Internal circulation evaporator with settling chamber

A settling chamber and evaporator technology, applied in evaporator accessories, vertical tube evaporators, etc., can solve problems such as affecting production capacity, evaporator capacity decline, thermal short circuit, etc., to save energy consumption, improve evaporation capacity, and eradicate heat. short circuit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

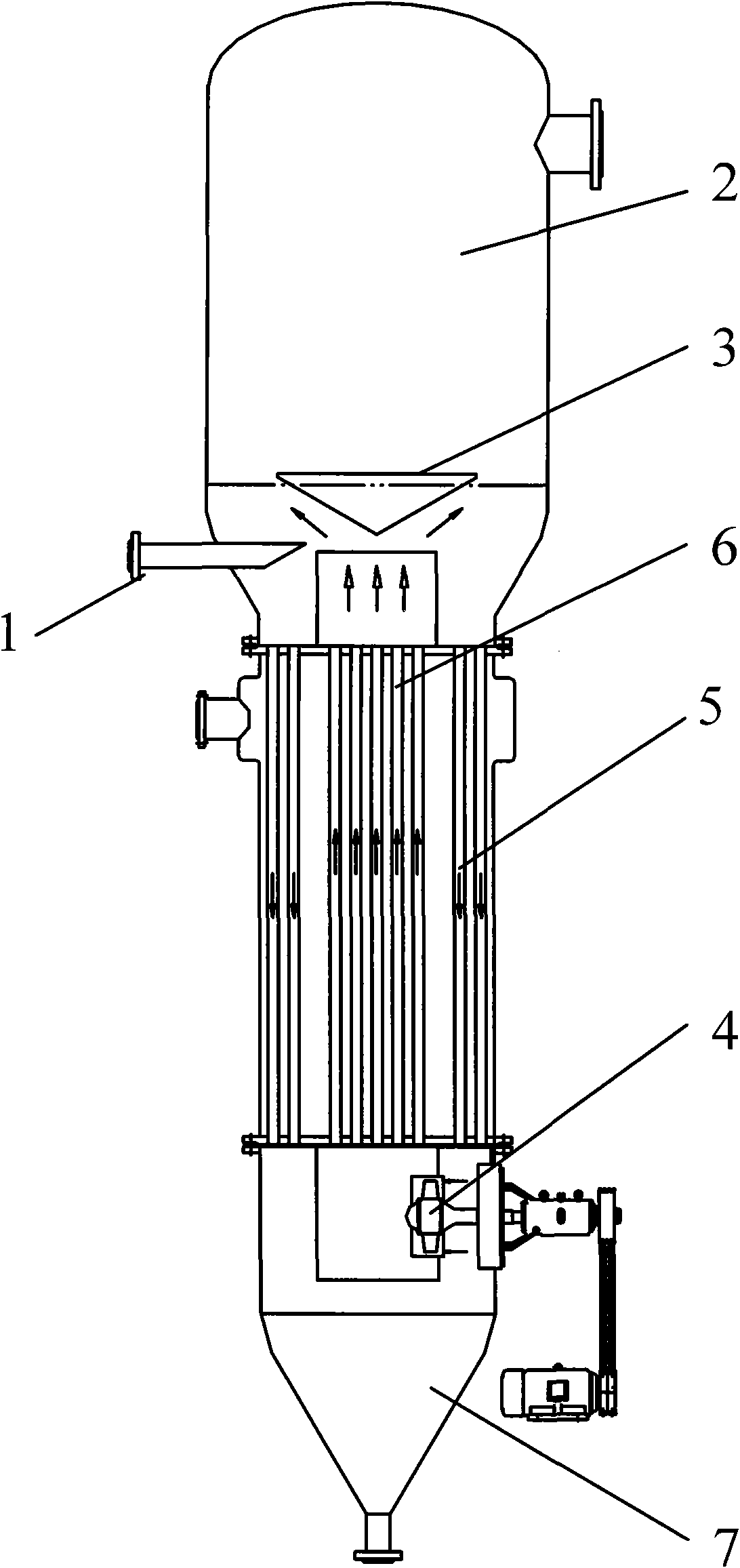

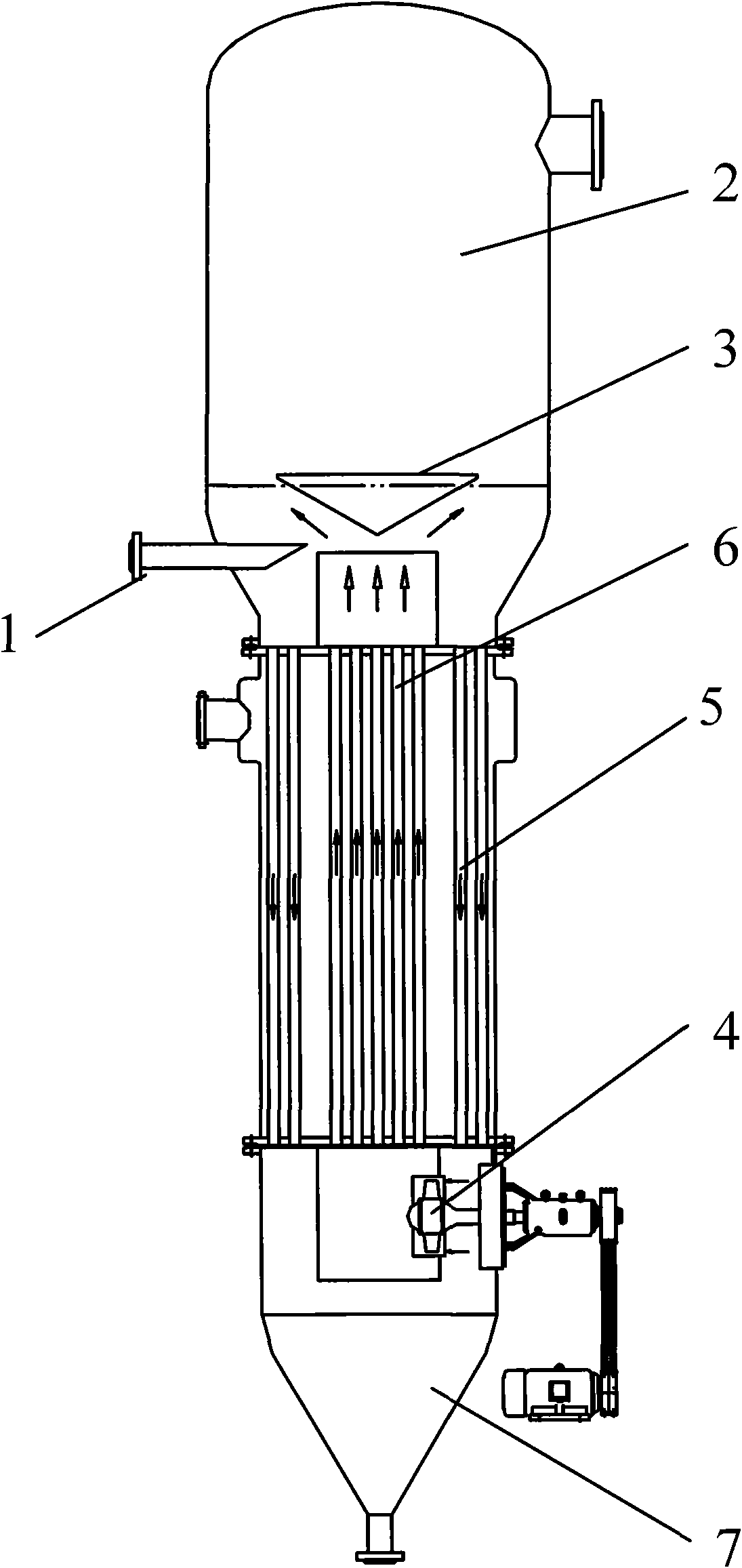

[0012] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0013] like figure 1 As shown, the indoor circulating evaporator with settling of the present invention includes a material inlet 1, a vapor-liquid separation chamber 2, a vapor-liquid uniform distributor 3, a forced circulation pump 4, a heating tube 5 in the outer heating ring, a heating tube 6 in the inner heating ring, and crystallization settling Chamber 7, the material inlet 1 is located between the vapor-liquid distributor 3 and the heating pipe 5 of the outer heating ring, the inner heating pipe 6 is located between the heating pipes 5 of the outer heating circle, and the vapor-liquid separation chamber 2 is located in the vapor-liquid distributor 3, the forced circulation pump 4 is located below the heating tube 5 of the outer heating ring, and the crystallization settling chamber 7 is fixed below t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap