Casing embedding steel ball part structure for motor

A technology of component structure and casing, applied in the direction of electrical components, electric components, casing/cover/support, etc., can solve the problems of poor electrical performance of the motor, large motor noise, affecting the service life of the motor, etc., and achieve improved electrical performance , reduce the noise source, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

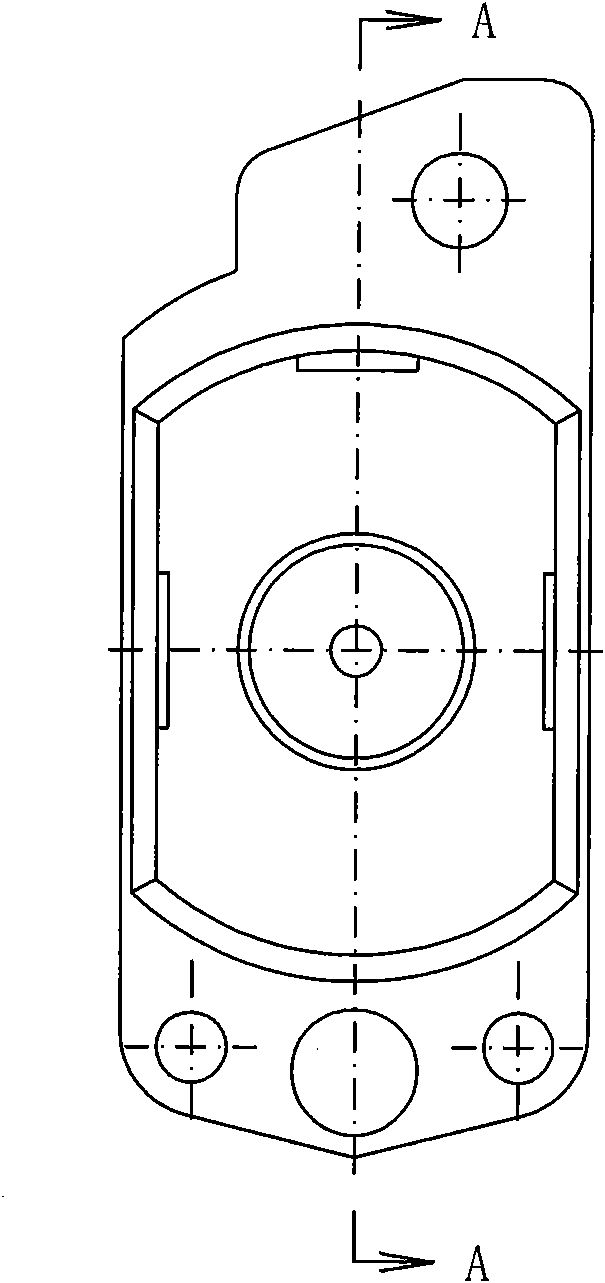

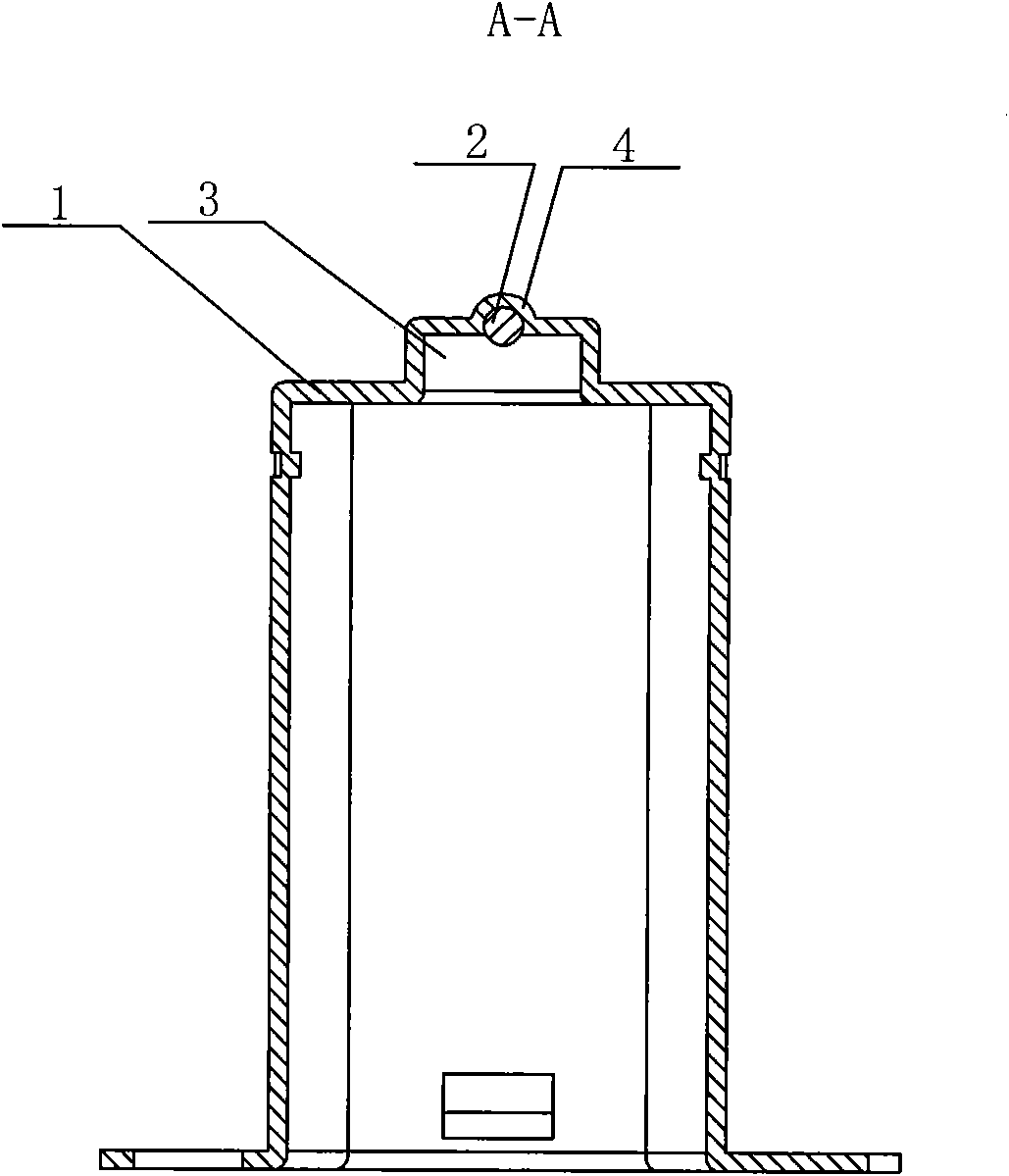

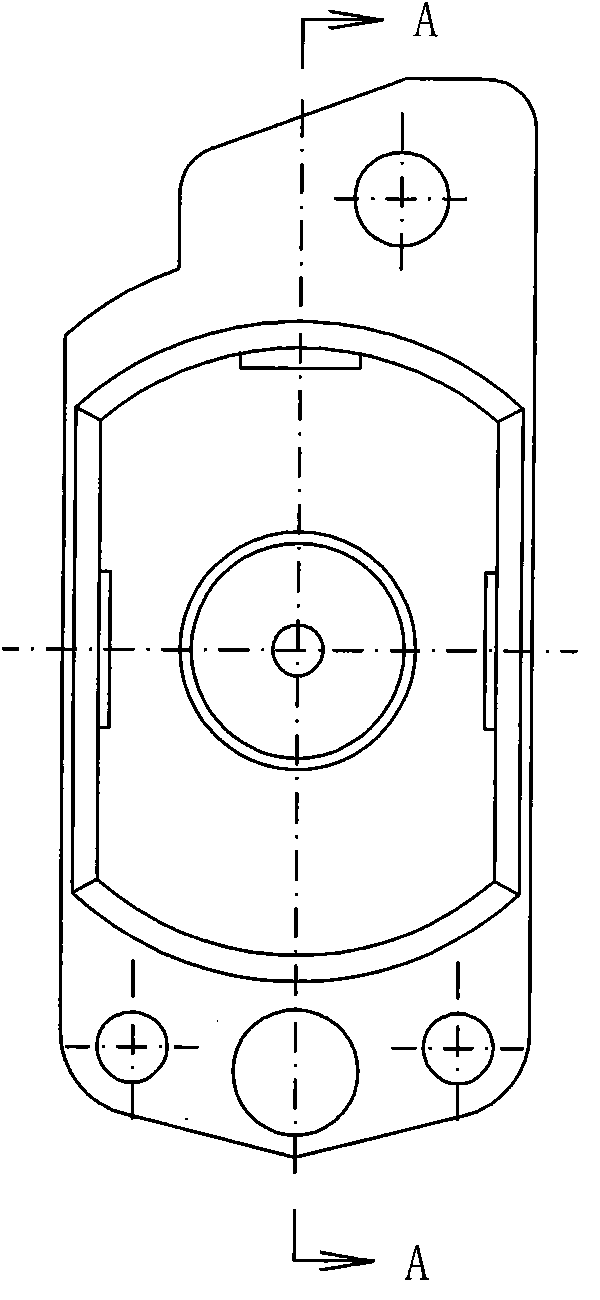

[0007] refer to Figure 1-2 , the specific embodiment adopts the following technical scheme: it is made up of casing 1, steel ball 2, bearing chamber 3 and hemispherical cavity 4, and the bottom of casing 1 is provided with bearing chamber 3, and the bottom of bearing chamber 3 is provided with hemispherical cavity 4. The steel ball 2 is tightly embedded in the hemispherical cavity 4 .

[0008] This specific embodiment can change the contact of the motor rotor shaft head from surface contact to point contact, avoiding the motor noise caused by the direct contact between the motor rotor shaft head and the casing when the motor is working, and effectively reducing the noise source of the motor. The service life of the motor is increased, and the electrical performance of the motor is improved.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap