Universal color master batch with high carbon black content and high melt flow rate and preparation method thereof

A flow rate, high melt technology, applied in the field of high carbon black content and high melt flow rate general-purpose color masterbatch and preparation, can solve the problem of low melt flow rate of color masterbatch, which cannot fully meet the needs of non-polar polymers and Issues such as the use of polar polymer systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

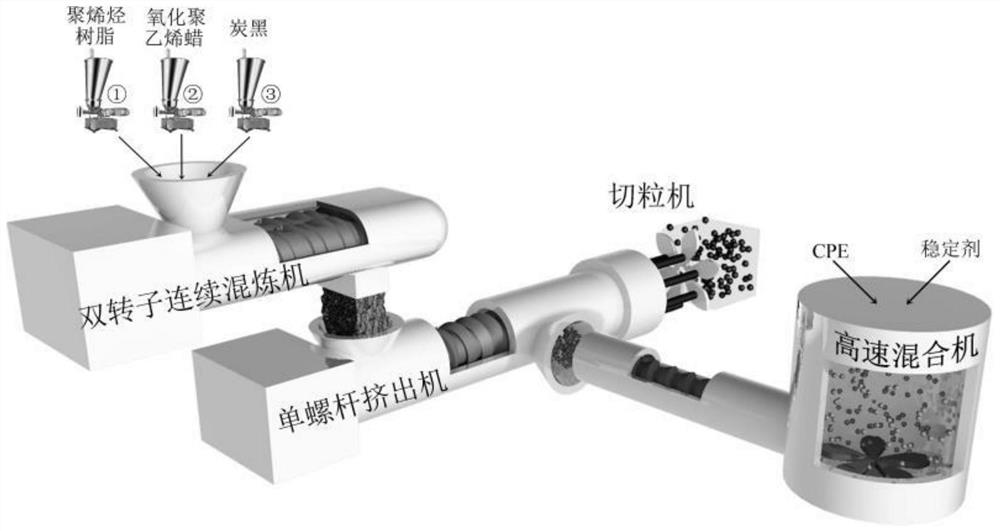

Method used

Image

Examples

Embodiment 1

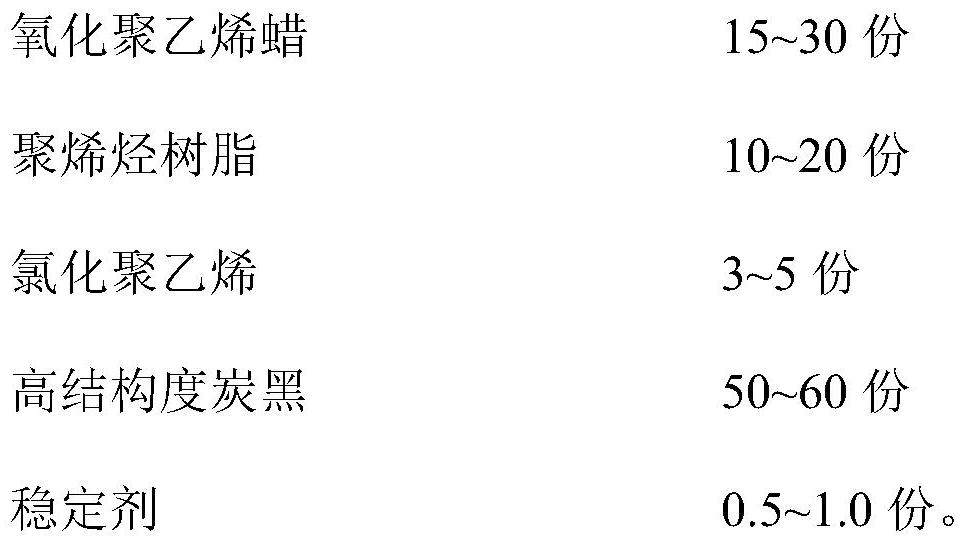

[0028] Raw material formula (mass ratio, parts): LDPE (load 2160g, MFR=100g / 10min at a temperature of 190°C) 16.5, oxidized PE wax (140°C viscosity 4000mPa.s, acid value 20mg KOH / g) 10, oxidized PE wax (140°C viscosity 6000mPa.s, acid value 30mg KOH / g) 10, oxidized PE wax (140°C viscosity 8000mPa.s, acid value 40mg KOH / g) 10, CPE (chlorine atomic mass fraction 33%, door Nickel viscosity ML(1+4) is 45 at 120°C, residual melting enthalpy is 0J / g)3, carbon black with high structure (particle size 15nm, specific surface area 100m 2 / g, oil absorption value 105mL / g, tinting strength 100) 50, antioxidant 1010 0.1, antioxidant 1680.15, calcium stearate 0.25.

[0029] Preparation Process:

[0030] High-speed mixing of chlorinated polyethylene resin and stabilizer: In a high-speed mixer, stir the powdered chlorinated polyethylene resin, metal soap heat stabilizer, antioxidant and other additives in a high-speed mixer at a low speed below 500rpm for 2 minutes, Start the high speed, th...

Embodiment 2

[0034] Raw material formula (mass ratio, parts): LLDPE (load 2160g, MFR=150g / 10min at a temperature of 190°C) 15, oxidized PE wax (140°C viscosity 8000mPa.s, acid value 10mg KOH / g) 26, CPE (chlorine The atomic mass fraction is 38%, the Mooney viscosity ML(1+4) is 55 at 120°C, the residual melting enthalpy is 5J / g)3, and the carbon black with high structure (particle size 20nm, specific surface area 120m 2 / g, oil absorption value 125mL / g, tinting strength 110) 55, antioxidant 1010 0.25, antioxidant 168 0.25, barium stearate 0.5.

[0035] Preparation Process:

[0036] High-speed mixing of chlorinated polyethylene resin and stabilizer: In a high-speed mixer, stir the powdered chlorinated polyethylene resin, metal soap heat stabilizer, antioxidant and other additives in a high-speed mixer at a low speed below 500rpm for 2 minutes, Start the high speed, that is, above 1000rpm, stir the material temperature to 60°C, and then discharge it into the jacketed water-cooled mixer to con...

Embodiment 3

[0040] Raw material formula (mass ratio, parts): HDPE (load 2160g, MFR=200g / 10min at a temperature of 190°C) 10, oxidized PE wax (140°C viscosity 6000mPa.s, acid value 15mg KOH / g) 24, CPE (chlorine The atomic mass fraction is 35%, the Mooney viscosity ML(1+4) is 48 at 120°C, the residual melting enthalpy is 1J / g)5, and the carbon black with high structure (particle size 18nm, specific surface area 110m 2 / g, oil absorption value 120mL / g, tinting strength 105)60, antioxidant 1010 0.2, antioxidant 168 0.3, calcium stearate 0.2, barium stearate 0.3.

[0041] Preparation Process:

[0042] High-speed mixing of chlorinated polyethylene resin and stabilizer: In a high-speed mixer, stir the powdered chlorinated polyethylene resin, metal soap heat stabilizer, antioxidant and other additives in a high-speed mixer at a low speed below 500rpm for 2 minutes, Start the high speed, that is, above 1000rpm, stir the material temperature to 50°C, and then discharge it into the jacketed water-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com