Wall thickness difference detector

A detector and wall thickness difference technology, applied in the field of wall thickness difference detectors, can solve the problems of uneven wall thickness, high false detection rate, low accuracy, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific structure of the wall thickness difference measuring instrument created by the present invention is further described in conjunction with the accompanying drawings and embodiments, and its features and advantages are more clear.

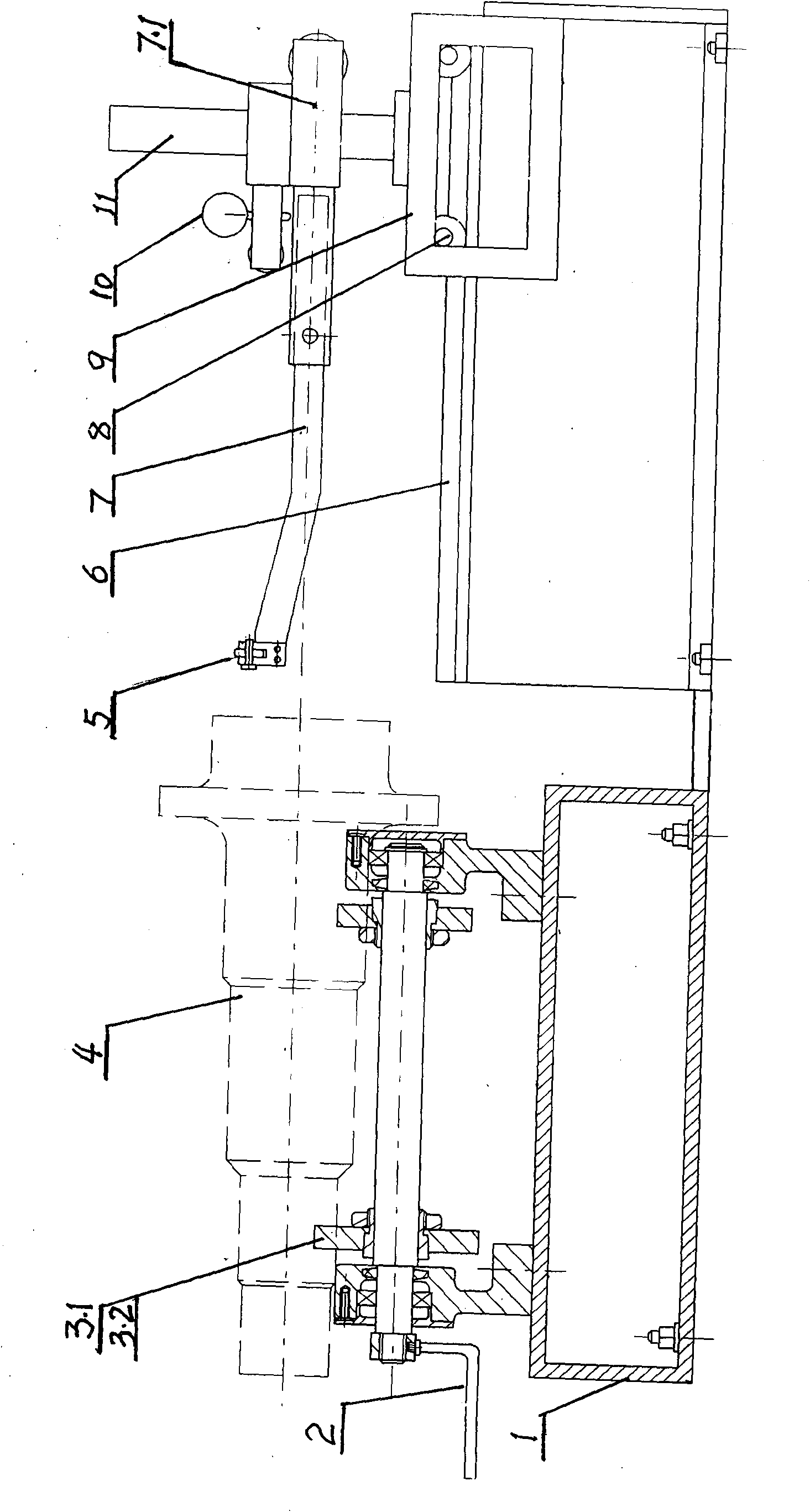

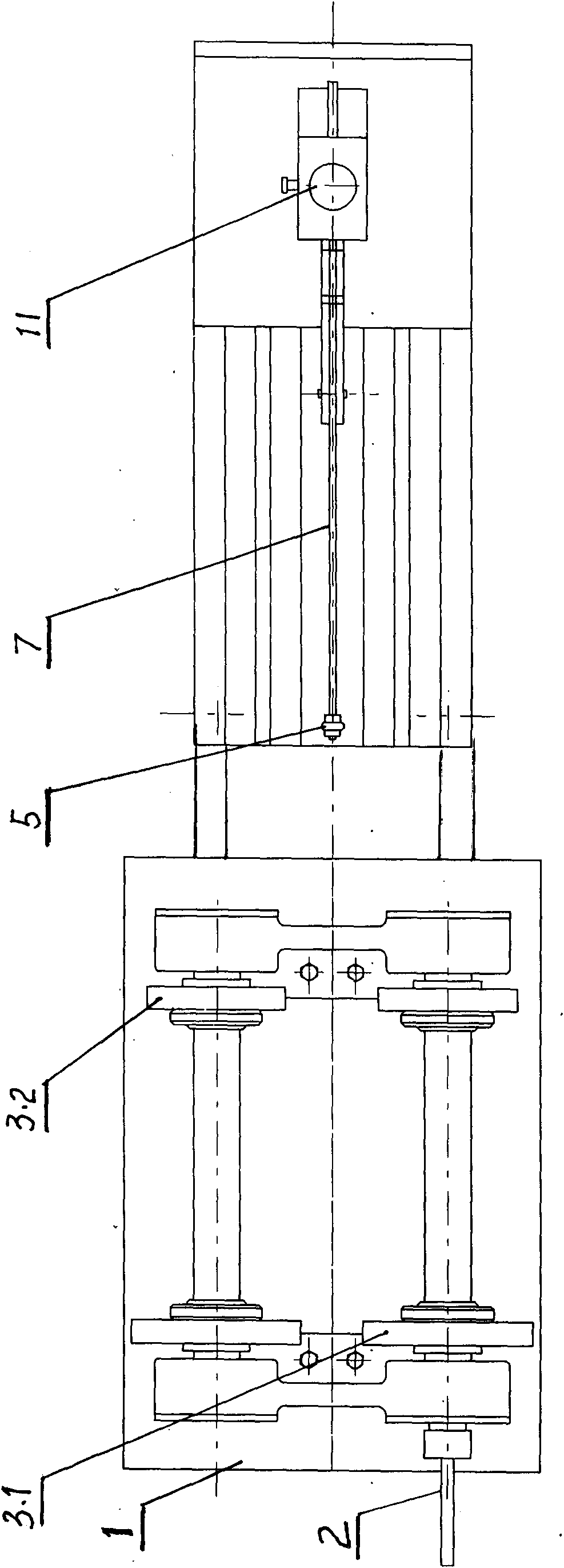

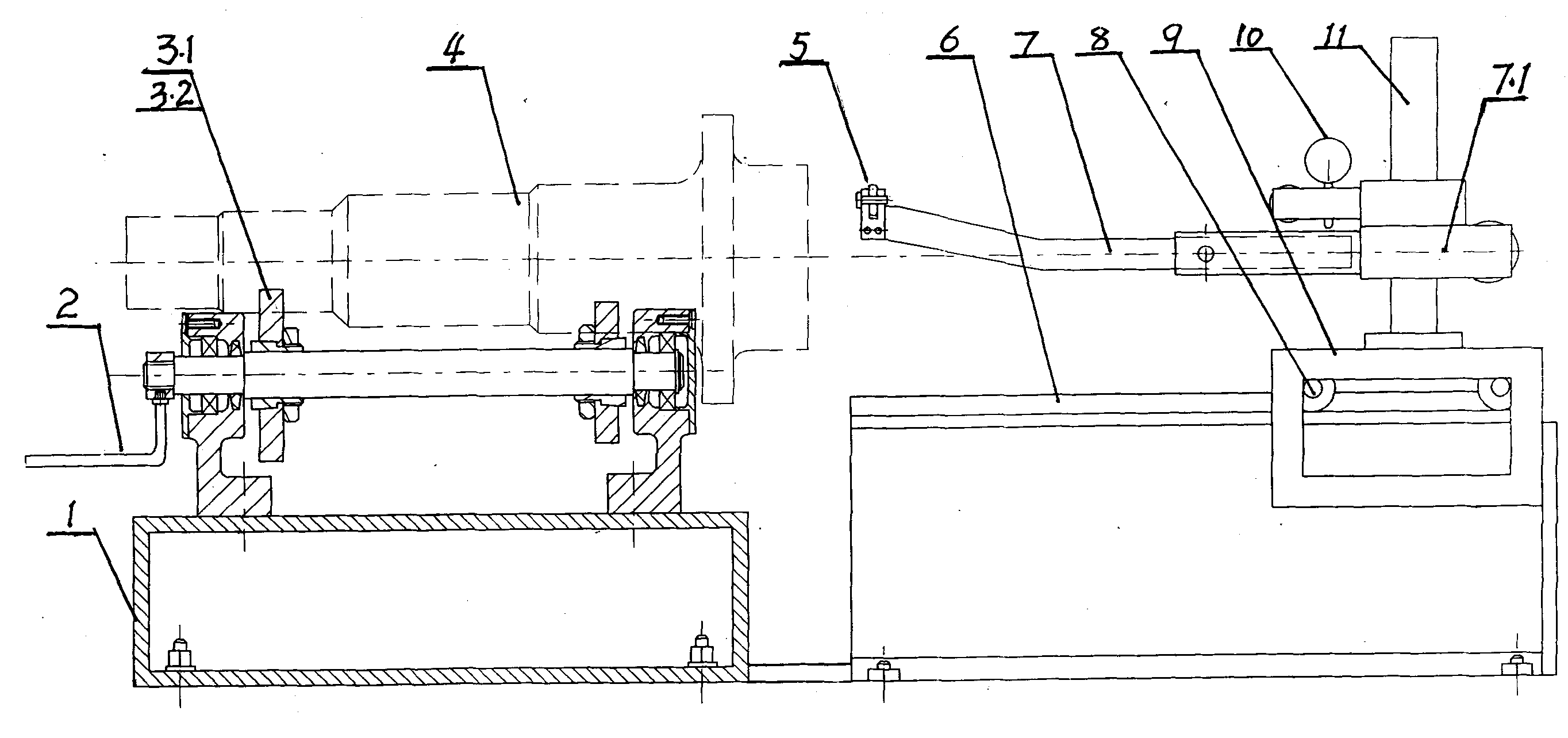

[0019] The present invention creates the embodiment of wall thickness difference detector, see figure 1 , figure 2 , its structure includes: a frame 1, on which a turntable for the inspected product is set, and a feed measuring table is correspondingly arranged on the axial right side of the turntable for the inspected product. The turntable of the inspected product adopts the drive roller 3.1 and the auxiliary roller 3.2 arranged side by side on the frame 1, and the handle 2 is connected to the left end of the shaft of the drive roller 3.1; A roller 8 is clamped on the guide rail 6, a supporting plate 9 is erected above the roller 8, a column 11 is connected on the supporting plate 9, and an adjustable measuring lever 7 is slee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap