Making method of shell and shell fabricated through method

A manufacturing method and a technology for a shell, which are applied to devices for coating liquids on surfaces, electrical equipment shells/cabinets/drawers, processes for producing decorative surface effects, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The manufacturing method of the shell of the present invention is used for making the shell with two or more colors, color gradient effect and soft hand feeling. The following is an example of making a shell with two color gradient effects and soft touch.

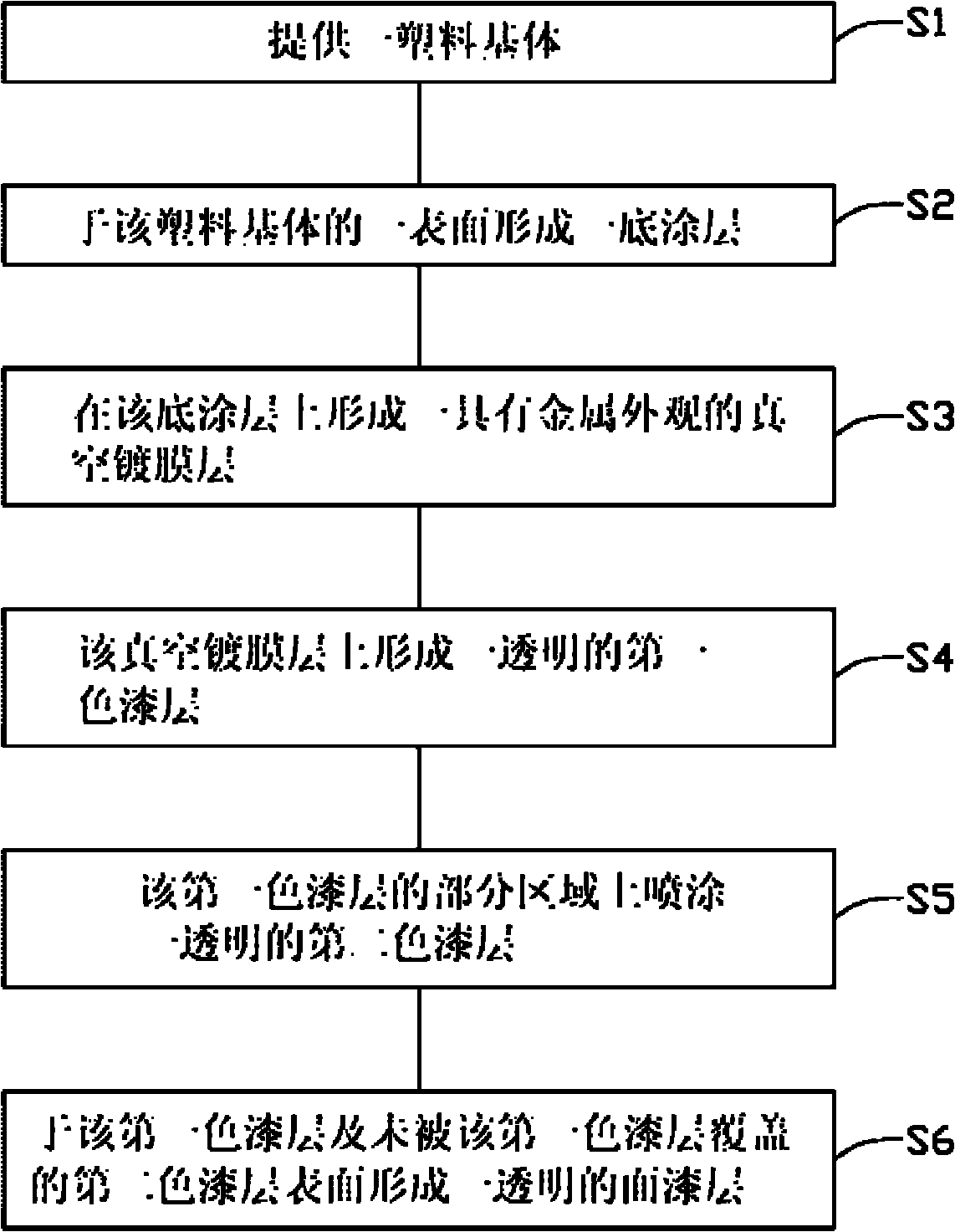

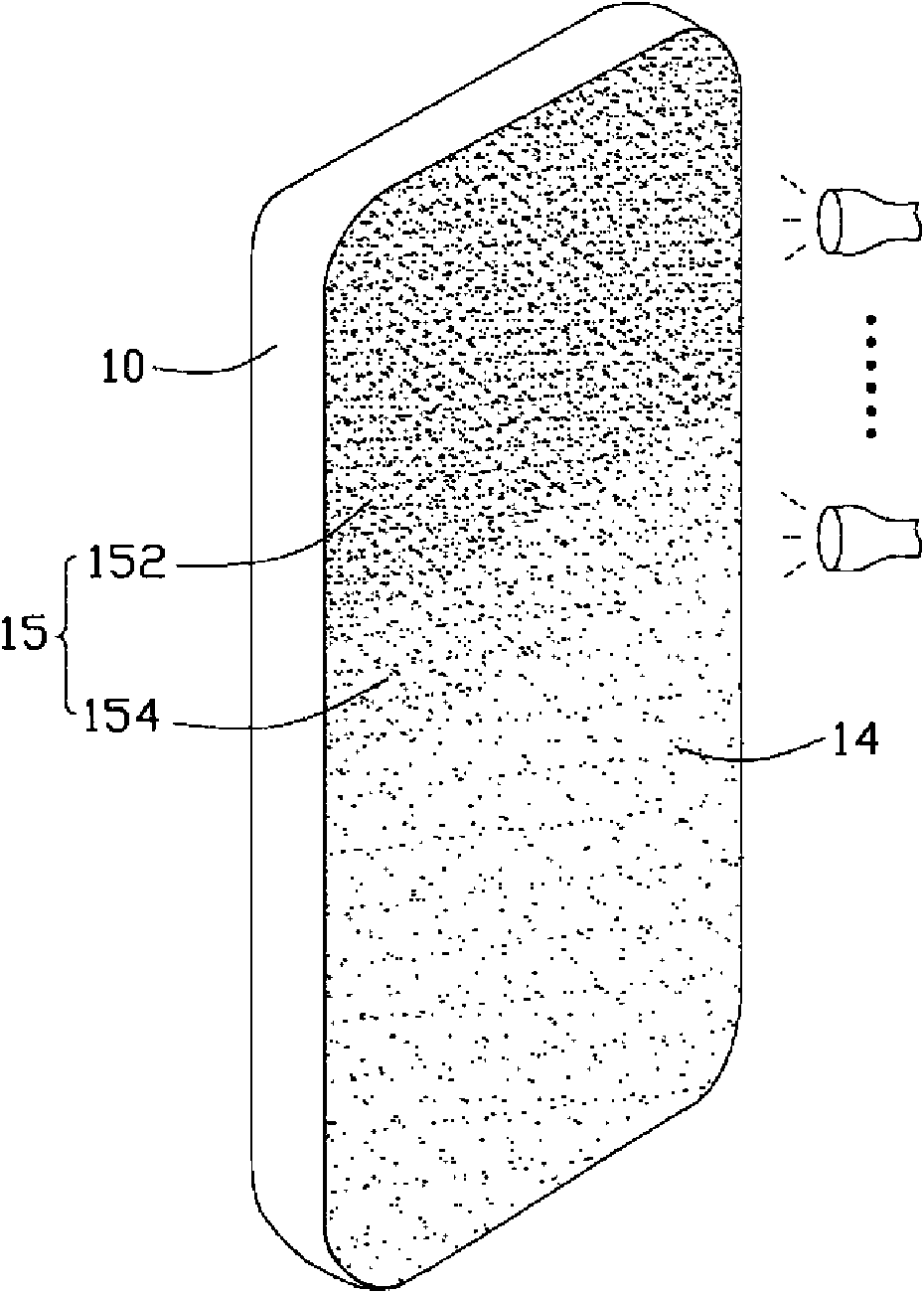

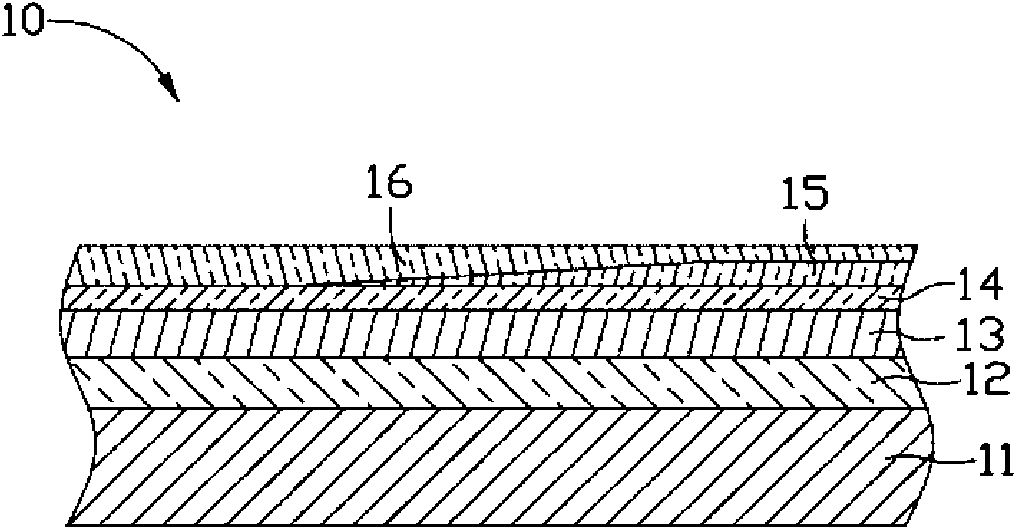

[0018] see figure 1 and image 3 , the housing 10 of the preferred embodiment of the present invention (such as image 3 Shown) the preparation method comprises the following steps:

[0019] Step S1 : providing a plastic base 11 . The plastic base body 11 can be injection molded, which has the structure of the housing to be produced. The plastic forming the plastic matrix 11 may be selected from polyethylene (PE), polyamide (PA), polycarbonate (PC), acrylonitrile styrene butadiene copolymer (ABS), polymethyl methacrylate (PMMA ) and polyethylene terephthalate (PET) and other plastics or a combination of several.

[0020] Step S2: forming (eg, spraying) a primer layer 12 on the surface of the plastic substrate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com