Clamping element

A technology of clamping parts and clamping, which is applied in the direction of clamps, manufacturing tools, etc., can solve the problems of large structural size, unsatisfactory stability and other problems of interference edge failure hidden dangers, and achieve high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

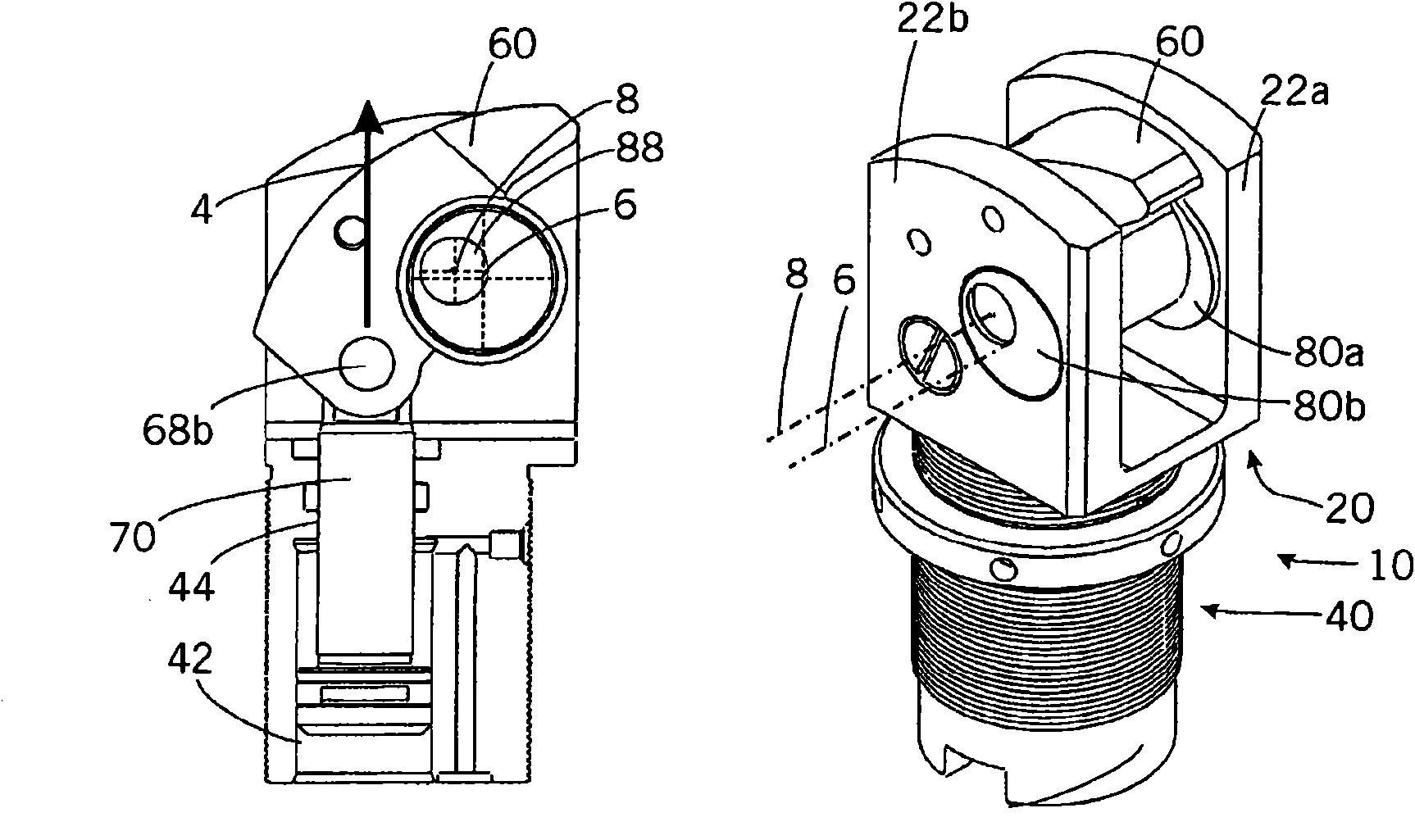

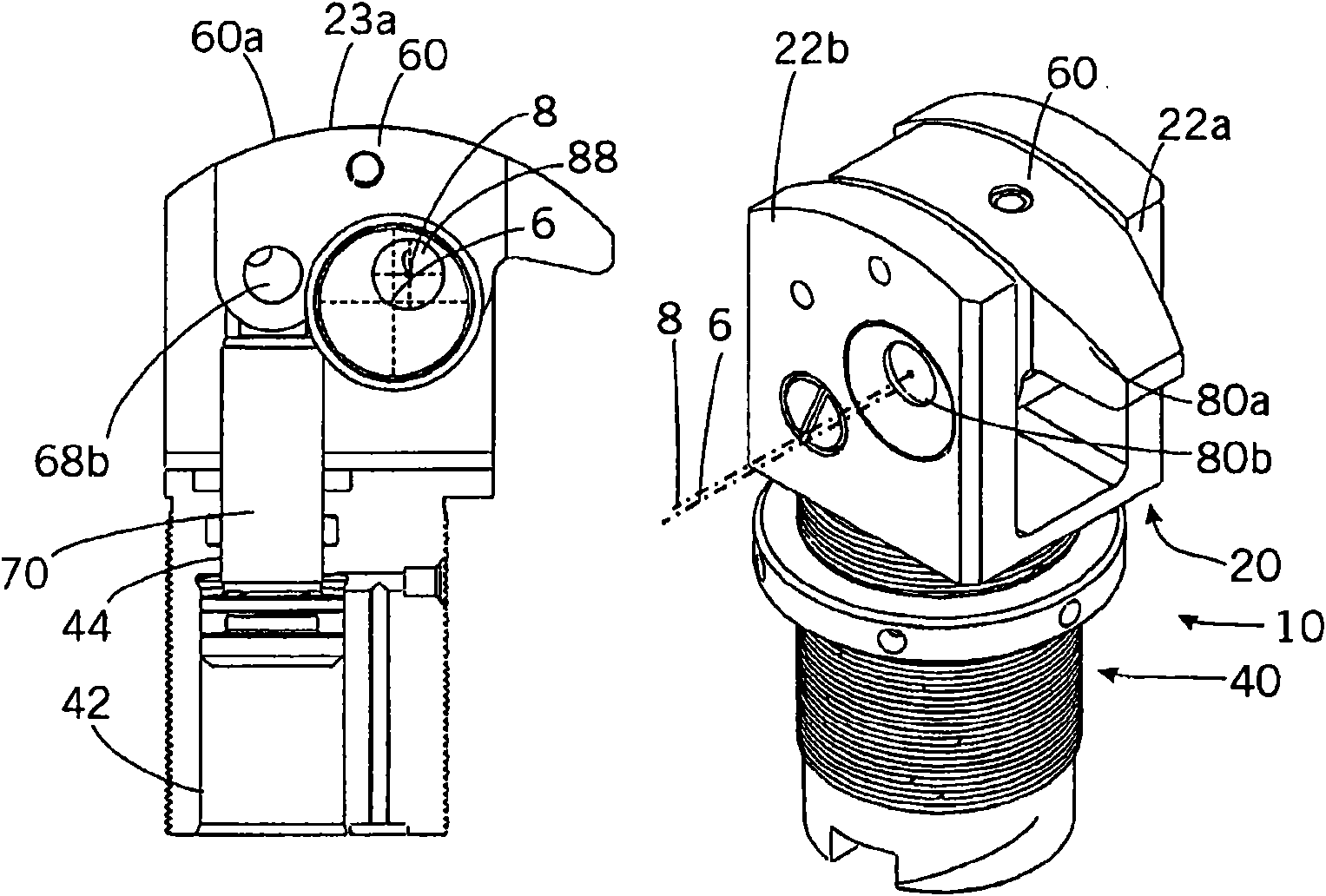

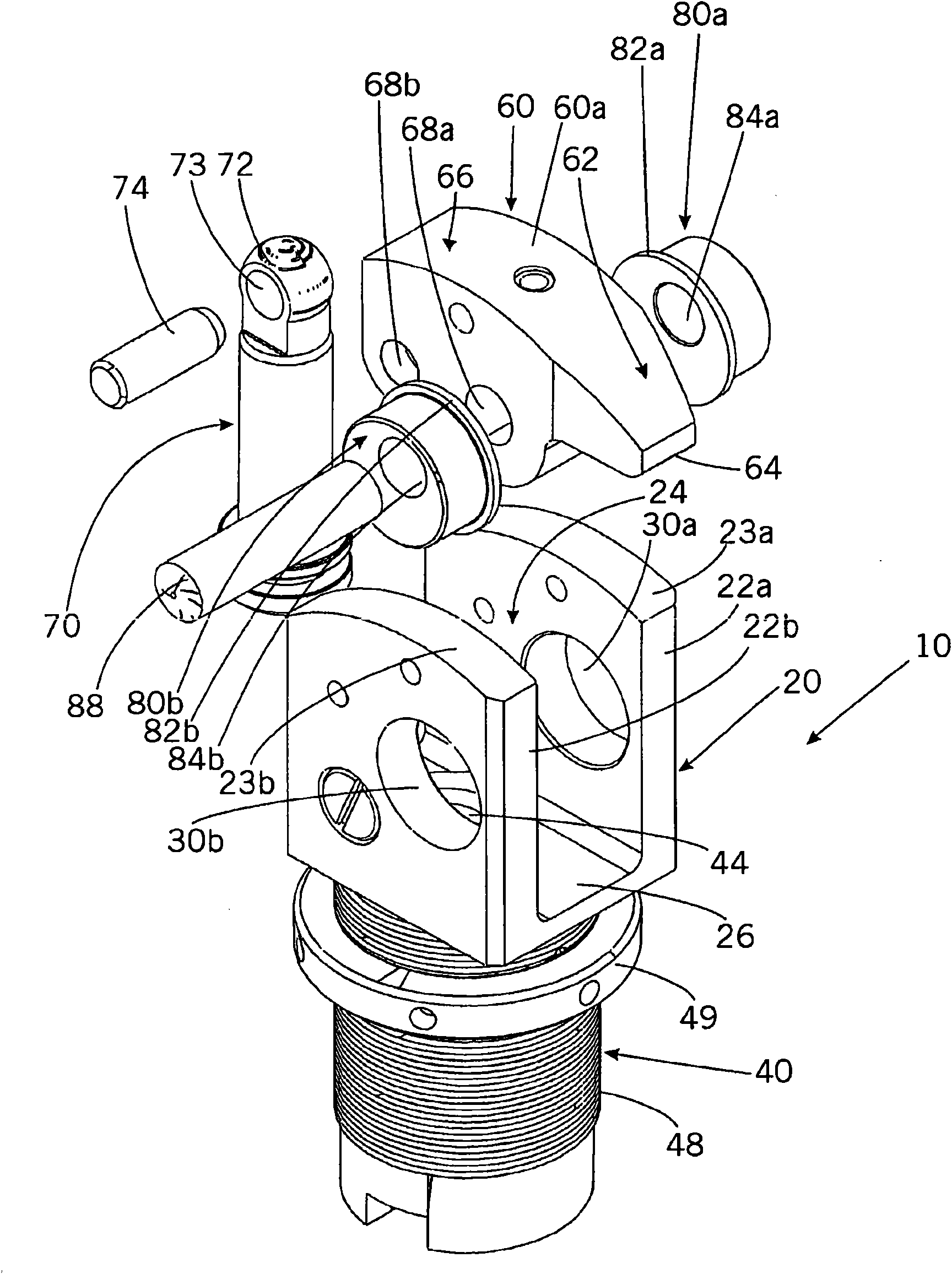

[0031] Figure 1a , 1b and 2 show a first embodiment of the clamping part and its individual components according to the invention.

[0032] by means of figure 2 as well as Figure 1a explain first Figure 1a , The various components of the embodiments of 1b and 2 and the connection of various components.

[0033] The clamping part has a housing 10 with a U-shaped fork section 20 and a cylindrical fastening section 40 connected thereto. The fork section 20 has two planar fork shoulders 22 a , 22 b which are arranged parallel to one another and laterally delimit a free space 24 located therebetween. The prong shoulders 22a, 22b are integrally formed on the base plate 26 at their lower ends. From this base plate 26 extends downward a cylindrical fixing section 40 . as Figure 1a As can be seen in the cross-sectional view of FIG. 1 , a cylinder bore 42 is provided in this fastening section, which serves to accommodate a piston 70 which will be described later. Concentrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com