A general-purpose color masterbatch with high carbon black content and high melt flow rate and its preparation method

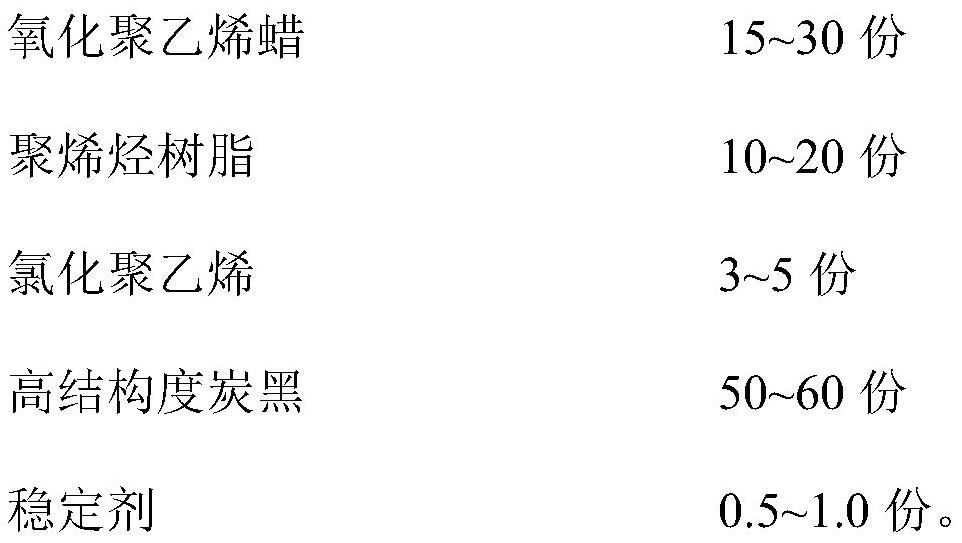

A flow rate, high melt technology, applied in the field of high carbon black content and high melt flow rate general-purpose color masterbatch and preparation, can solve the problem that can not fully meet the use of non-polar polymer and polar polymer system, color masterbatch Solve the problems of low flow rate of granular melt, and achieve the effect of good dispersion, high coloring strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

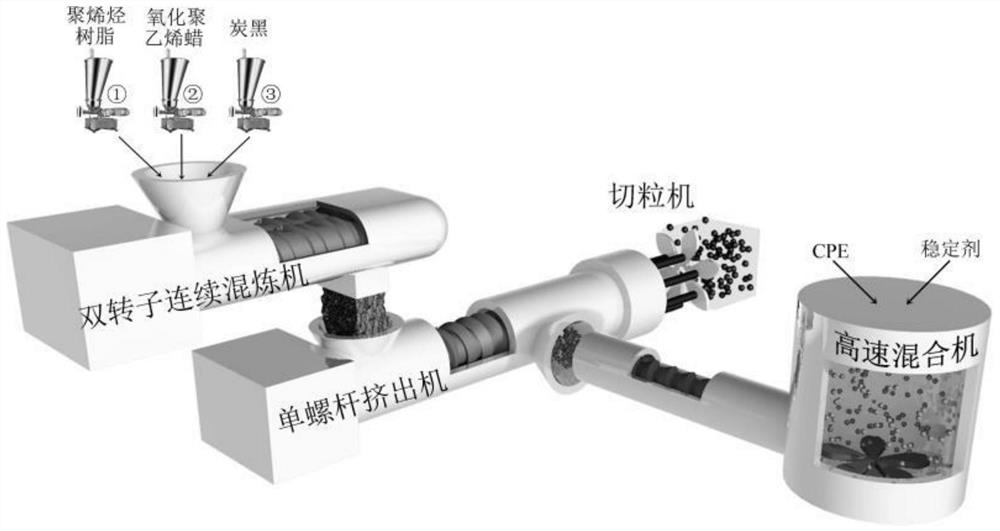

Method used

Image

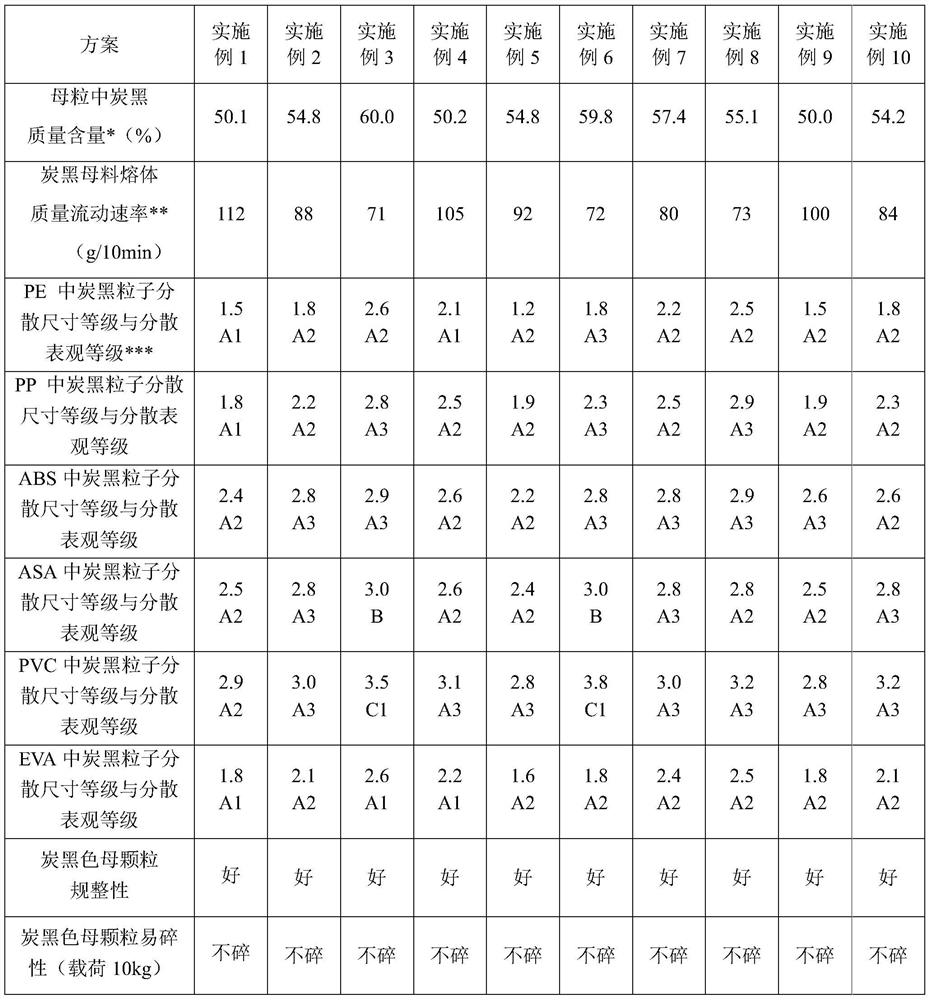

Examples

Embodiment 1

[0028] Raw material formula (mass ratio, parts): LDPE (load 2160g, MFR=100g / 10min at a temperature of 190°C) 16.5, oxidized PE wax (140°C viscosity 4000mPa.s, acid value 20mg KOH / g) 10, oxidized PE wax (140°C viscosity 6000mPa.s, acid value 30mg KOH / g) 10, oxidized PE wax (140°C viscosity 8000mPa.s, acid value 40mg KOH / g) 10, CPE (chlorine atomic mass fraction 33%, door Nickel viscosity ML(1+4) is 45 at 120°C, residual melting enthalpy is 0J / g)3, carbon black with high structure (particle size 15nm, specific surface area 100m 2 / g, oil absorption value 105mL / g, tinting strength 100) 50, antioxidant 1010 0.1, antioxidant 1680.15, calcium stearate 0.25.

[0029] Preparation Process:

[0030] High-speed mixing of chlorinated polyethylene resin and stabilizer: In a high-speed mixer, stir the powdered chlorinated polyethylene resin, metal soap heat stabilizer, antioxidant and other additives in a high-speed mixer at a low speed below 500rpm for 2 minutes, Start the high speed, th...

Embodiment 2

[0034] Raw material formula (mass ratio, parts): LLDPE (load 2160g, MFR=150g / 10min at a temperature of 190°C) 15, oxidized PE wax (140°C viscosity 8000mPa.s, acid value 10mg KOH / g) 26, CPE (chlorine The atomic mass fraction is 38%, the Mooney viscosity ML(1+4) is 55 at 120°C, the residual melting enthalpy is 5J / g)3, and the carbon black with high structure (particle size 20nm, specific surface area 120m 2 / g, oil absorption value 125mL / g, tinting strength 110) 55, antioxidant 1010 0.25, antioxidant 168 0.25, barium stearate 0.5.

[0035] Preparation Process:

[0036] High-speed mixing of chlorinated polyethylene resin and stabilizer: In a high-speed mixer, stir the powdered chlorinated polyethylene resin, metal soap heat stabilizer, antioxidant and other additives in a high-speed mixer at a low speed below 500rpm for 2 minutes, Start the high speed, that is, above 1000rpm, stir the material temperature to 60°C, and then discharge it into the jacketed water-cooled mixer to con...

Embodiment 3

[0040] Raw material formula (mass ratio, parts): HDPE (load 2160g, MFR=200g / 10min at a temperature of 190°C) 10, oxidized PE wax (140°C viscosity 6000mPa.s, acid value 15mg KOH / g) 24, CPE (chlorine The atomic mass fraction is 35%, the Mooney viscosity ML(1+4) is 48 at 120°C, the residual melting enthalpy is 1J / g)5, and the carbon black with high structure (particle size 18nm, specific surface area 110m 2 / g, oil absorption value 120mL / g, tinting strength 105)60, antioxidant 1010 0.2, antioxidant 168 0.3, calcium stearate 0.2, barium stearate 0.3.

[0041] Preparation Process:

[0042] High-speed mixing of chlorinated polyethylene resin and stabilizer: In a high-speed mixer, stir the powdered chlorinated polyethylene resin, metal soap heat stabilizer, antioxidant and other additives in a high-speed mixer at a low speed below 500rpm for 2 minutes, Start the high speed, that is, above 1000rpm, stir the material temperature to 50°C, and then discharge it into the jacketed water-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com