Hinged shack for coach

A technology for articulated sheds and passenger cars, which is applied to vehicle parts, passages for connecting vehicles, transportation and packaging, etc., can solve the problems of troublesome installation and maintenance, high maintenance costs, complex structure of articulated sheds, etc., and achieves improved strength and rigidity. The effect of improving rigidity and strengthening strength

Active Publication Date: 2011-01-05

JOINTECH (SUZHOU) VEHICLE SYST CO LTD

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Existing hinged sheds could not house these lines safely and securely

At present, the rear-mounted vehicles introduced in my country, the structure of the hinged shed is relatively complicated, the installation and maintenance are troublesome, and the maintenance cost is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

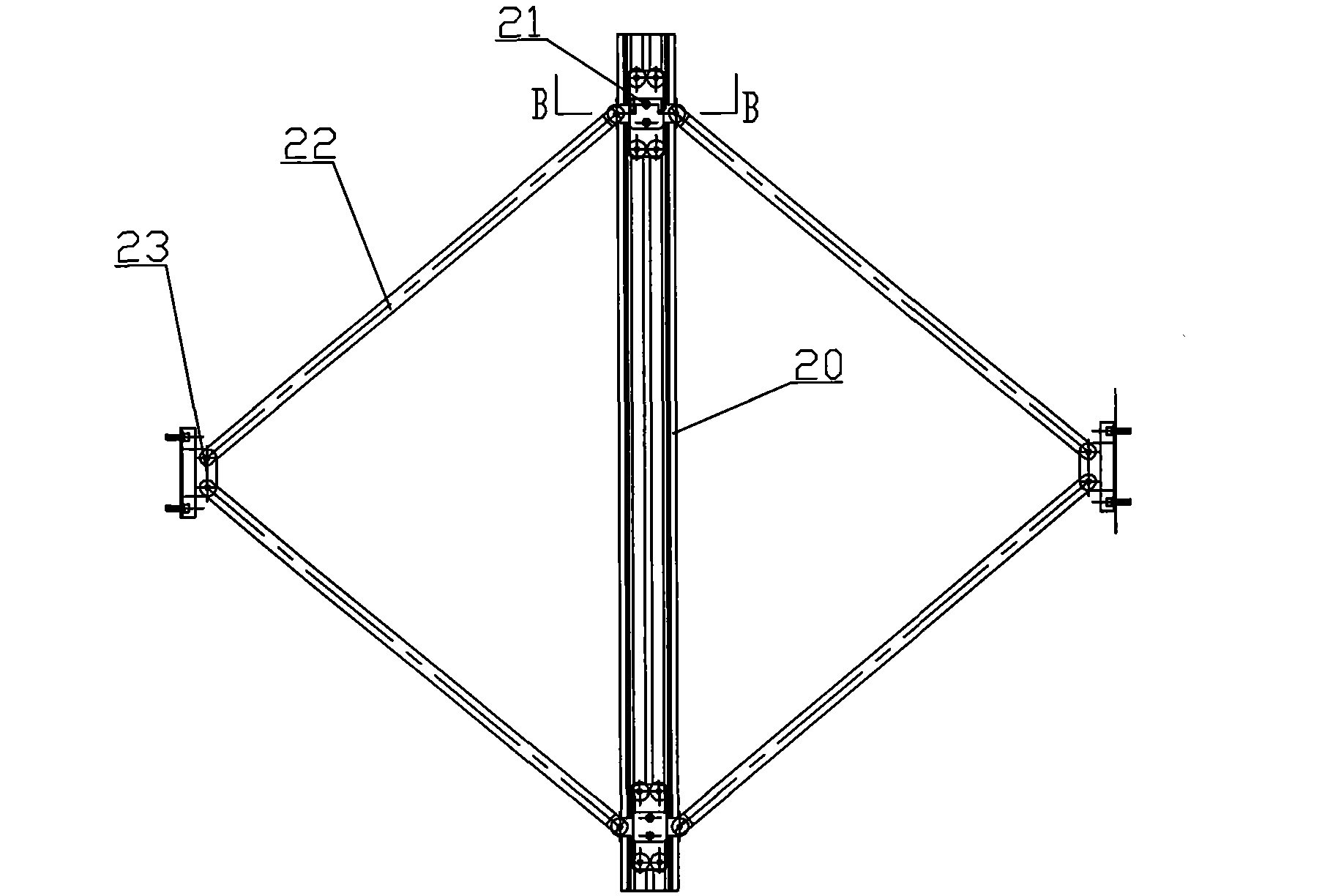

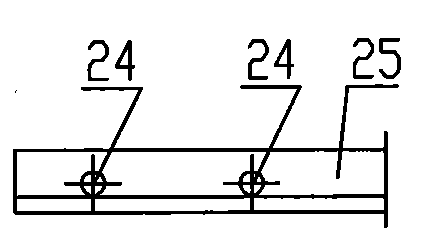

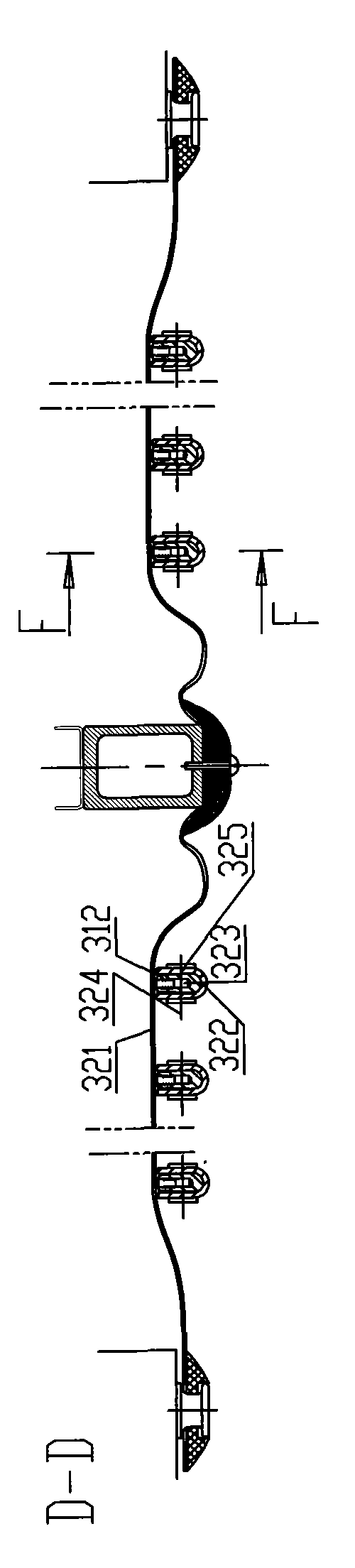

The invention provides a hinged shack for a coach, wherein a gantry frame comprises a closed framework; a hanging frame connected with the center of a lower cross frame through a joint bearing is connected with a back carriage; a telescopic hinged shack is respectively and symmetrically connected with the front and the back sides of the gantry frame; a slide rail in an equiangular mechanism is fixedly connected with the upper side of the two side doorframes in the inner side of the gantry frame; two pulleys are arranged on the beam of the slide rail; the pulleys are hinged with one end of a pull rod, and the other end of the pull rod is connected with a front carriage and the back carriage through a fixed seat; the telescopic hinged shack comprises an external shack, a ceiling, a bottom shack and corner shacks which are mutually connected into a whole; the external shack and the bottom shack are correspondingly and fixedly connected with the gantry frame; the ceiling is arranged belowthe upper shack wall of the external shack and fixedly connected with the side walls of the external shack; the corner shacks are fixedly connected with the side walls of the external shack; clampingsectional materials made of rigid materials are arranged on at least a part of folded seam of each shack wall; and a wire harness frame is arranged in the space between the external shack and the ceiling and fixed on the front and the back carriages through mounting plates. The hinged shack has the advantages of high supporting intensity, good impermeability, and uniform deformation and safe and reliable passing of pipelines when cornering.

Description

A passenger car hinged shed technical field The invention belongs to the technical field of large highway passenger cars and provides a passenger car hinged shed for connecting front and rear compartments of a large passenger car. Background technique In the prior art hinged sheds for passenger cars, the shed body is generally made of soft fabrics such as canvas or artificial leather, and its transverse section is in the shape of a "door", that is, the bottom of the shed body is open. This hinged shed has the following disadvantages: 1. The shed body is soft, the support strength is low, and it is easy to deform, which affects the overall appearance and beauty of the shed body. When the vehicle turns, the deformation of the inner and outer sides of the hinged shed is uneven; 2. The shed bottom is open, dust-proof and cold-proof. Difference. Now the large passenger cars with new two-compartment communication often change the front engine to the rear engine structure. Th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B60D5/00

Inventor 郝庆军

Owner JOINTECH (SUZHOU) VEHICLE SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com