Dust-removing device for inkjet printer

A technology of inkjet printers and dust removal devices, which is applied in printing devices, printing, etc., and can solve problems such as abnormal sensing functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

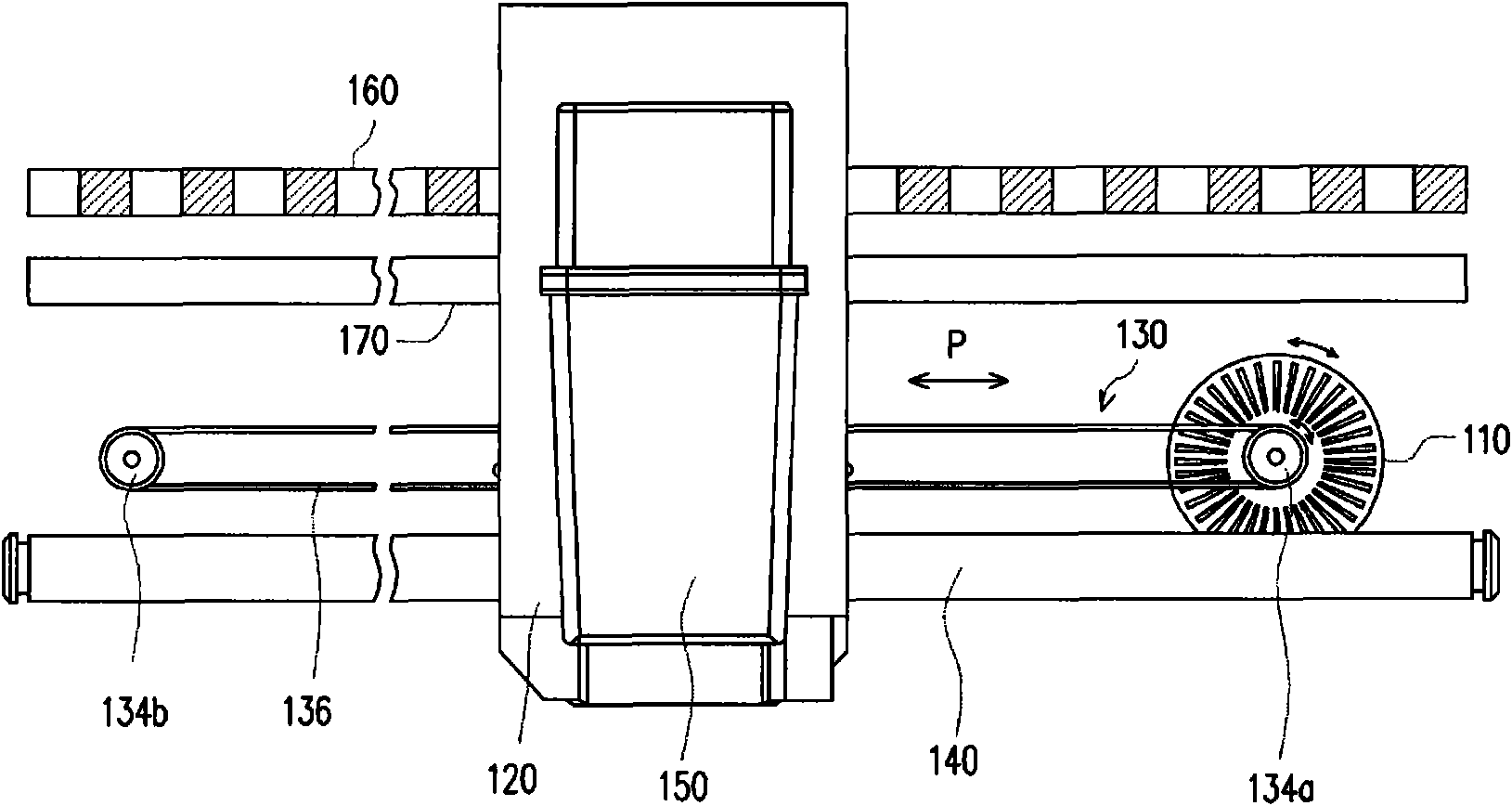

[0039] Please refer to figure 1 , figure 1 It is a schematic diagram of a part of the internal structure of a printer according to an embodiment of the present invention, wherein the printer includes a transmission mechanism 130 , a shaft 140 , a bearing seat 120 , an optical ruler 160 and a long plastic part 170 . The bearing base 120 is slidably disposed on the guide rod 140 , and the transmission mechanism 130 is connected to the bearing base 120 for driving the bearing base 120 to move along a path P. As shown in FIG. The ink clip 150 is detachably disposed on the bearing base 120 and can move along with the bearing base 120 for printing. The transmission mechanism 130 includes a stepping motor 110, a pulley 134a, a driven pulley 134b and a belt 136, wherein the stepping motor 110 is used to drive the pulley 134a to rotate to drive the belt 136, and the bearing seat 120 is connected to the belt 136 and is received by the belt 136. Driven to move along the path P.

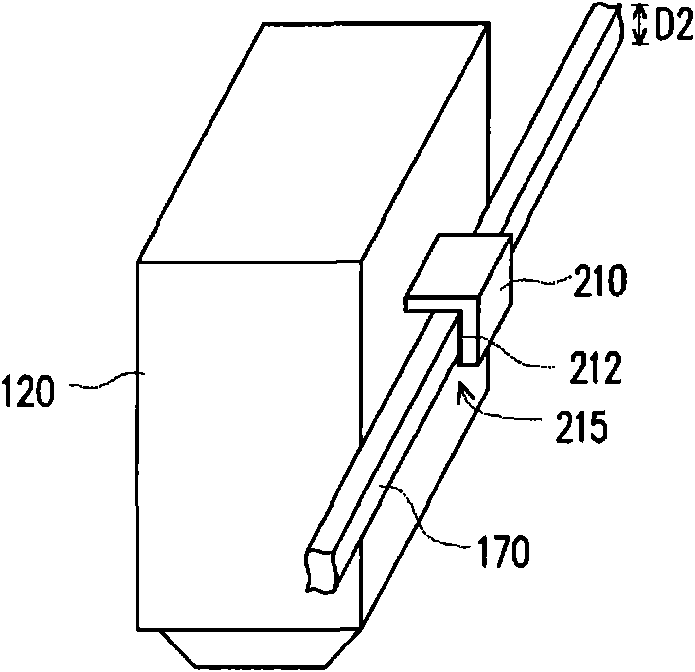

[004...

no. 2 example

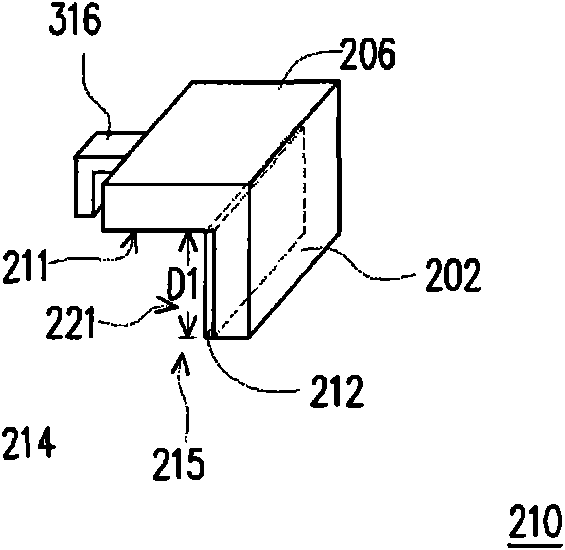

[0047] The friction device of the present invention is not limited to the above-mentioned Figure 2B The inverted L shape in the above can also be implemented by using a ㄇ shape, a semicircle, etc. with an opening structure. Please refer to Figure 3A and Figure 3B , Figure 3A It is a schematic diagram of the structure of the friction device and the bearing seat according to the second embodiment of the present invention, wherein the friction device 310 is in the shape of a ㄇ. Figure 3B It is a structural schematic diagram of the friction device according to the second embodiment of the present invention. Figure 3B A friction device 310 in the shape of an ㄇ is shown in the figure. The friction device 310 has a first side wall portion 202 , a second side wall portion 204 and a top 206 , and forms an accommodating portion 215 in the shape of a ㄇ shape. The main difference between the friction device 310 and the friction device 210 is the second side wall part 204, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com