Method for arranging parallel steel wire stay cable

An installation method and cable-stayed technology, which is applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., can solve problems such as low construction efficiency, long construction period, and great influence on bridge alignment, so as to prevent accidents caused by falling cables and facilitate the construction process , The effect of personnel operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

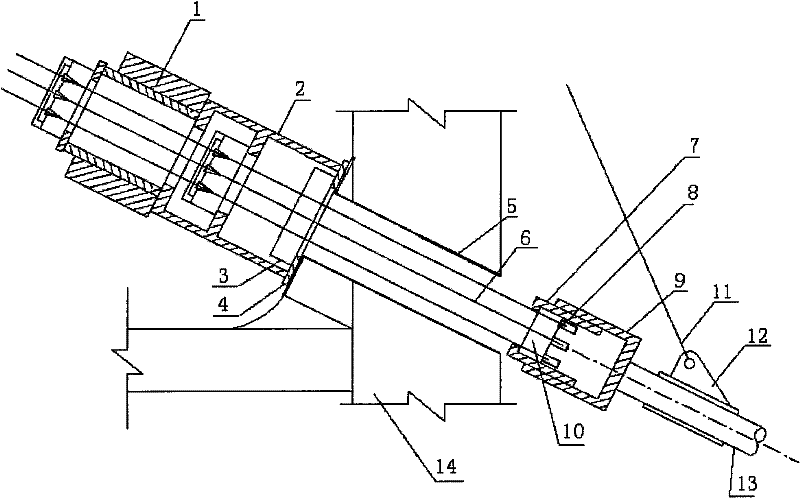

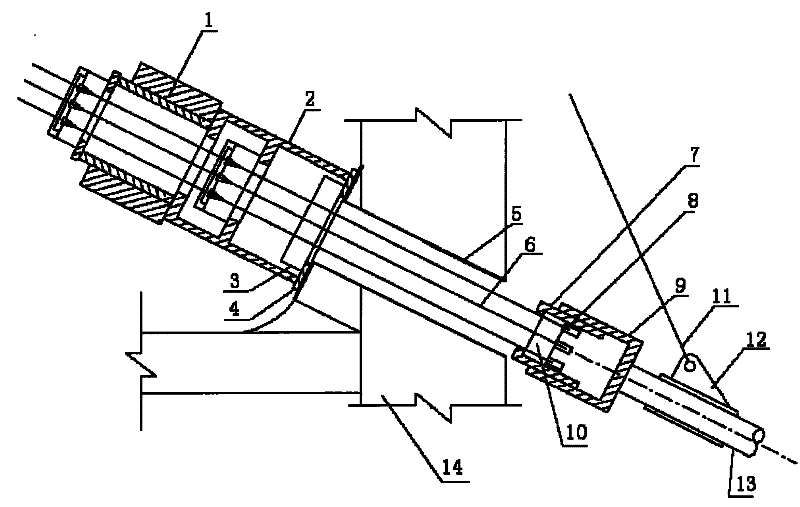

[0019] The installation method of parallel steel wire stay cable of the present invention is referring to accompanying drawing, carries out according to the following steps:

[0020] 1. Spread the stay cables on the bridge deck;

[0021] 2. Install the anchor head 9 at the tower end of the stay cable;

[0022] 3. Arrange the planetary jack 1, the planetary jack support 2 and the tower end anchor nut 3 of the stay cable vertically and centrally on the anchor plate 4 provided at the inner side of the cable guide 5 on the wall of the cable tower 14;

[0023] 4. Determine the length of the traction steel strand 6 according to the traction force required to pull the stay cable 13 to the cap on the tower end anchor head 9 according to the pre-calculated stay cable 13 under the condition that the tower end anchor head 9 is installed And the number of roots, the traction steel strand 6 is connected to the tower end anchor head 9 of the stay cable through the pressure sleeve 7, the P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com