Upper buckle positioning device

A technology of positioning device and buckle groove, which is applied in the direction of tools for sewing clothes, etc., can solve the problems of positioning device damage, increased workload, and high cost of use, and achieve the effects of reducing cost of use, prolonging service life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

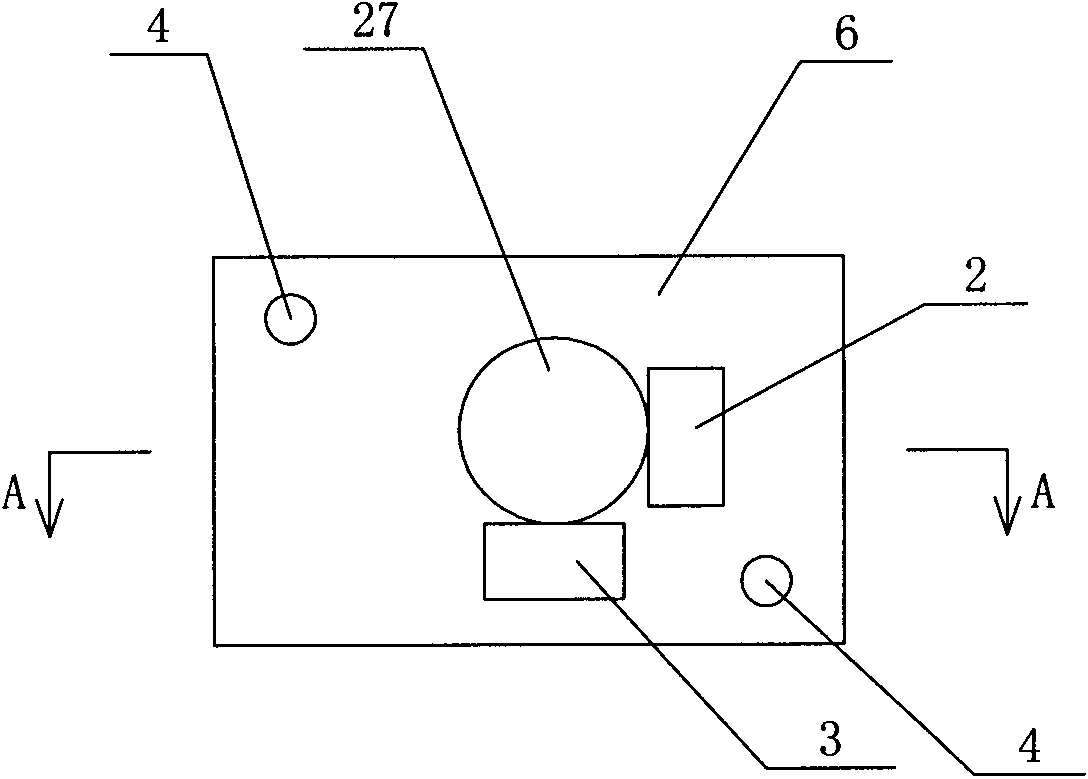

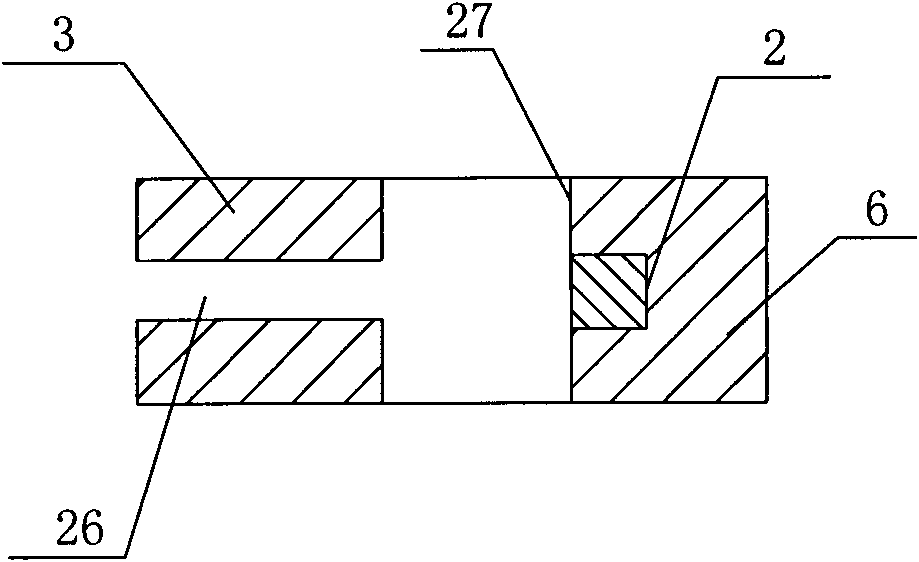

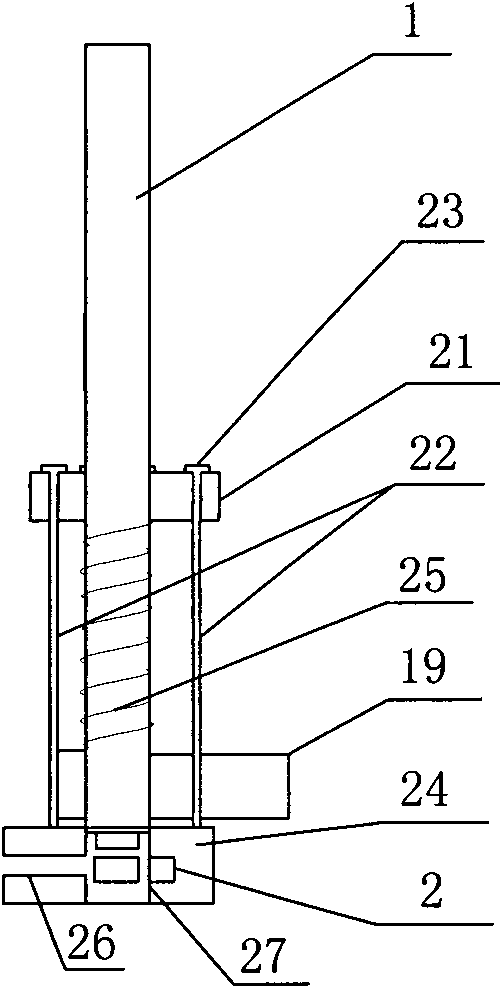

[0017] Such as figure 1 with figure 2 As shown, the buckle positioning device of the present invention includes a plate body 6. The plate body 6 is provided with punched through holes 27 up and down. The middle of the punched through holes 27 is connected with a horizontally arranged upper buckle groove 26. The upper buckle groove 26 opens in One side of the plate body 6; in the plate body 6 adjacent to the punched through hole 27, a first permanent magnet 2 and a second permanent magnet 3 are embedded, and the first permanent magnet 2 is located at the punched through hole 27 on the opposite side of the upper buckle groove 26 Where, the second permanent magnet 3 and the first permanent magnet 2 are distributed at right angles along the circumferential direction of the punched through hole 27. Wherein, the first permanent magnet 2 and the second permanent magnet 3 are both tangent to the punched through hole 27; the plate body 6 is a rectangular plate body, and guide rods are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com