Metal casing of pre-stranded suspension clamp

A metal casing and suspension wire clip technology is applied in the direction of the cable suspension device, etc., to achieve the effect of convenient installation, solving difficulties and dangers, and fast fitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

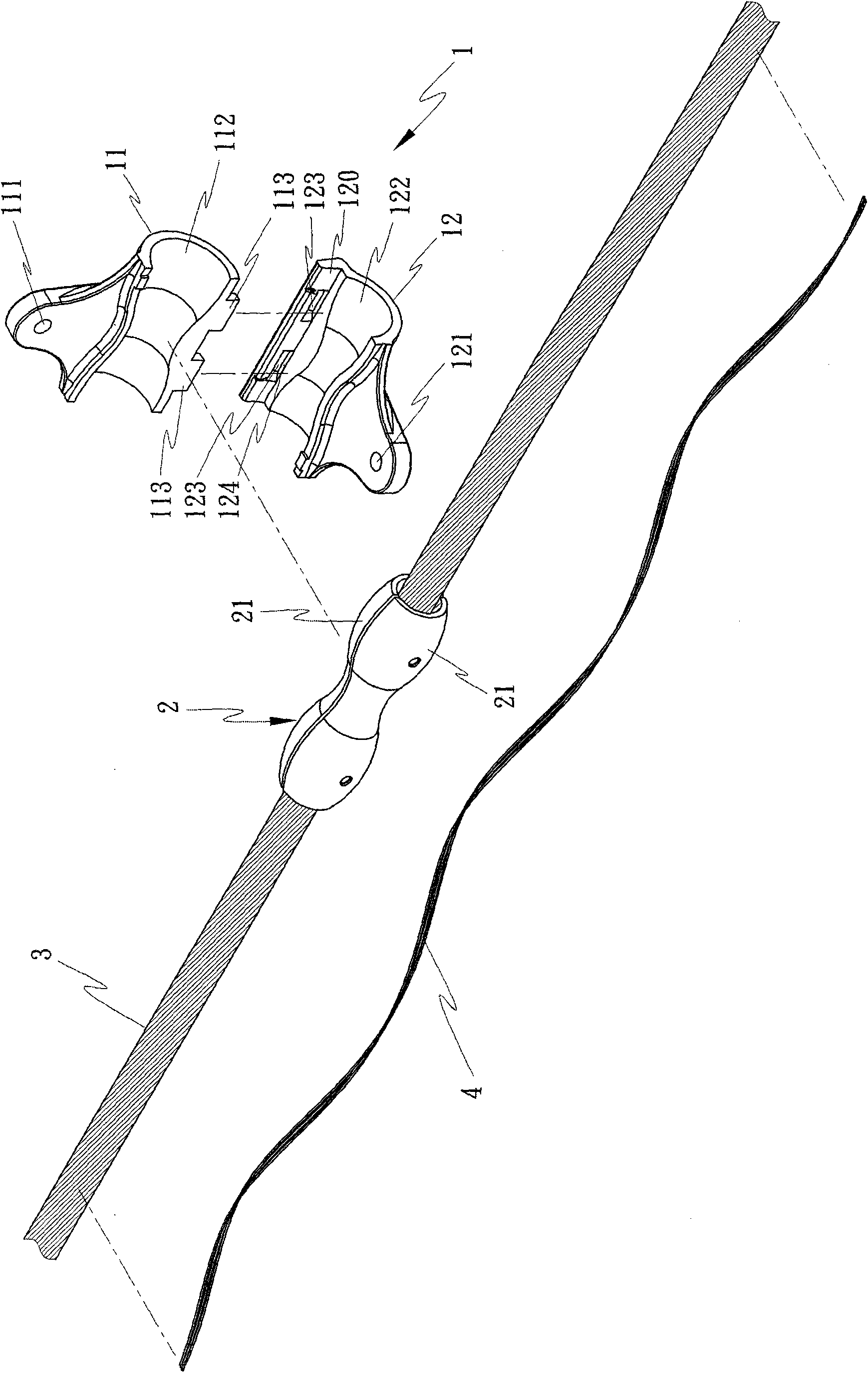

[0024] Such as figure 1 As shown, the metal casing design of the present invention is a pre-twisted suspension clamp, which is mainly composed of two matched and separated metal half casings 11 and metal half casings 12 to form a set of metal casings 1. When in use, it is Cooperate with a set of rubber inner pads 2 (composed of two semi-arc pads 21 and 22, see Figure 8 or Figure 9 ) is pre-clamped at the selected position of the wire 3, and is wrapped and fixed by using a plurality of small sections of pre-twisted wire 4, and then cooperates with two metal half-sheaths 11 and metal half-sheath 12 to clamp the lock from the outside Solid, thereby completing the combined composition of a pre-twisted suspension clamp.

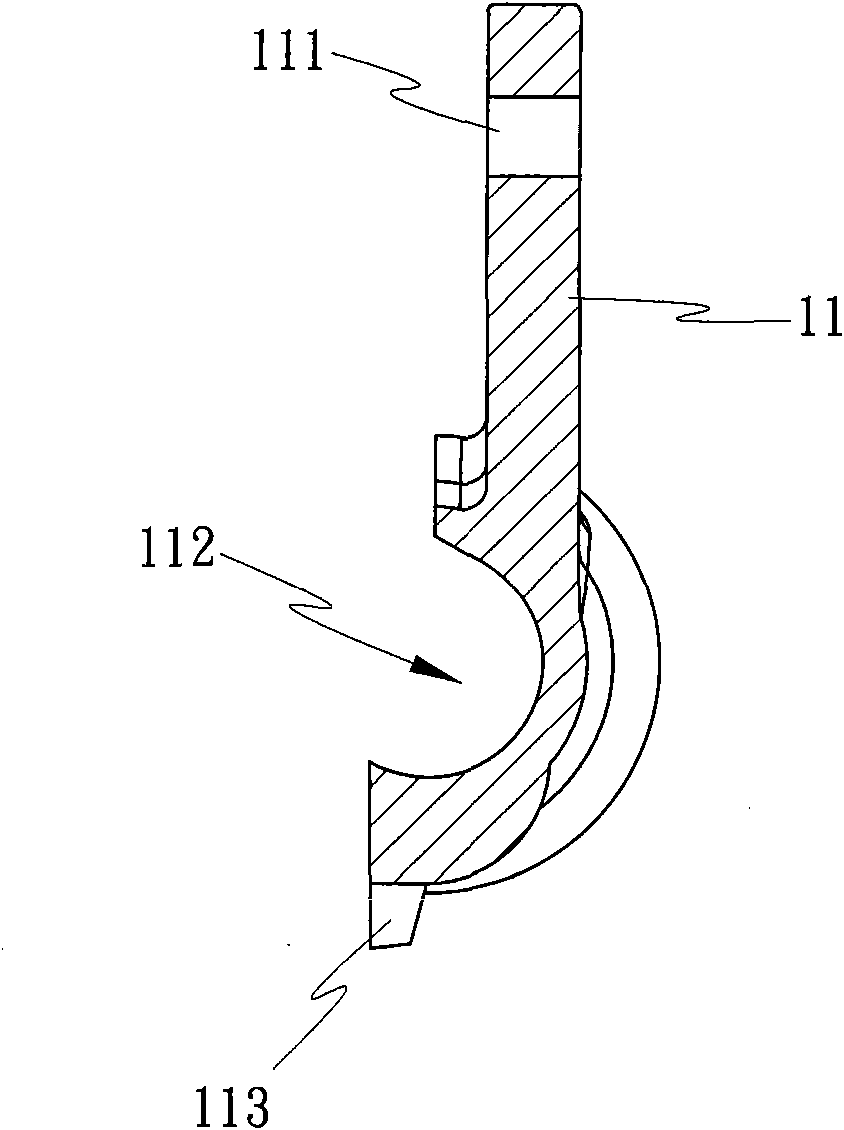

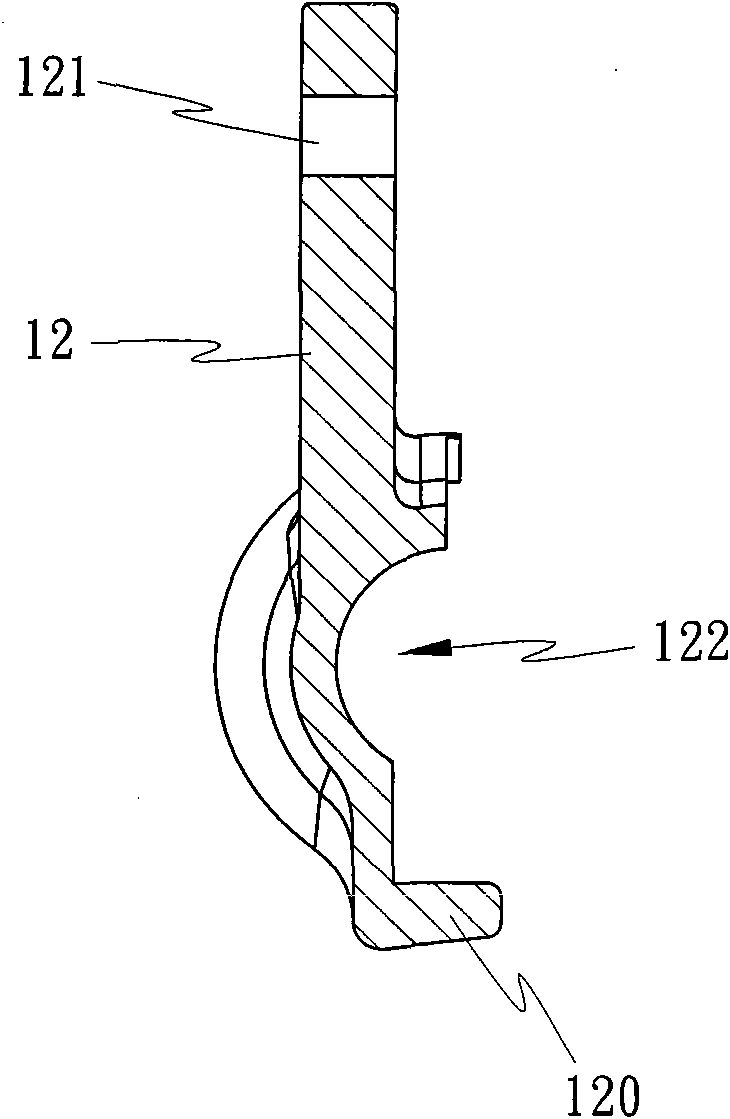

[0025] According to the design of the present invention, in order to improve the metal casing 1, each metal half casing 11 and metal half casing 12 have a keyhole portion 111 and a keyhole portion 121 extending from the upper end, and the main features are:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com