Electrolysis direct current system online insulated monitoring device and a monitoring method

An insulation monitoring device and DC system technology, which is applied in the direction of fault location, test circuit, and test dielectric strength, etc., can solve the problem of inability to detect in time, inability to realize the insulation of the DC busbar to the ground, and inability to realize real-time online monitoring of the DC busbar and other problems, to achieve the effect of low equipment and installation costs, novel and reasonable layout, safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

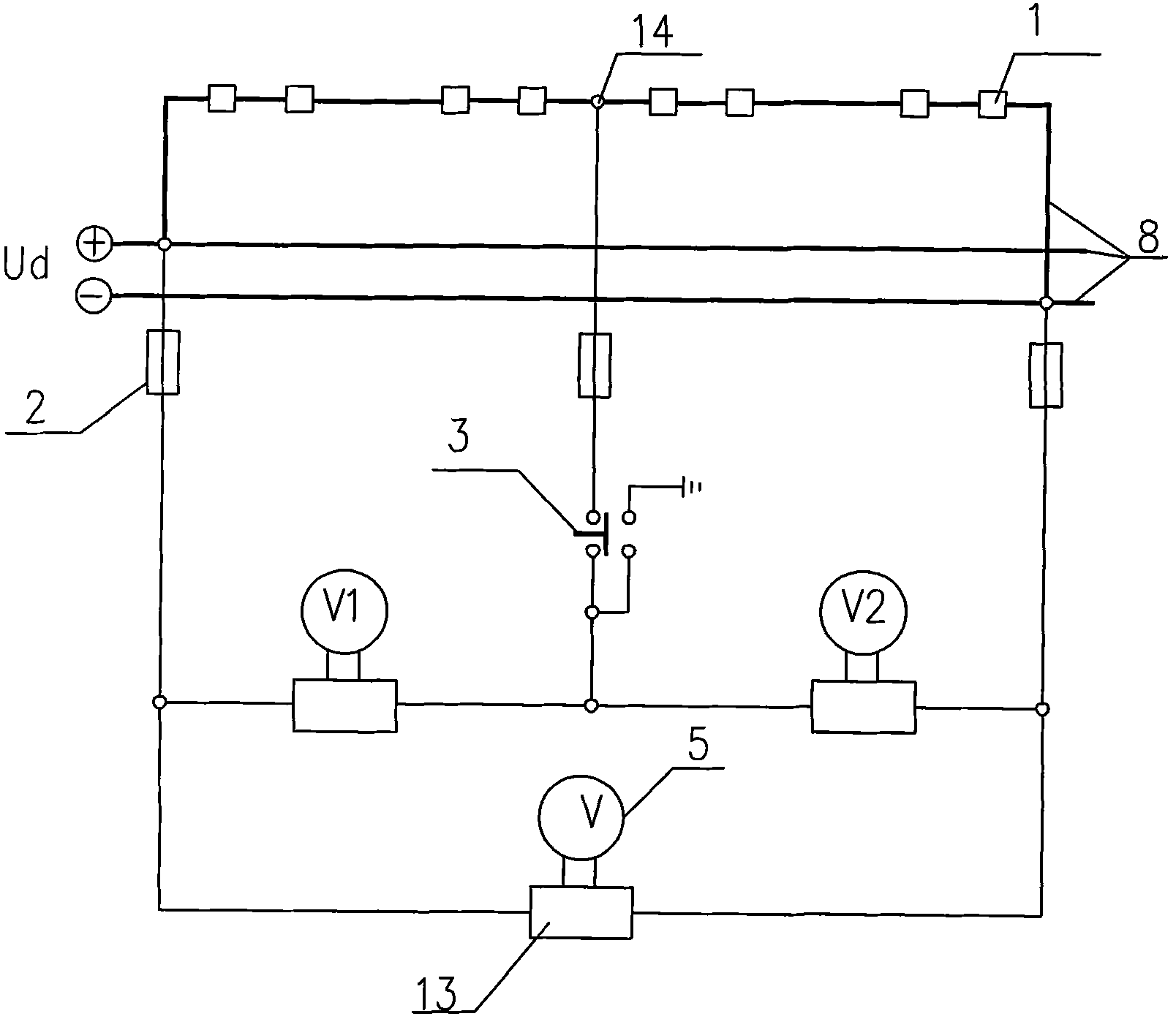

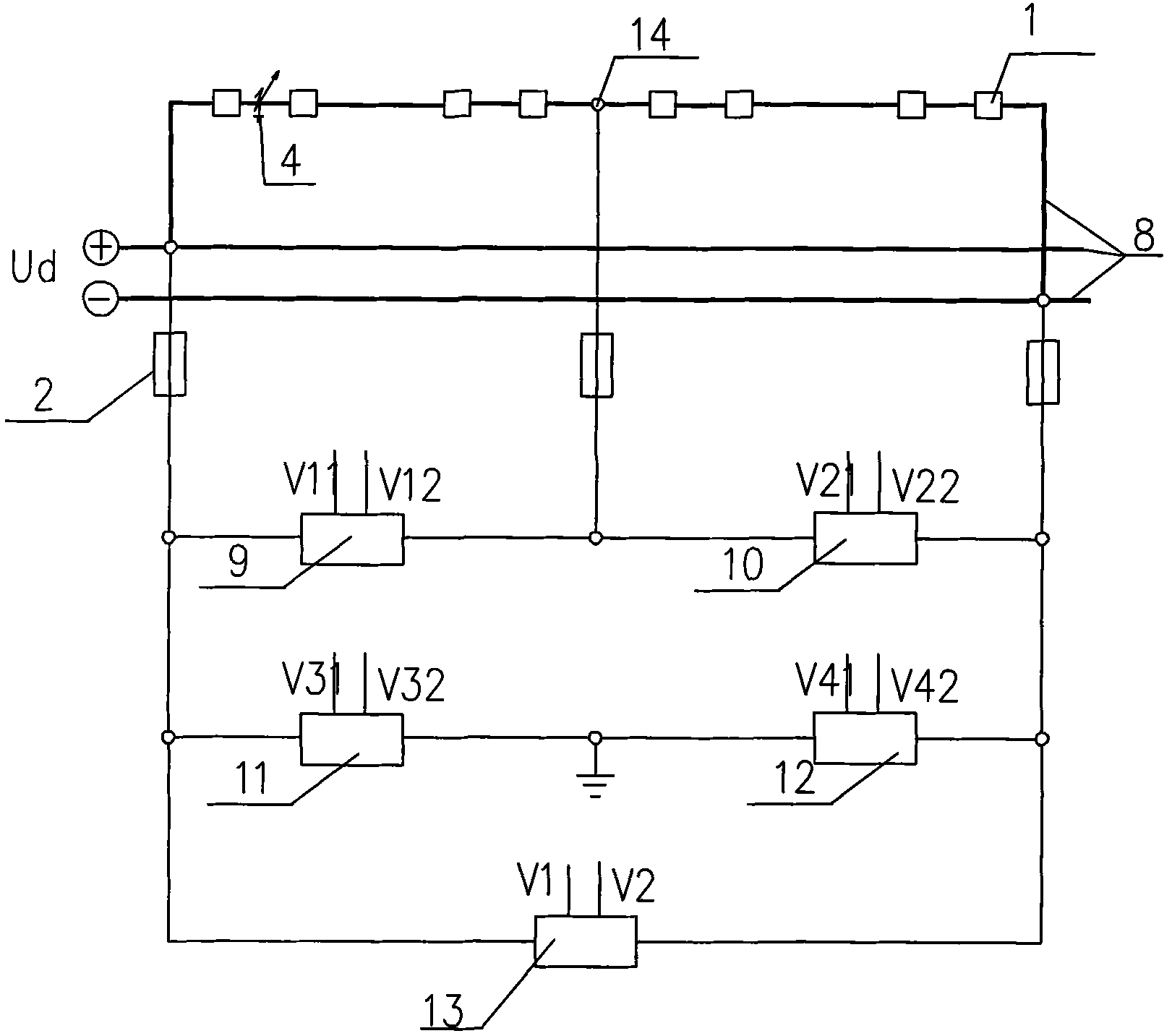

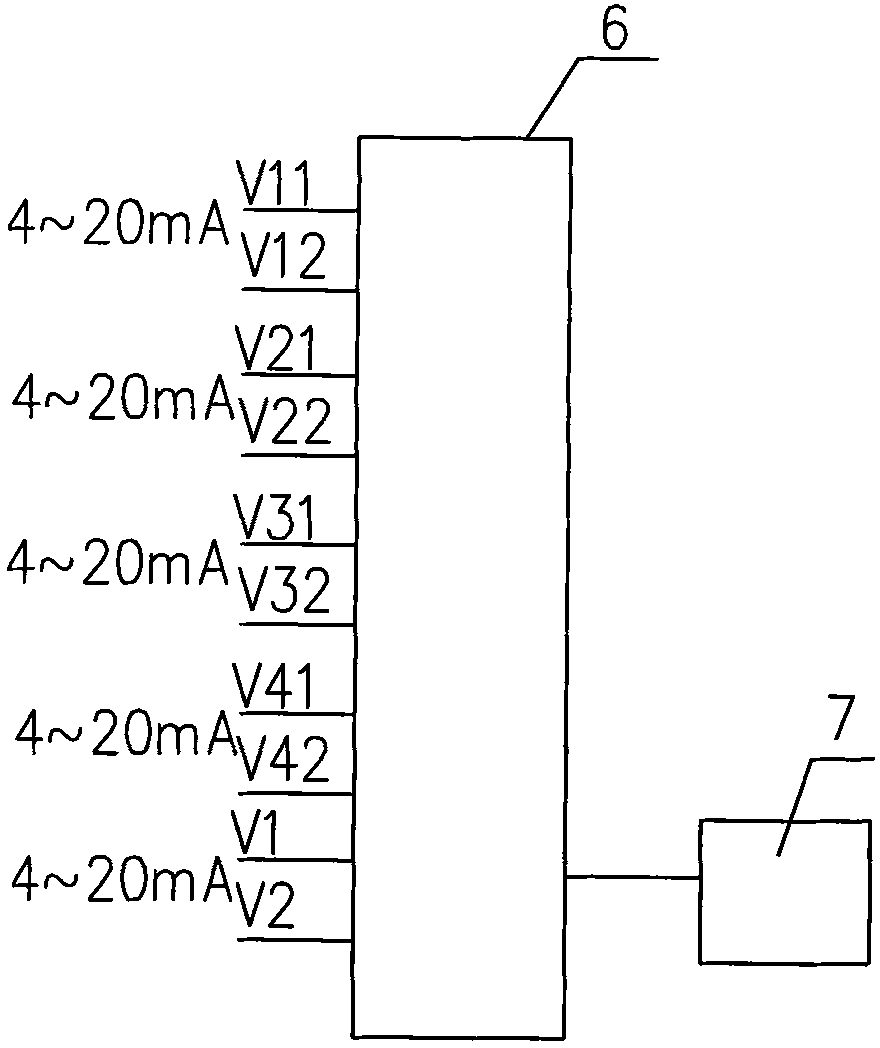

[0016] Such as figure 2 As shown, an on-line insulation monitoring device for an electrolytic DC system in the present invention includes a first voltage transmitter 9 and a second voltage transmitter 10 connected in series at both ends of the large electrolytic DC bus voltage Ud, and the first voltage transmitter connected in series The fifth voltage transmitter 13 connected in parallel with the transmitter 9 and the second voltage transmitter 10 is arranged on the electrolytic tank 1 at both ends of the electrolytic DC bus voltage, and the DC bus 8 is used between the electrolytic DC bus voltage and the electrolytic tank 1 Connection, the third voltage transmitter 11 and the fourth voltage transmitter 12 are connected in series at both ends of the electrolytic DC bus voltage, the first voltage transmitter 9 and the second voltage transmitter 10 are connected with the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com