Self-adaptive plate mounting robot

A robot and self-adaptive technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of time-consuming and laborious installation personnel, difficulty in ensuring installation accuracy, cumbersome installation process, etc., and achieve the effect of reducing work intensity, ensuring accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

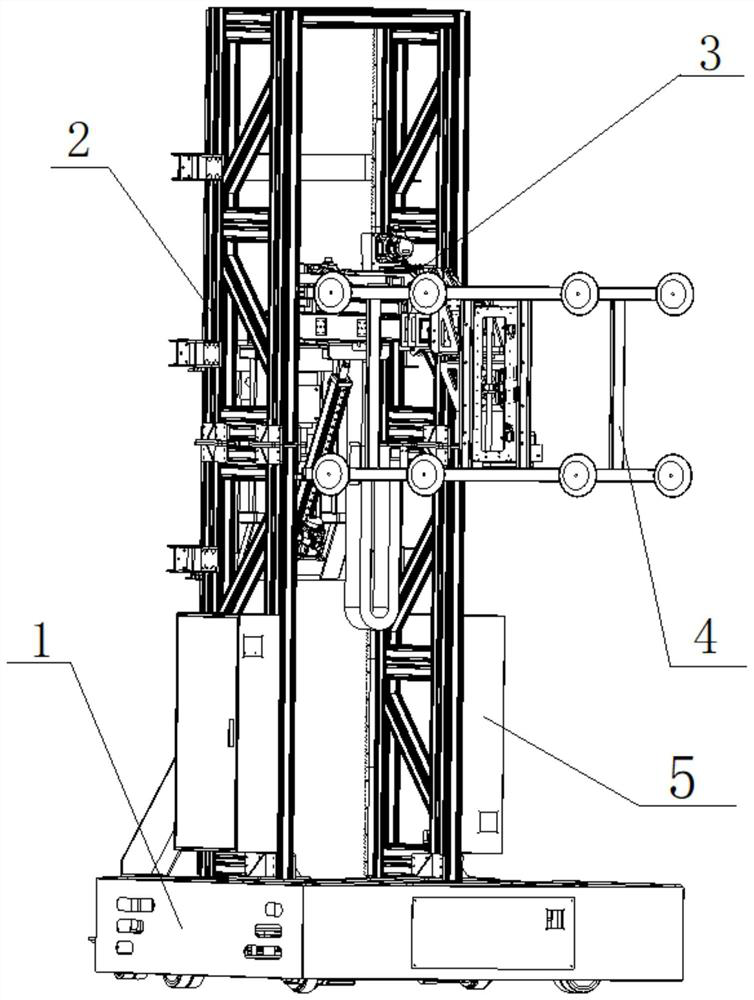

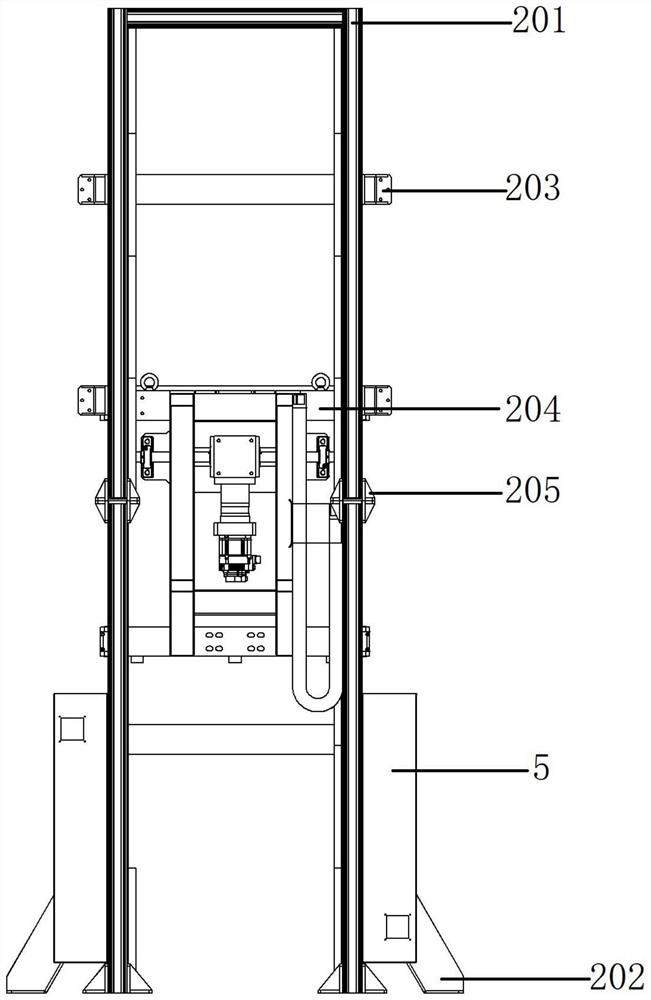

[0033] The present invention provides an adaptive panel installation robot (robot for short), which is characterized in that the robot includes a mobile base 1, a lifting device 2, a mechanical arm 3, an end effector 4 and a robot control cabinet 5;

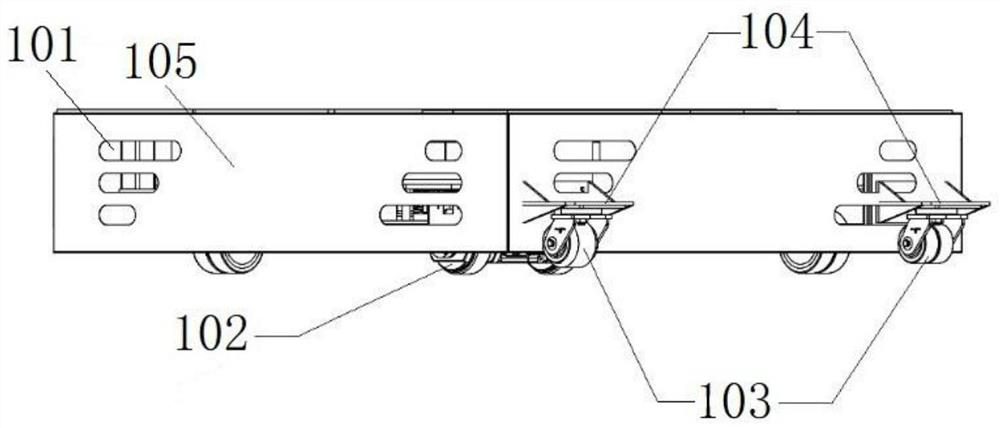

[0034] The mobile base 1 is used to drive the robot to move in any direction, and the lifting device 2 is arranged on the mobile base 1 to realize the lifting of the mechanical arm 3 in the height direction;

[0035] Said includes the inner link 301 of the mechanical arm, the outer link 302 of the mechanical arm, the first telescopic actuator 303, the second telescopic actuator 304, the first pitch link 305, the second pitch link 306, the third telescopic actuator 307, and the mechanical arm c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com