Gas-blast arc extinction lightning protection gap for power equipment

A gas blowing arc extinguishing and power equipment technology, applied in electrical components, circuit devices, emergency protection circuit devices, etc., can solve the problems of short service life, high operating costs, frequent maintenance and replacement, etc., to achieve low operating costs, reduce Lightning trip rate and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The substantive content of the present invention will be described in further detail below in conjunction with some examples.

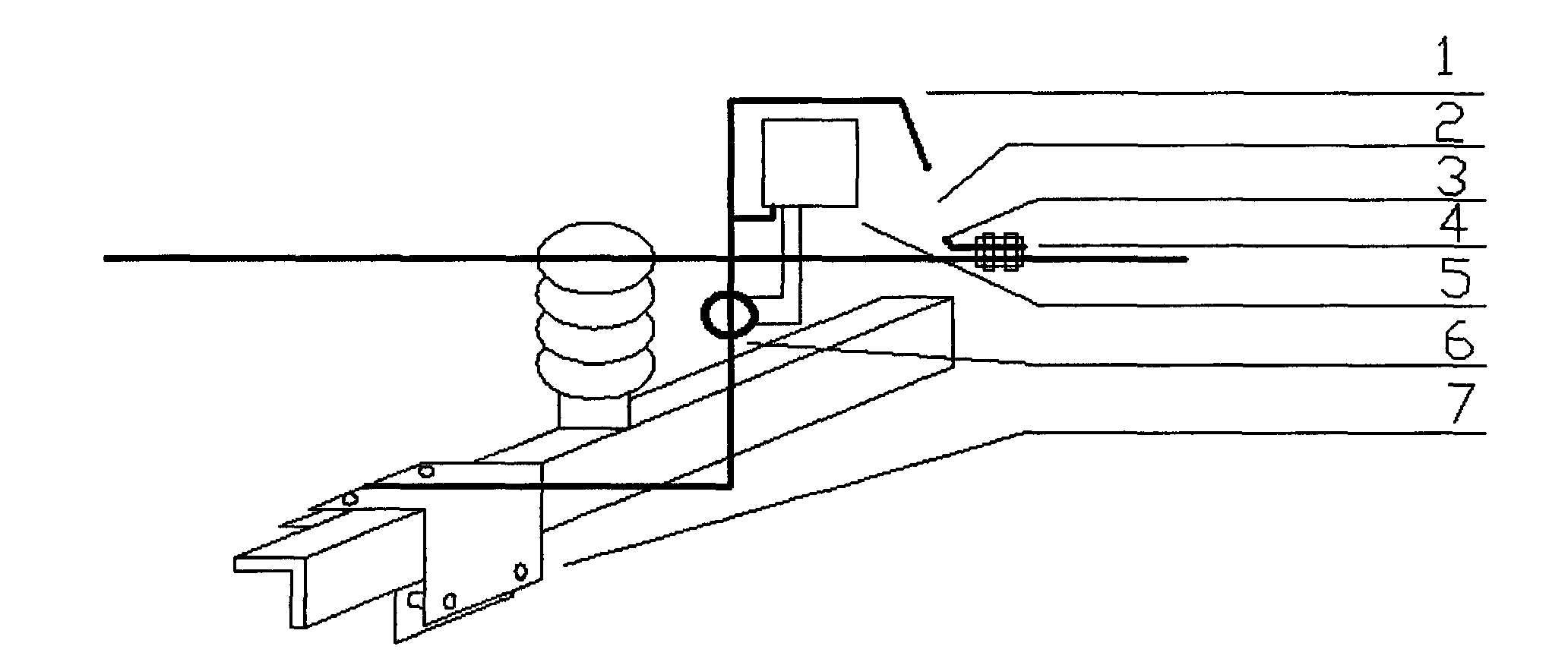

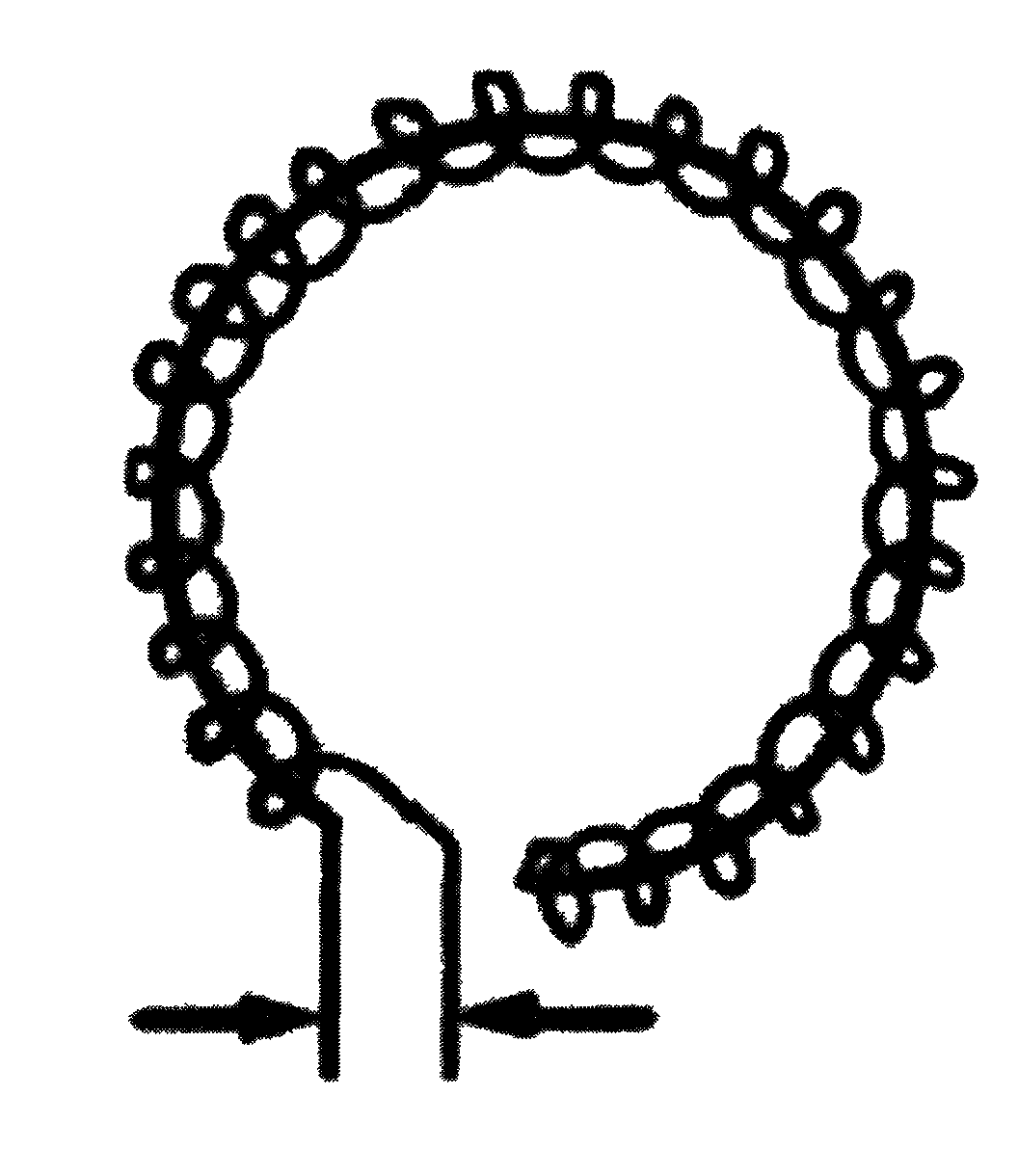

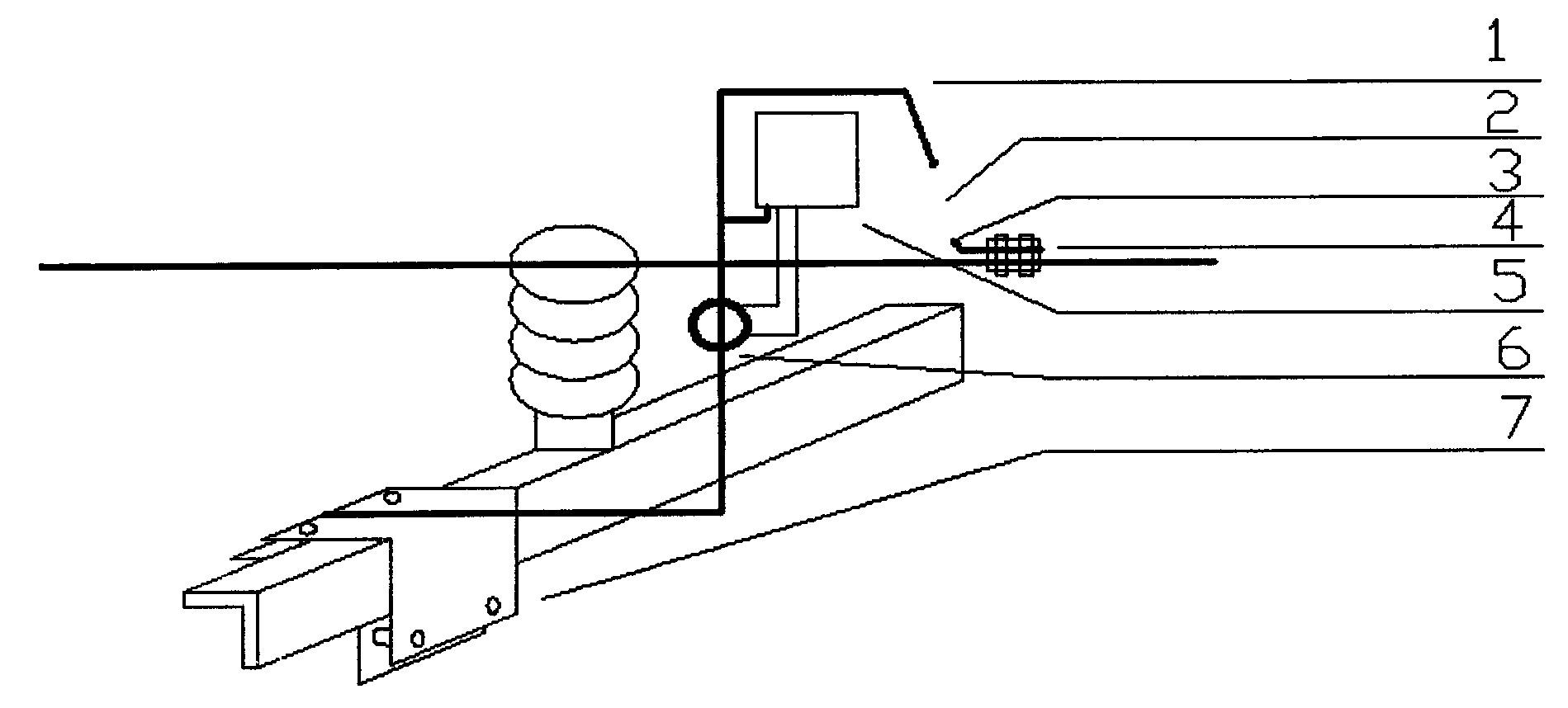

[0021] cling to figure 1 As shown, this gas blowing arc extinguishing lightning protection gap includes grounding electrode 1, grounding connector 7, high voltage electrode 3, high voltage side connecting body 4, gas generator 5, signal detection unit 6 and other components. One end of the high-voltage side connector 4 connected to the electrode gap 2 is the high-voltage electrode 3 ; the other end of the ground connector 7 connected to the electrode gap 2 is the ground electrode 1 . The high-voltage side connecting body 4 and the grounding connecting body 7 are connected to the high-voltage electrode 3 and the grounding electrode 1 respectively, and an electrode gap 2 is formed between the high-voltage electrode 3 and the grounding electrode 1. The whole device passes through the high-voltage side connecting body 4 and the grounding connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com