Antenna mounting frame

A technology for mounting brackets and antennas, which is applied in the direction of antennas, antenna supports/mounting devices, electrical components, etc., and can solve problems such as easy deviation from required angles, decreased positioning accuracy, and angle offsets, so as to save labor and improve accuracy Controlled, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

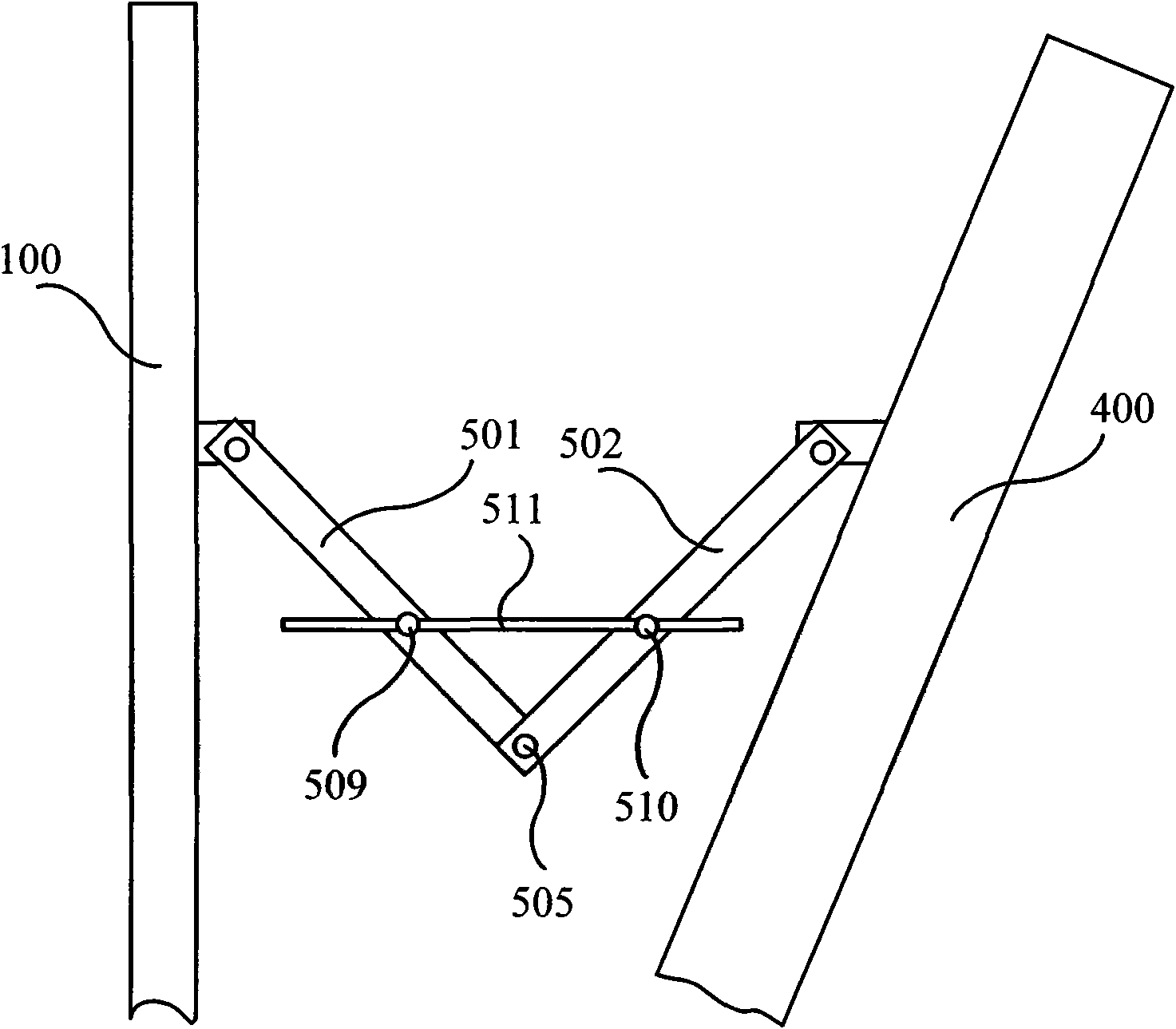

[0047] figure 2 It is a schematic structural diagram of the adjustment assembly in the antenna mounting frame provided by the first embodiment of the present invention. The antenna installation frame of this embodiment includes an adjustment assembly connected between the antenna 400 and the support body 100 , and the adjustment assembly includes: an adjustment arm and an adjustment screw 511 . In this embodiment, the number of adjusting arms is two, that is, the first adjusting arm 501 and the second adjusting arm 502, and the first adjusting arm 501 and the second adjusting arm 502 are connected to each other with the first pivot shaft 505 as the connecting shaft, And can be relatively rotated in an adjustment plane, the antenna 400 and the support body 100 can be respectively connected with the first adjustment arm 501 and the second adjustment arm 502 . The adjustment plane is the plane where the plane hinge structure formed by the first adjustment arm 501 and the second...

no. 2 example

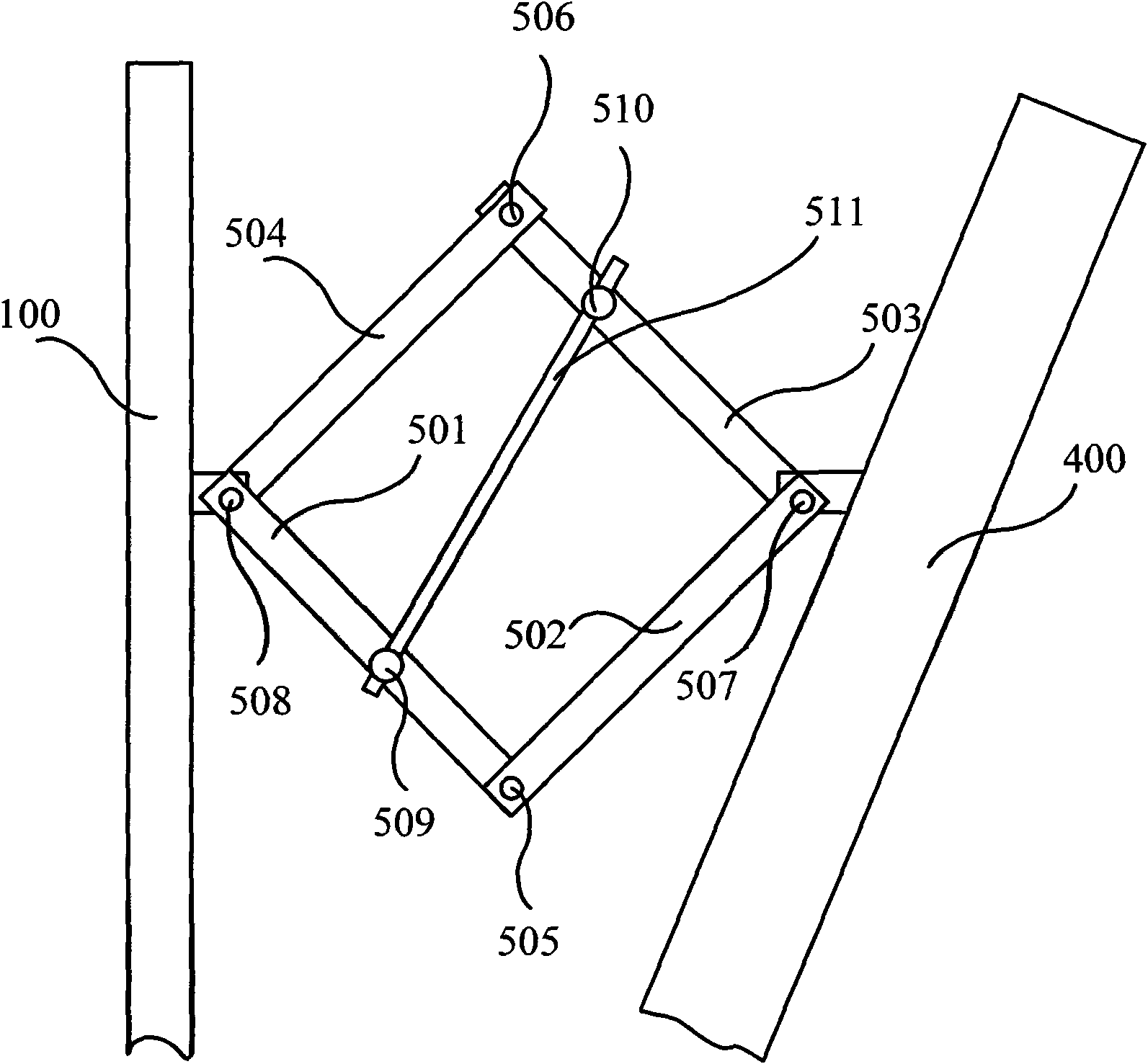

[0051] image 3 It is a schematic structural diagram of the adjustment assembly in the antenna mounting bracket provided by the second embodiment of the present invention. The antenna installation frame of this embodiment includes an adjustment assembly connected between the antenna 400 and the support body 100 , and the adjustment assembly includes: an adjustment arm and an adjustment screw 511 . The number of adjusting arms is four, that is, the first adjusting arm 501, the second adjusting arm 502, the third adjusting arm 503 and the fourth adjusting arm 504, and the four adjusting arms are connected to each other by two pairs of four pivot shafts respectively. like image 3 As shown, the first adjusting arm 501 and the second adjusting arm 502 are rotatably connected through the first pivot shaft 505, the second adjusting arm 502 and the third adjusting arm 503 are rotatably connected through the third pivot shaft 507, and the third adjusting arm 503 The fourth adjusting...

no. 3 example

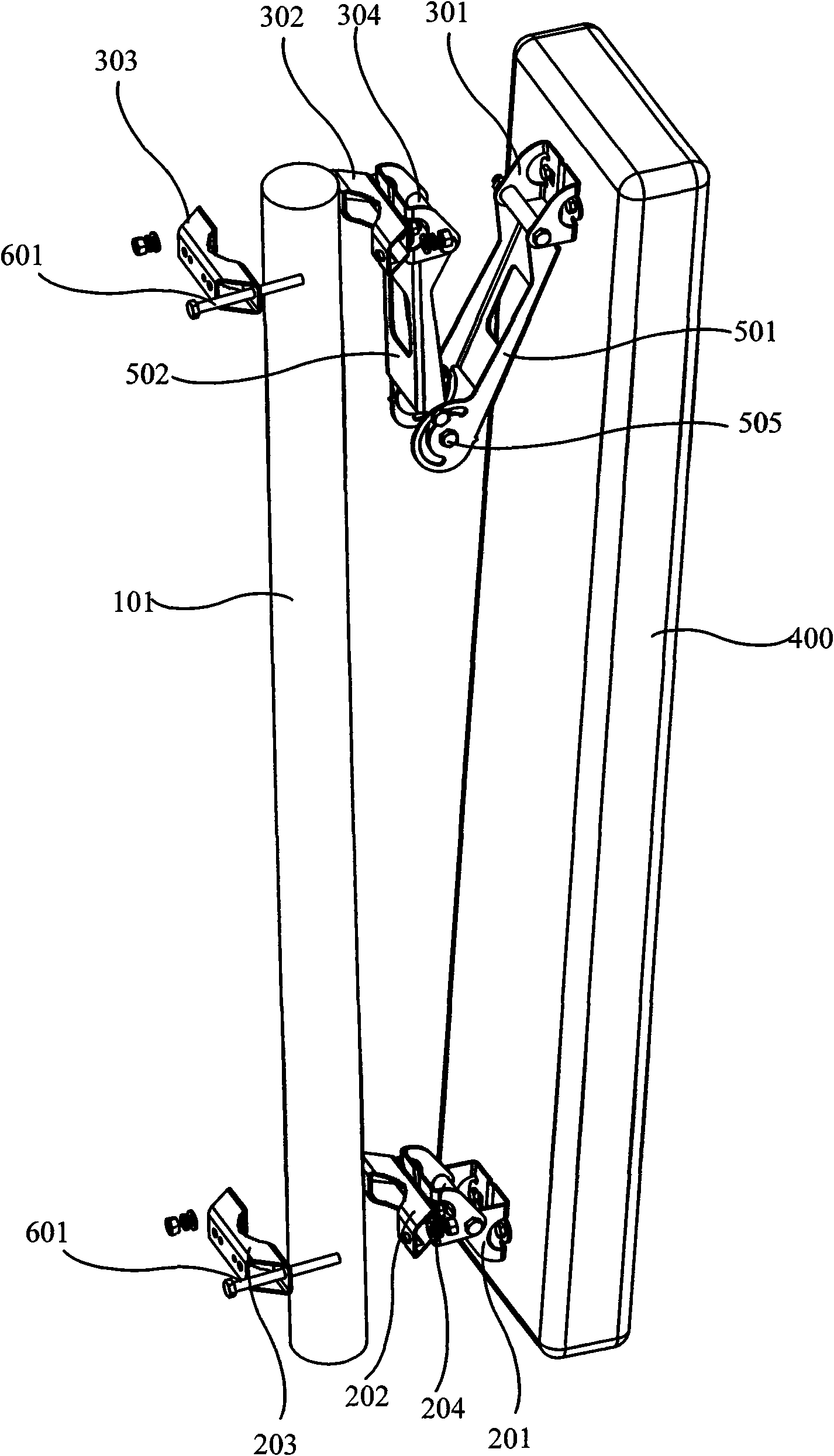

[0059] Figure 4It is a schematic structural diagram of the antenna mounting frame provided by the third embodiment of the present invention, and specifically shows a disassembled structure in a ready-to-assemble state. The antenna mounting frame includes an adjustment assembly, and the adjustment assembly can use the technical solution provided by the above-mentioned first or second embodiment. In this embodiment, the structure of the adjustment assembly of the four adjustment arms provided by the second embodiment is used as an example for illustration. . The adjustment assembly is connected between the antenna 400 and the support body 100 through the upper assembly, and a lower assembly is also connected between the antenna 400 and the support body 100 .

[0060] Specifically, the lower assembly includes a first lower mounting part 205 , a second lower mounting part 206 and a third rotating shaft 207 . The first lower mounting part 205 is used to be fixedly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com