Stacking machine and lifting appliance thereof

A spreader and main body technology, applied in the direction of lifting devices, etc., can solve the problems of affecting operators and low efficiency of stacking operations, and achieve the effect of eliminating the forward tilt angle, improving the efficiency of stacking operations, and ensuring the levelness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that the embodiments in this application and the features in the embodiments can be combined with each other if there is no conflict. Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

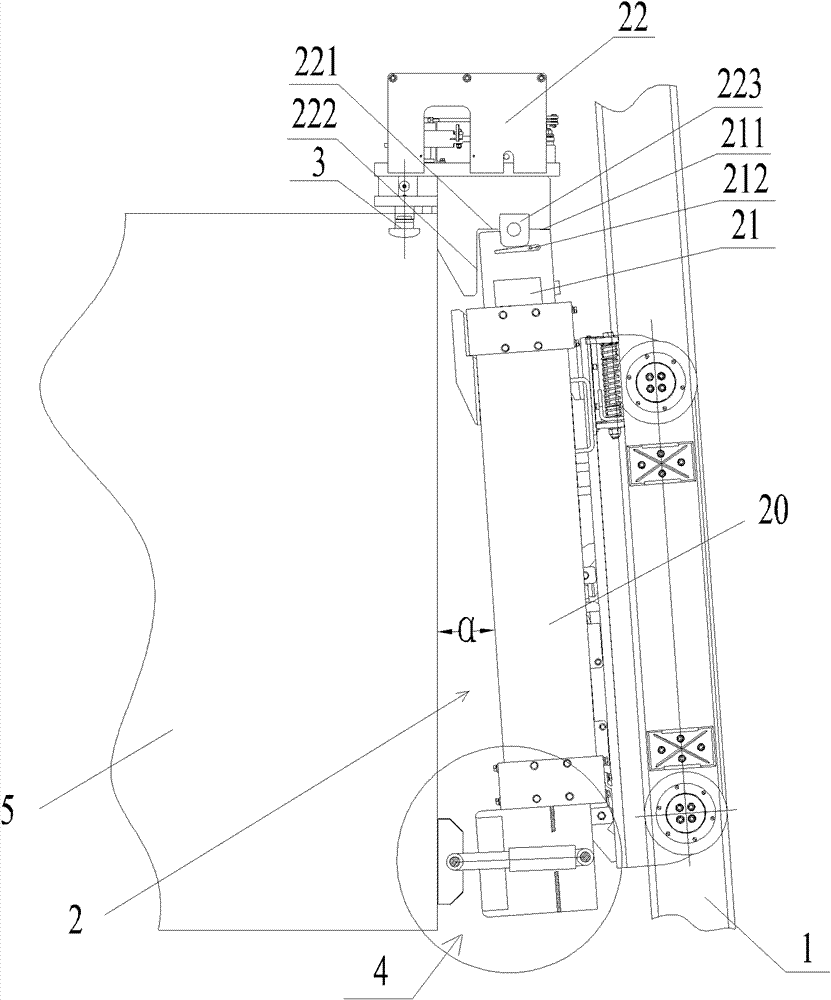

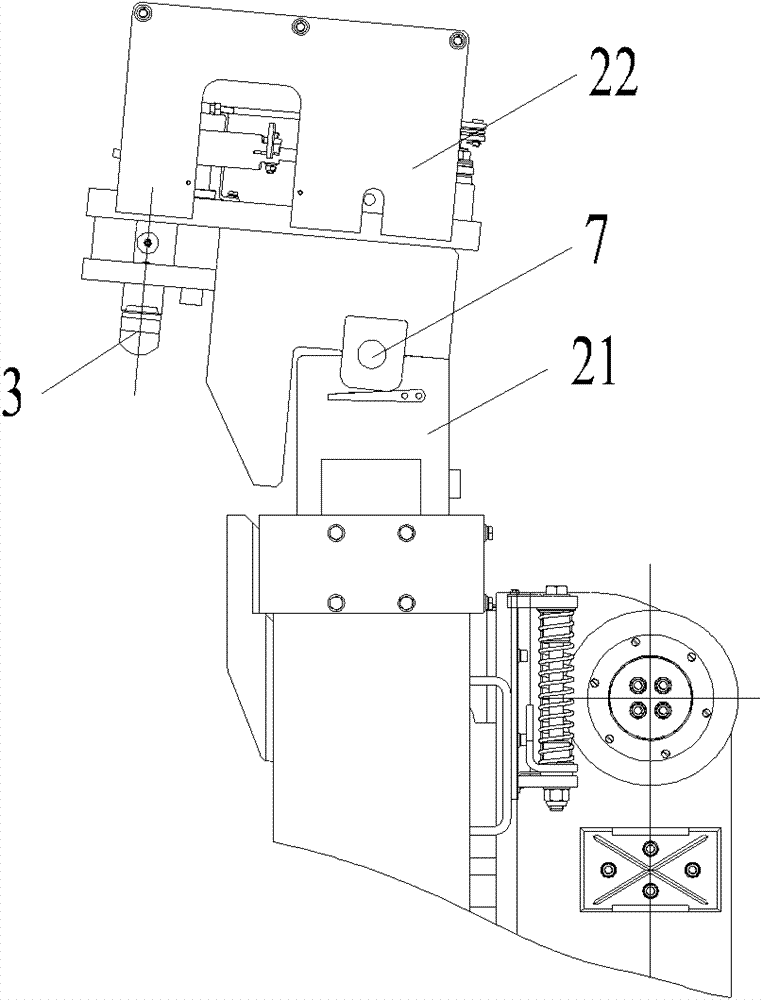

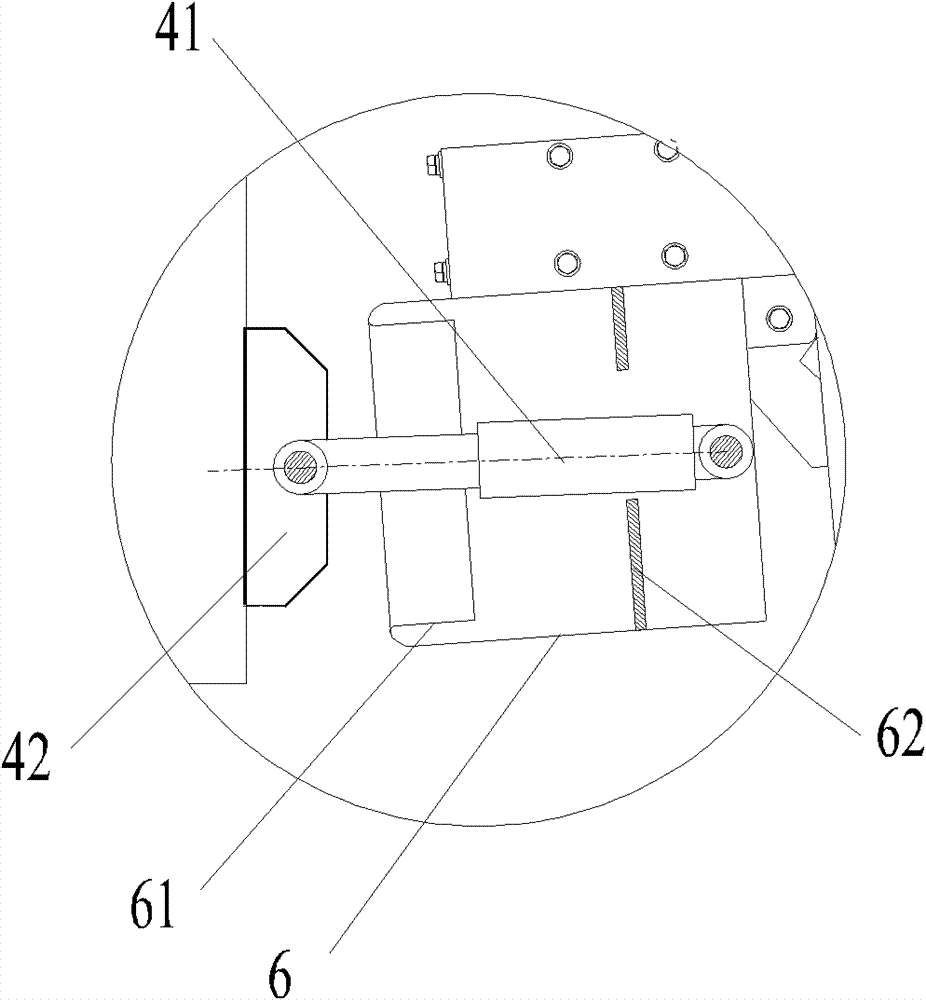

[0023] See Figure 1 to Figure 5 , Shows the structure of a spreader according to the present invention and a stacker with the spreader. As shown in the figure, the stacker according to the present invention includes a mast 1 and a spreader 2.

[0024] Among them, the mast (same as the spreader bracket) 1 is usually installed longitudinally in front of the driver's cab of the stacker, and moves with the stacker body. The spreader 2 includes: a spreader main body 20, which cooperates with the mast 1 and can move longitudinally along the mast 1; a spreader head 22, the first end is hinged to the upper end of the spreader main body 20, and the second end is provided for connecting the contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com