120 ton platform wagon with standard gauge

A standard gauge and flat car technology, which is applied in the direction of freight cars, transport passenger cars, railway car body parts, etc., can solve the problems of long underframe length and small load capacity, so as to reduce self-weight, increase load, fatigue strength and service life Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

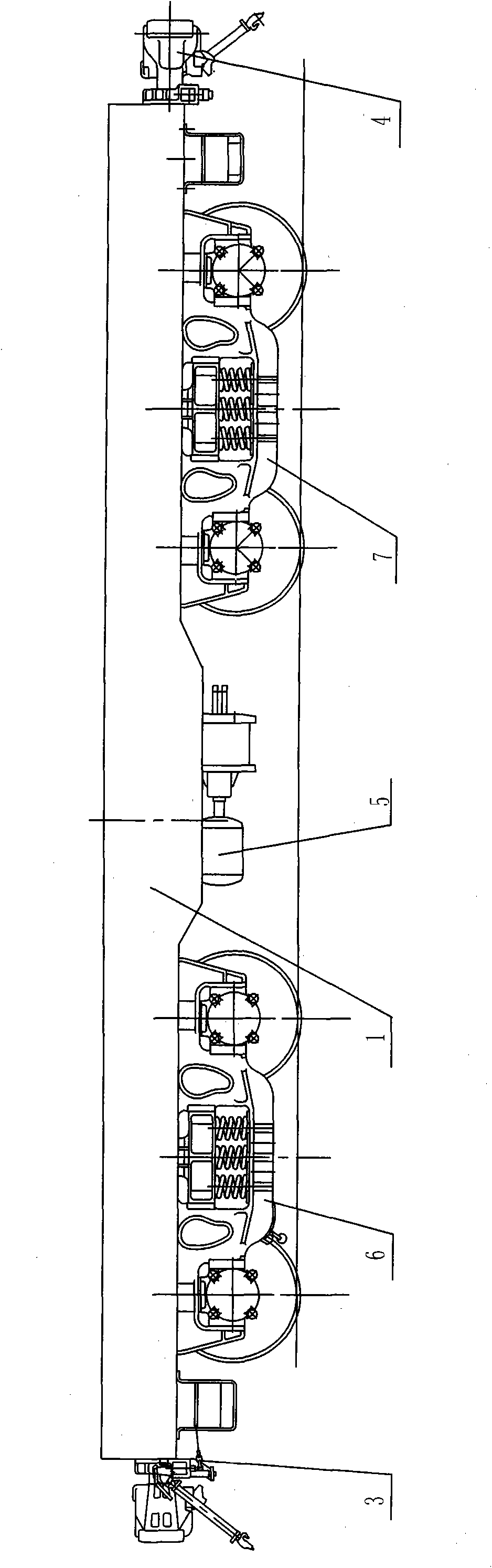

[0023] A 120-ton flat car with a standard gauge load, its composition includes: an underframe assembly 1 and a floor 2, one side of the underframe assembly 1 is connected to the hand brake device 3, and the other side of the underframe assembly 1 is connected to the coupler The buffer device 4, the bottom of the underframe assembly 1 is connected to the air steering device 5, the left half of the underframe assembly 1 is connected to the left bogie 6, and the right half of the underframe assembly 1 is connected to the right bogie 7, the upper end of the underframe assembly 1 is connected to the floor 2.

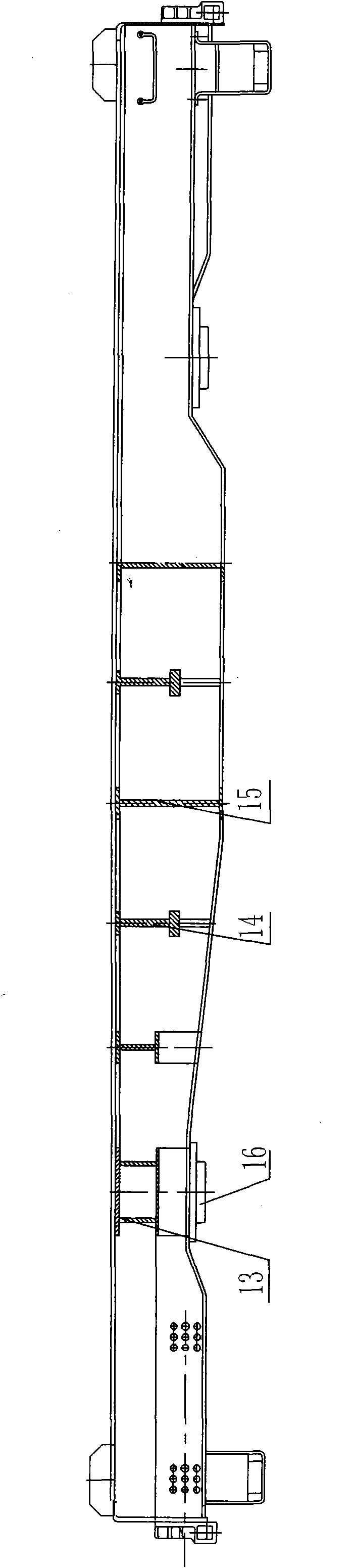

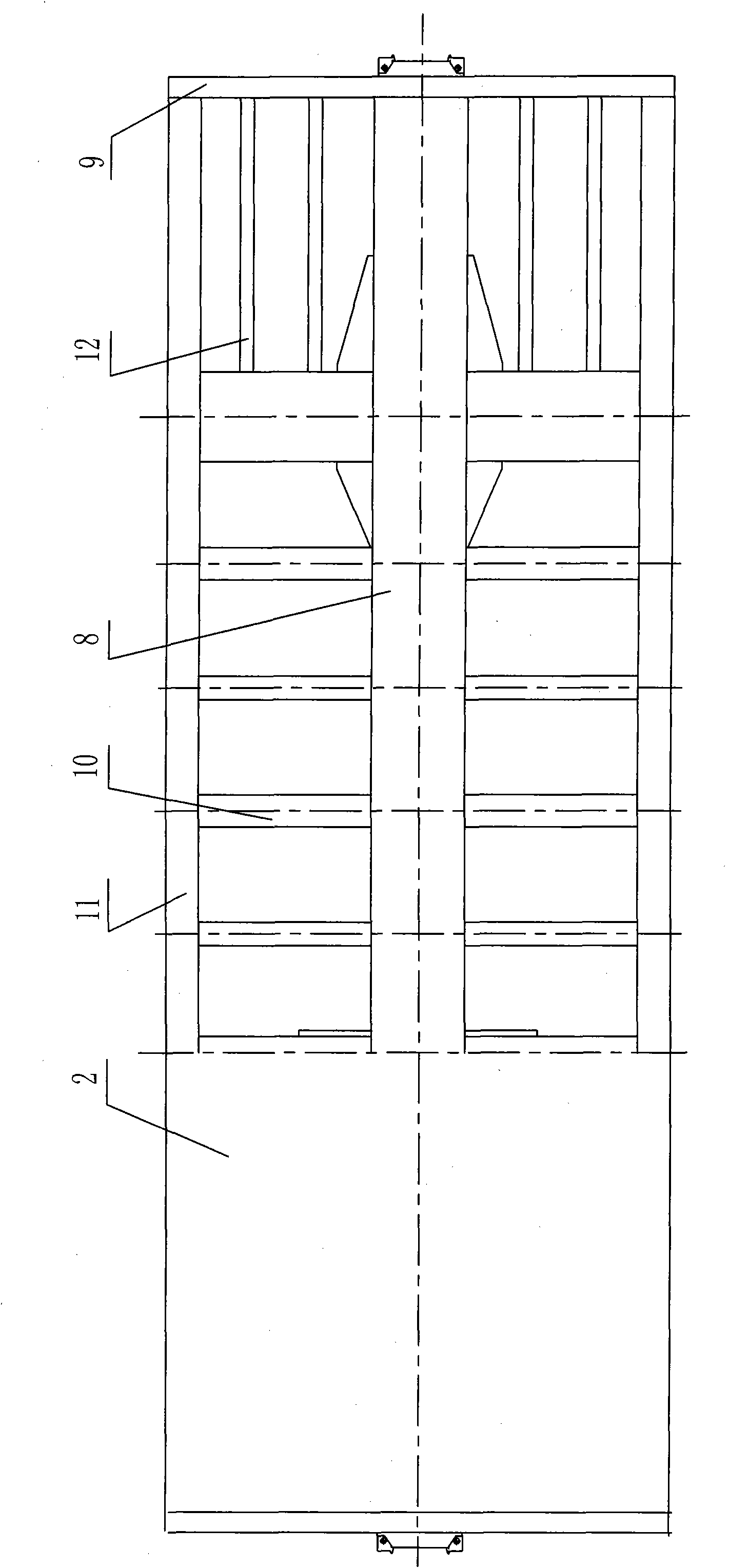

[0024] The 120-ton flat car with a standard gauge load, the underframe assembly 1 includes a center beam 8, the two ends of the center beam 8 are respectively connected to end beams 9, and the two sides of the center beam 8 are connected to reinforcing beams 10. The reinforcing beam 10 is connected to the side beam 11, the auxiliary beam 12 is installed between the middle bea...

Embodiment 2

[0028] In the 120-ton flat car with a standard gauge load of Example 1, the upper center plate and the lower center plate are made of cast steel, the lower side bearing iron is made of cast steel, and the hand brake device is NSW type hand brake, the coupler buffer device adopts 13B type coupler and ST type buffer, and the described air brake device adopts GK type three-way valve, 356×254 brake cylinder, DN32 main pipe and DN20 branch pipe.

Embodiment 3

[0030] For the 120-ton flat car with standard gauge load described in embodiment 1 or 2, the underframe assembly left bogie (one), air brake device, right bogie, underframe accessories, coupler buffer device, Hand brake assembly. Cargo is carried on the underframe assembly, and a left bogie and a right bogie are installed under the underframe assembly. The two bogies are the running parts of the car, running on the standard gauge. A hand braking device and a coupler buffer device are provided at the end of the chassis assembly, and air braking devices are provided on both sides of the lower part of the chassis assembly. The hand brake device and air brake device ensure accurate parking and safe operation of the vehicle, and the coupler buffer device plays a role of connection and buffer between vehicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com