Bridge crane telescopic sleeve type rigid positioning device

A technology of telescopic sleeves and bridge cranes, applied in transportation and packaging, load hanging components, rail systems, etc., can solve problems such as poor structural stability, inability of ordinary cranes to meet precise positioning, and low positioning accuracy. Reliable and efficient hoisting and positioning of goods, the effect of high-precision rigid fast hoisting and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

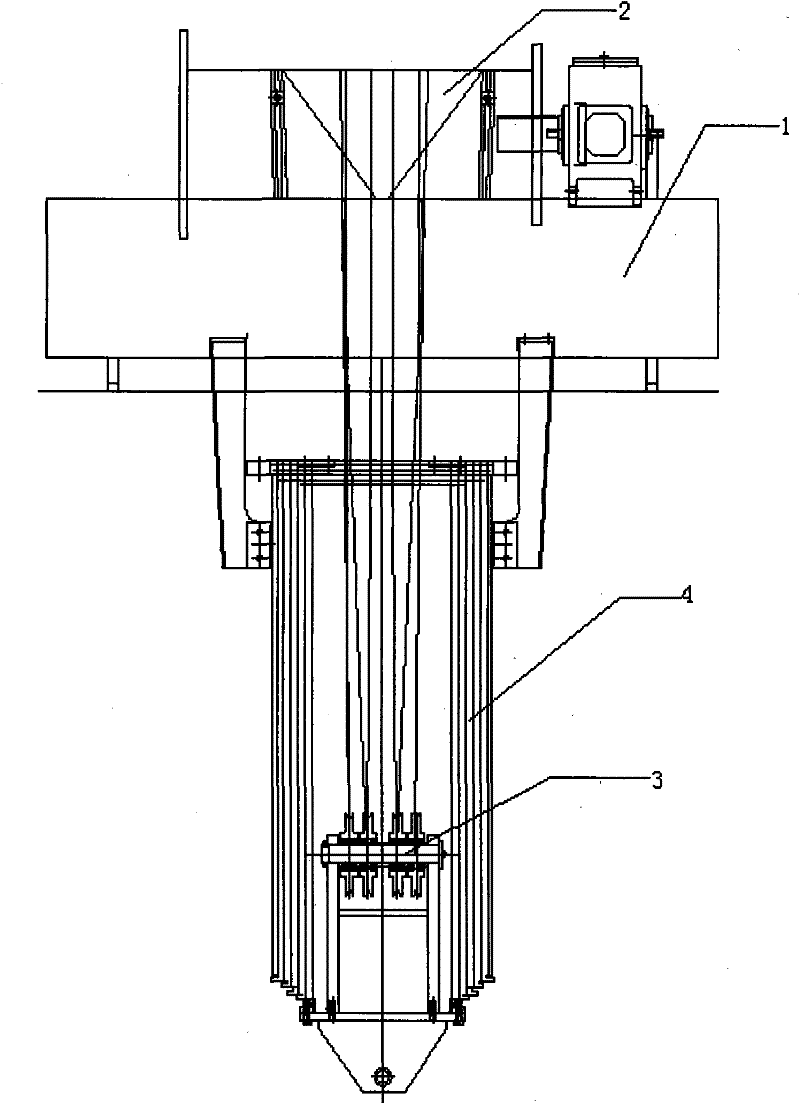

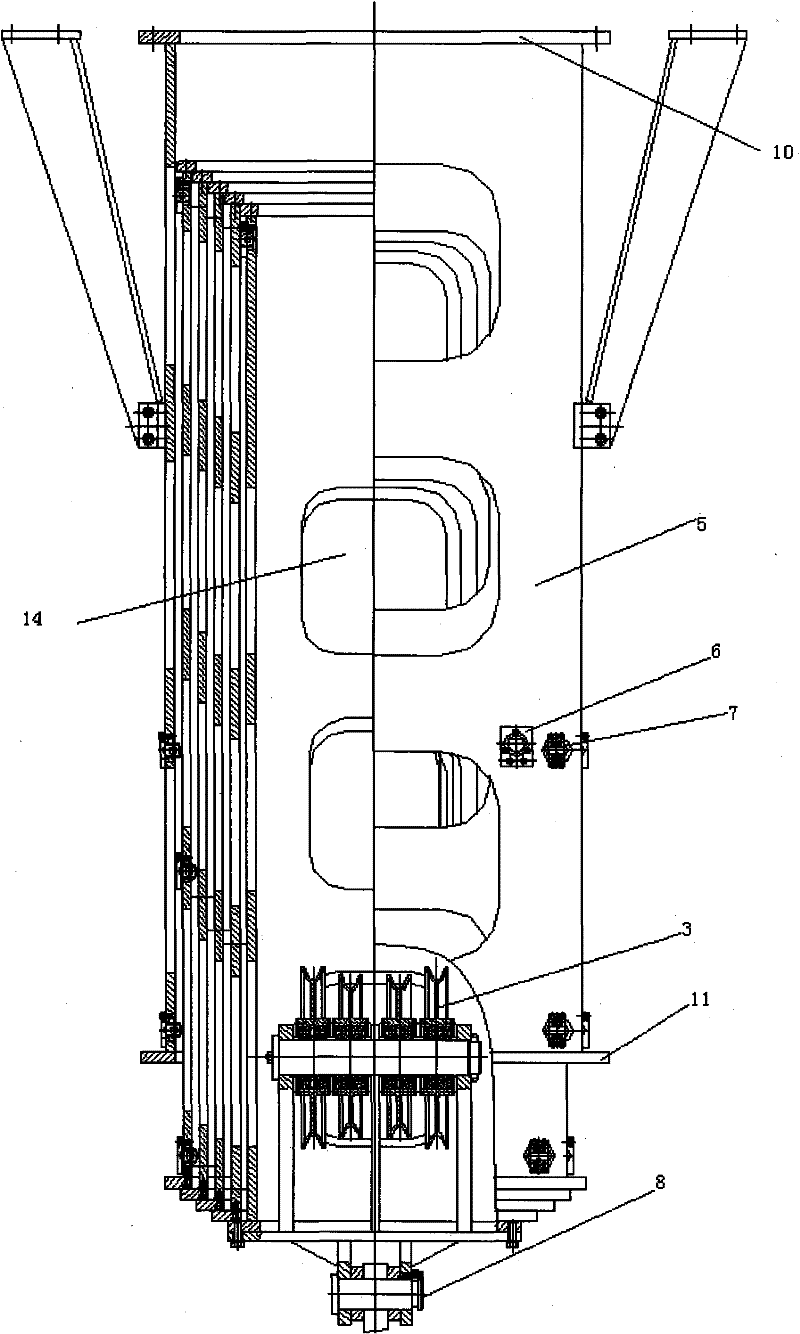

[0012] Such as figure 1 , the rigid positioning device of the present invention is installed in the general bridge crane hoisting device, and a set of hoisting mechanism 2 is fixed on the trolley 1 platform of the bridge crane, and a motor is installed on the trolley 1, and the motor is connected with the hoisting mechanism 2. The telescopic sleeve group 4 is set on the bottom surface of the trolley 1, and the movable pulley group 3 is arranged in the telescopic sleeve group 4. The movable pulley group 3 is connected with the hoisting mechanism 2 through a wire rope. When the motor drives the hoisting mechanism 2 to move, the wire rope drives Movable pulley block 3 moves up and down.

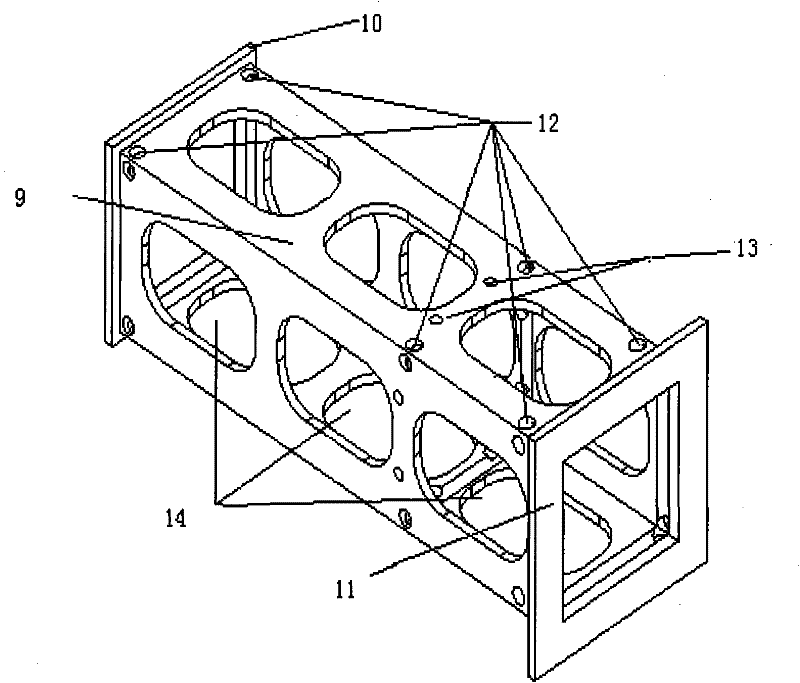

[0013] Such as figure 2 As shown, the telescopic sleeve group 4 is composed of a multi-section sleeve 5 , a protruding part 6 and a rolling bearing 7 . Among them, the multi-section sleeve 5 is a multi-sleeve structure that is inserted in order from large to small in section, and can be teles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com