Handheld jigsaw

A reciprocating saw, hand-held technology, applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., can solve the problems of small reciprocating saw, expensive, inclined, etc., to achieve the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

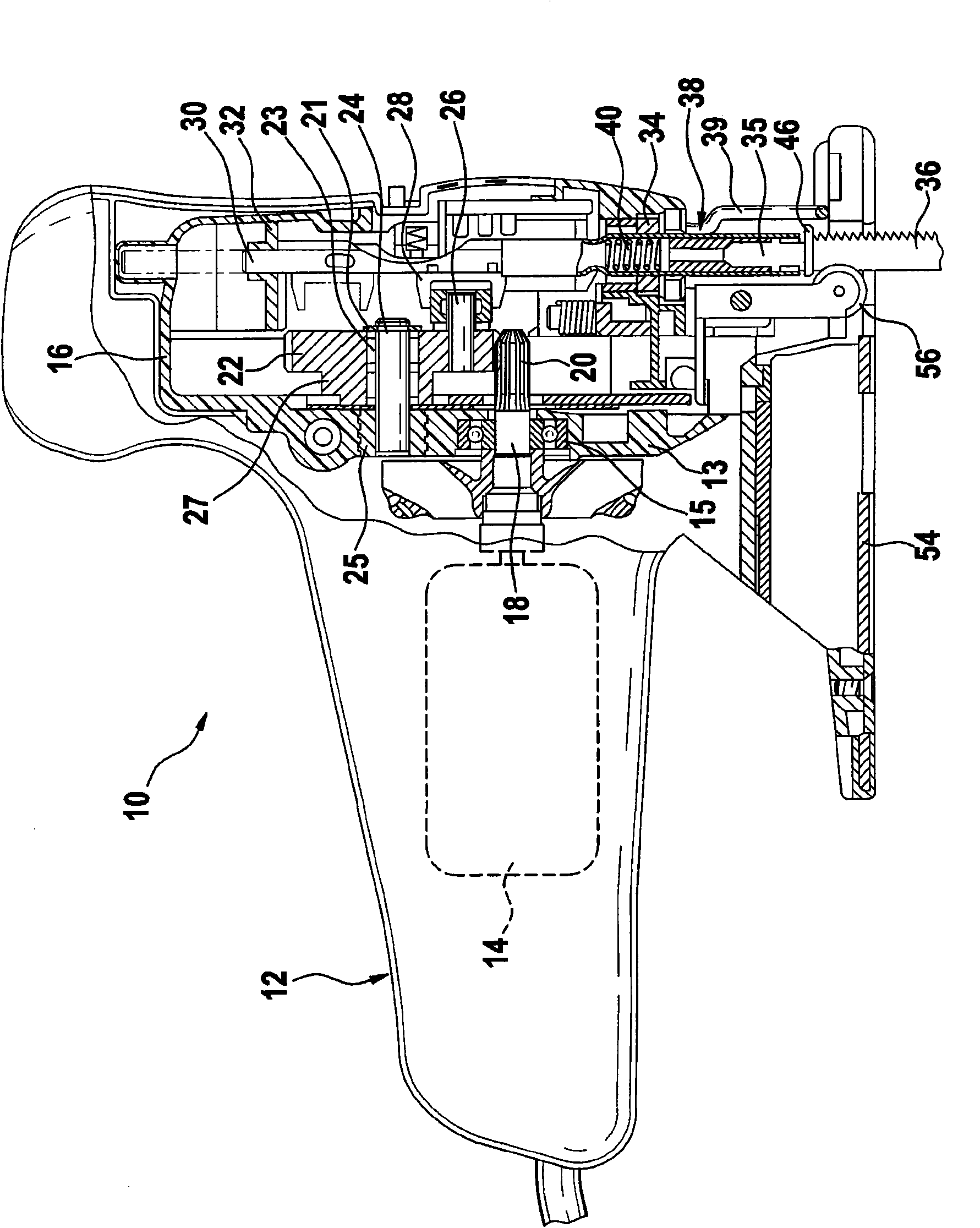

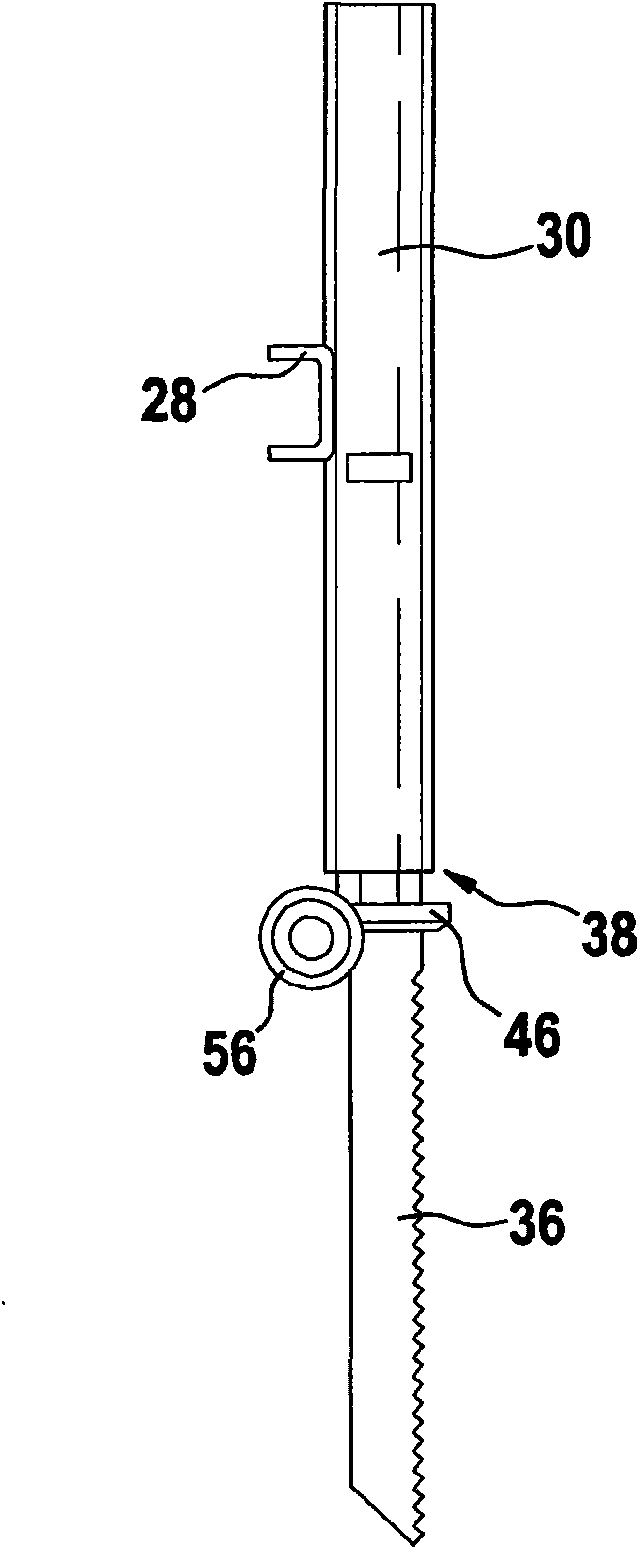

[0021] figure 1 The jigsaw 10 shown in includes a housing 12 in which a symbolic motor 14 is provided. The motor 14 is used to drive the reciprocating rod 30 and impart a reciprocating motion to the reciprocating rod through the transmission device 20, 22, 26, 28, and the reciprocating motion is transmitted to the saw blade 36. The saw blade 36 is detachably clamped in the saw blade clamping device 38 at the end of the reciprocating rod 30.

[0022] The housing 12 is swingably connected to the bottom plate 54 on its bottom surface, and the saw blade 36 penetrates the bottom plate downward so as to be able to perform sawing under the bottom plate 54.

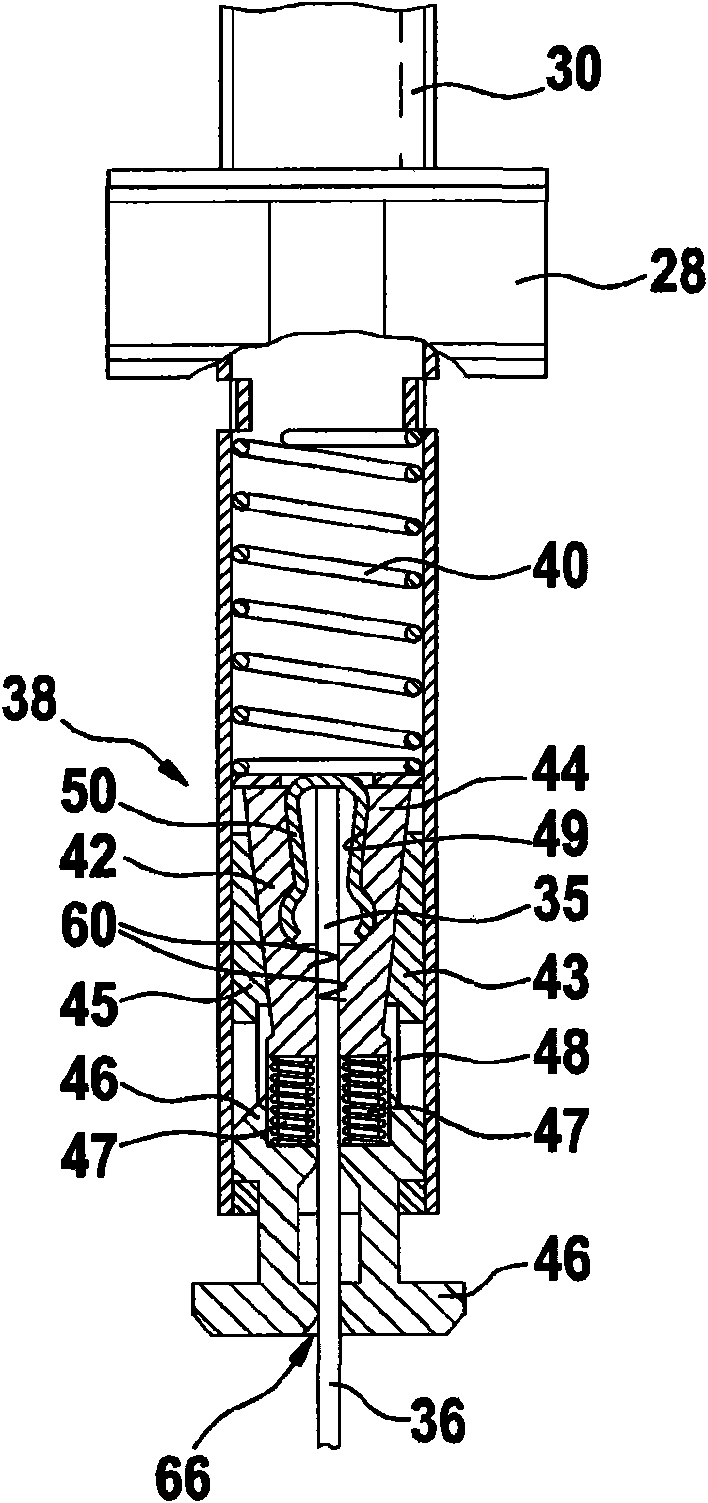

[0023] The reciprocating rod 30 configured as a continuous and smooth circular tube is linearly movably supported by upper and lower reciprocating rod bearings 32, 34 in the housing 12, and is provided with a reciprocating rod integrated in the tube at its lower end for The saw blade clamping device 38 that receives the saw blade 20....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com