Medical suture needle

A suture needle and medical technology, applied in the field of medical suture needles, can solve the problems of metal wire breakage, breakage, etc., and achieve the effect of improving fragility, improving thread fragility, and improving fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

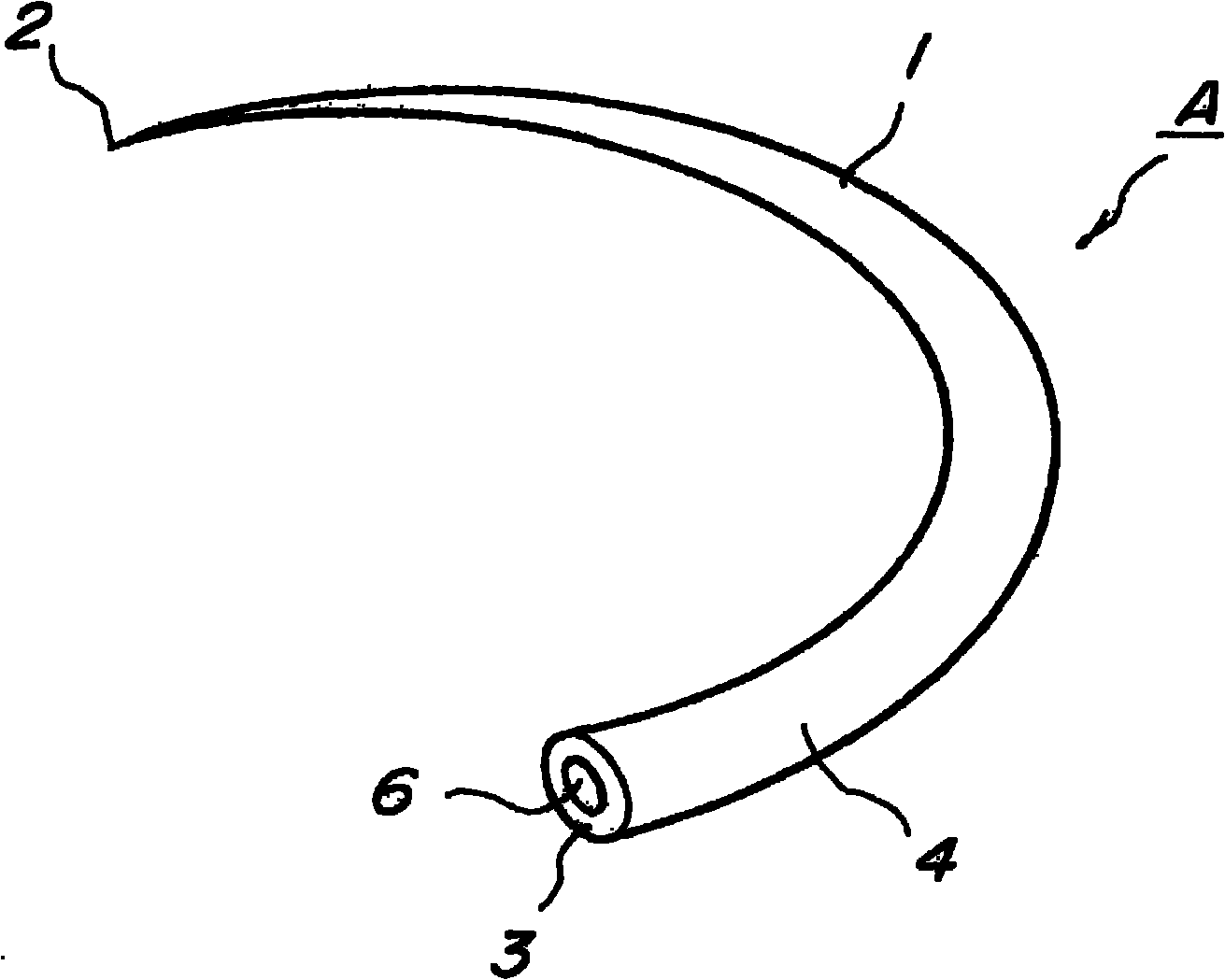

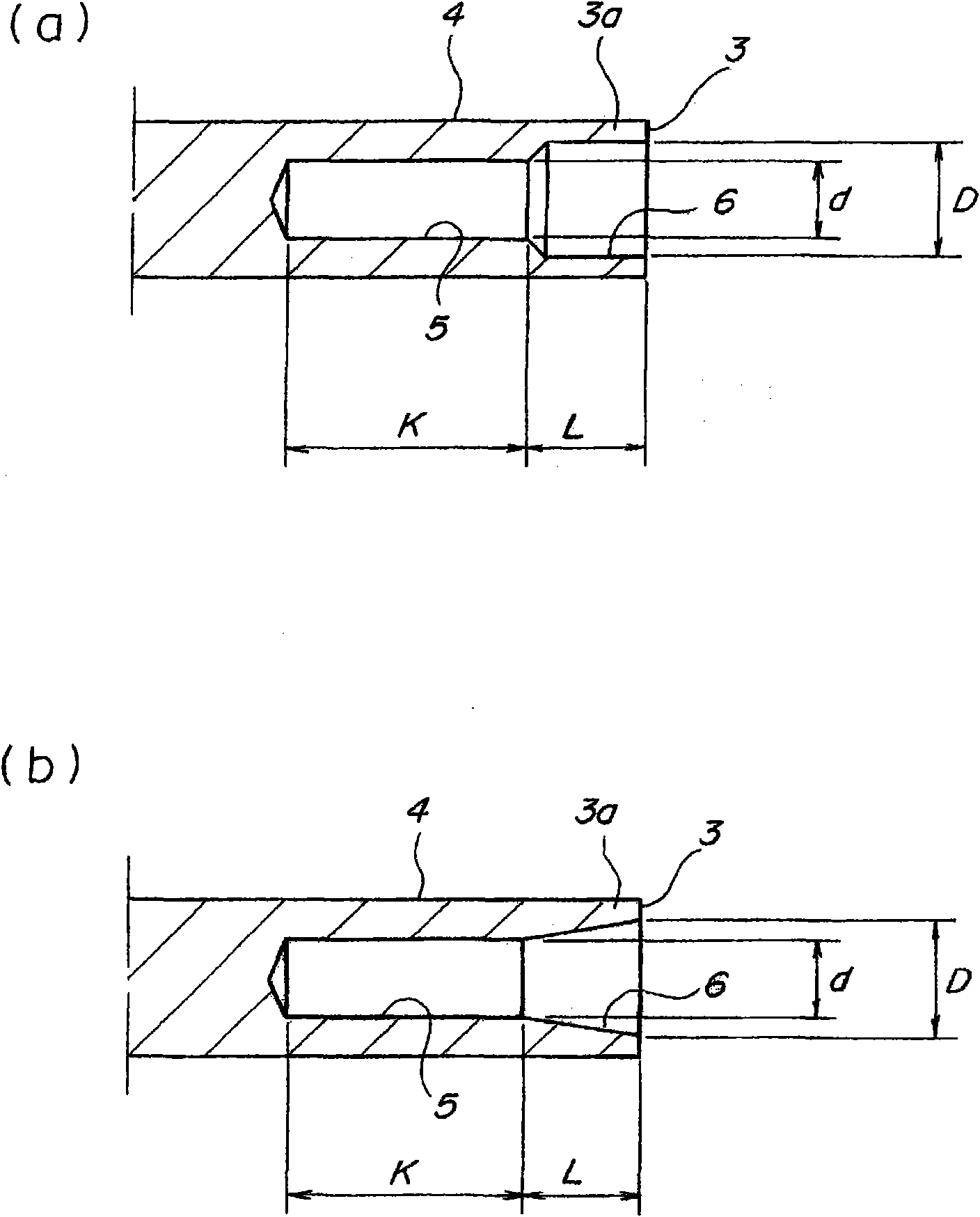

[0040] Next, the structure of the suture needle according to this embodiment will be described with reference to the drawings. figure 1 It is a figure explaining the whole structure of a suture needle. figure 2 It is a cross-sectional view of the base end portion of a suture needle, and is a diagram illustrating the structure of a blind hole and a countersink hole.

[0041] figure 1 The shown medical suture needle A is a suture needle that pierces the bone when suturing the bone. The other end is formed with a base end face 3 . In addition, the base end surface 3 side of the needle body 1 is formed as a base end portion 4 .

[0042] In this embodiment, the cross section of the needle body 1 is formed in a circle, but it is not limited to this cross section shape, and may be formed in a polygonal shape including a triangle in cross section, and a blade is formed on any edge. In addition, the needle point 2 is not limited to a sharp point, but may be a so-called blunt nee...

Embodiment 2

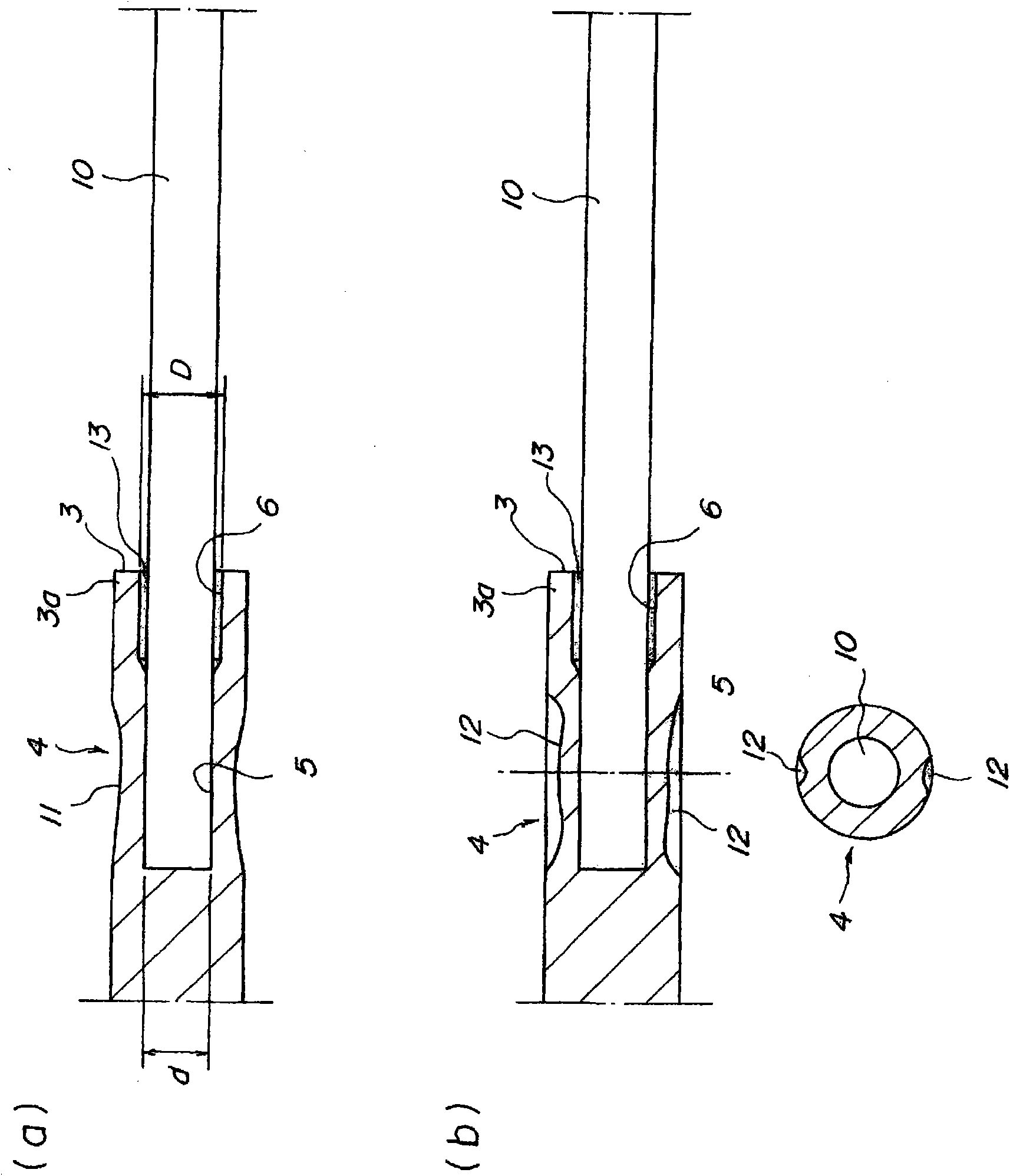

[0055] Next, the above-mentioned experimental results will be described, and prior to the description, the structure of the threaded suture needle according to this embodiment will be described with reference to the drawings. image 3 It is a diagram illustrating a state in which a thread is combined with a blind hole formed in a suture needle. Figure 4 It is a figure explaining the state which carried out the bending test of the thread|yarn bonded to the suture needle. In addition, in the figure, the same code|symbol is attached|subjected to the same part as the above-mentioned Example, and it demonstrates.

[0056] In the suture needle with thread (medical suture needle) according to the present invention, a blind hole and a countersink are formed on the base end surface of the suture needle configured to be able to pierce bone, and a metal thread 10 is integrally integrated with the blind hole. . In the present invention, it is necessary to form a blind hole and a counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com