Passengers conveying apparatus

A technology of passenger conveying equipment and guide rails, which is used in transportation and packaging, escalators, etc., can solve the problems of falling off of fixed parts, insufficient fixing force, contact of connecting members, etc., and achieve the effect of ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

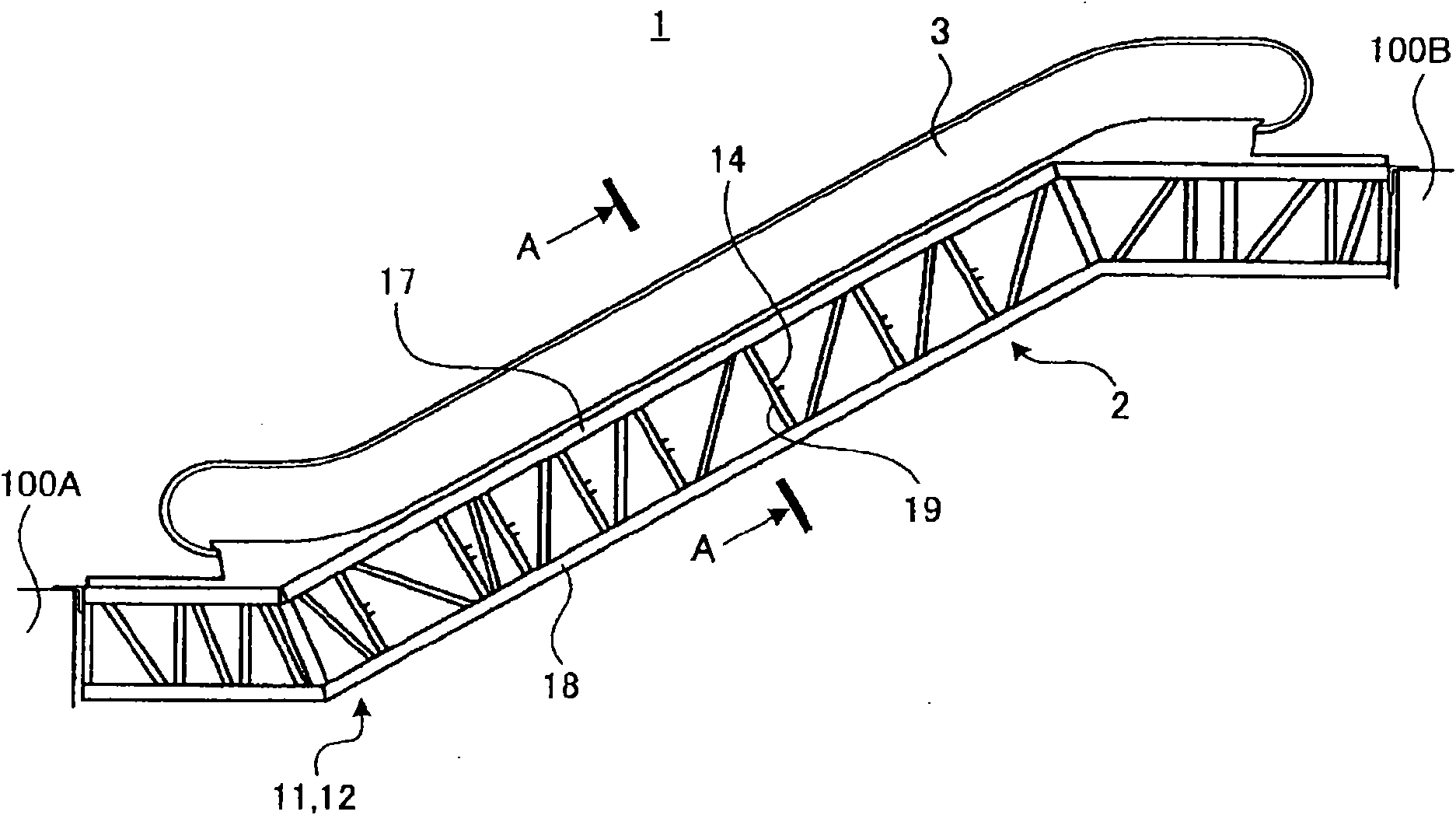

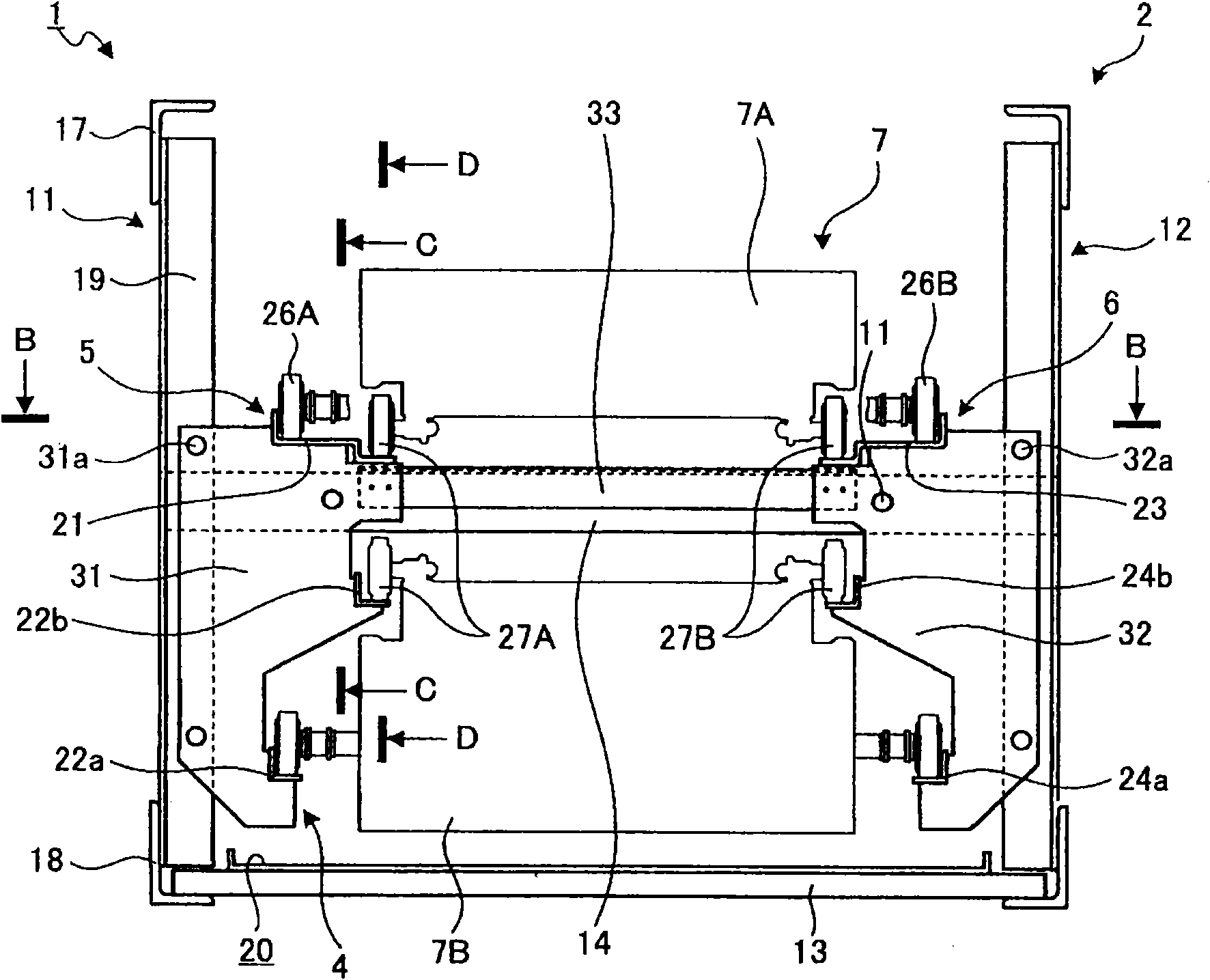

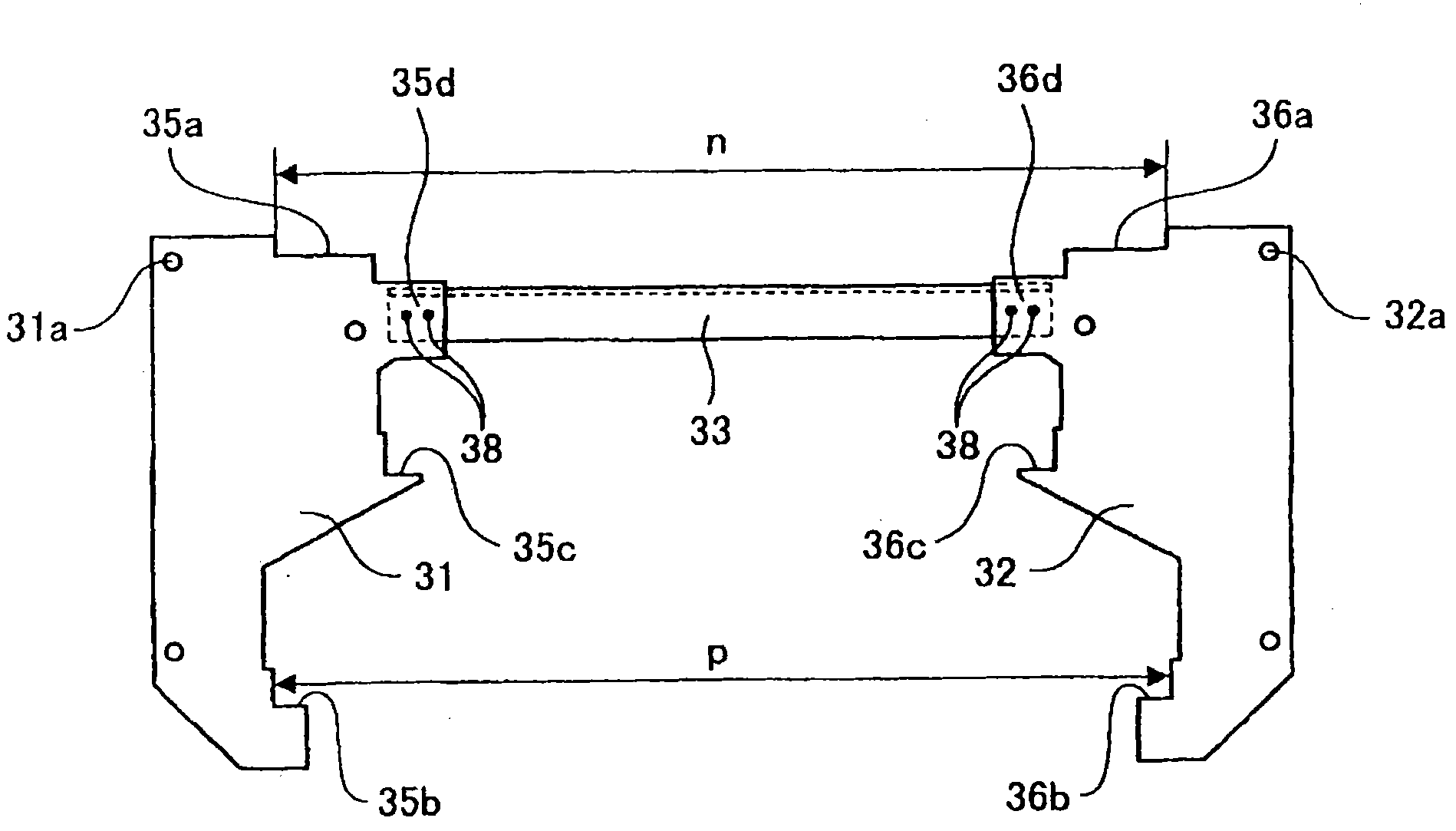

[0050] First refer to figure 1 with figure 2 A first embodiment of the passenger conveying facility of the present invention will be described.

[0051] figure 1 It is a schematic configuration diagram showing the first embodiment of the passenger conveying facility of the present invention. figure 2 is along figure 1 Sectional view of line A-A.

[0052] The passenger conveying facility 1 is a so-called escalator which is an inclined passenger conveying facility installed between a lower floor 100A and an upper floor 100B of a building. This passenger conveying apparatus 1 has a truss 2 , a railing portion 3 , a rail support unit 4 , a first rail 5 and a second rail 6 , and a plurality of steps 7 .

[0053] The trusses 2 are installed across the lower floor 100A and the upper floor 100B. Hereinafter, the width direction of the truss 2 when viewing the truss 2 from 100 A of lower floor floors is made into the left-right direction. The truss 2 is used to support the rai...

no. 2 approach

[0089] Next, refer to Figure 9 with Figure 10 A second embodiment of the passenger conveyor facility according to the present invention will be described.

[0090] Figure 9 It is a cross-sectional view showing the second embodiment of the passenger conveying facility of the present invention. Figure 10 is along Figure 9 Sectional view of E-E line.

[0091] The passenger conveying facility 51 of the second embodiment has the same structure as the passenger conveying facility 1 of the first embodiment described above. This passenger conveyor 51 differs from the passenger conveyor 1 only in the rail support unit 54 . The guide rail support unit 54 will be described below, and the same parts as those of the passenger conveyor 1 will be denoted by the same symbols, and repeated description will be omitted.

[0092] The rail supporting unit 54 is composed of a first rail supporting member 31 supporting the first rail 5, a second rail supporting member 32 supporting the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com