 6 that can be buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com