Garbage can cover capable of automatically opening cover

A trash can, automatic technology, applied in the direction of trash can, garbage collection, household appliances, etc., can solve the problems of small motor torque, large load, easy damage, etc., to achieve the effect of not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Regarding the technology, means and effects of the present invention, a preferred embodiment is given in conjunction with the drawings to describe in detail below. This is for illustrative purposes only and is not limited by this structure in the patent application.

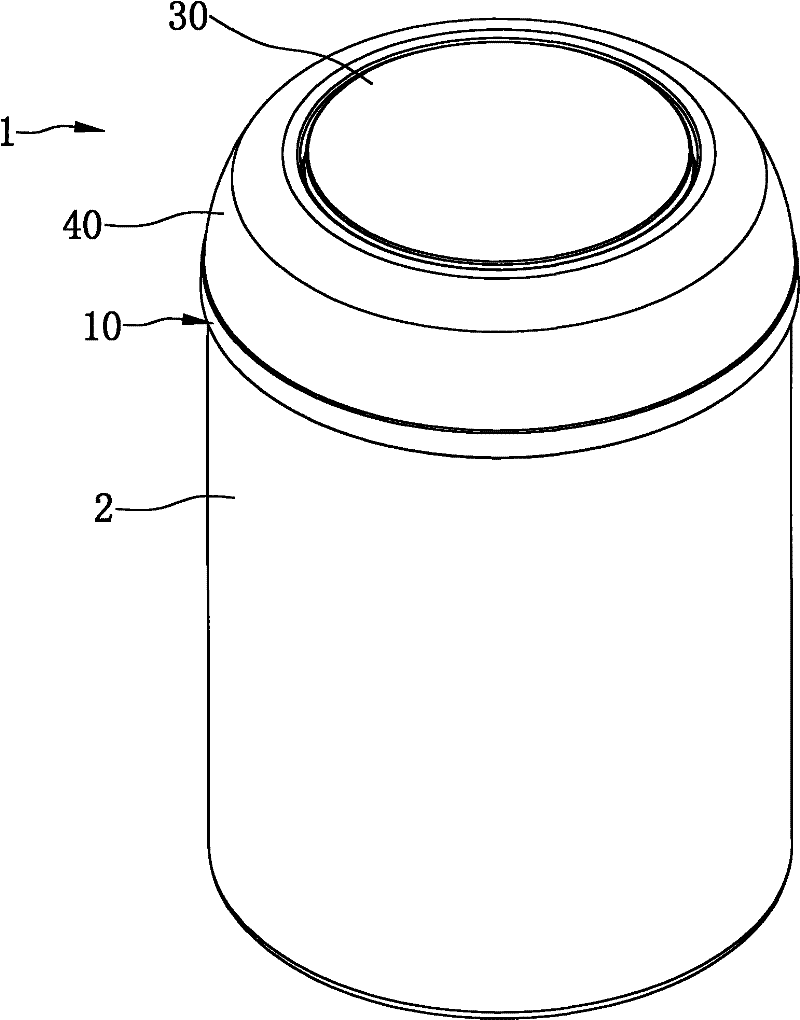

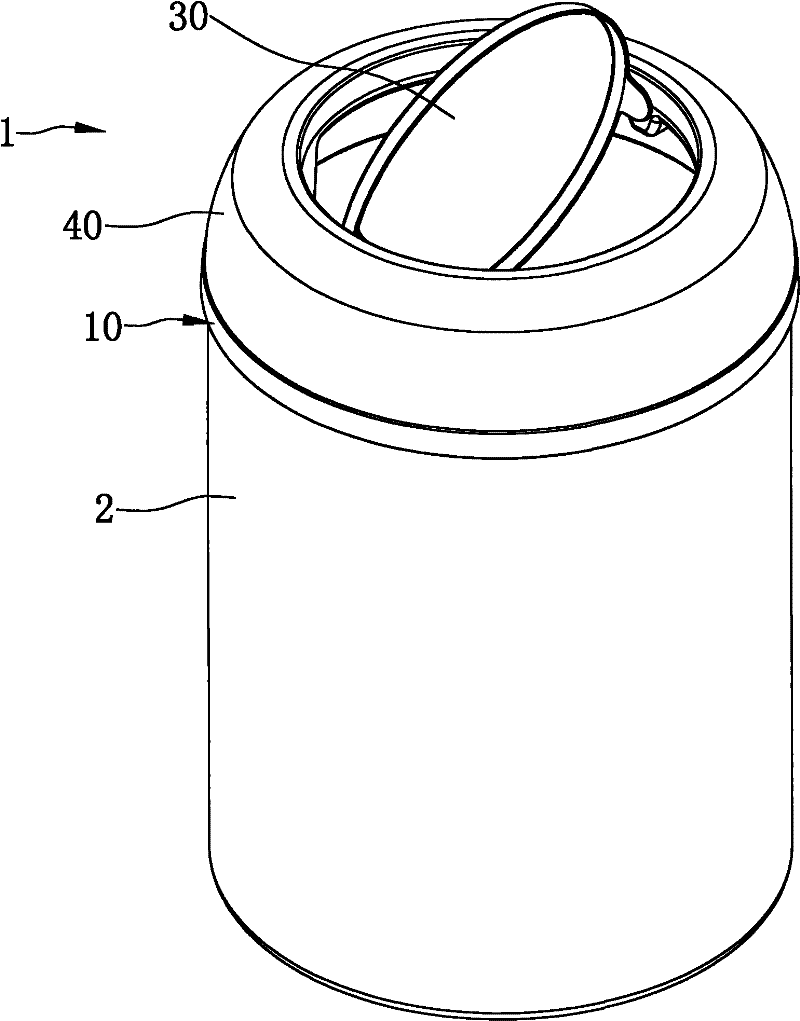

[0032] Reference figure 1 versus figure 2 , Are the three-dimensional appearance view and the three-dimensional exploded view of the trash can with the trash can lid with the automatic lift lid of the present invention. The trash can with the trash can lid with automatic lid of the present invention includes a trash can lid 1 with an automatic lid and a barrel body 2. The trash can lid 1 includes a lid 30, and the lid 30 can automatically Turn it over to make the trash can be closed or open.

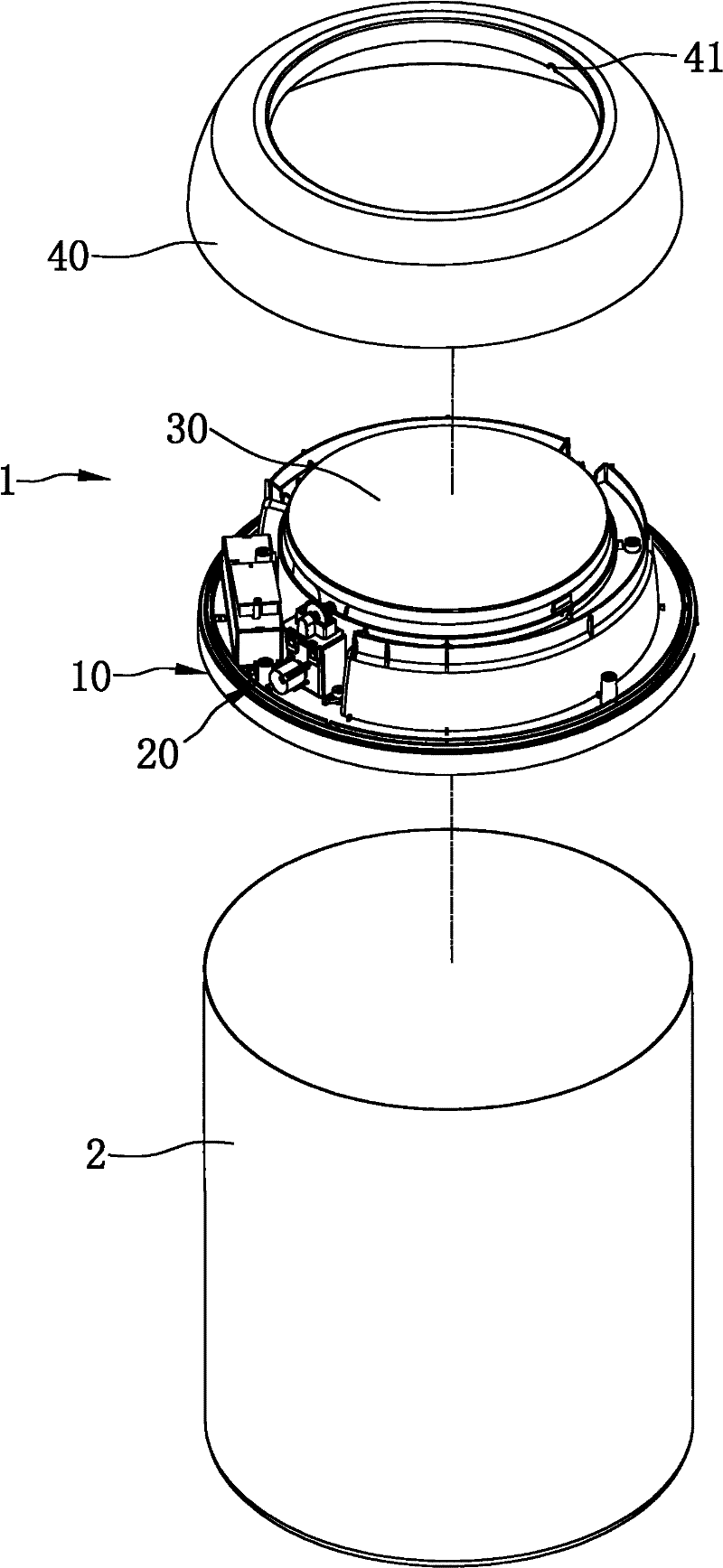

[0033] Reference image 3 , Is a three-dimensional exploded view of a trash can with a trash can lid with an automatic lid. The trash can cover 1 is combined with the open end of the barrel body 2, and the end of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com