Clamp and method for quickly installing torsion spring

A torsion spring and clamp technology, which is applied in the field of clamps for quick installation of torsion springs and the field of quick installation of torsion springs, can solve problems such as torsion springs hurting people, and achieve the effect of simple installation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

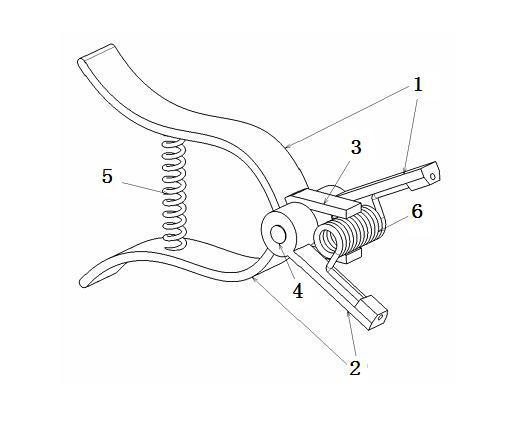

[0013] see image 3 , the invention discloses a torsion spring clamp for quick installation. As shown in the figure: it includes two symmetrical clamp arms 1, 2 connected axially by a rotating pin shaft 4 in the middle, and the clamp arms 1, 2 are divided into a front section and a rear section by a shaft joint; the clamp arm The inner ends of the front sections of 1 and 2 each have a positioning hole, and a return pressure spring 5 is connected between the inner ends of the rear sections of the clamp arms 1 and 2; the rotating pin shaft 4 is fixed through a positioning groove forward Positioning clip 3.

[0014] The steps of quick installation of torsion spring using the above-mentioned clamps are (please combine image 3 refer to Figure 4 ): Insert the torsion spring 6 into the positioning groove of the positioning clip 3 of the clamp to prevent the torsion spring from turning over when it is twisted and deformed by force, and it is easy to pop out and hurt people; back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com