Patents

Literature

39results about How to "Construction work safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shield machine belt pressure chamber opening operation construction method

ActiveCN101539023AReasonable construction steps and parametersConstruction work safetyTunnelsShield machineShort cycle

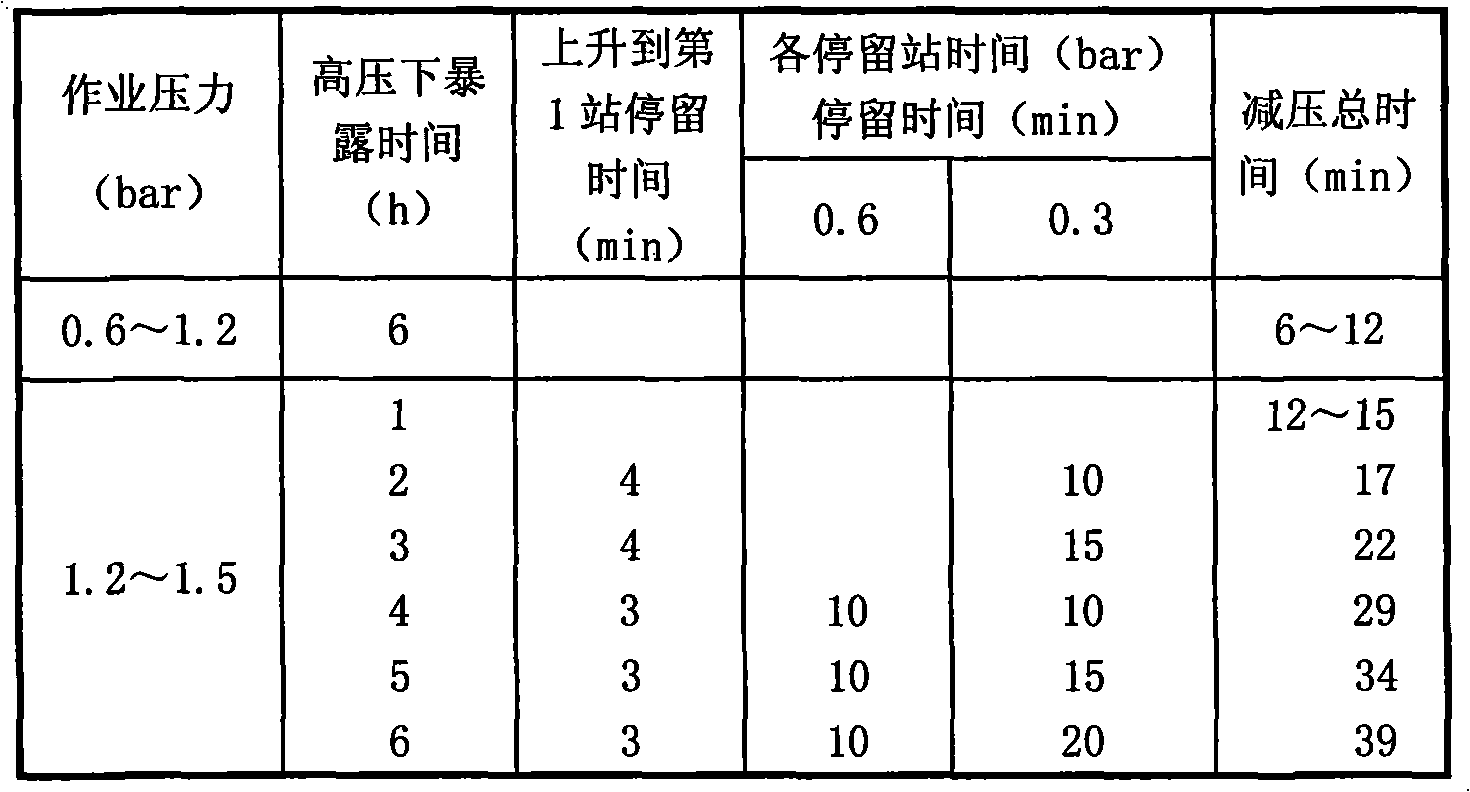

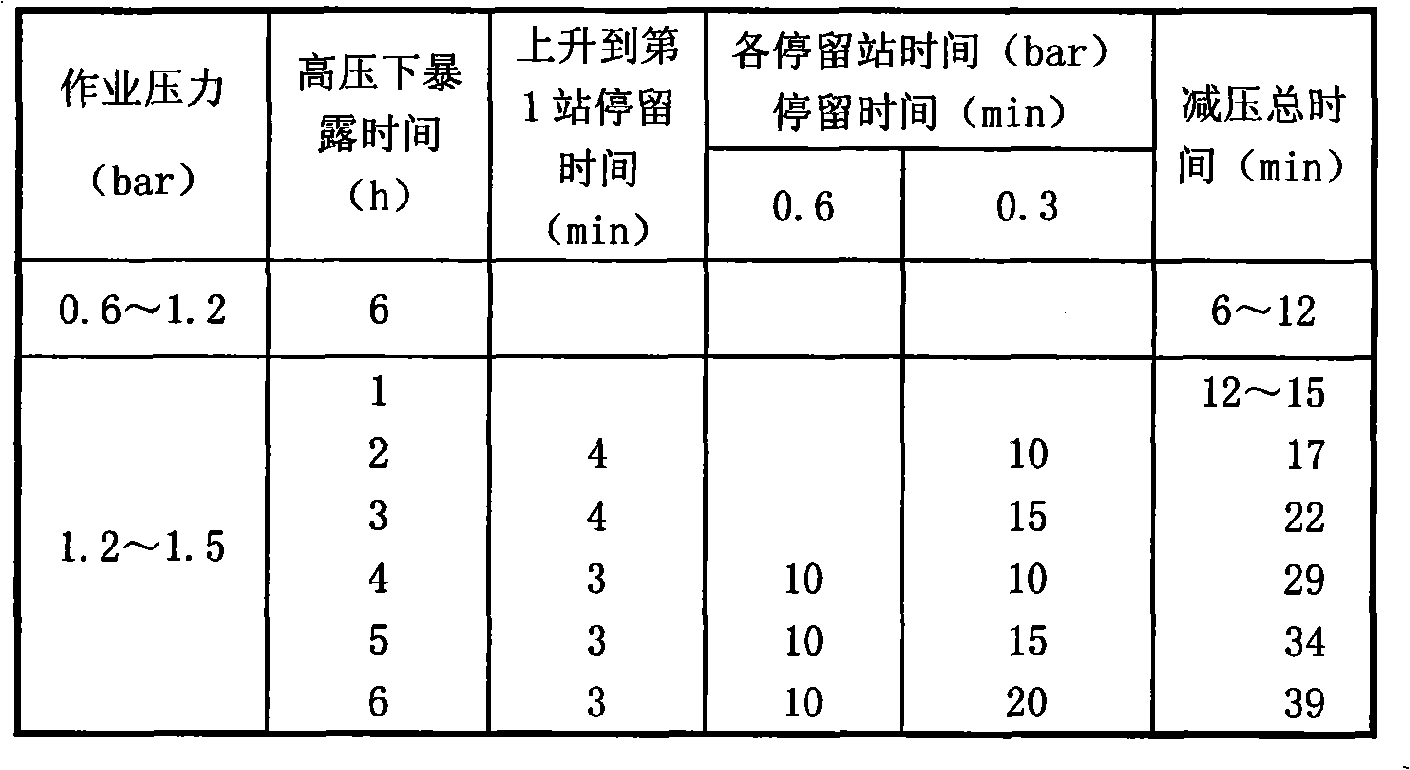

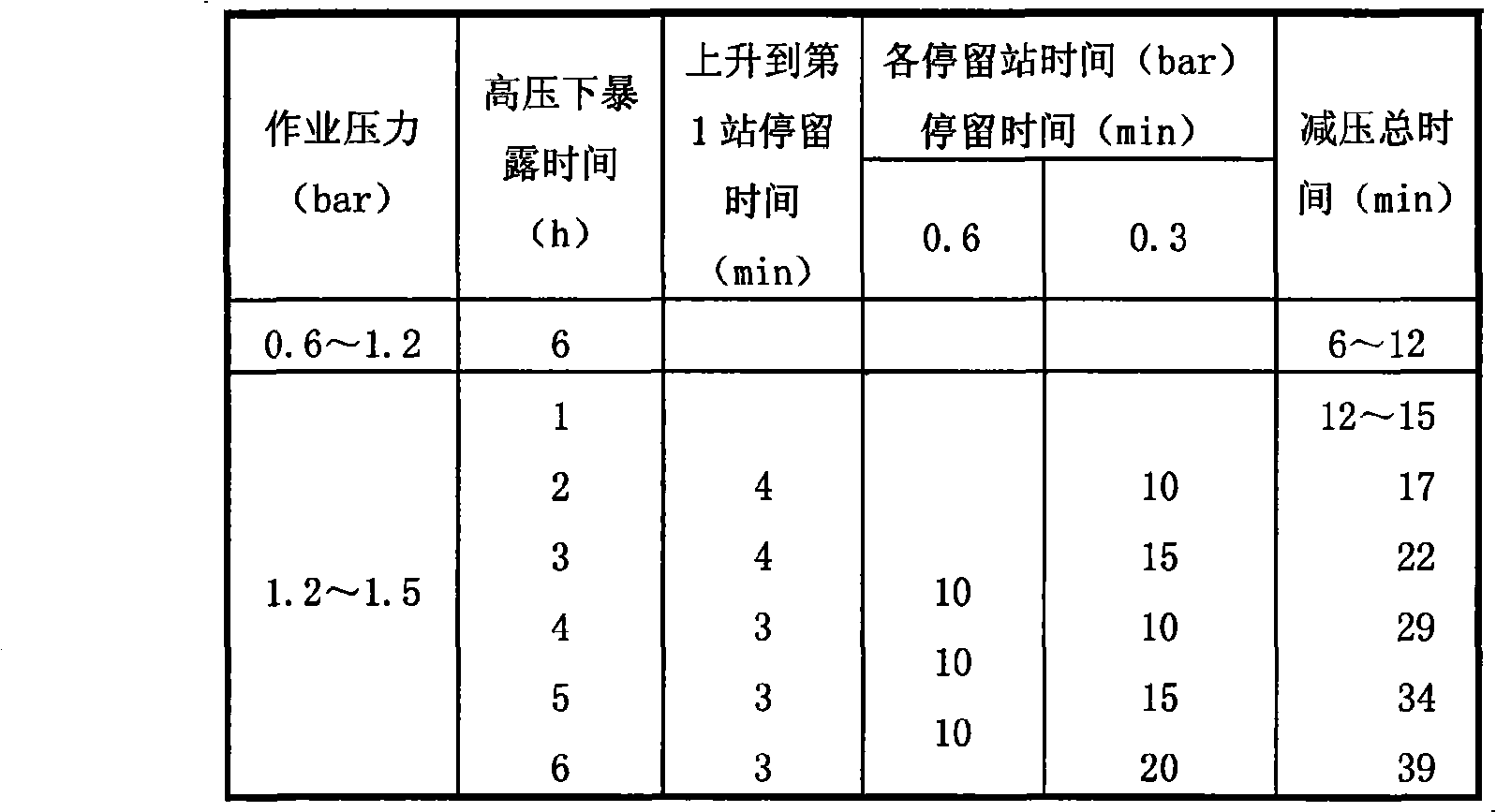

The invention relates to a shield machine belt pressure chamber opening operation construction method. The method comprises the following steps: adjusting the posture of a shield, setting up tunneling parameters, and injecting bentonite slurry into a shield cutter head and the circumference thereof so as to make the soil mass around a tunnel face and the shield form a clay film capable of blocking off a leakage passage; establishing the air pressure in the soil chamber; carrying out the pressurization and chamber entry, making staff enter a personal gateway to check and change a cutter or even check the cutter head, and the like; carrying out decompression and chamber exiting; and after the operation is completed, injecting bentonite into the soil chamber through a pipeline, and staring the cutter head and a jack to restore the shield tunneling after the soil pressure balance is rebuilt in the soil chamber. The method reduces the gas permeability of a stratum by 30 percent compared with that of the original stratum, thereby meeting the belt pressure requirements, not only ensuring the safety of the workers operating in the soil chamber, but also ensuring the soil mass stability of the tunnel face. The method brings about a good strengthening effect and little ground surface deformation; as the reinforcement is carried out inside the tunnel, the method does not occupy ground area and brings about little influence on the ambient environment and urban traffic; and the method has the characteristics of high construction efficiency, short cycle, and low cost.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

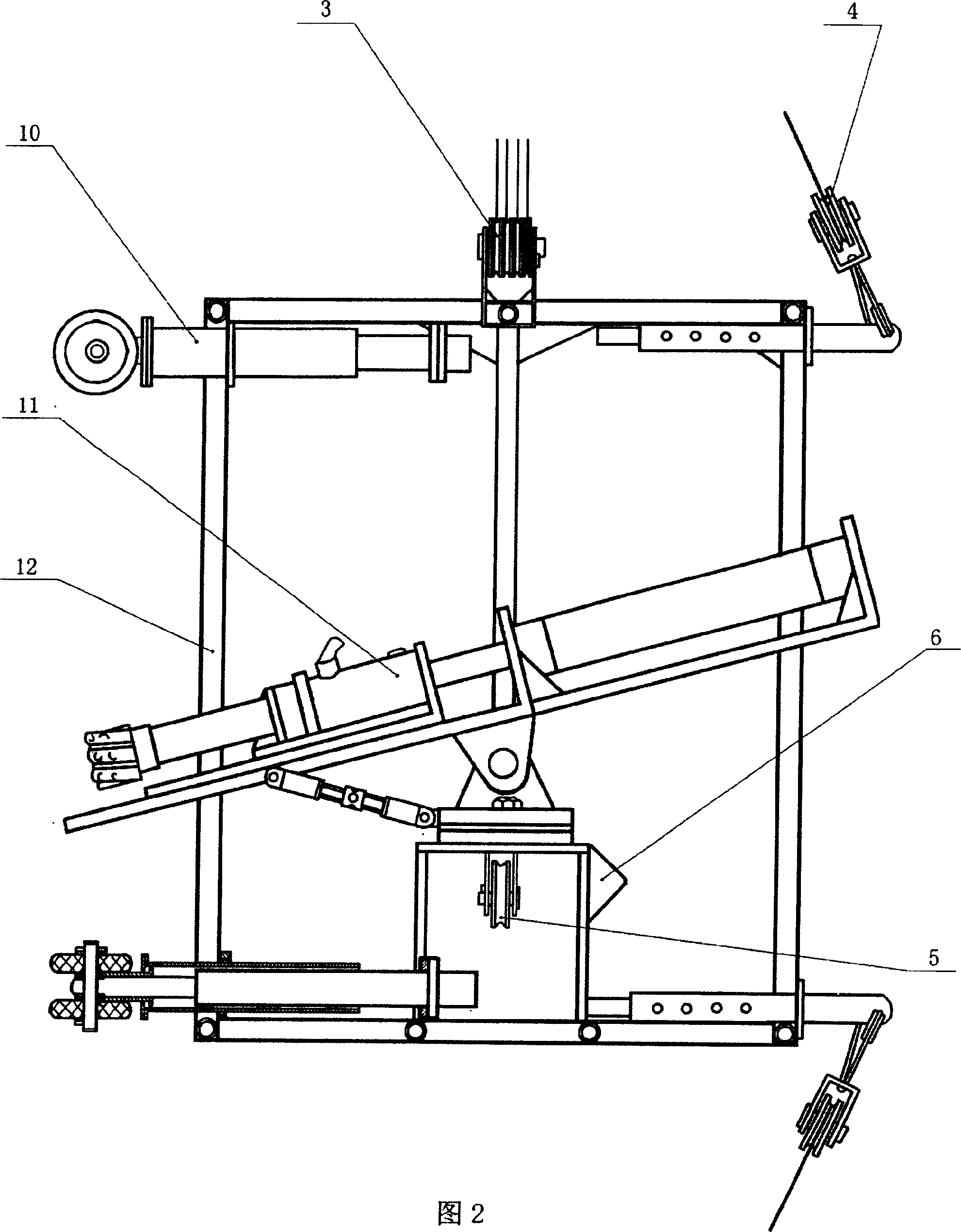

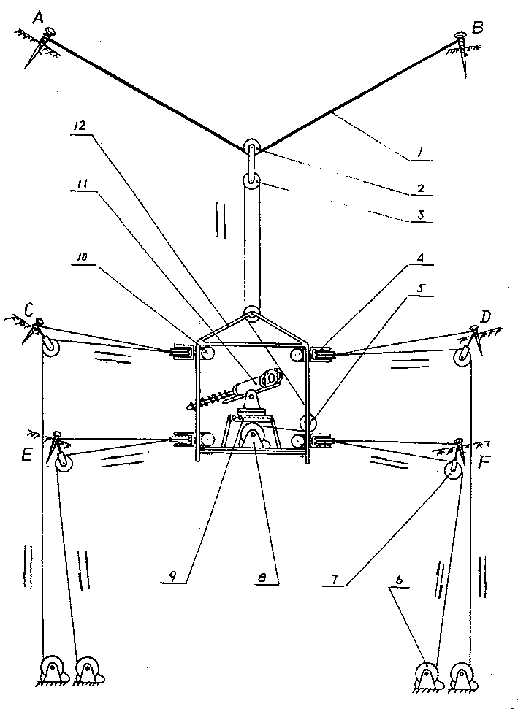

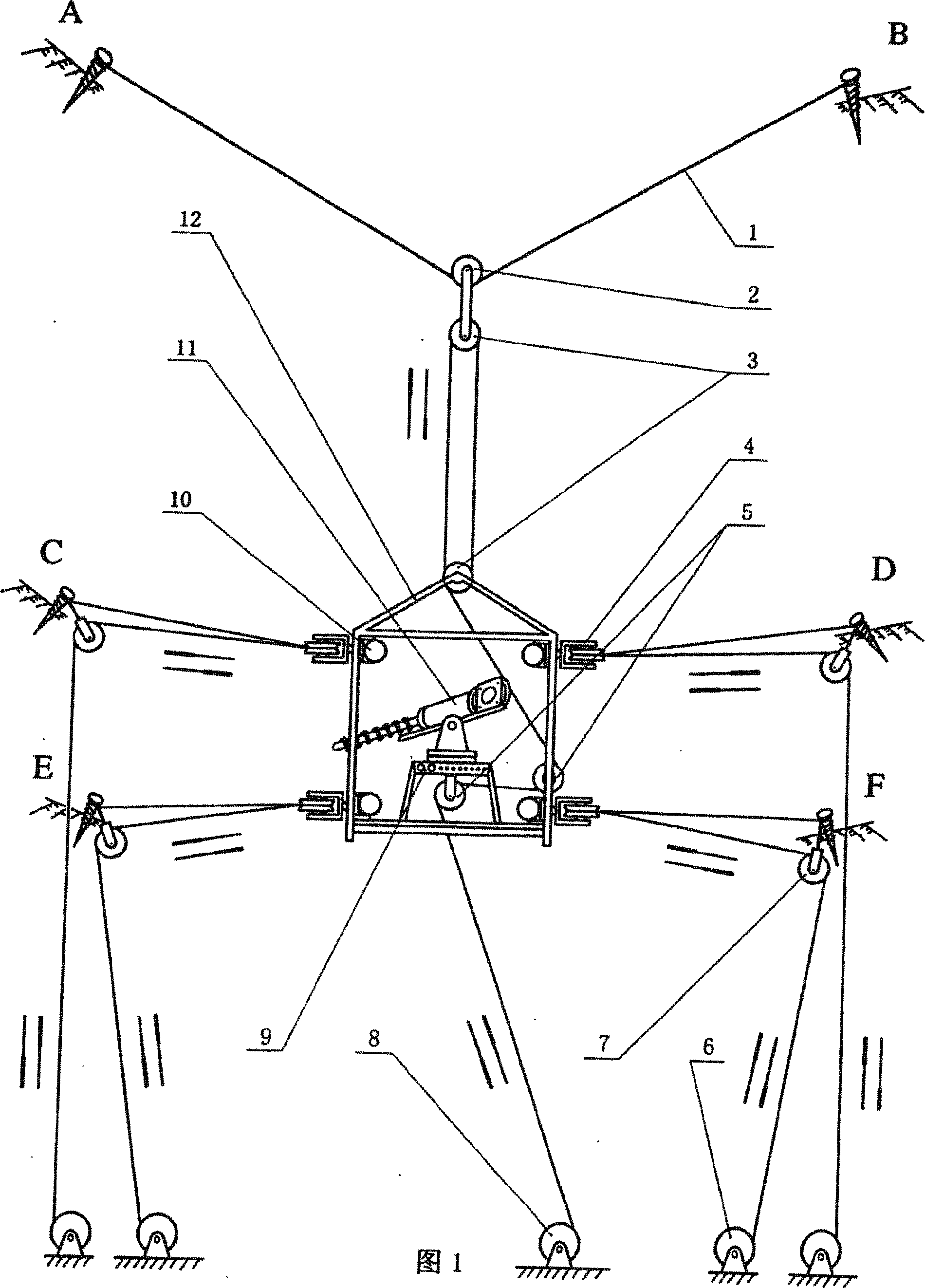

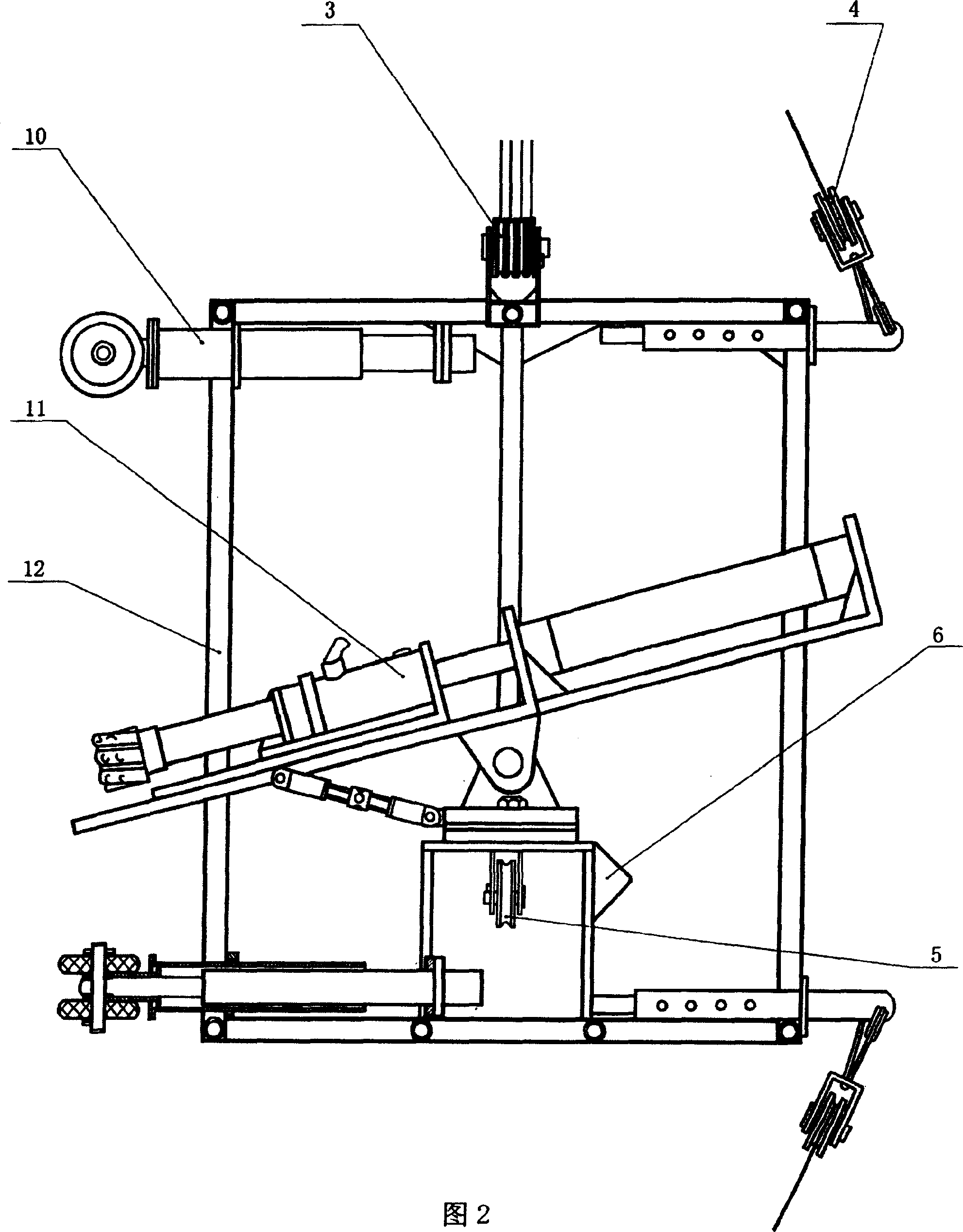

High grade rock and soil anchoring construction method and apparatus

InactiveCN1544765AMove safely on your ownConstruction work safetyBulkheads/pilesBuilding support scaffoldsSteep slopeDrill floor

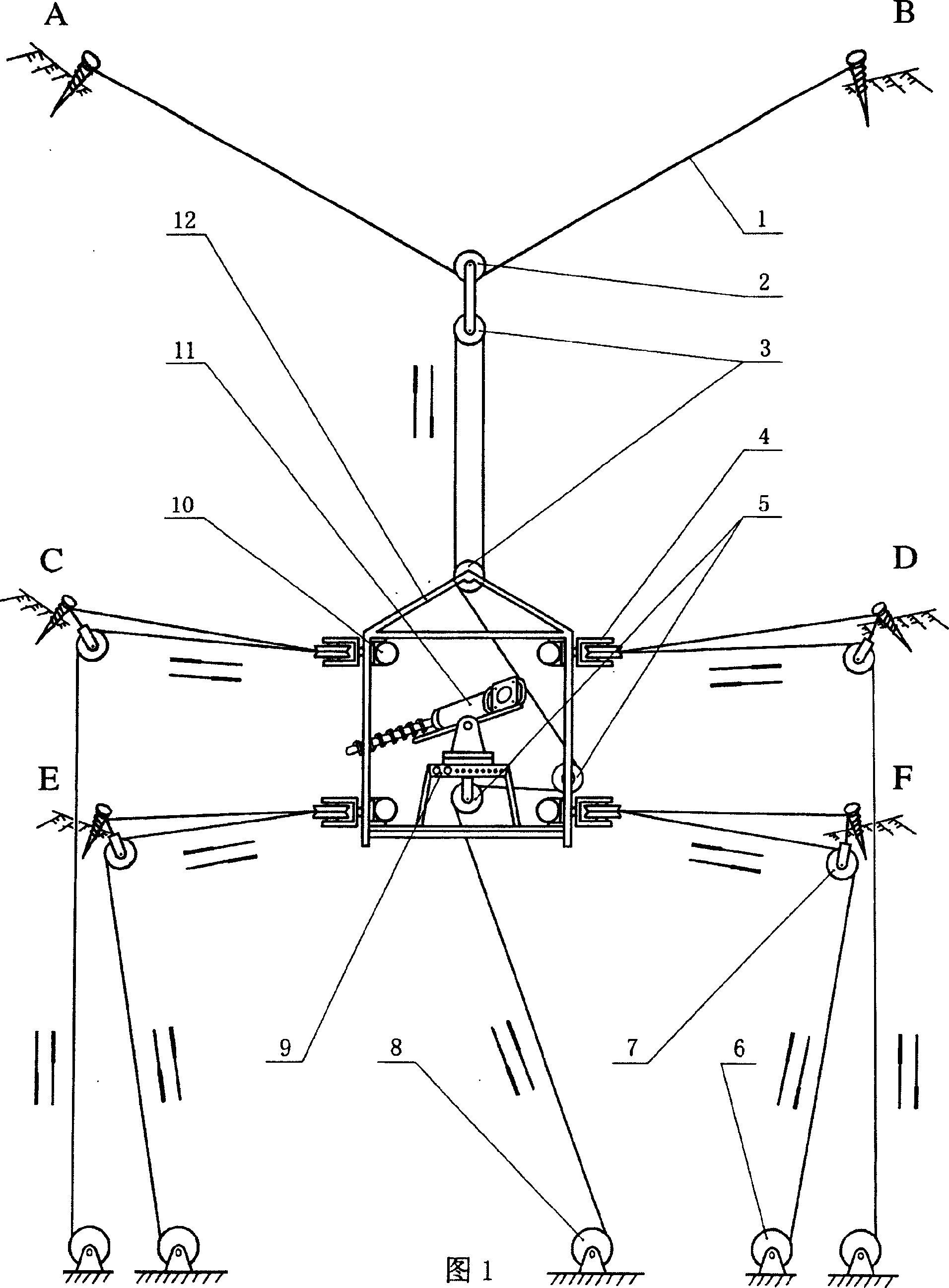

The invention is a method and device of slope rock anchoring construction by using cables to pull drill floor for locating and applying pressure. The method: according to the six (or four) anchoring points preset in the range of anchoring operation surface, linking two points in the high position by a steel cable, hanging the drill floor under the pulley rolling on the steel cable through pulley group, using a steel rope fixed on the ground for lifting the jenny to make the drill floor vertically move up and down through the pulley group; using four steel ropes of four transverse moving jennies all fixed on the ground to make the drill floor move left and right through the turning pulleys on the anchoring points and the drill floor. There are four extension and turning truckles on one side of the drill floor, near the steep slope. The anchored driller on the drill floor can regulate the angle of drilling hole on the horizontal and vertical surfaces. When constructing, using operation control button on the drill floor to control to lift the jenny and transverse moving jennies so as to move the drill floor to hole drilling position and make the drill floor closely adhere to the slope, and at the same time support up the supporting legs of the extension and turning truckles to press the drill floor in the hole position for drilling hole.

Owner:石午江

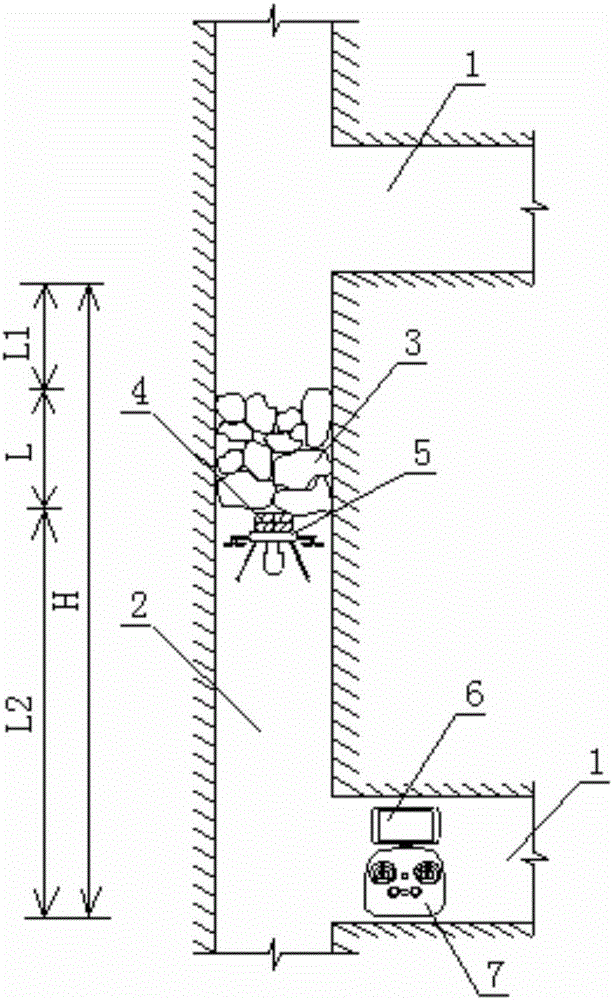

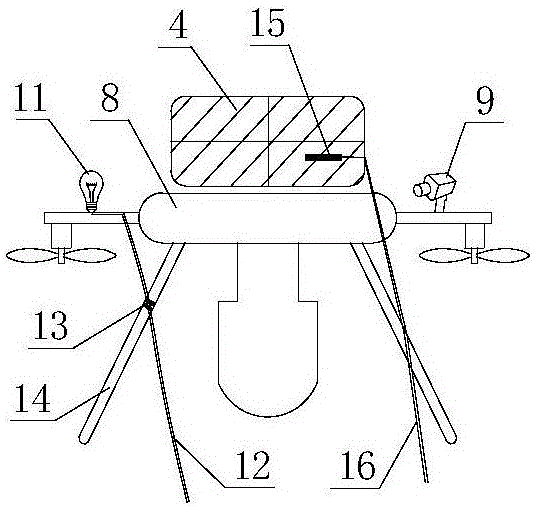

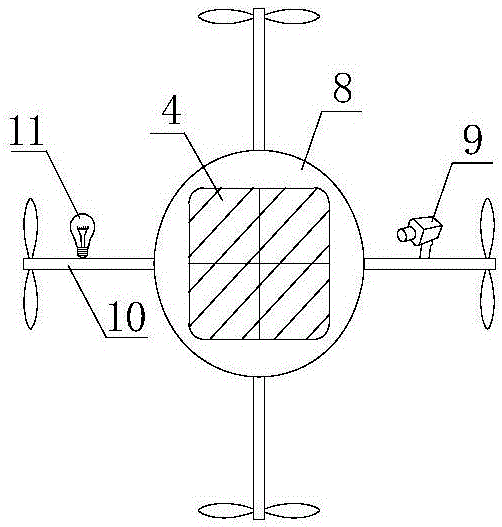

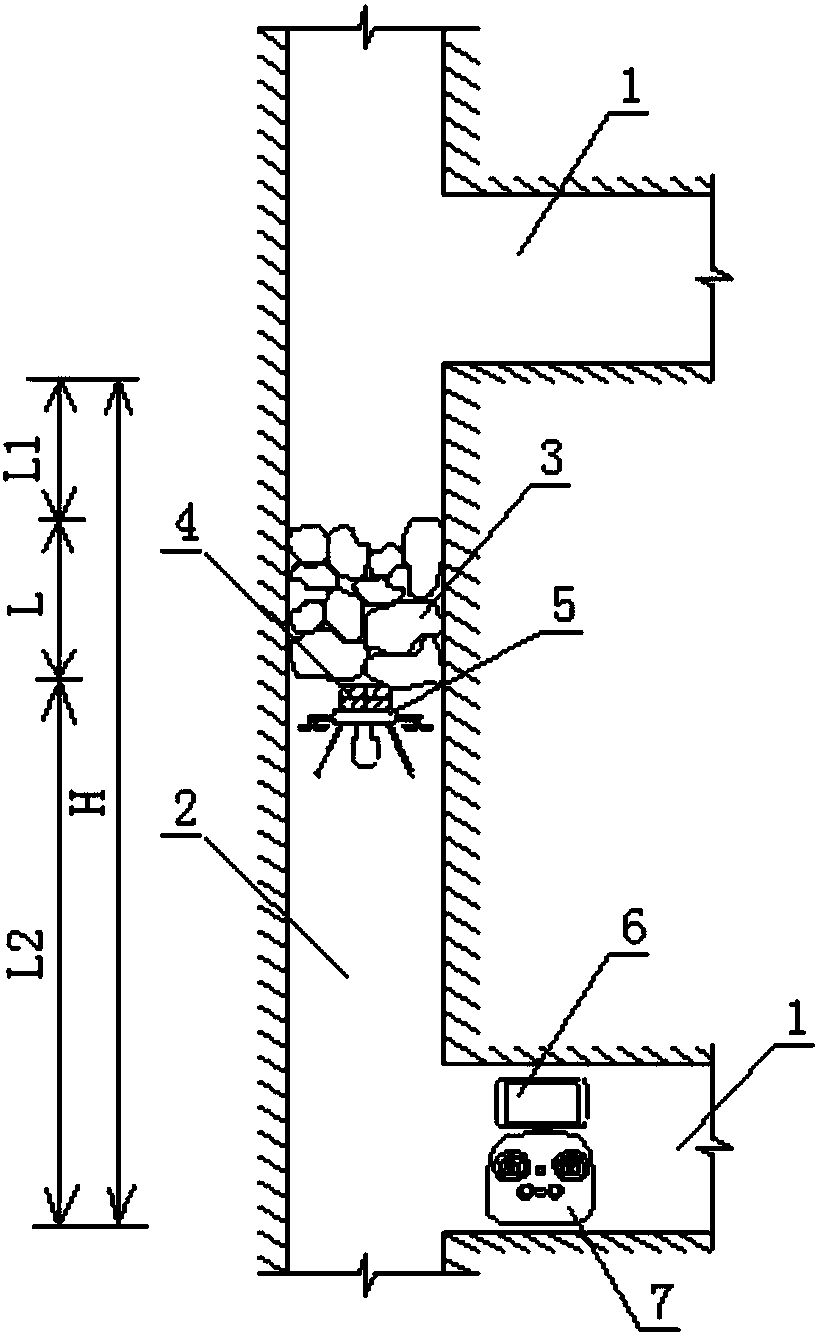

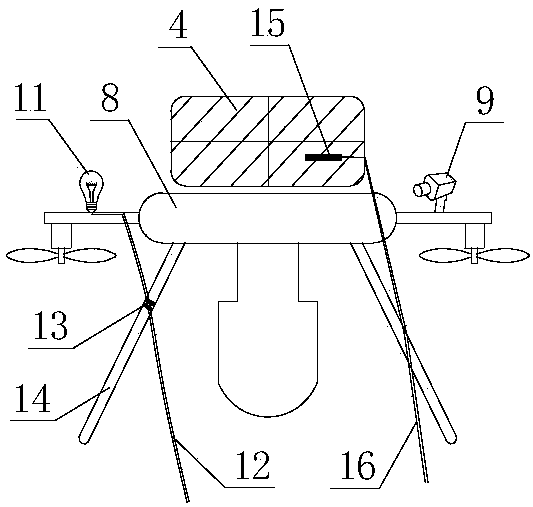

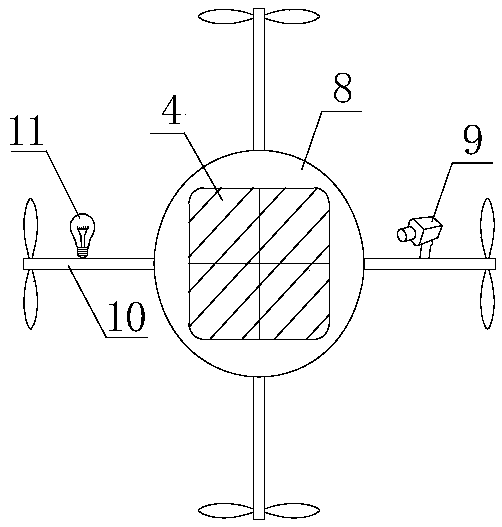

Winze blockage blasting device and method

The invention discloses a winze blockage blasting device and method. The device comprises an aircraft and a wireless remote controller; a loading platform for fixing a charge is arranged on the top of the aircraft, a camera used for monitoring the position of the charge and the position of a blockage object in real time is arranged on the aircraft, and the wireless remote controller is in signal connection with a flying drive module of the aircraft through a communication module, and is further connected with a display device in communication with the camera. The remote control aircraft is firstly used for estimating the thickness of the blockage object, explosives are mounted on the aircraft, the aircraft is remotely controlled to convey the explosives to the selected position below the blockage object, the explosives are detonated, and the blockage is blasted for dredging. According to the device, the aircraft can reliably and accurately blast the charge in a manner of being tightly attached to the bottom of the blockage object of a winze, although the aircraft is destroyed together with the explosives after blasting, the obvious time and cost advantages are achieved compared with other winze dredging manners, and the construction work safety is ensured.

Owner:CENT SOUTH UNIV

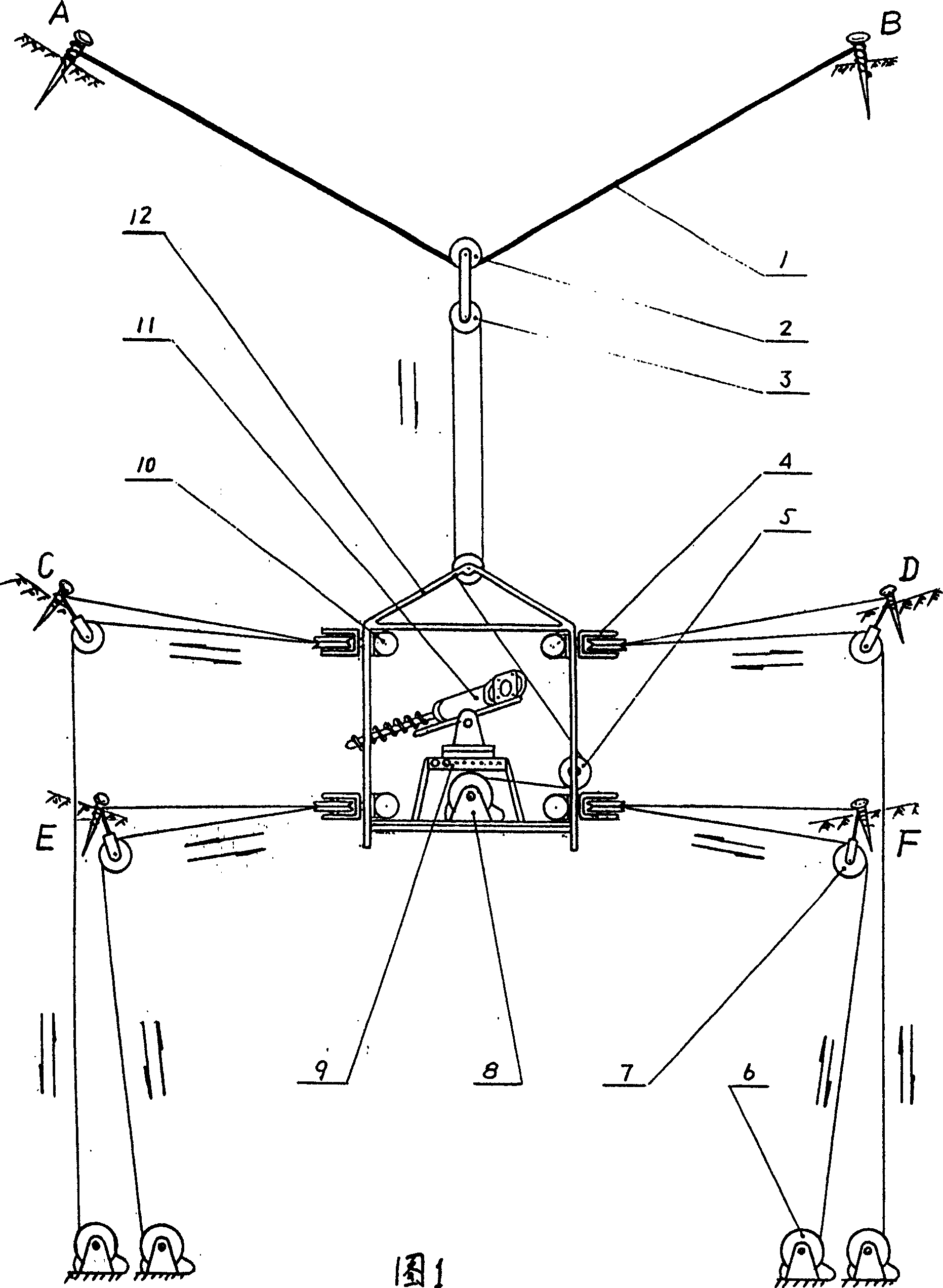

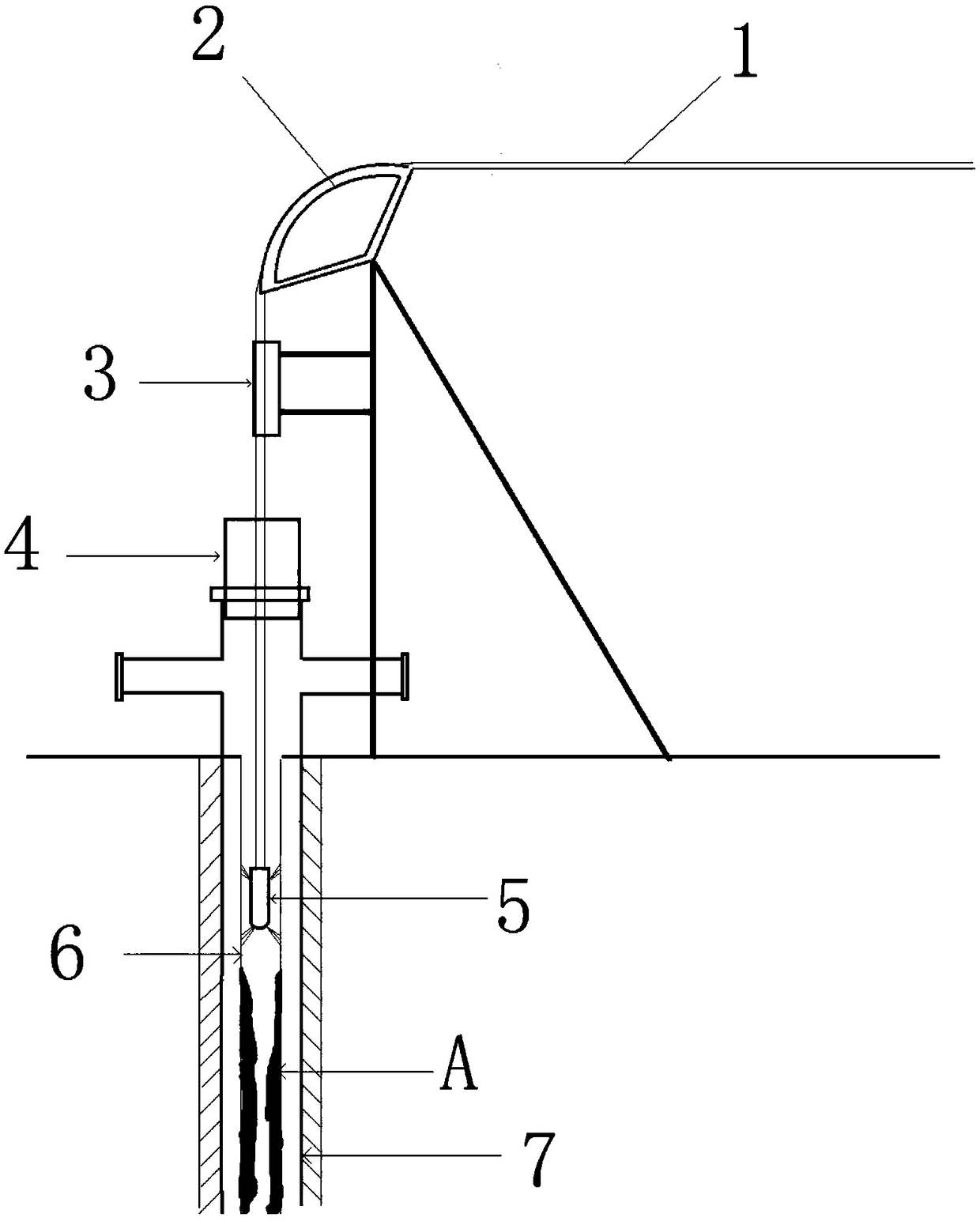

High slope rock and soil anchoring construction method and apparatus

InactiveCN1469017AMove safely on your ownConstruction work safetyExcavationsBulkheads/pilesBlock and tackleEngineering

The present invention is high slope rock and soil anchoring construction method and apparatus. The construction method includes presetting six anchoring points within the anchoring construction range, connecting two upper anchoring points via a steel cable; suspending drilling table via a pulley block under one suspended pulley rolling on the steel cable; connecting four transversely shifting winders fixed on the ground to other four anchoring points separately via four steel cables via the pulley; and operating the winders for the drilling table move vertically and transversely while closing to slope. The anchoring drilling machine on the drilling table can regulate its drilling angle in both vertical direction and horizontal direction. The construction method and apparatus of the present invention is practical, safe and reliable.

Owner:石午江

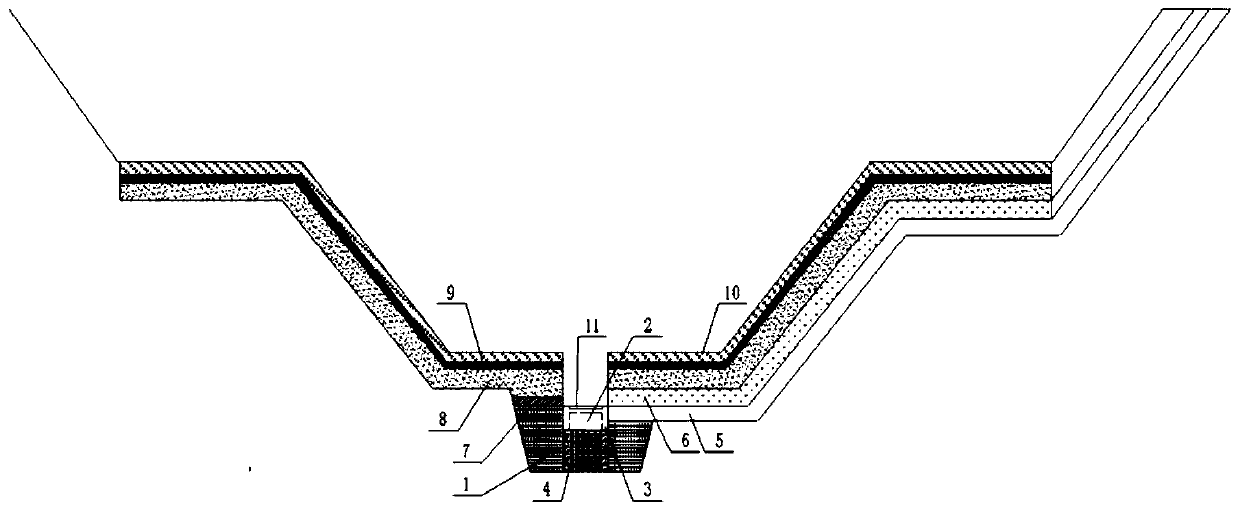

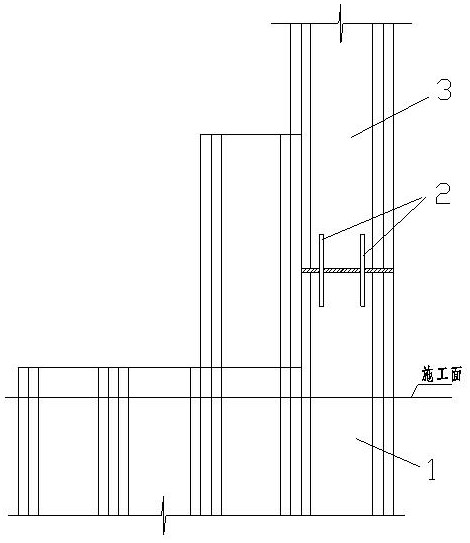

Underground construction blind shaft drainage system and construction method

PendingCN110219313AImprove the pumping effectImprove stabilityFoundation engineeringEngineeringWater collection

The invention belongs to the field of building construction, and particularly relates to an underground construction blind shaft drainage system and a construction method. The underground constructionblind shaft drainage system comprises a water collection pit arranged in a deep foundation pit in an excavation, a pumping system arranged in the water collection pit and a drainage ditch arranged atthe deep foundation pit top in an excavation; the pumping system is a submerged pump with a protective shell, and water in the water collection pit is discharged through the submerged pump; and filtering fillers are arranged at the periphery of the protective shell of the submerged pump of the water collection pit in a filling mode, construction is carried out after a foundation pad layer, a waterproof later and a concrete layer are sequentially poured on a cob wall, and corresponding backfill of all functional layers is carried out on the water collection pit before a raft is poured. The underground construction blind shaft drainage system has good stability and high anti-interference performance; a drainage pipe does not penetrate through the waterproof layer and a raft foundation, construction is not interfered, water pumping cannot be stopped in the overall process of pouring, the situation that drainage is stopped in the concrete pouring process due to the fact that the drainagepipe penetrates through the foundation is avoided, and the problem of leakage existing in waterproofing of the raft foundation is solved; and the whole construction operation is safe and reliable, andthe quality is guaranteed.

Owner:CHINA MCC5 GROUP CORP

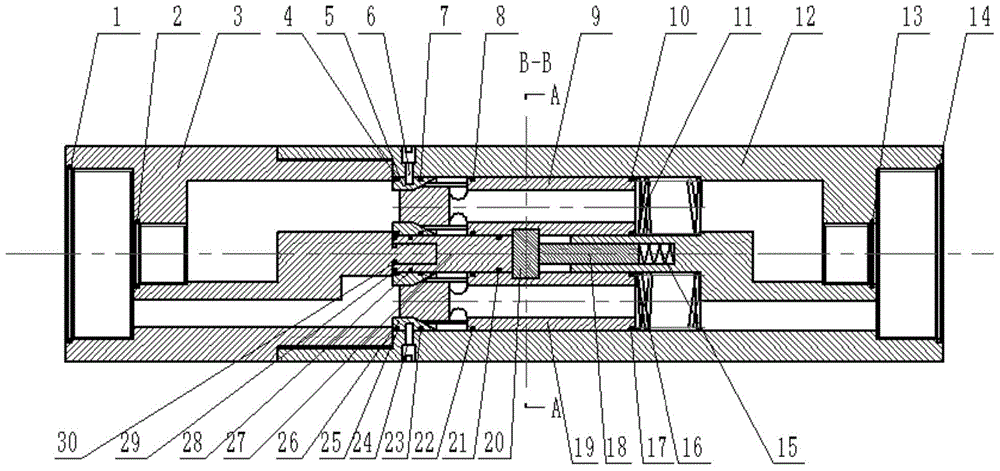

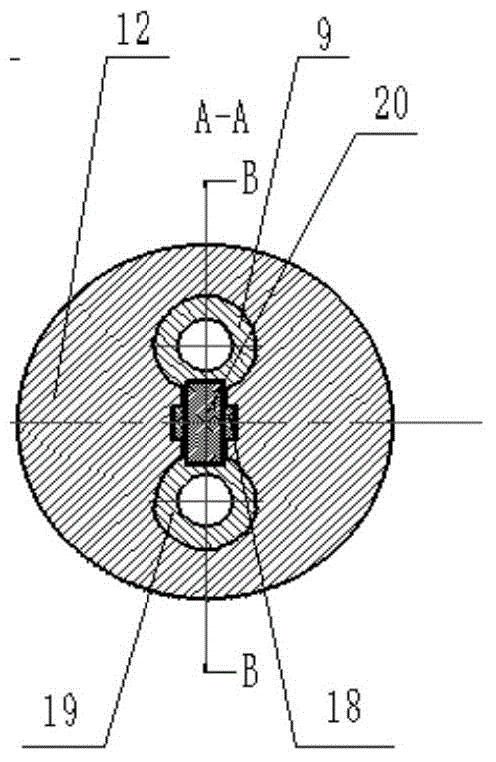

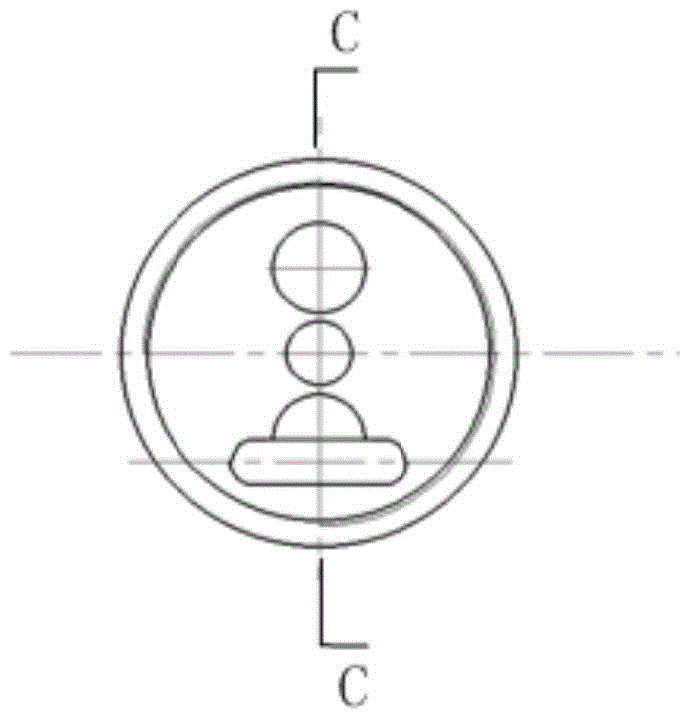

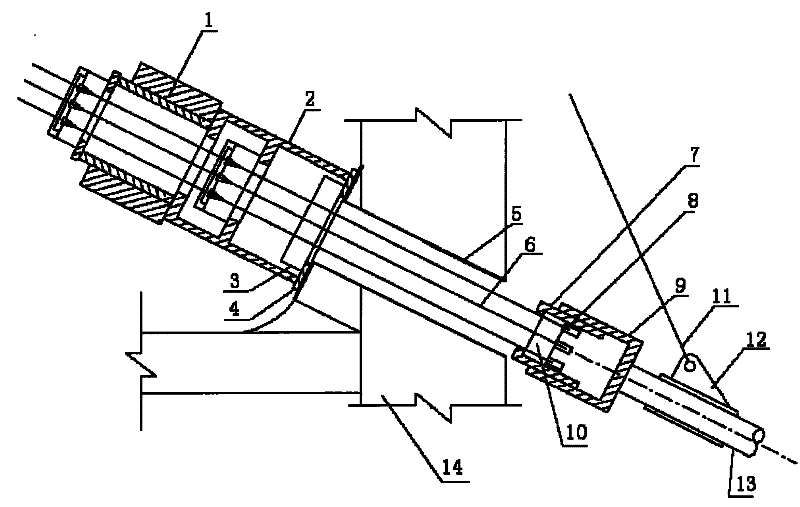

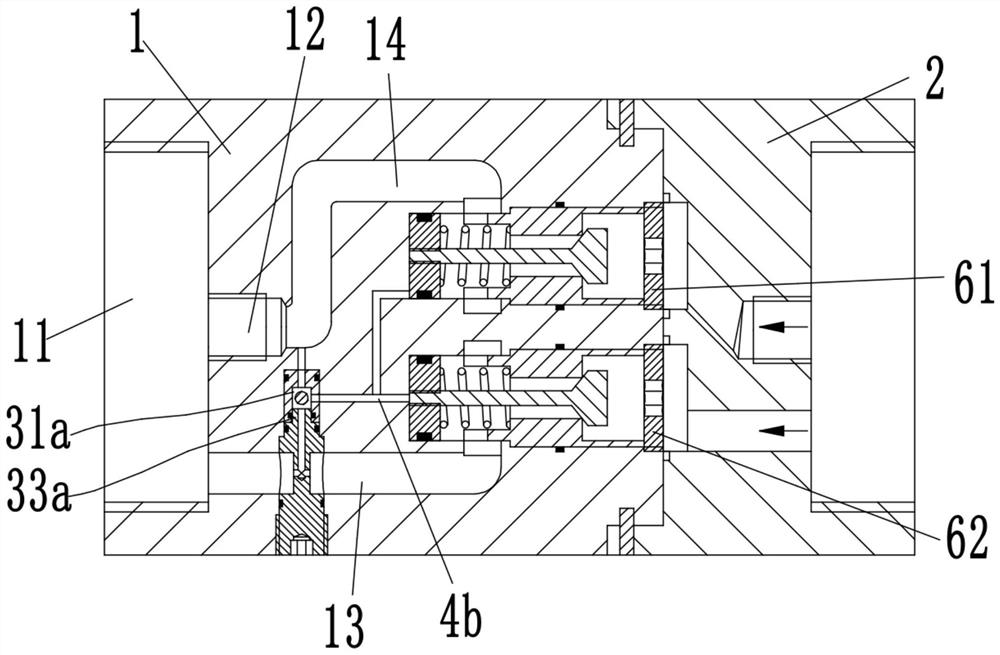

Plunger-type double-passage different-direction synchronous joint control check valve for double-layer continuous oil pipe

ActiveCN104806200AEffectively closedPrevent returnConstructionsWell/borehole valve arrangementsPistonCheck valve

The invention discloses a plunger-type double-passage different-direction synchronous joint control check valve for a double-layer continuous oil pipe, which is arranged between the double-layer oil pipe pipelines. The plunger-type double-passage different-direction synchronous joint control check valve comprises a left valve body, a right valve body, an inner passage piston, an inner passage piston seat, an outer passage piston, an outer passage piston seat, a long pin, a crossing plunger, a slide block, an inner passage piston return spring, an outer passage piston return spring and a slide block return spring. According to the plunger-type double-passage different-direction synchronous joint control check valve, the parts such as the piston, the return spring, the movable slide block and the like are simultaneously and additionally installed in the inner layer and the outer layer of continuous oil pipe passages, a different-direction synchronous joint control design scheme is adopted, a double-passage different-direction joint control check valve device is formed, so that when accidents happen, the passages of the inner and the outer continuous oil pipes are effectively sealed, the return of the well liquid is prevented, and the blowout is prevented.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

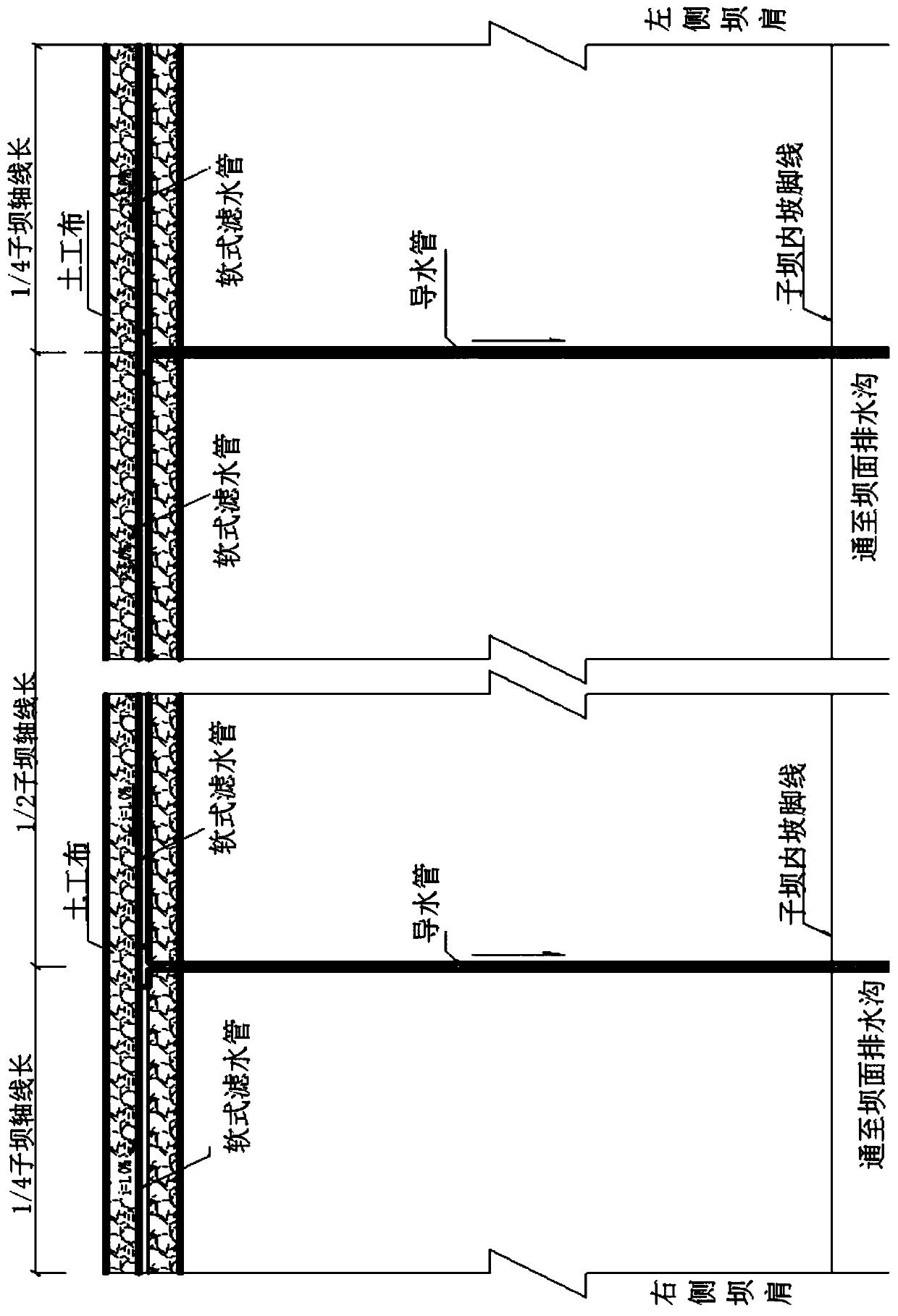

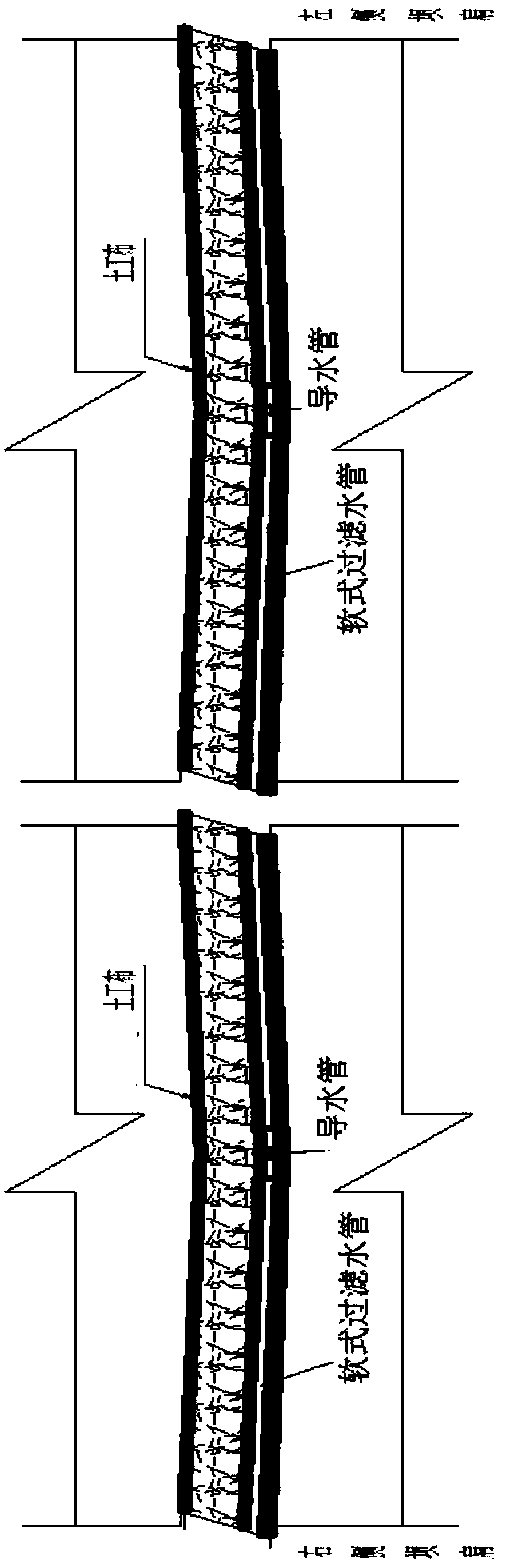

Seepage draining system layered arrangement method for decreasing seepage line buried depth of tailings reservoir

The invention relates to a seepage draining system layered arrangement method for decreasing the seepage line buried depth of a tailings reservoir. The seepage draining system layered arrangement method comprises the following steps: (1) if the initial-stage dam elevation of the tailings reservoir is N meters, according to the tailings accumulation body beach face seepage draining condition, 1 ton layers of seepage draining blind ditches are formed in a layered mode and designed at different elevations of N+H meters, N+2H meters, N+3H meters, N+4H meters... and N+nH meters of a tailings accumulation dam, and the seepage draining blind ditches are parallel to the dam axes of sub dams and are away from the dam axes of all the stages of sub dams by M meters; (2) each layer of seepage draining blind ditch parallel to the corresponding dam axis is located in front of the corresponding stage of sub dam by M meters, and composed of peastone, a soft water filter pipe and a 400 g / m<2> wrappinggeotechnical cloth; (3) one end of each layer of water guiding pipe perpendicular to the corresponding dam axis is connected with the soft water filter pipe in the corresponding seepage draining blind ditch parallel to the corresponding dam axis through a tee joint; (4) tailings drawing and seepage draining system construction are independently and alternately conducted in a zoned mode; and (5) operation of the tailings reservoir is detected and repaired. According to the seepage draining system layered arrangement method, the seepage line buried depth can be decreased, and it is guaranteed that the dry beach length of the tailings reservoir meets the design specification requirements.

Owner:NANJING MEISHAN METALLURGY DEV +1

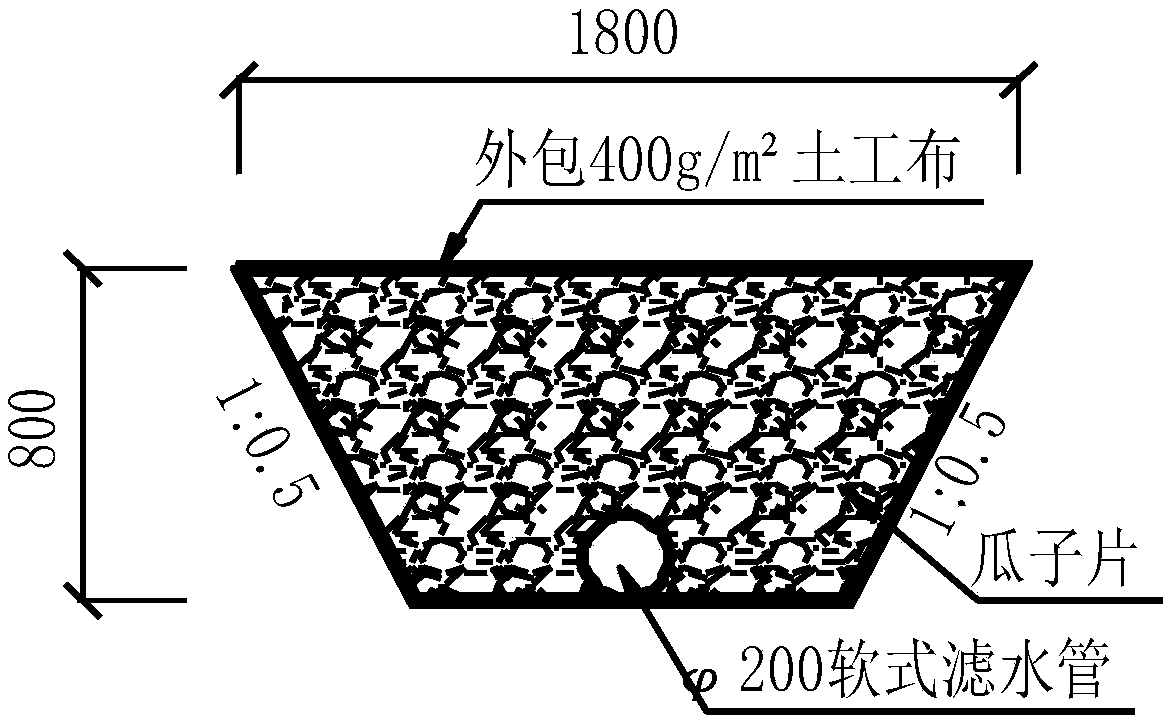

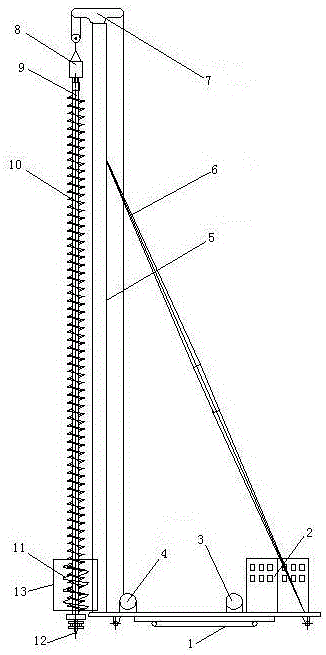

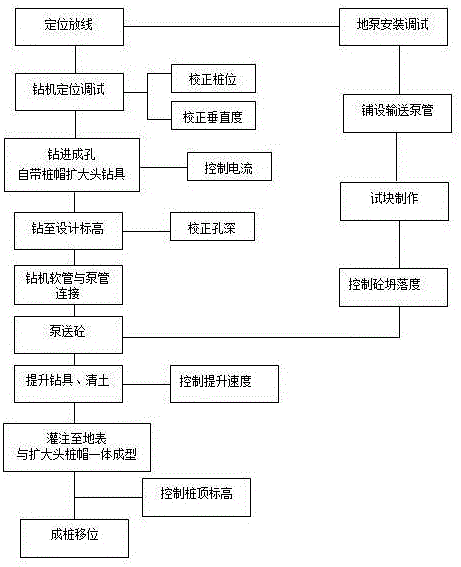

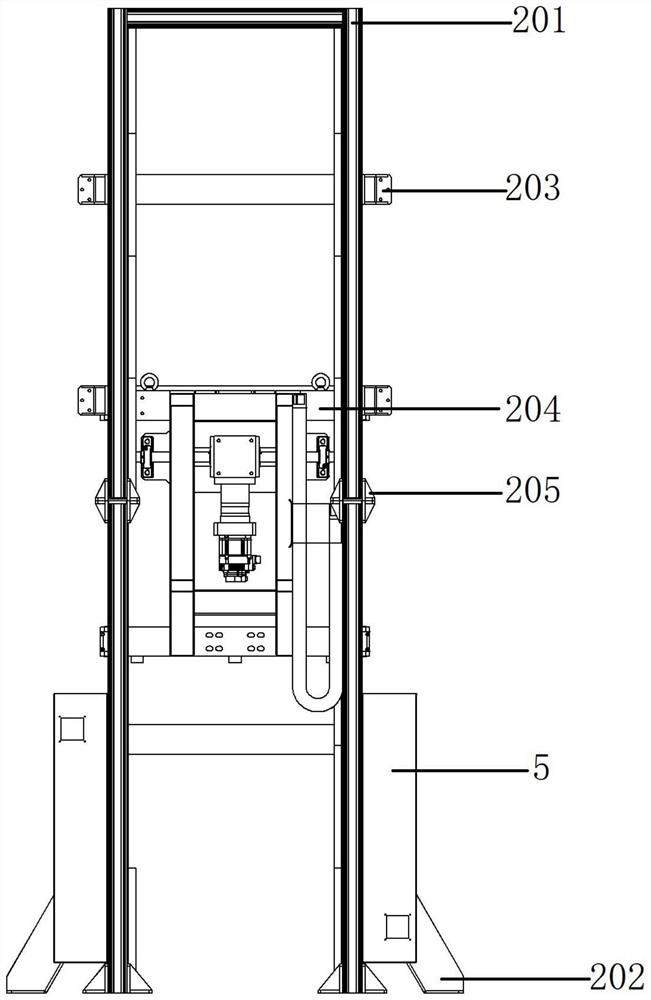

Novel long spiral drilling hole cast-in-situ pile top and cap integrated construction device

InactiveCN105862733AThe overall structure design is reasonableControl construction work safetyDrilling rodsDrilling casingsDrill bitDrill pipe

The invention belongs to the technical field of building construction foundation drilling tool application, and particularly discloses a novel long spiral drilling hole cast-in-situ pile top and cap integrated construction device which comprises an automatic walking vehicle, a power distribution operation room, three door head pulleys, a main rotating and winnowing machine, a support, a rock supporting rod, a horizontal head sliding member, a power transmission box, a drilling rod, a drilling rod blade, a drilling sleeve and an alloy drill bit. The power distribution operation room, the door head pulleys, the main rotating and winnowing machine and the support are arranged on the automatic walking vehicle, two ends of the rack supporting rod are connected with the support respectively, the horizontal head sliding member is arranged on the support, the power transmission box is connected with the horizontal head sliding member, the drilling rod is connected with the power transmission box, the drilling rod blade is arranged on the drilling rod, the drilling sleeve is arranged at the end of the drilling rod, a spiral connecting groove is formed inside the drilling sleeve, one end of the drilling sleeve is movably connected with the support, and the alloy drill bit is arranged at the end of the drilling rod. The problems that existing long spiral drilling machines are low in efficiency and instable in integral structure and prestress cannot reach production construction requirements are solved, the novel long spiral drilling hole cast-in-situ pipe top and cap integrated construction device is reasonable in design, meets construction standards and requirements, can integrally form pile body and pile cap concrete quickly in a high-quality manner, raw materials are saved, and production cost is lowered.

Owner:JIANGSU CHANGXIN BASIC ENG

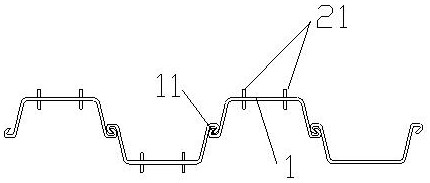

Larsen steel sheet pile sinking method for avoiding obstacles in air

InactiveCN112627169AImprove construction efficiencyImprove construction qualityBulkheads/pilesStructural engineeringSheet pile

The invention discloses a Larsen steel sheet pile sinking method for avoiding obstacles in the air. The Larsen steel sheet pile sinking method comprises the following steps that the height of the obstacles in the air is determined through measurement of a total station, grooves are polished on two sides of welding ends of steel sheet piles, stiffening steel sheets for the welding ends of the steel sheet piles are manufactured, a first steel sheet pile is driven and ensured to be vertical, and pile sinking is stopped when the pile is sunk to 1.0 m away from the ground; and the four stiffening steel plates are welded to the two faces of the top ends of the steel sheet piles, the steel sheet piles to be lengthened are stably inserted into stiffening steel plate gaps formed in the tops ends of the sunk steel sheet piles, a steel sheet pile butt joint is welded firstly, then the stiffening steel plates and the steel sheet piles are welded, and pile sinking continues after the steel sheet piles and the stiffening steel plates are welded and cooled till construction of the foundation pit enclosure steel sheet pile structure is completed. According to the Larsen steel sheet pile sinking method for avoiding the obstacles in the air, the steel sheet piles are vertically welded and connected, welded joints are lengthened in a reinforced mode, the influence of the obstacles in the air on steel sheet pile construction is effectively avoided, construction operation safety is guaranteed, and the construction efficiency and construction quality of the steel sheet piles are improved.

Owner:CHINA MCC20 GRP CORP

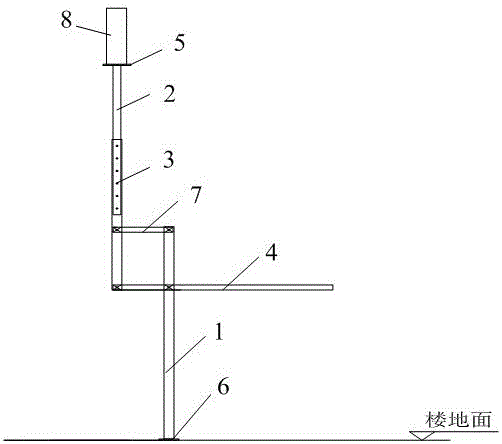

Top plate drilling device and application method thereof

InactiveCN106695356ASolve the distance differenceSolve positioningLarge fixed membersFloor slabEngineering

The invention provides a top plate drilling device and an application method thereof. The top plate drilling device comprises a vertical rod, a supporting rod, a handle rod and a connecting rod. One end of the vertical rod is hinged to one end of the connecting rod. One end of the supporting rod is hinged to one end of the handle rod. An electric drill is fixed to the other end of the supporting rod. The other end of the connecting rod is hinged to the position, located above the hinged end of the supporting rod and the handle rod, of the supporting rod. The position, located below the hinged end of the vertical rod and the connecting rod, of the vertical rod is hinged to the handle rod. A parallelogram is enclosed by the supporting rod, the connecting rod, the handle rod and the vertical rod in the hinged positions. The top plate drilling device has the beneficial effects that the structure is simple; installation is convenient; drilling operation can be completed on a floor slab by workers; and the labor intensity of the workers is relieved.

Owner:湖南省第五工程有限公司

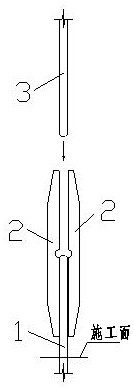

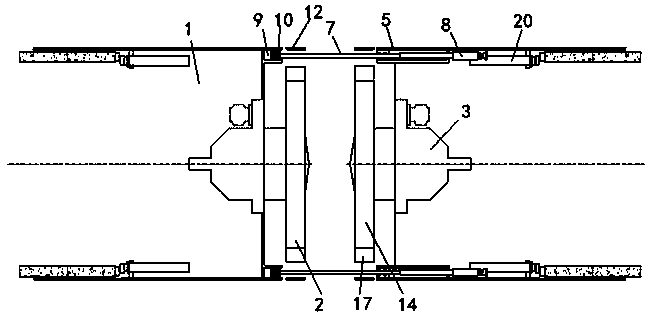

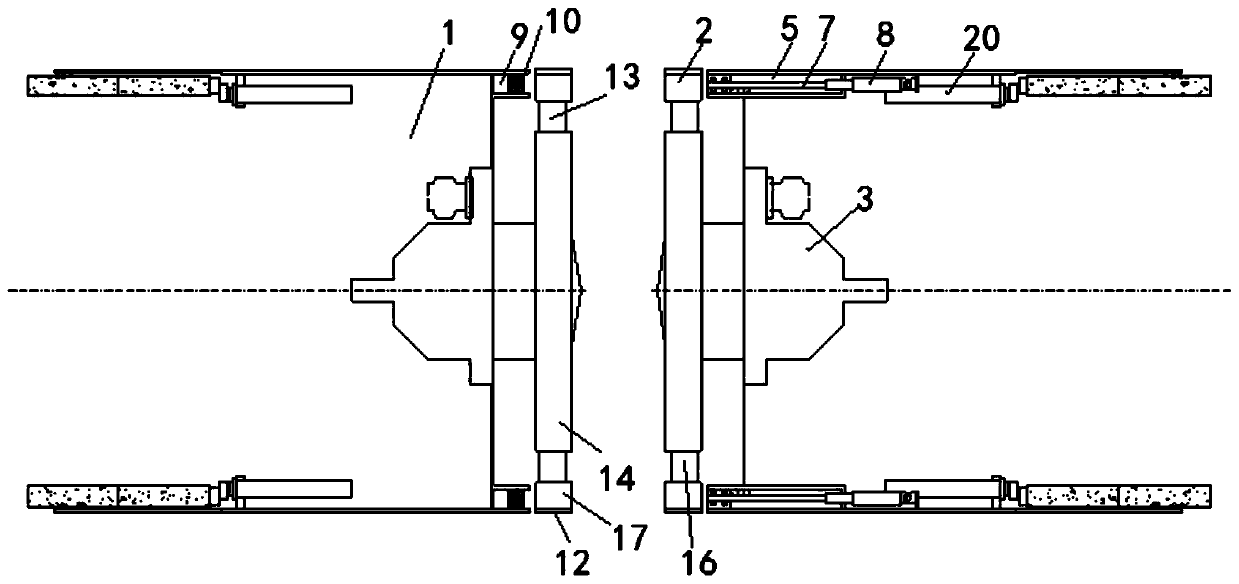

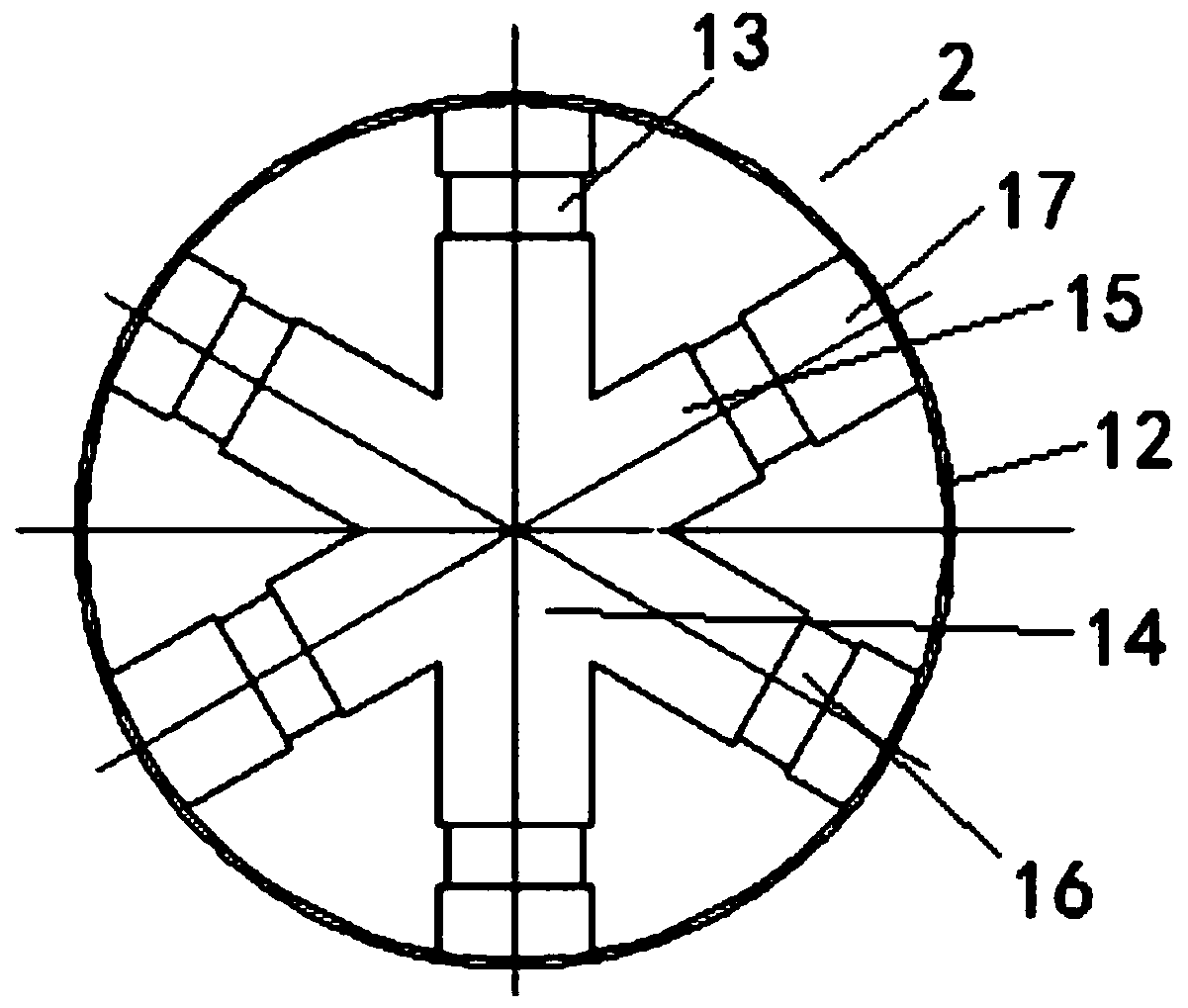

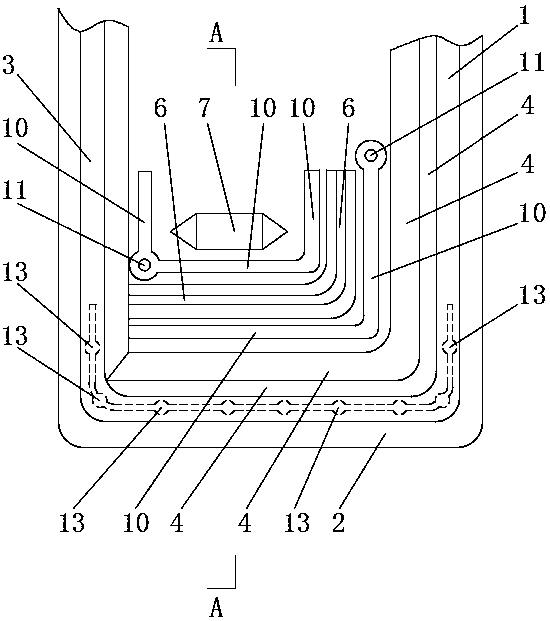

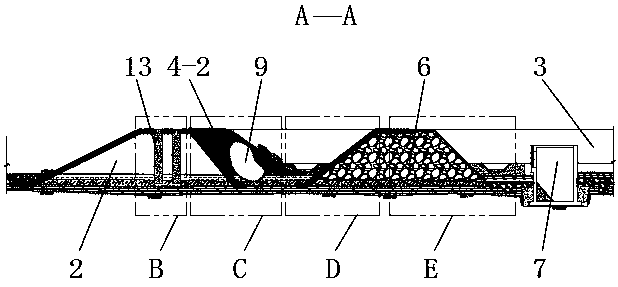

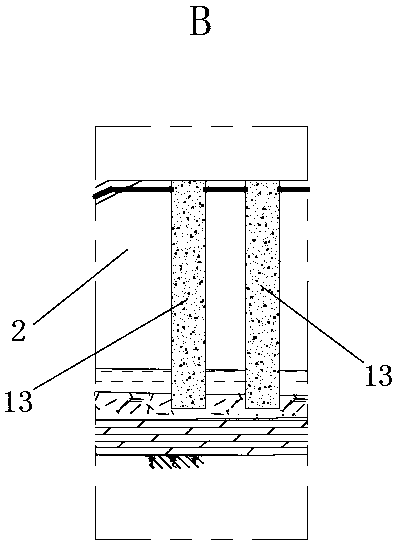

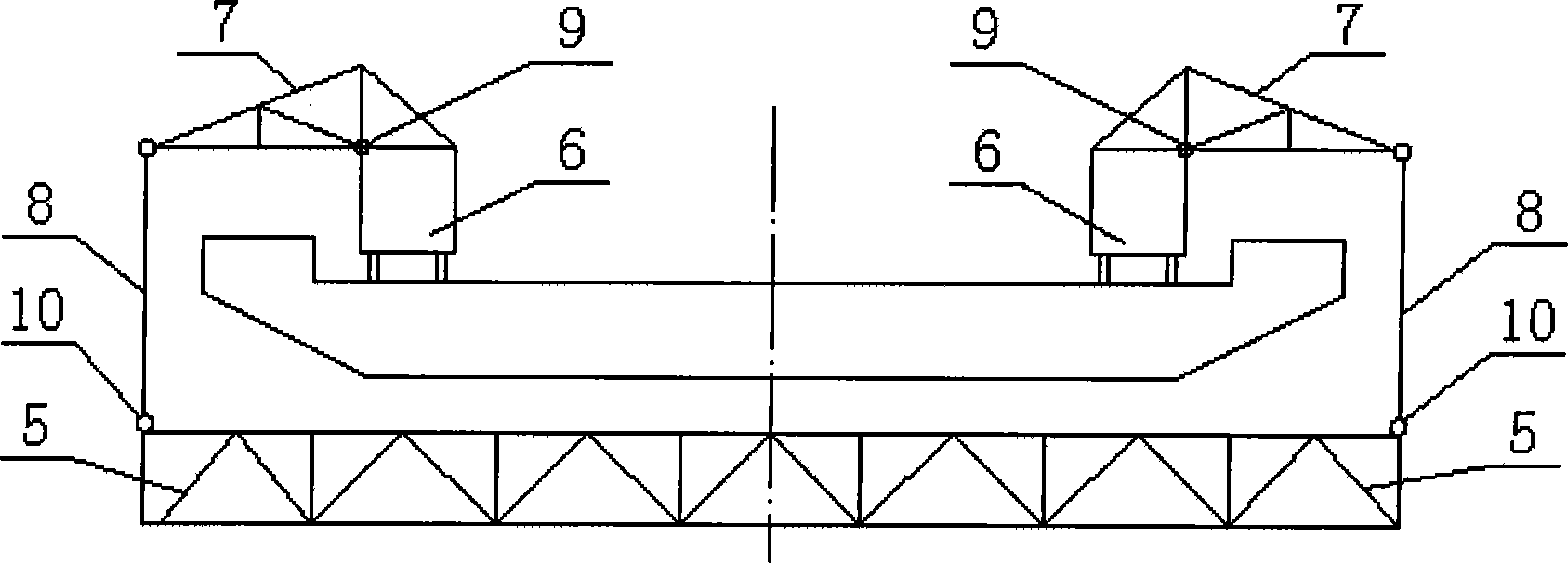

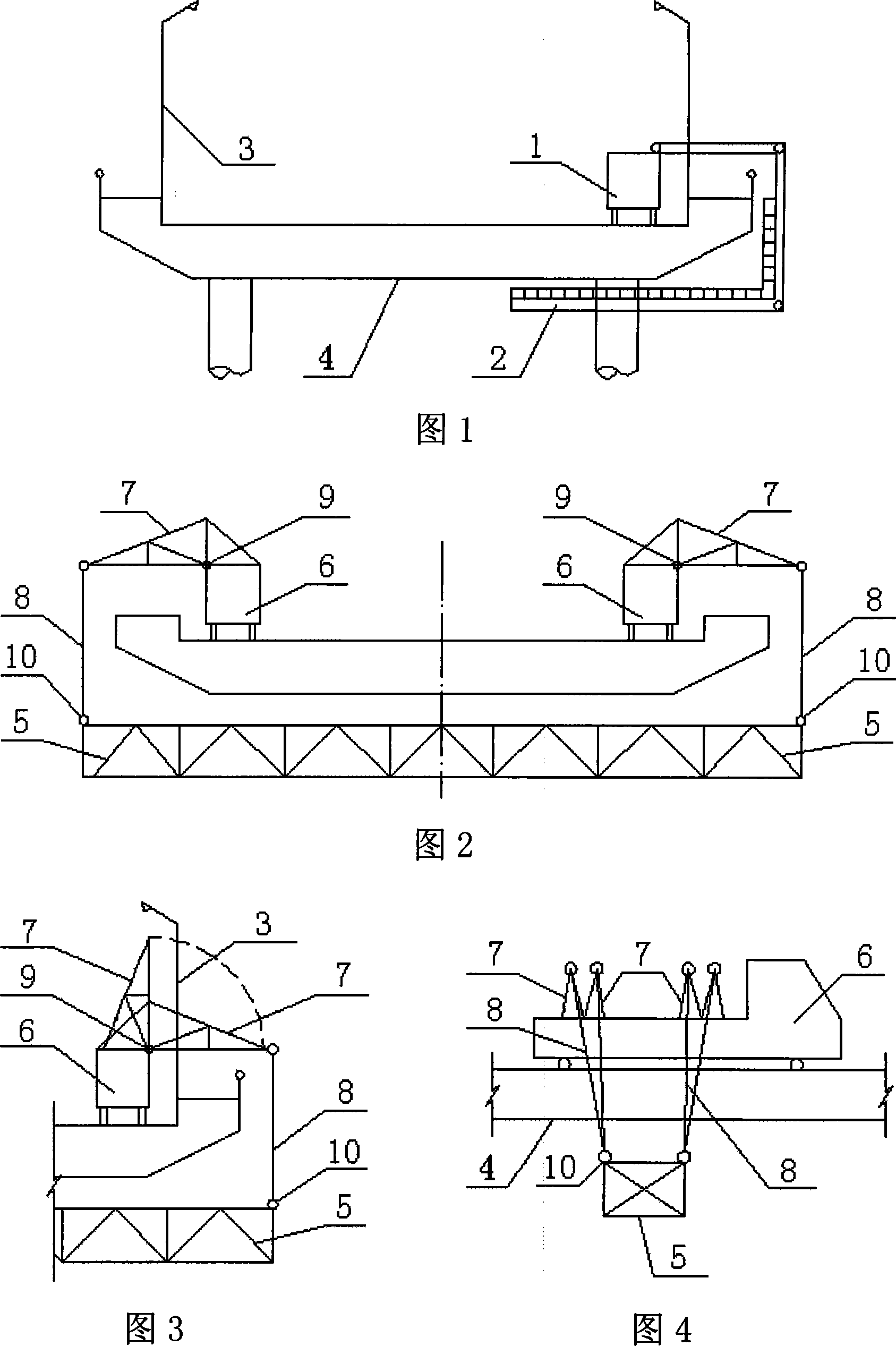

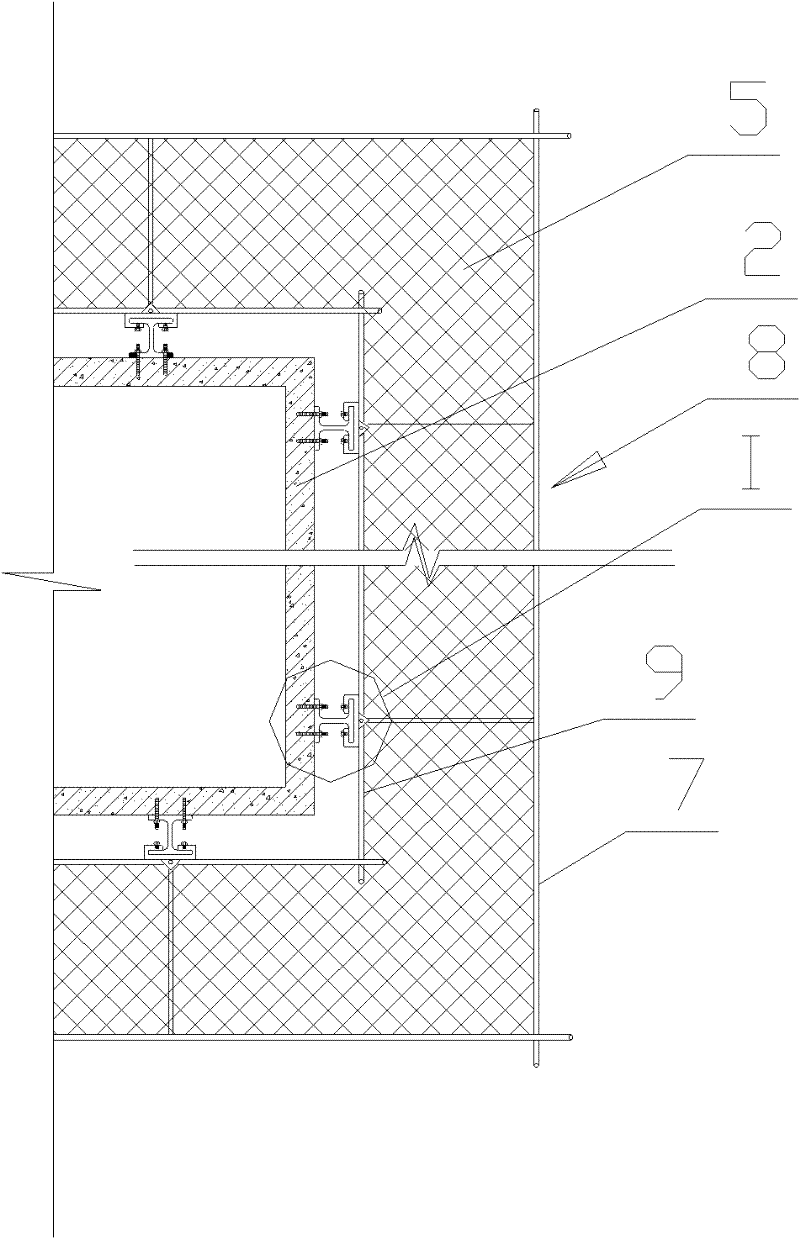

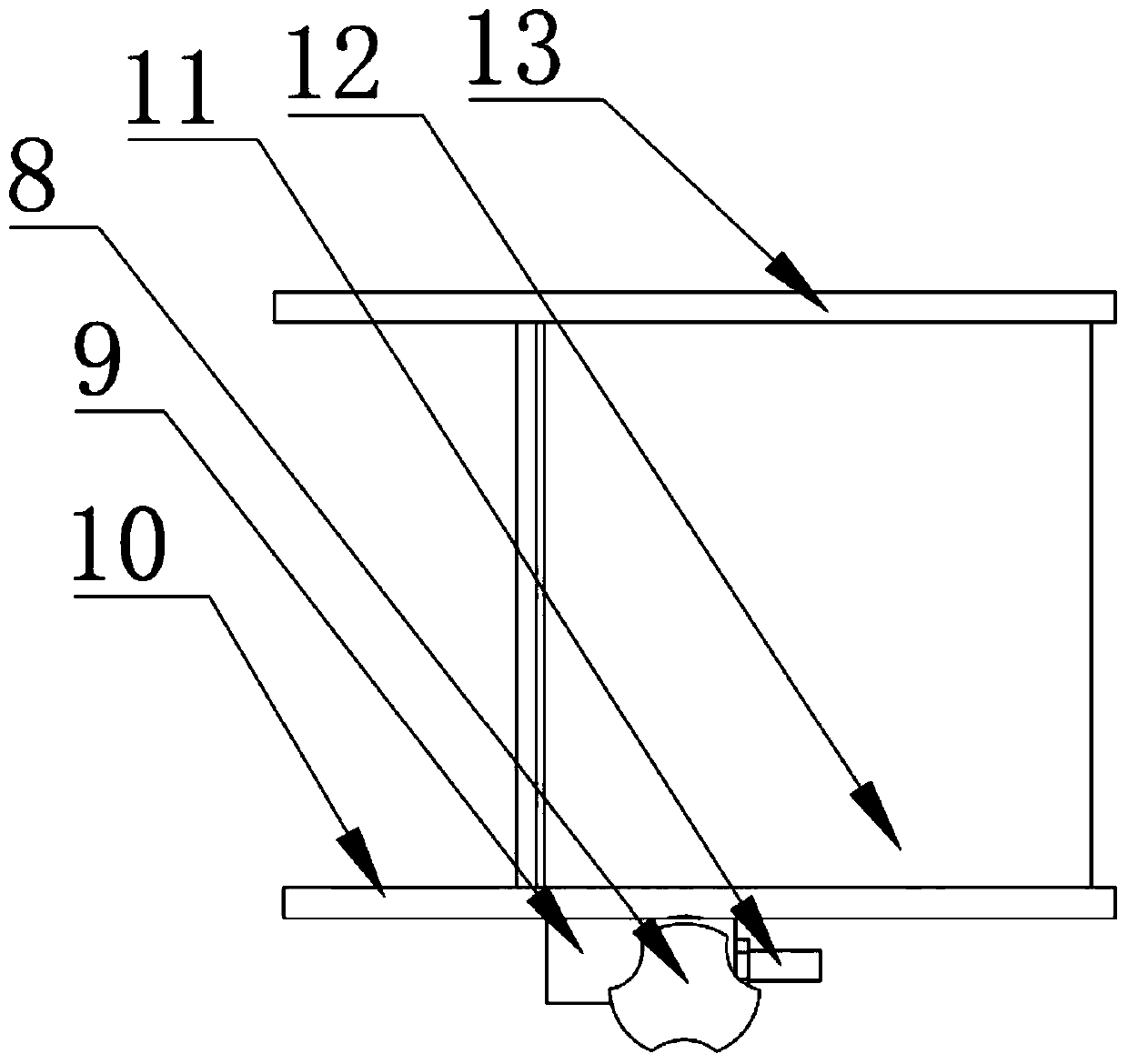

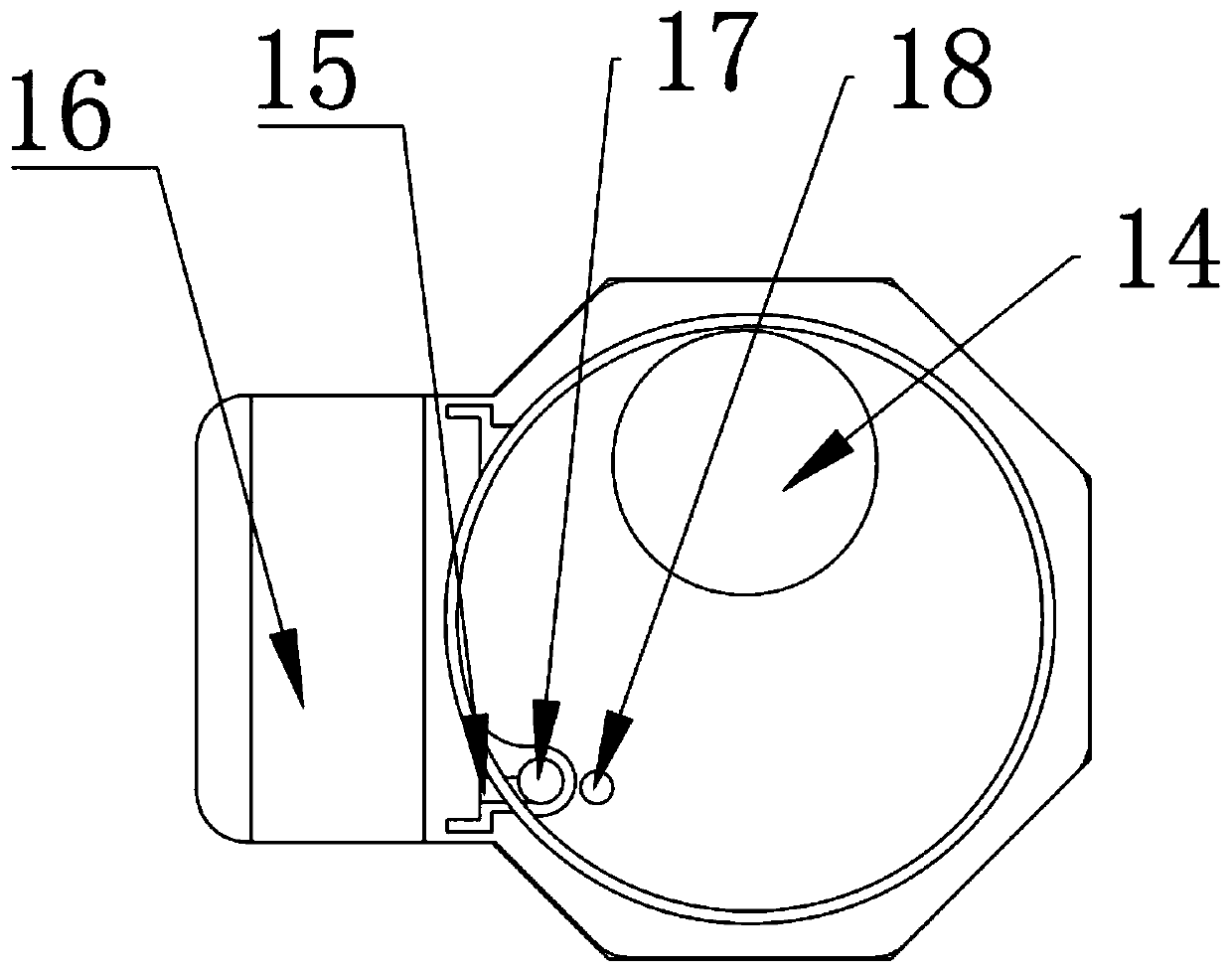

Shield underground butt-jointing structure and construction method

PendingCN110242311AConstruction work safetyReduce construction costsUnderground chambersTunnel liningShield tunnelingUnderground pipeline

The invention discloses a shield underground butt-jointing structure. Inserting ring chambers (5) are arranged on the inner surface of a shield shell of a shield tunneling machine (1), first sealing pieces (6) are arranged at the front ends of the inserting ring chambers (5), inserting rings (7) are arranged in the inserting ring chambers (5), and the tail ends of the inserting rings (7) are connected with jacks (8); and receiving ring chambers (9) corresponding to the inserting ring chambers (5) are arranged on the inner surface of a shield shell of another shield tunneling machine (1), and second sealing pieces (10) are arranged in the receiving ring chambers (9). The invention further discloses a construction method of the shield underground butt-jointing structure. According to the shield underground butt-jointing structure and the construction method of the shield underground butt-jointing structure, no working well needs to be arranged, butt-jointing sites are not affected by the ground, the geology and underground pipelines, the construction is carried out under the protection of the steel inserting rings, the construction operation can be carried out safely and reliably, the construction cost is greatly saved, and the construction period is greatly shortened.

Owner:江苏格睿特管网工程有限公司

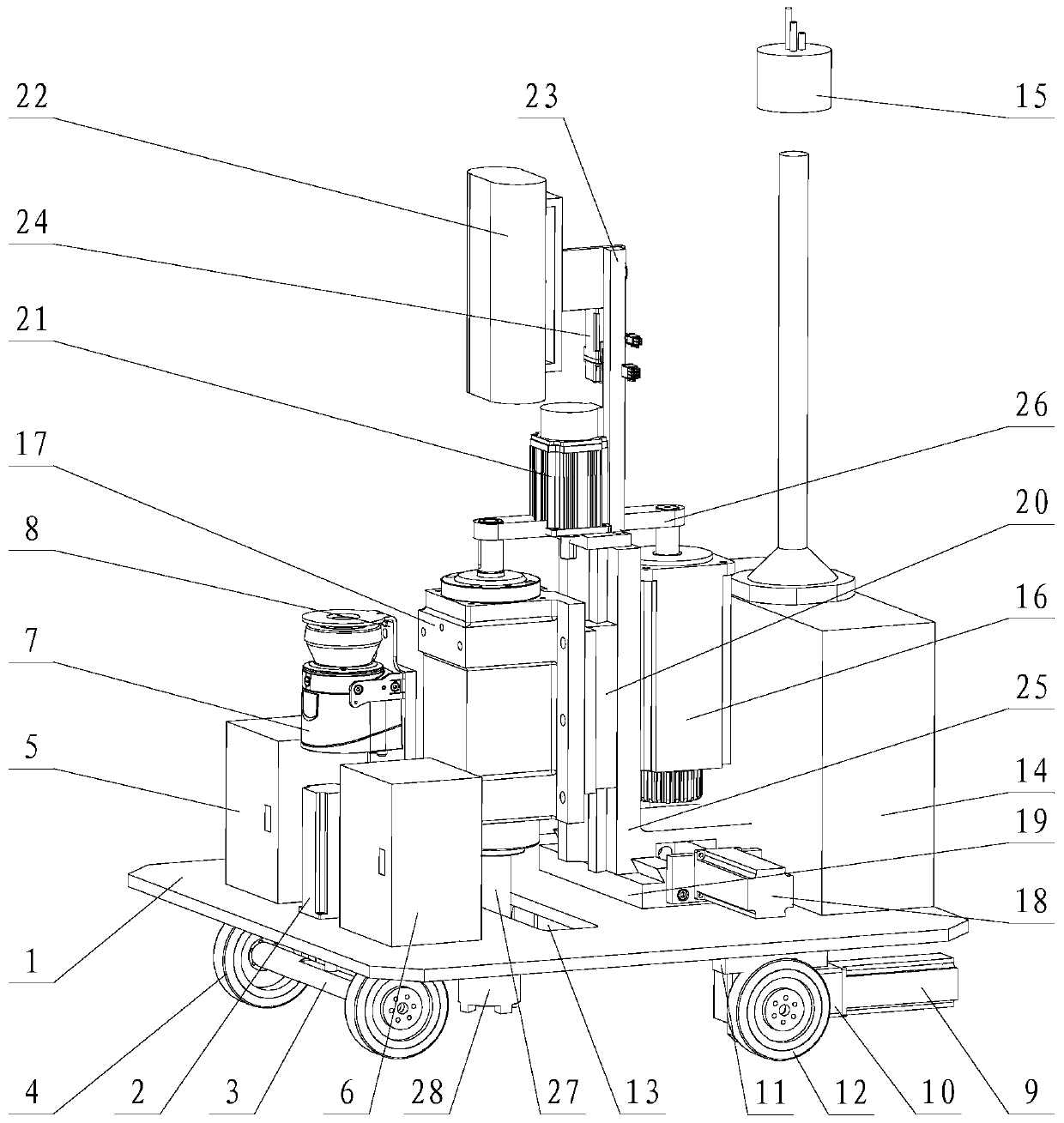

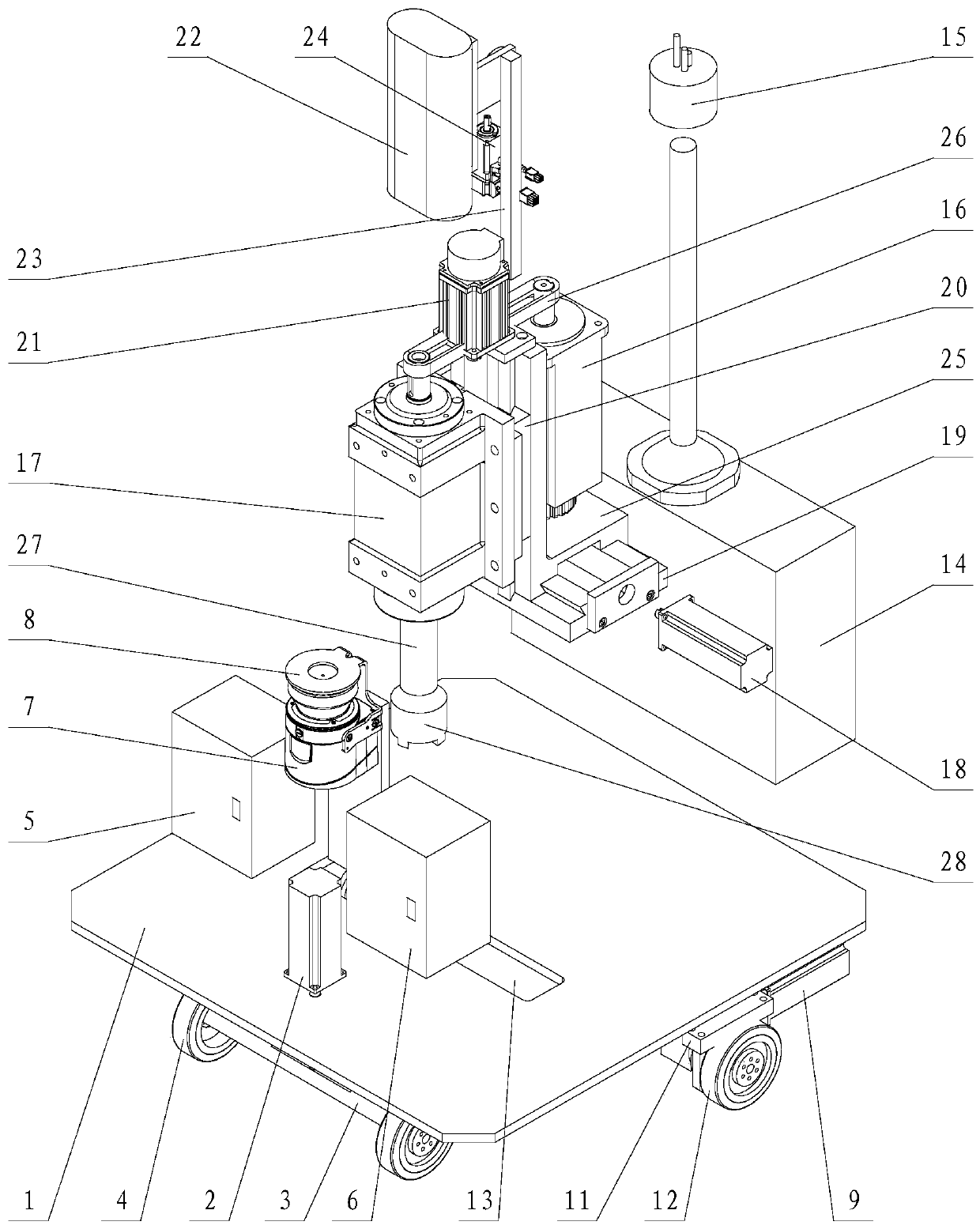

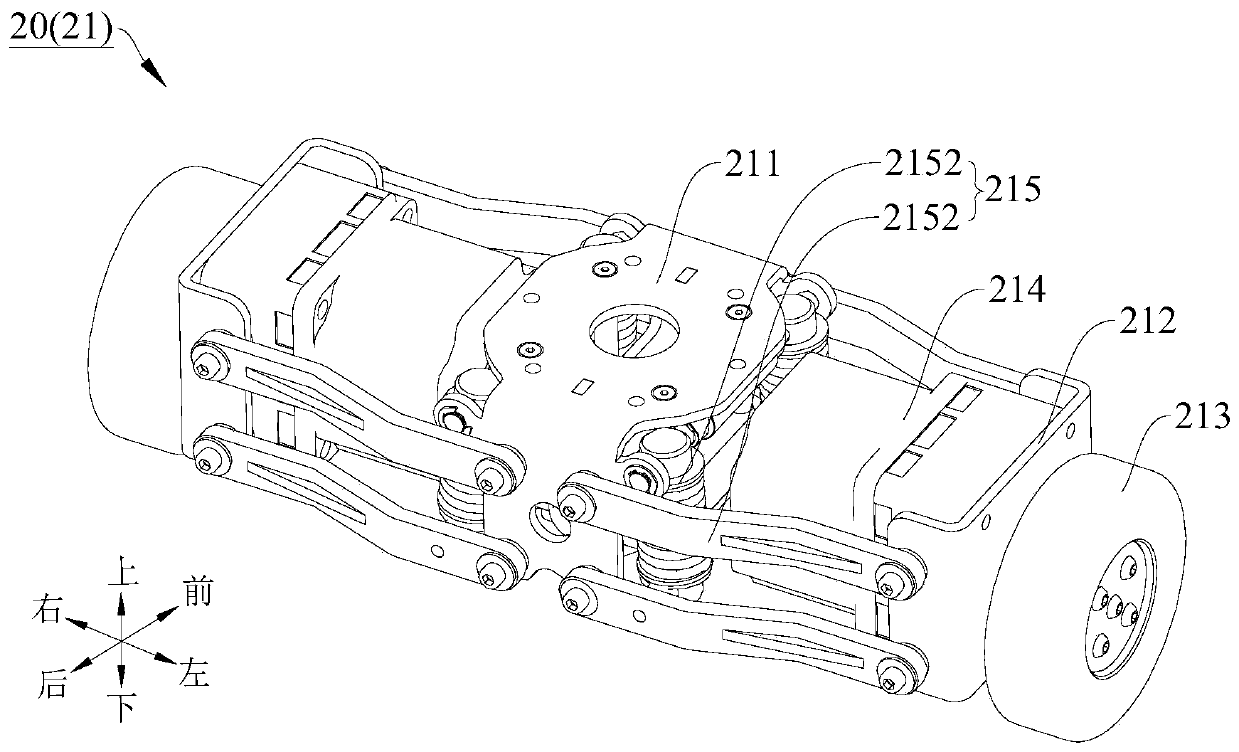

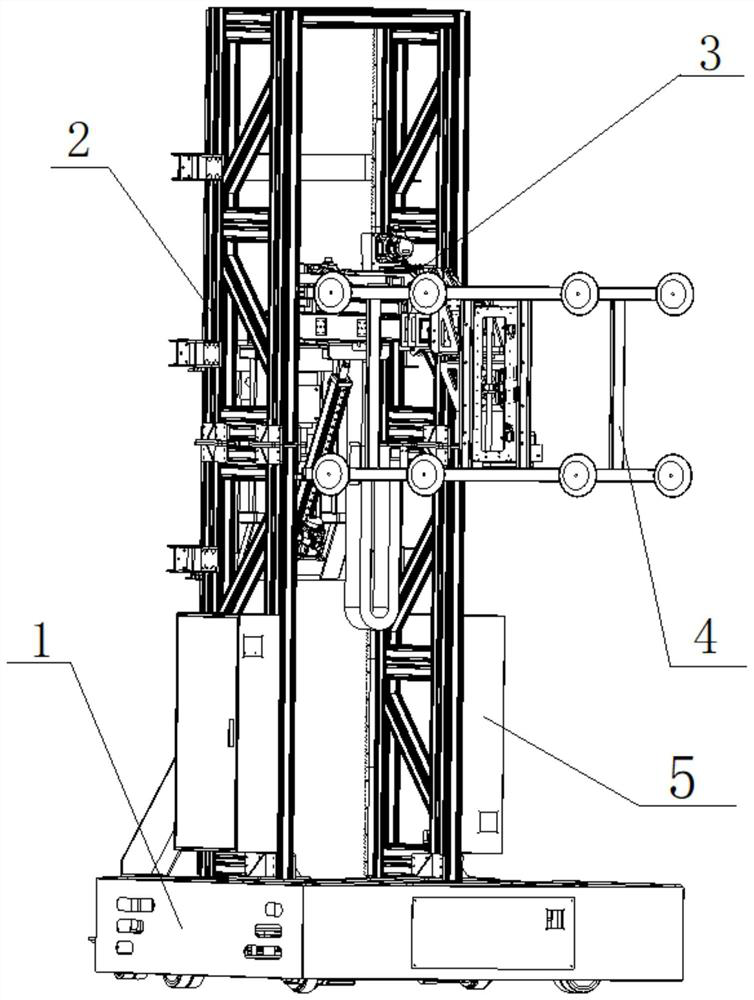

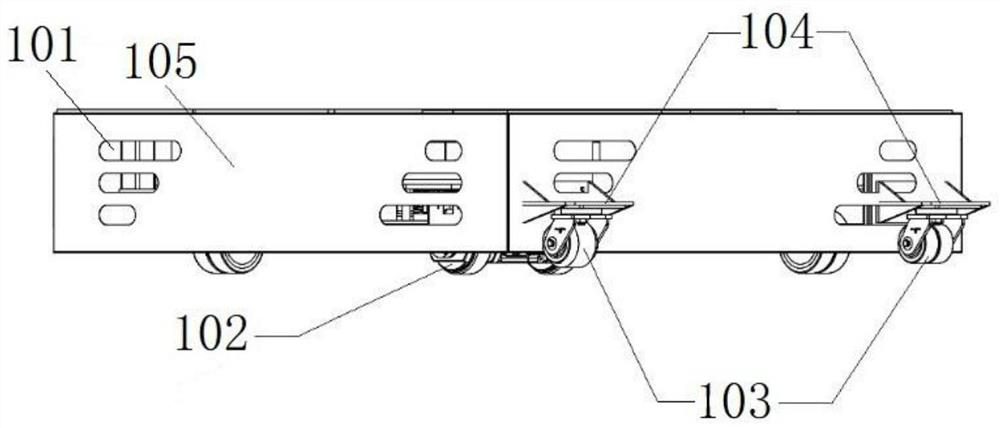

Ground construction robot

PendingCN110259128AHigh densityImprove efficiencyBuilding material handlingManipulatorSteering wheelDrive wheel

The invention relates to a ground construction robot. A steering wheel control motor, a driving wheel power source, and a sliding table transverse base are respectively mounted on a chassis, the output end of the steering wheel control motor is connected with a steering wheel, and a driving wheel is driven by the driving wheel power source; a sliding plate transverse motor is mounted on the sliding table transverse base, the output end drivesa sliding table longitudinally base to move in a reciprocate mode opposite to the sliding table transverse basethrough a transverse transmission mechanism, aspindle power motor and a Z-axis longitudinal sliding plate control motor are mounted on the sliding table longitudinalbase respectively, the Z-axis longitudinal sliding plate control motor drives a boring and milling head to rise and fall in a reciprocate mode relative to the Z-axis longitudinal sliding plate through a longitudinal transmission mechanism,the spindle power motor is connected to the input end of the boring and milling head through a transmission mechanism, the output end of the boring and milling head is connected to one end of a spindle,the other end of the spindle is connected to an end effector. According to theground construction robot,integration of measurement and construction is realized, precision of ground construction and the efficiency of ground constructionare greatly improved, and the construction period is shortened.

Owner:姜奕丞

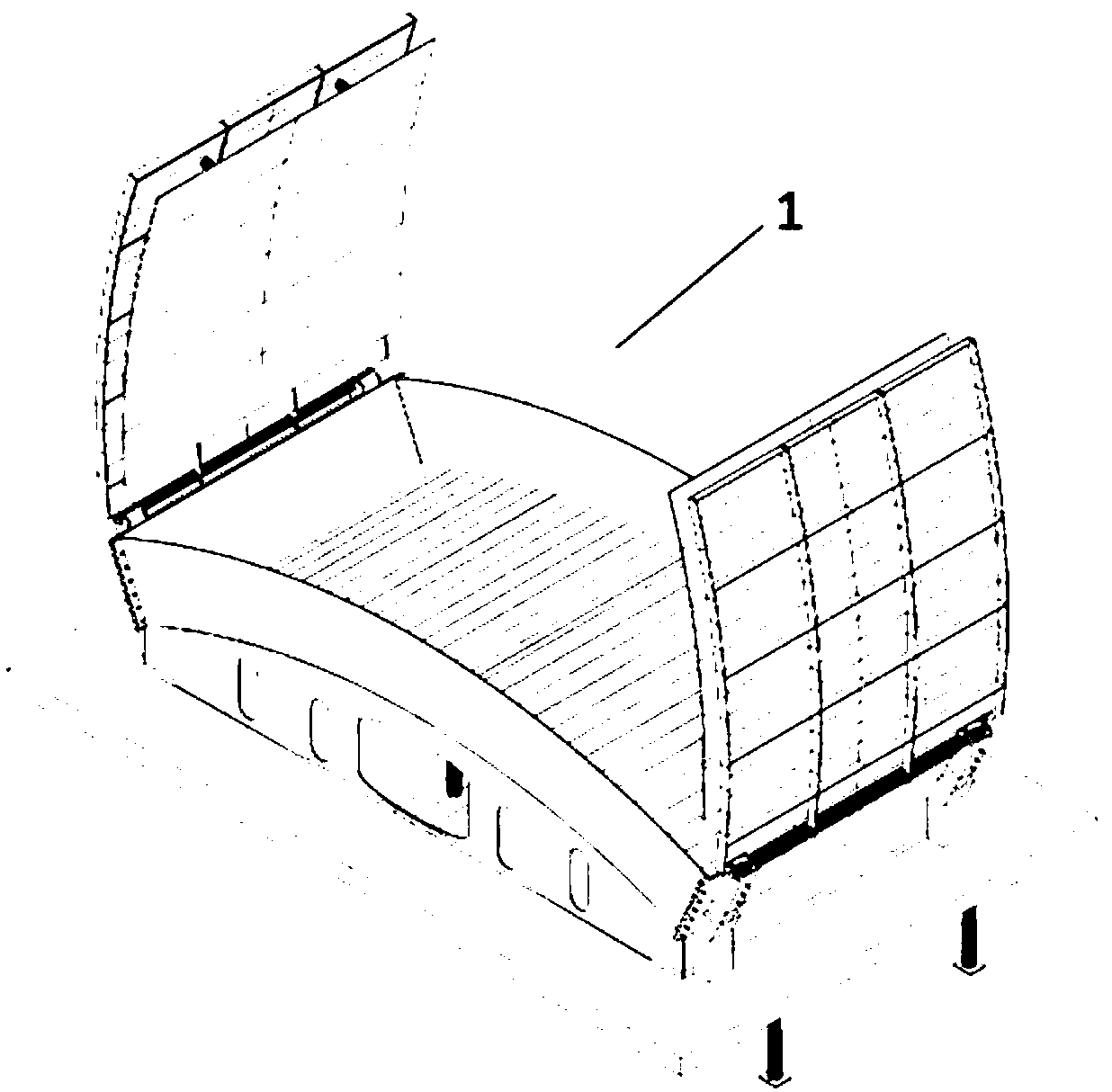

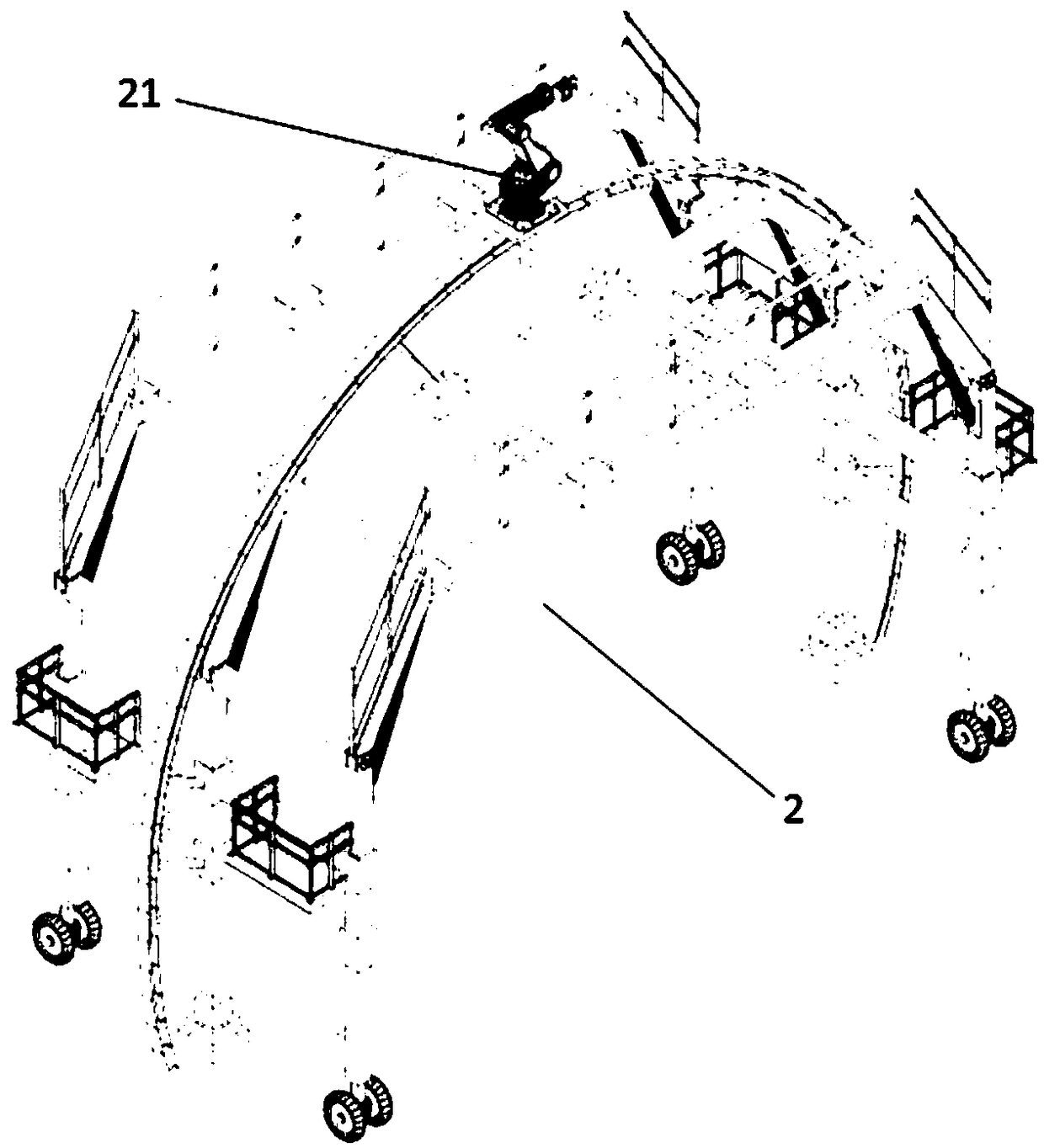

Operating diseased tunnel fabricated treatment construction method

ActiveCN108798721AImprove targetingHigh degree of mechanizationUnderground chambersTunnel liningMedicineLine structure

The invention discloses an operating diseased tunnel fabricated treatment construction method applied to the field of tunnel engineering disease treatment. Based on a traditional fabricated lining structure construction working method, the characteristics of diverse types and different degrees of operating diseased tunnels and the requirements of tunnel operating for timeliness and safety are combined, the processes of disease treatment object identification, treatment range selecting, fabricated lining designing, lining segment production, matched machine and tool selection, determining of anon-site construction scheme and the like are combined, and thus the operating diseased tunnel fabricated lining structure treatment construction method is put forward. The disease treatment method has the advantages that the quality is reliable, rapidness and stability are achieved, adaptability is high, the accelerating working speed is high, the mechanical degree is high, and traffic interference is less.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Cofferdam structure for water taking head structure construction in river and construction method thereof

ActiveCN108277815AImprove structural strengthReduce leakageHydro energy generationFoundation engineeringGeomembraneCofferdam

The invention relates to the technical field of cofferdams, and discloses a construction method of a cofferdam structure for the water taking head structure construction in a river. A first widened cofferdam is arranged on the inner side of the end cofferdam of an outer cofferdam. A second widened cofferdam is arranged on the inner side of the front end of an upper cofferdam. Composite geomembraneis laid between the first widened cofferdam and the end cofferdam and between the second widened cofferdam and the upper cofferdam. An inner cofferdam is built between the first widened cofferdam andthe lower cofferdam. The construction area of the water taking structure is located on the area between the lower cofferdam and the inner cofferdam. A plurality of pile bodies are arranged at the front end of the upper cofferdam and the front end of the lower cofferdam, and in the cofferdam body of the end cofferdam in a high-pressure jet grouting manner. A waterproof curtain is formed between every two adjacent pile bodies. According to the construction method of the cofferdam structure for the water taking head structure construction in the river, because of the widened cofferdams, the composite geomembrane and the pile bodies, the seepage amount of the part, at the front end, of the structure of of the outer cofferdam is greatly reduced, and the structural strength of the outer cofferdam is enhanced; and meanwhile, because of the inner cofferdam, the construction operation in the construction area of the water taking head structure is safer and more reliable, and construction operation can be effectively carried out on the water taking head structure.

Owner:CHINA MCC5 GROUP CORP

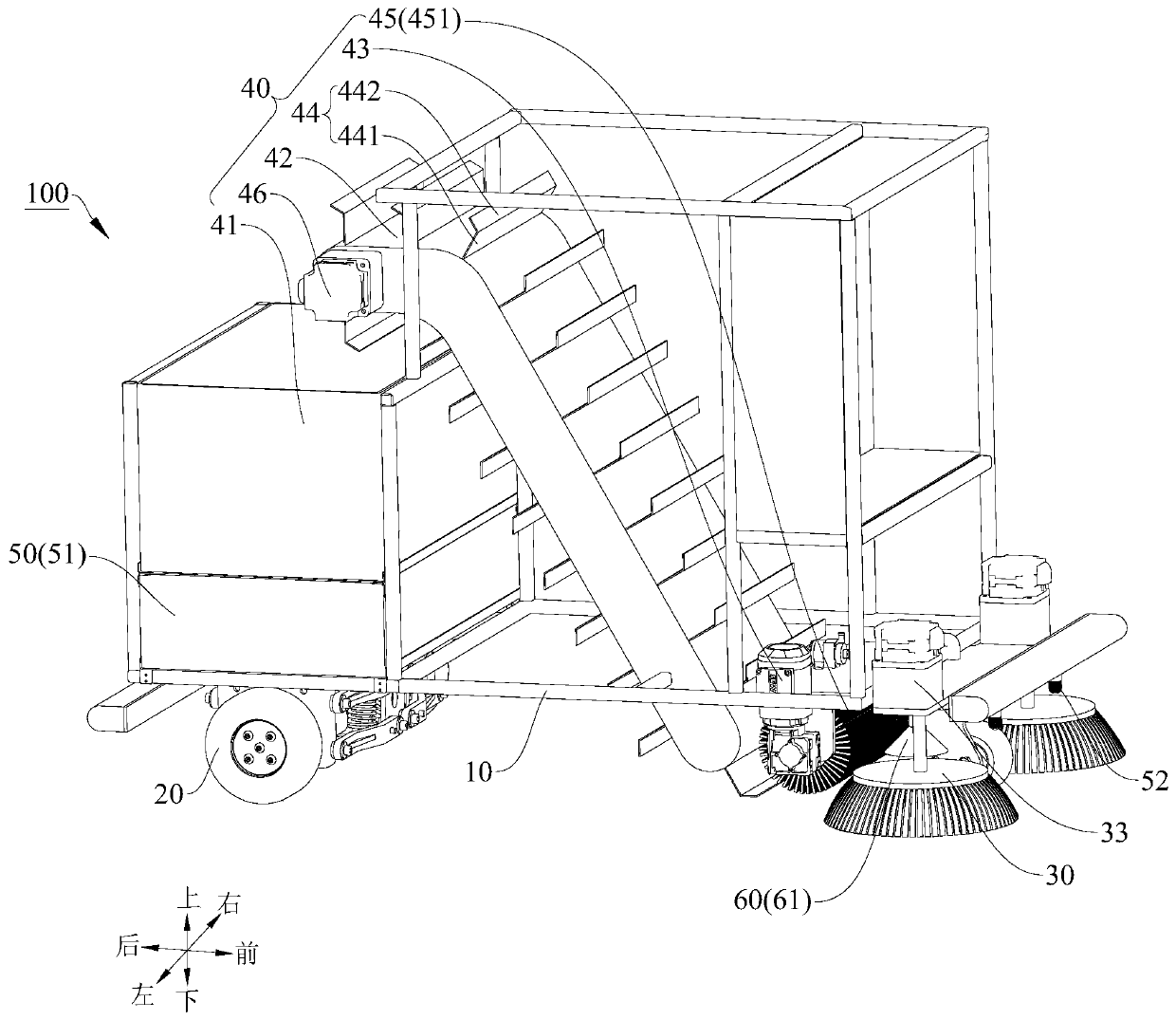

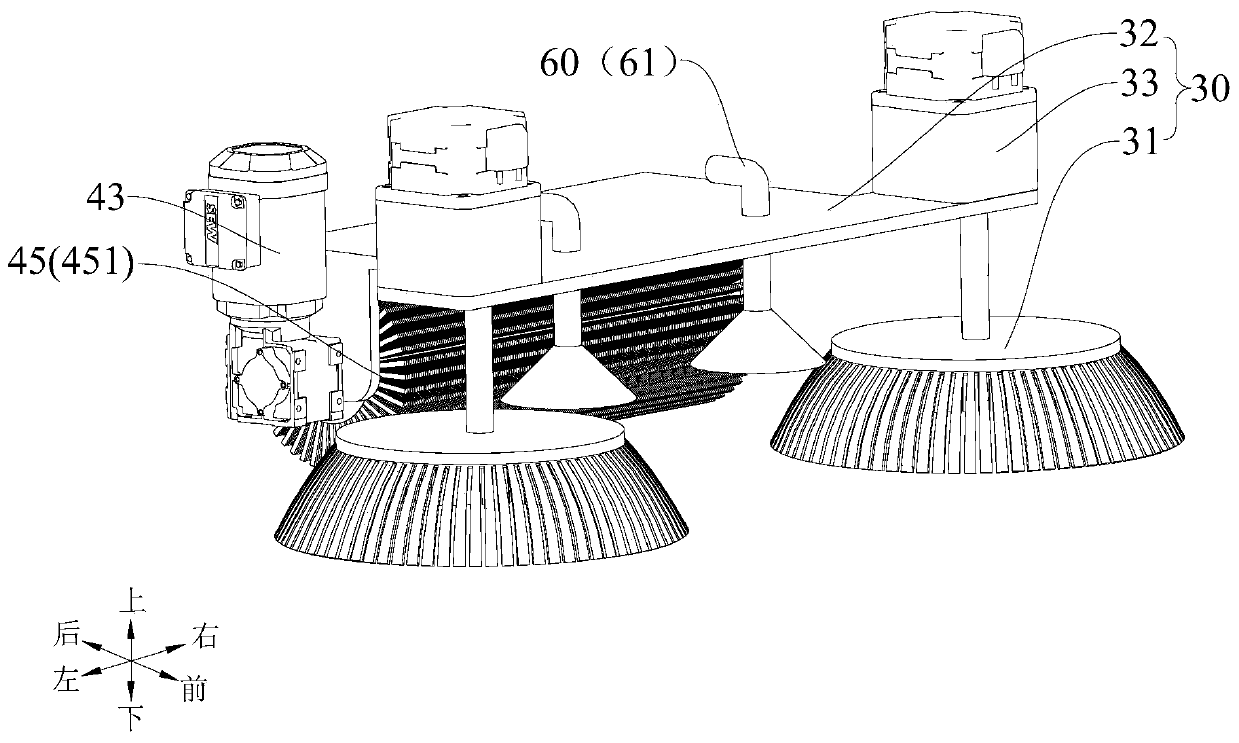

Belt type field cleaning robot

InactiveCN110670526AConstruction work safetyReduce labor costsRoad cleaningControl engineeringProcess engineering

The invention discloses a belt type field cleaning robot. The belt type field cleaning robot comprises a rack, a driving system, a sweeping system and a garbage transferring system. The driving systemis arranged on the rack so as to drive the belt type field cleaning robot to walk. The sweeping system is arranged on the rack. The sweeping system comprises a sweeping piece for sweeping ground garbage to a centralized area. The garbage transferring system comprises a garbage can, a conveying belt and a plurality of belt wheels used for supporting moving of the conveying belt. The conveying beltis movable between the centralized area and the dustbin so as to transfer the ground garbage into the dustbin. Through cooperation of the sweeping system and the garbage transferring system, the automatic centralized recycling treatment of the garbage in the construction operation can be realized, the labor cost is saved, the cleaning efficiency is improved, the construction environment can be improved, and a worker can conveniently carry out safe construction operation.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Detachable convenient-to-transport rail flat car and using method

PendingCN111619597ACombination structure is simple and feasibleEasy to installRailway braking systemsCarriagesTrackwaySubway line

The invention relates to the technical field of existing subway line track laying construction, and particularly relates to a detachable convenient-to-transport rail flat car and a using method. The rail flat car comprises a wheel set, a foot stool and an anti-slip safety pin structure, wherein the anti-slip safety pin structure comprises safety pin fixing pieces and an anti-slip safety pin, the anti-slip safety pin fixing pieces are arranged on the axle in a bilateral symmetry mode, fixing holes are formed in the anti-slip safety pin fixing pieces, and one ends of the anti-slip safety pins can penetrate through the fixing holes to be matched with the wheel rails so as to fix the relative positions of the wheel rails and the axle. Compared with the prior art, the combined structure is simple, feasible and easy to assemble and disassemble, and has the advantages that the foot stool and the wheel set axle can be separated, the whole vehicle is disassembled and assembled quickly, and transition transportation and quick operation are facilitated; the wheel set can be connected with different foot stools, so that different transportation effects are achieved, and the applicability is wider; and the anti-slip safety pin is additionally arranged, and the parking safety is further guaranteed.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

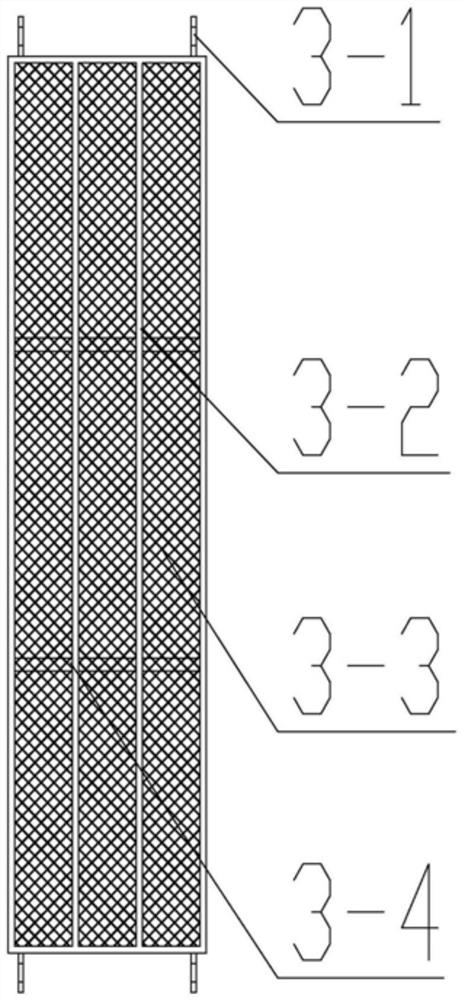

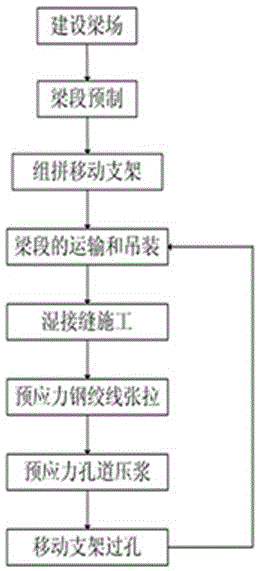

A construction method of simply supported beam segments of bridges in plateau alpine regions

ActiveCN104594200BConstruction quality is easy to controlReduce construction costsBridge erection/assemblyBridge materialsYardPlateau

The invention discloses a bridge simply supported beam segment assembling construction method for a frigid plateau region. The method comprises the steps of girder fabrication yard building, beam segment prefabricating, mobile support assembling, beam segment conveying and hoisting, wet joint construction, prestressed steel strand tensioning and prestressed duct grouting. According to the construction method, SX64 / 2200 mobile supports are adopted, the construction technology is advanced, the mechanical degree is high, the bridge forming speed is high, and no interference is produced for underbridge traffic; frigid plateau region wet joint construction is carried out inside the mobile supports, and the construction quality is easy to control; due to the fact that frigid plateau region box beam segment assembling construction is mainly carried out inside the mobile supports, construction is safe.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

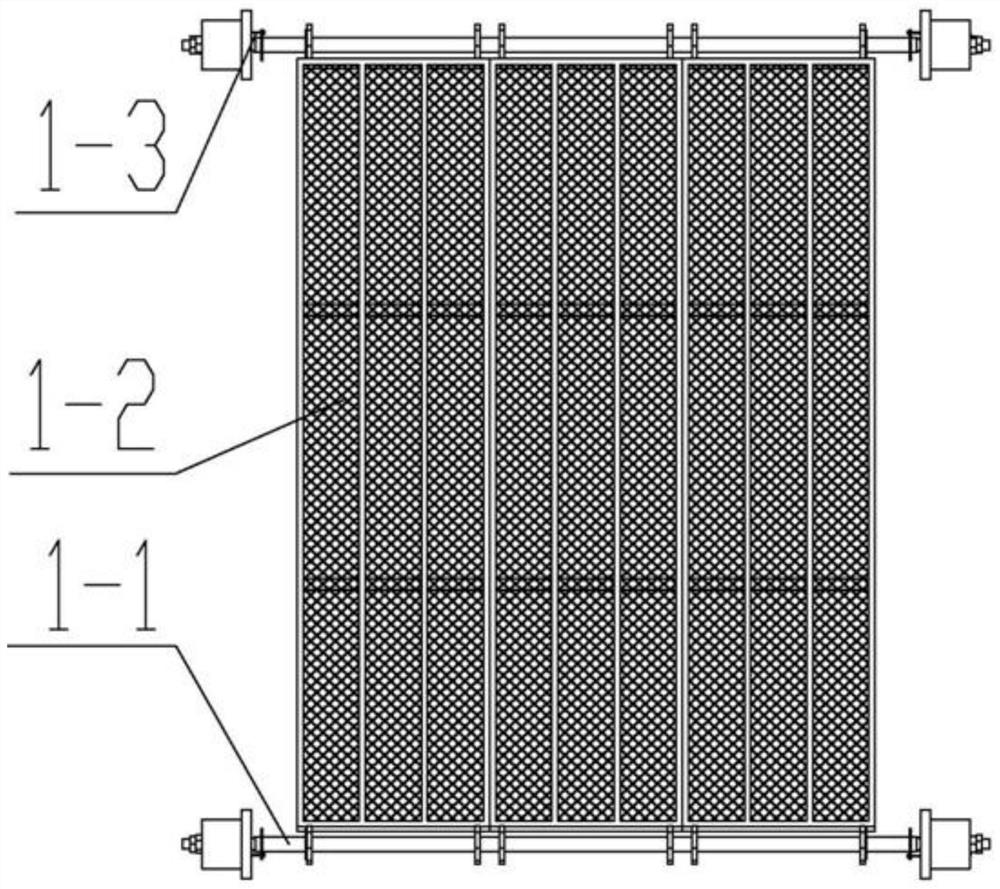

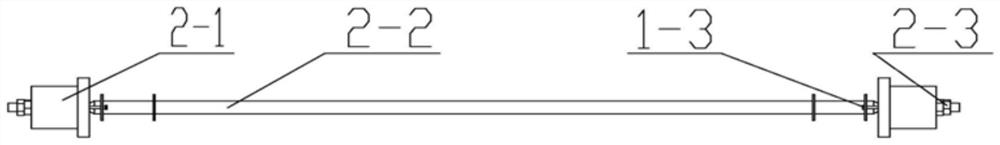

Method for arranging parallel steel wire stay cable

ActiveCN101967796BPrevent rope accidentsConstruction work safetyBridge structural detailsBridge erection/assemblyLinear controlCable transport

The invention discloses a method for arranging a parallel steel wire stay cable, which comprises the following steps of: 1) arranging a tower end anchor head at the end of the stay cable; 2) arranging a planetary jack and a tower end anchor head nut of the stay cable on an anchor backing plate which is arranged at the pipe orifice of a cable guide pipe on the inner side of the wall of a cable bent tower; 3) lengthening a pulling steel stranded wire meeting the requirement at the tower end anchor head of the stay cable; 4) hoisting the tower end anchor head of the stay cable to a position nearby the pipe orifice of the cable guide pipe on the outer side of the wall of the cable bent tower by using a hoisting machine on the top of the cable bent tower; 5) pulling the end of the pulling steel stranded wire to pass through the cable guide pipe and anchoring on the planetary jack; and 6) pulling the pulling steel stranded wire by using the planetary jack, pulling part of the tower end anchor head of the stay cable to exceed the anchor backing plate and screwing the tower end anchor head nut of the stay cable at the tower end anchor head so as to cap the tower head anchor head. The method can effectively avoid the sling accidents of the stay cable, makes the whole construction process convenient and quick and contributes to the linear control of bridges.

Owner:HUNAN ROAD & BRIDGE CONSTR GROUP

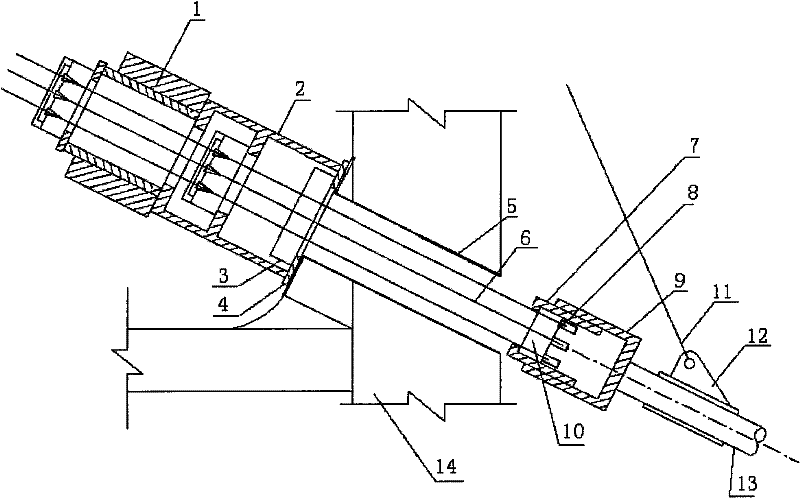

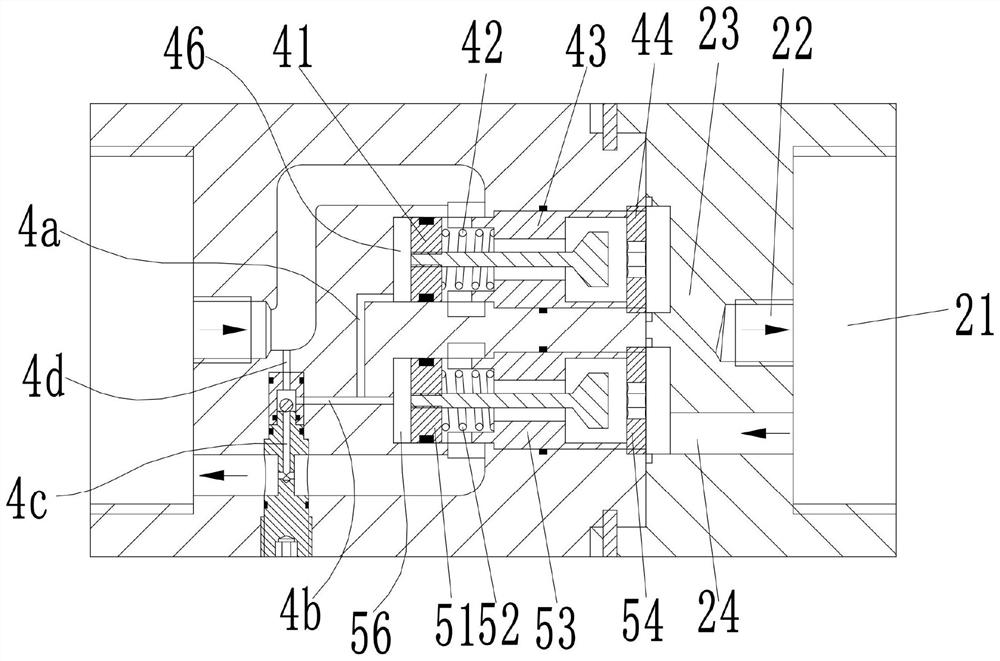

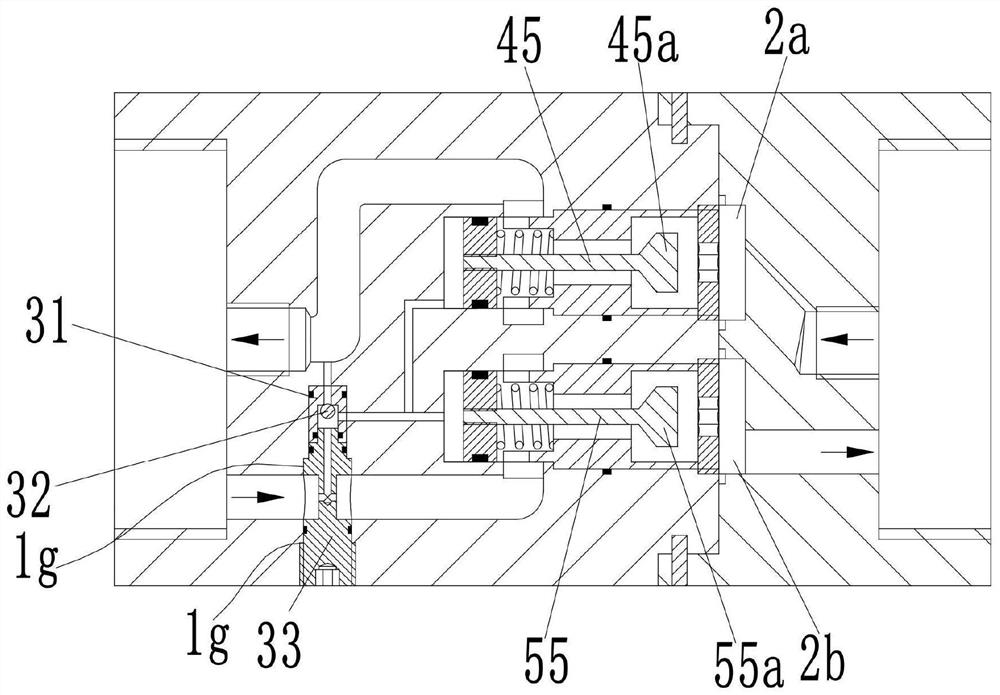

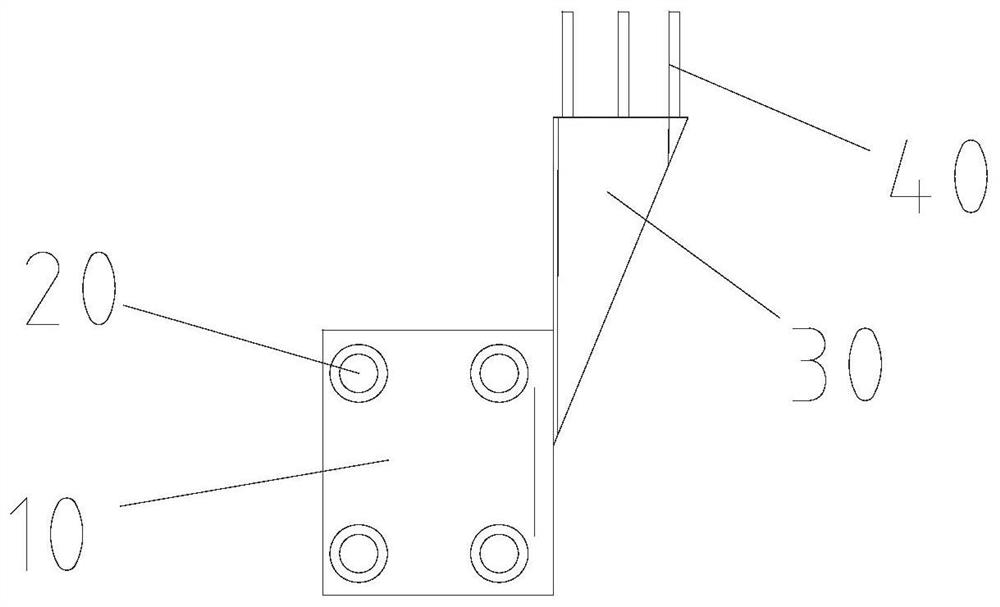

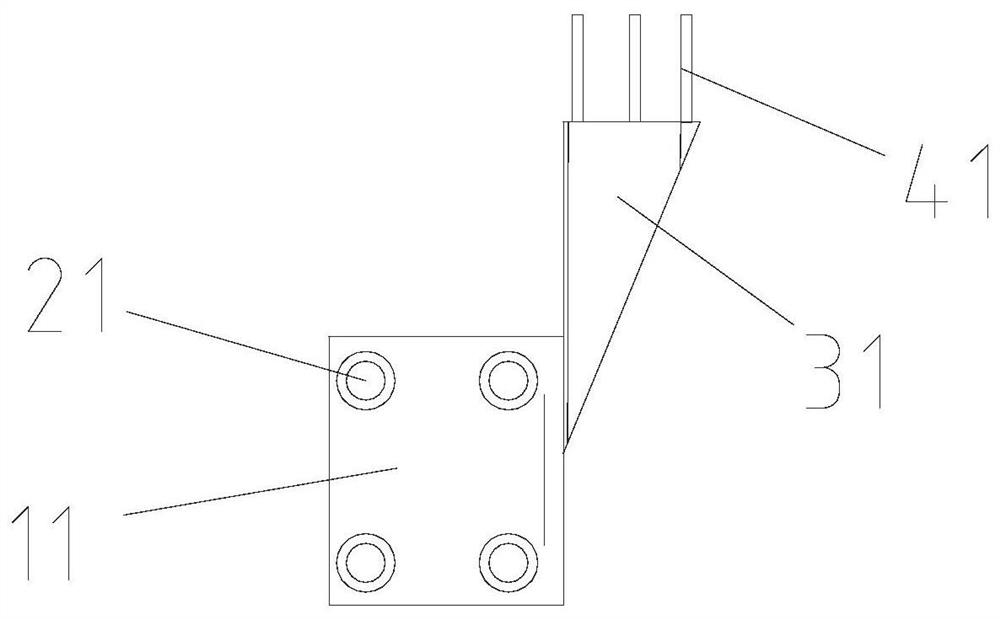

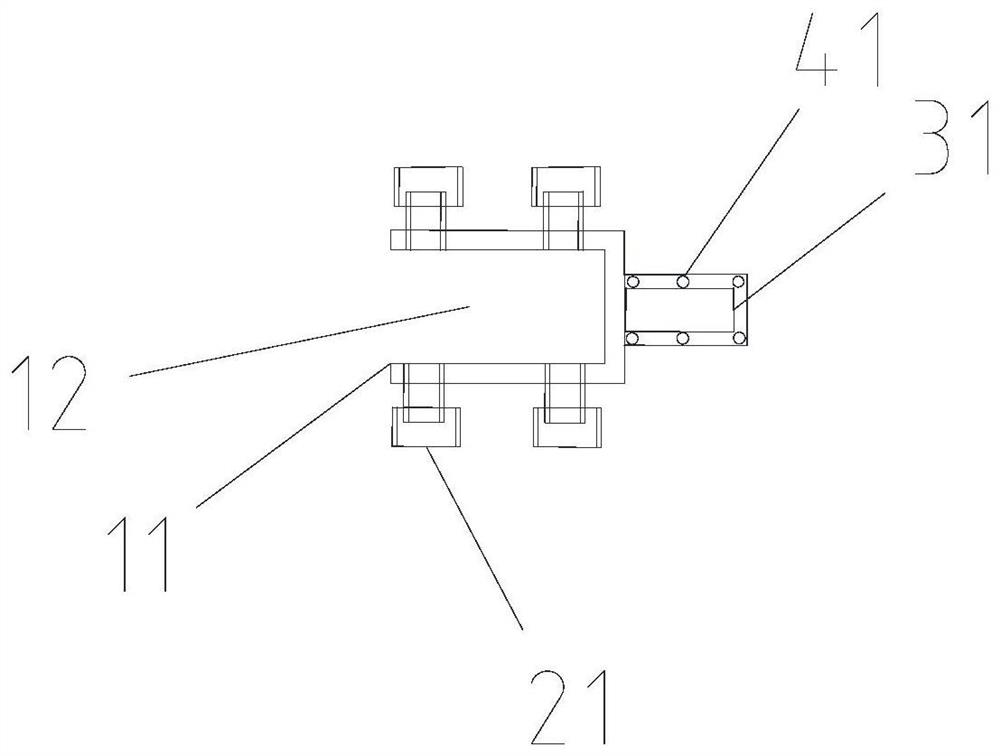

Check valve for downhole double-layer coiled tubings

PendingCN111827928AClosed on and offPrevent returnWell/borehole valve arrangementsSealing/packingCoiled tubingCheck valve

The invention discloses a check valve for downhole double-layer coiled tubings. The check valve is arranged between the downhole double-layer coiled tubings; the right end of the check valve communicates with the shaft bottom; the check valve comprises a left valve body; a left first threaded hole connected with the coiled tubing on the outer layer and a left second threaded hole connected with the coiled tubing on the inner layer are formed in the left end of the left valve body; a left second through hole communicating with the left first threaded hole and a left first through hole communicating with the left second threaded hole are formed in the left valve body; a right valve body is fixedly mounted at the right end of the left valve body; a right first threaded hole connected with thecoiled tubing on the outer layer and a right second threaded hole communicating with the coiled tubing on the inner layer are formed in the right end of the right valve body; a right second through hole communicating with the right first threaded hole and a right first through hole communicating with the right second threaded hole are formed in the right valve body; and a shuttle valve component,an inner-layer check valve component and an outer-layer check valve component are arranged in the left valve body. The check valve can effectively seal a passage of the coiled tubings on the inner and outer layers in the case of an unexpected situation to prevent well liquid from reversing out so as to prevent a gas blowout accident.

Owner:邵玉刚

Device for detecting and maintaining mobile bridge structure

ActiveCN101215821BEasy to detectEasy constructionBridge structural detailsBridge erection/assemblyCable stayedRoad surface

Owner:WUDA JUCHENG STRUCTURE CO LTD

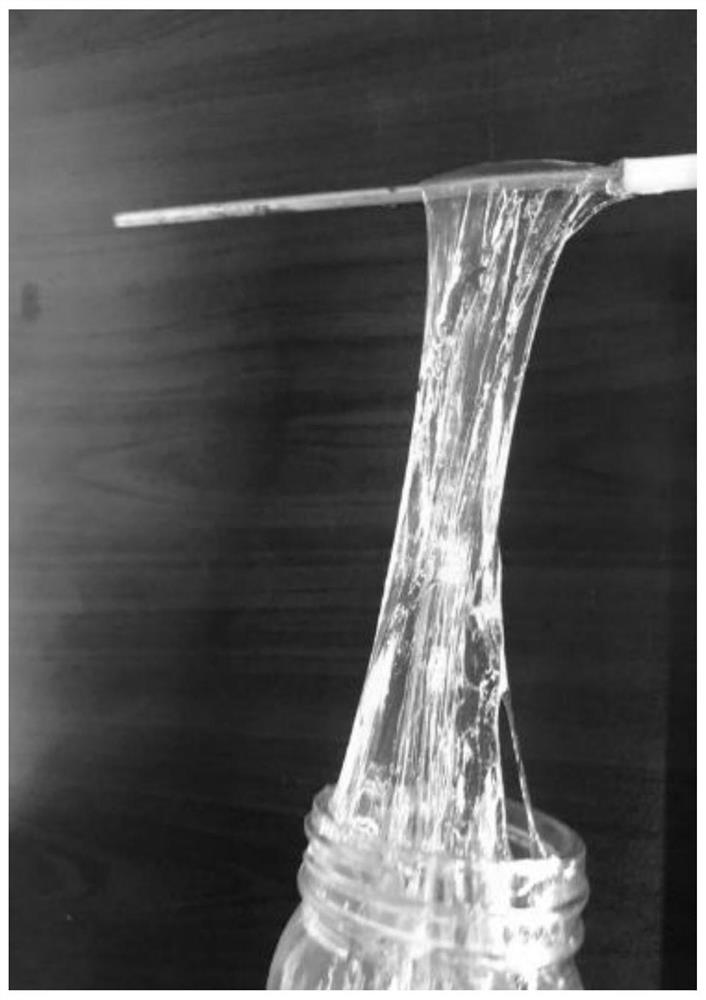

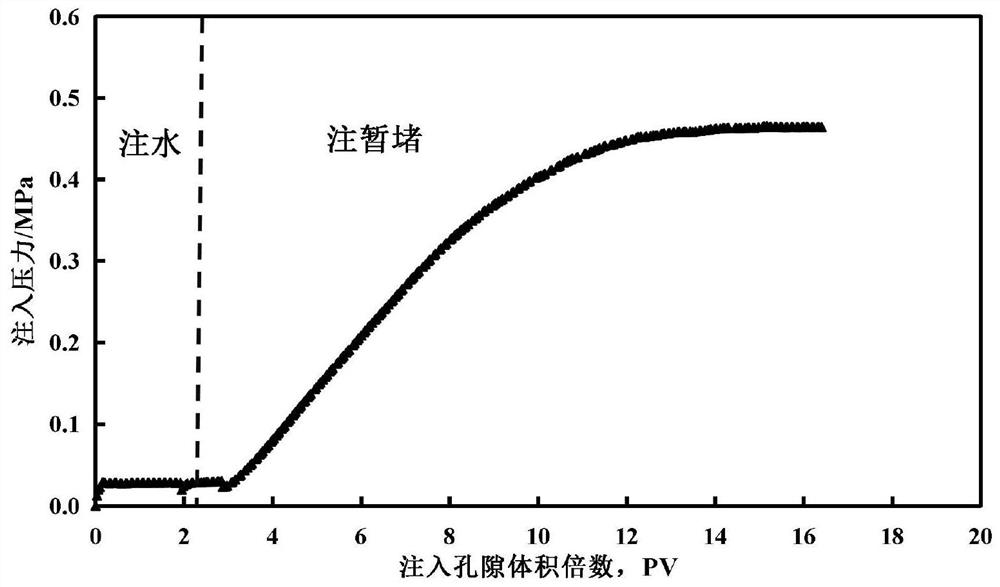

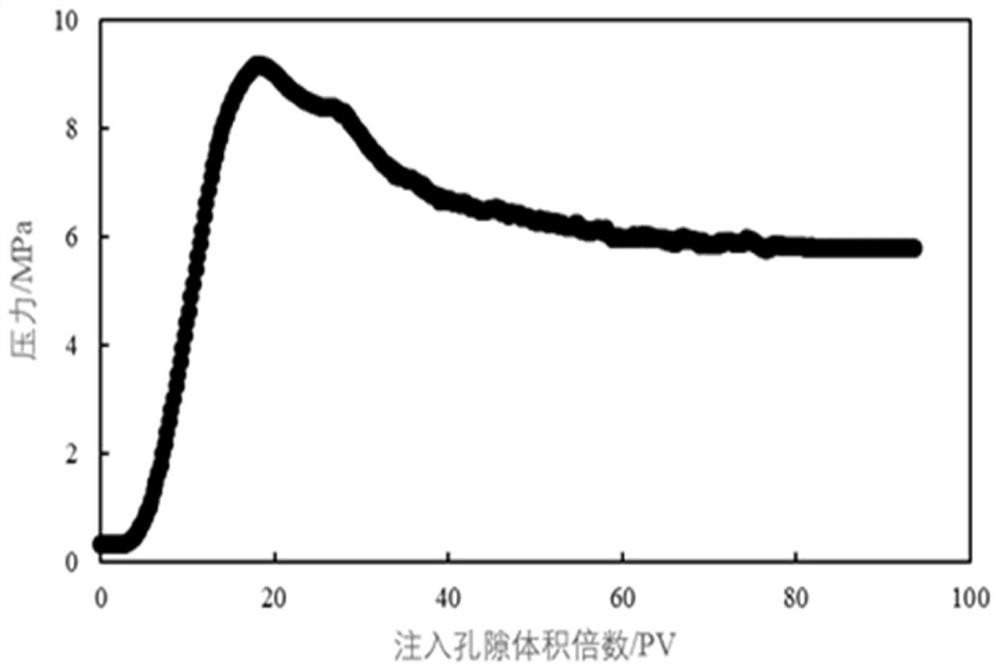

A sewage mixing temporary plugging agent for oilfield water injection wells and its preparation method

Owner:SOUTHWEST PETROLEUM UNIV

A chute blockage blasting device and method

The invention discloses a winze blockage blasting device and method. The device comprises an aircraft and a wireless remote controller; a loading platform for fixing a charge is arranged on the top of the aircraft, a camera used for monitoring the position of the charge and the position of a blockage object in real time is arranged on the aircraft, and the wireless remote controller is in signal connection with a flying drive module of the aircraft through a communication module, and is further connected with a display device in communication with the camera. The remote control aircraft is firstly used for estimating the thickness of the blockage object, explosives are mounted on the aircraft, the aircraft is remotely controlled to convey the explosives to the selected position below the blockage object, the explosives are detonated, and the blockage is blasted for dredging. According to the device, the aircraft can reliably and accurately blast the charge in a manner of being tightly attached to the bottom of the blockage object of a winze, although the aircraft is destroyed together with the explosives after blasting, the obvious time and cost advantages are achieved compared with other winze dredging manners, and the construction work safety is ensured.

Owner:CENT SOUTH UNIV

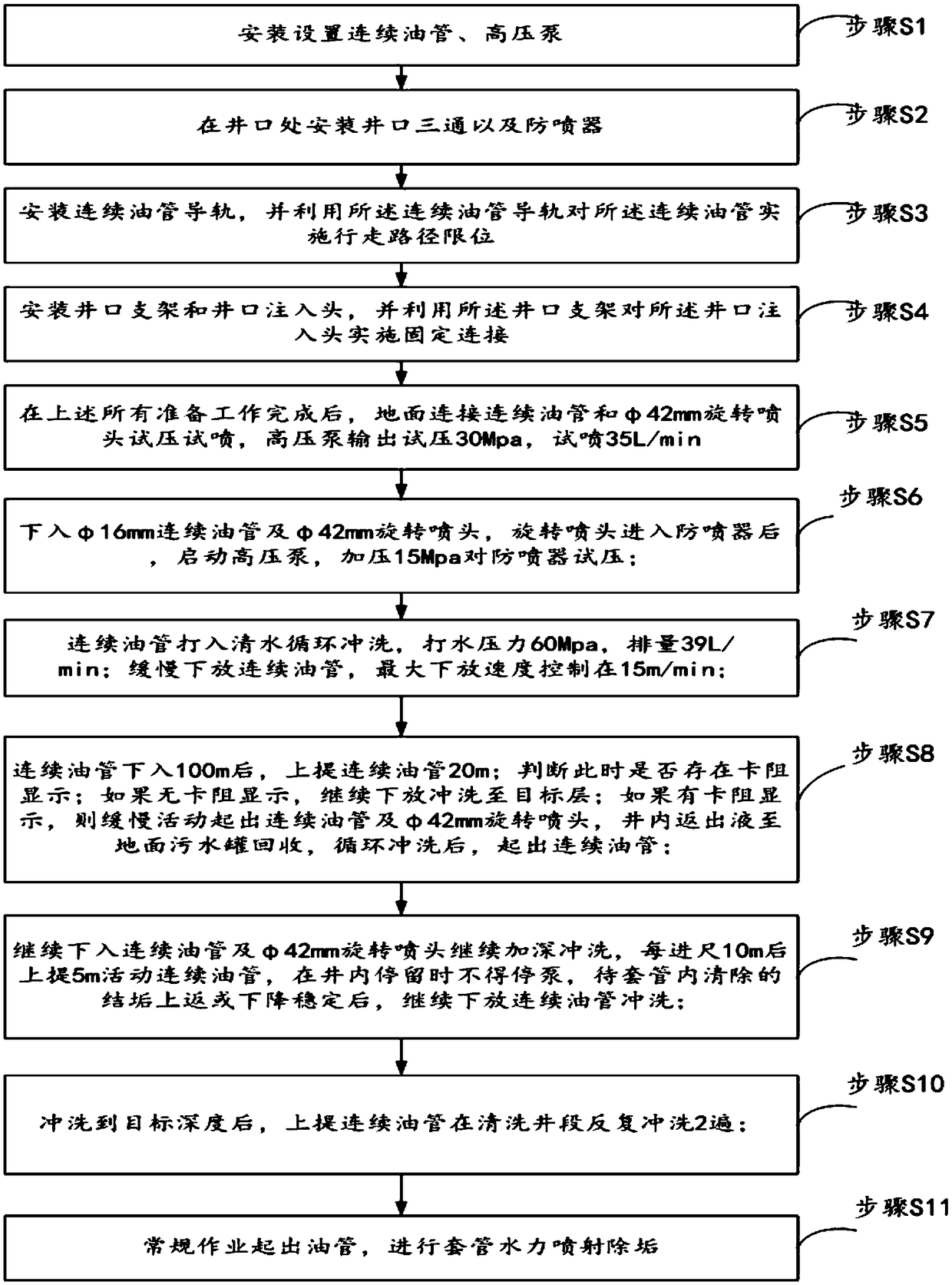

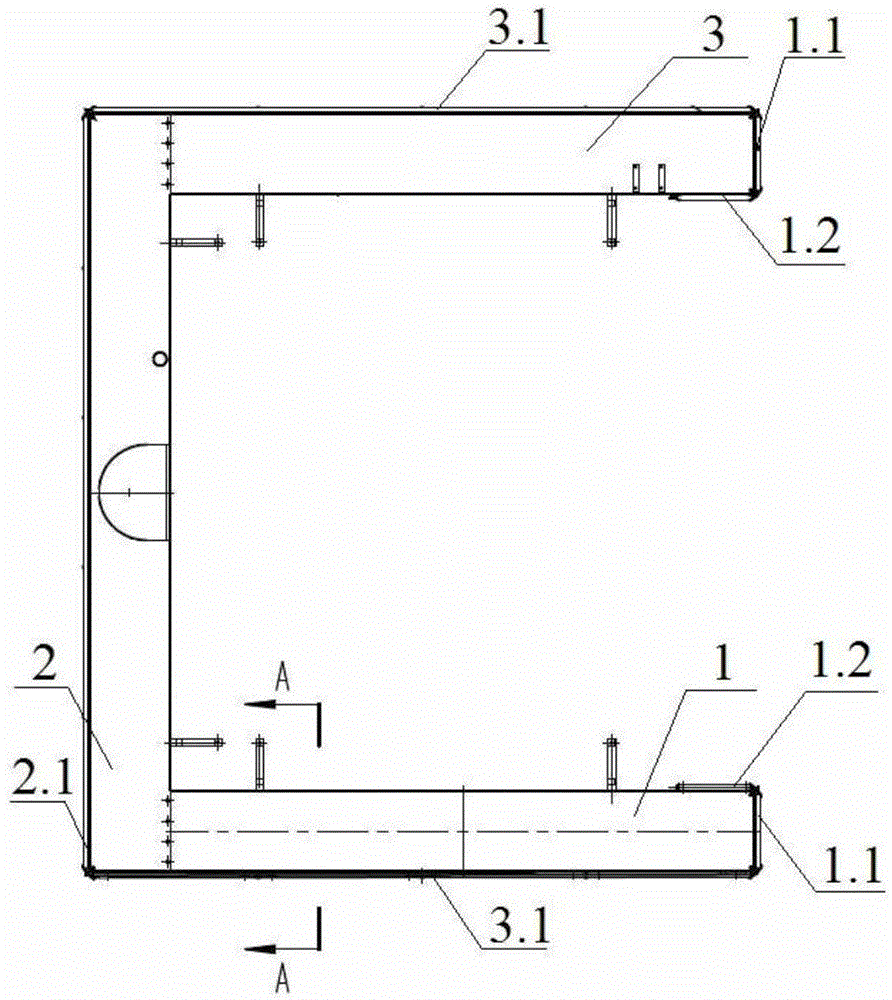

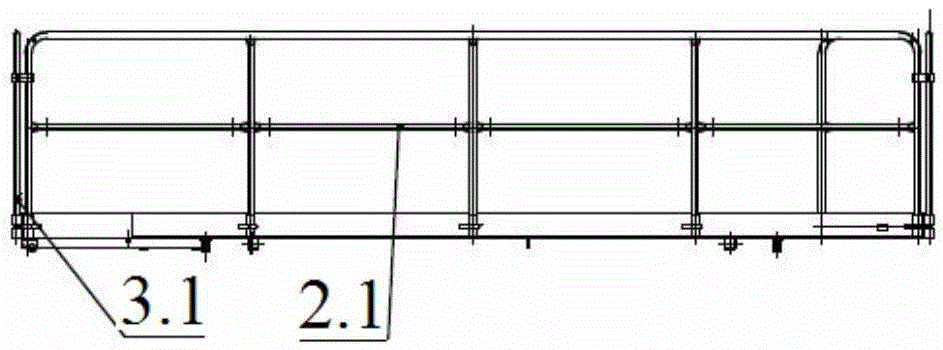

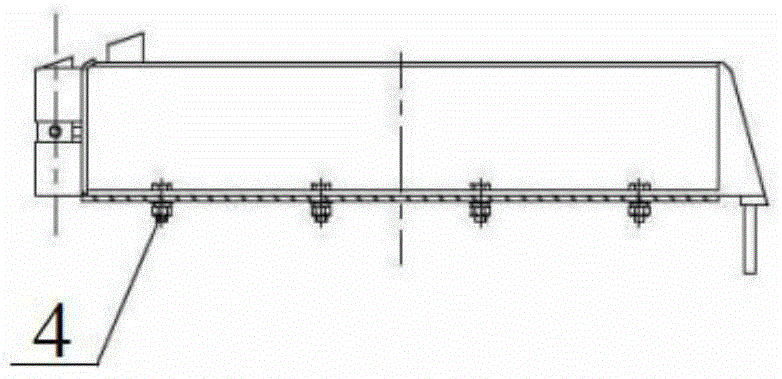

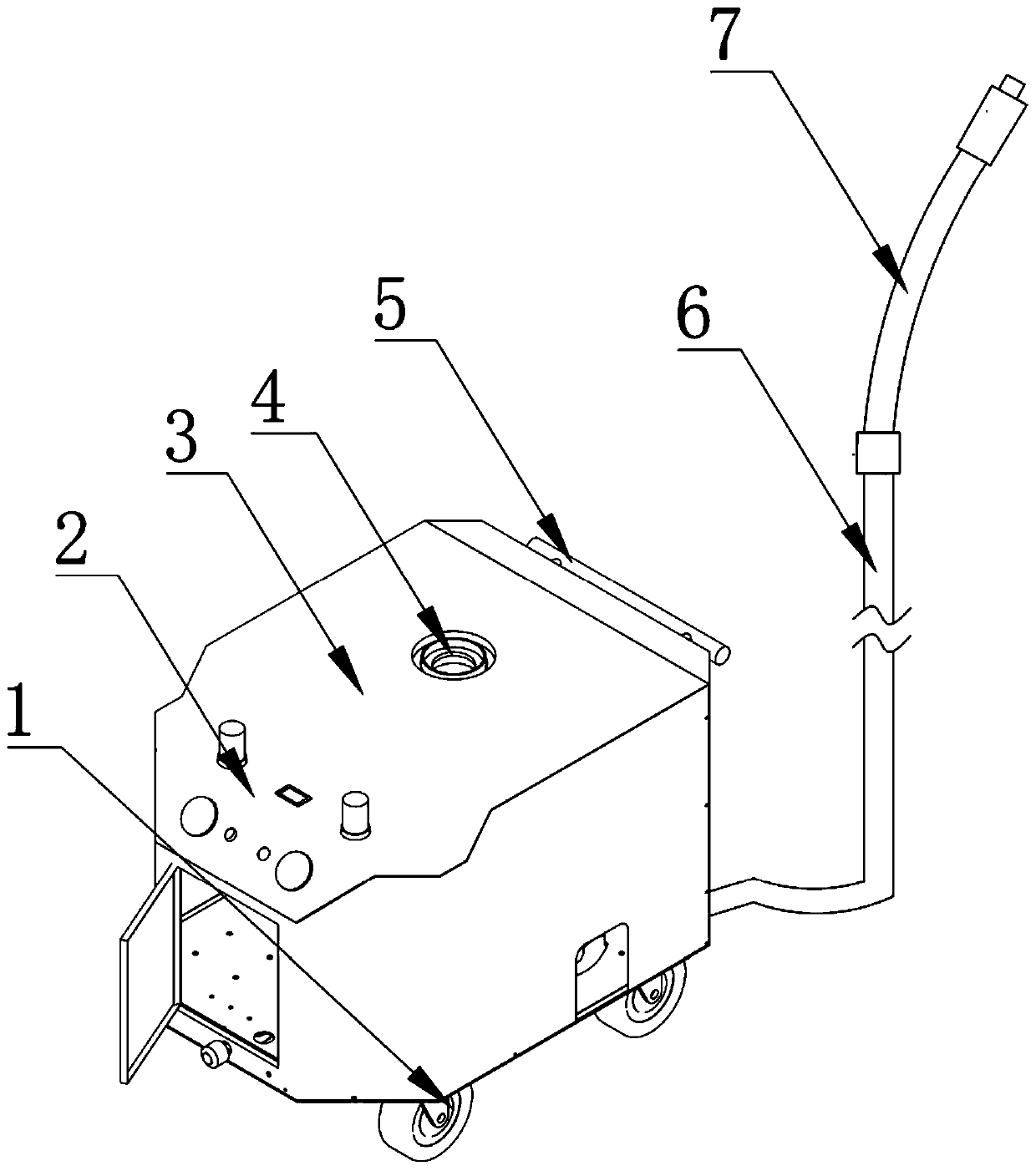

Oil well pipe sleeve scale cleaning method

ActiveCN108999593AGood descaling effectConstruction work safetyCleaning apparatusWater floodingCoiled tubing

The invention discloses an oil well pipe sleeve scale cleaning method. The oil well pipe sleeve scale cleaning method comprises the following steps: installing and setting a coiled tubing and a high pressure pump; installing a coiled tubing guide rail; installing a wellhead bracket and a wellhead injection head; connecting a ground to the coiled tubing and a Phi 42mm rotating nozzle to test pressure and spraying, wherein the output test pressure of the high pressure pump is 30Mpa, and the spraying test is 35L / min; inputting a Phi 16mm coiled tubing and a Phi 42mm rotary nozzle, starting thehigh pressure pump after the rotary nozzle enters a blowout preventer, pressurizing 15Mpa to test the blowout preventer; continuing to input the coiled tubing and the rotating nozzle, continuing to perform deepening and flushing, and lifting the movable coiled tubing by 5 m after every drilling footage of 10 m, wherein the pump must not be stopped during staying in the well; and continuing to input the coiled tubing to perform flushing after upward movement and dropping of the removed scale in the sleeve are stable is stable. The oil well pipe sleeve scale cleaning method is suitable for sleeve descaling of producing wells in water flooding, ternary composite flooding, polymer flooding and other oil field production manners, and has an obvious descaling effect.

Owner:大庆荣氏采油技术开发有限公司

Operating platform and tower crane for climbing frame

The invention discloses an operating platform for a climbing frame and a tower crane, which belong to the technical field of construction machinery and include a flipping movable platform that can be installed on the climbing frame platform. It is retracted or opened for the introduction or maintenance of standard joints; the flipping movable platform includes a support platform (9) for human body standing, and a number of railing inserts (10) for installing anti-skid railings are arranged on the outside of the support platform, and the support platform A number of supporting chassis (8) are installed at the bottom, and chassis connecting plates (11) for structural fixing are installed between the supporting chassis. The present invention installs an overturning movable platform on the climbing frame platform. When the overturning movable platform is opened, the working space of the operator is effectively increased, the labor intensity is low, and the maintenance difficulty is small; when the overturning movable platform is overturned and retracted, the introduction of standard joints is not affected. ;Anti-slip railings can be installed on the overturning movable platform to effectively ensure the safety of construction operations.

Owner:XUZHOU CONSTR MACHINERY

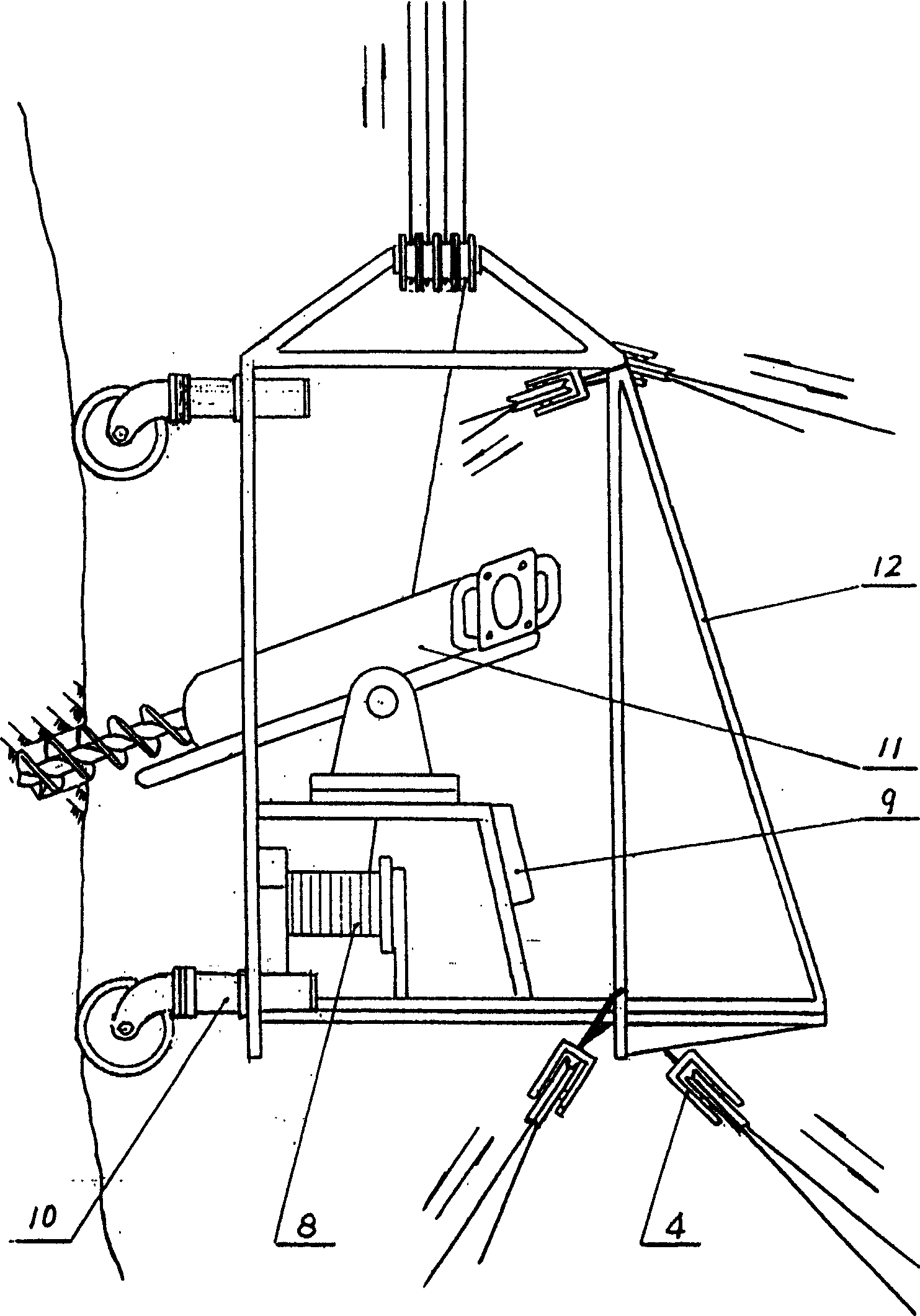

High grade rock and soil anchoring construction method and apparatus

InactiveCN1228511CMove safely on your ownConstruction work safetyBulkheads/pilesBuilding support scaffoldsBlock and tackleSteep slope

The invention is a method and device of slope rock anchoring construction by using cables to pull drill floor for locating and applying pressure. The method: according to the six (or four) anchoring points preset in the range of anchoring operation surface, linking two points in the high position by a steel cable, hanging the drill floor under the pulley rolling on the steel cable through pulley group, using a steel rope fixed on the ground for lifting the jenny to make the drill floor vertically move up and down through the pulley group; using four steel ropes of four transverse moving jennies all fixed on the ground to make the drill floor move left and right through the turning pulleys on the anchoring points and the drill floor. There are four extension and turning truckles on one side of the drill floor, near the steep slope. The anchored driller on the drill floor can regulate the angle of drilling hole on the horizontal and vertical surfaces. When constructing, using operation control button on the drill floor to control to lift the jenny and transverse moving jennies so as to move the drill floor to hole drilling position and make the drill floor closely adhere to the slope, and at the same time support up the supporting legs of the extension and turning truckles to press the drill floor in the hole position for drilling hole.

Owner:石午江

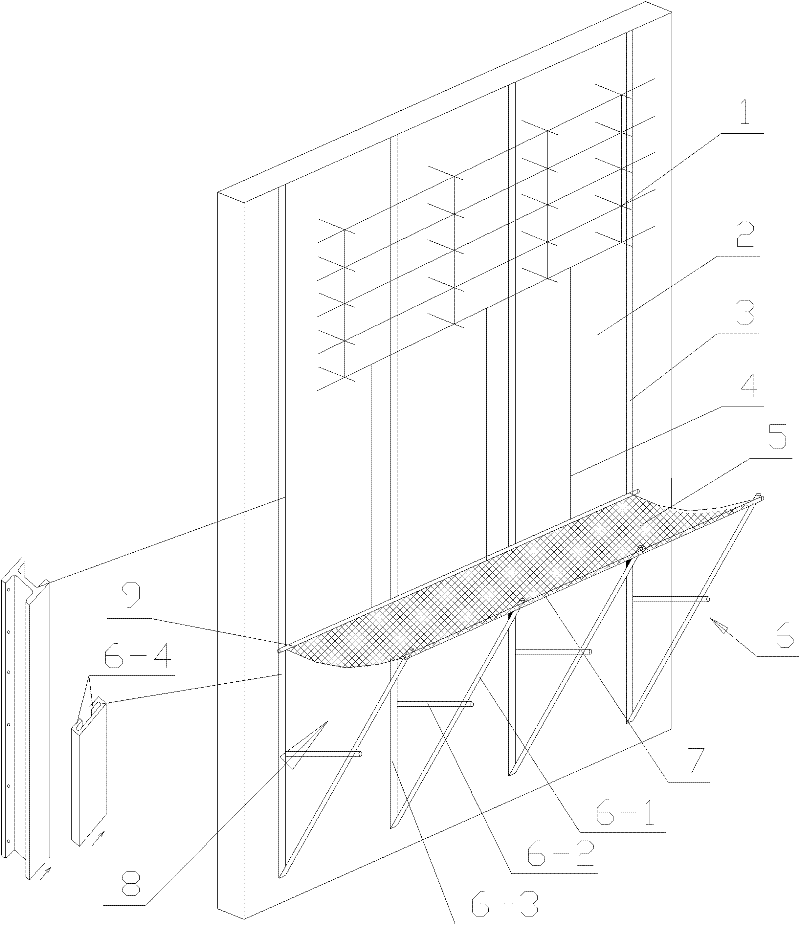

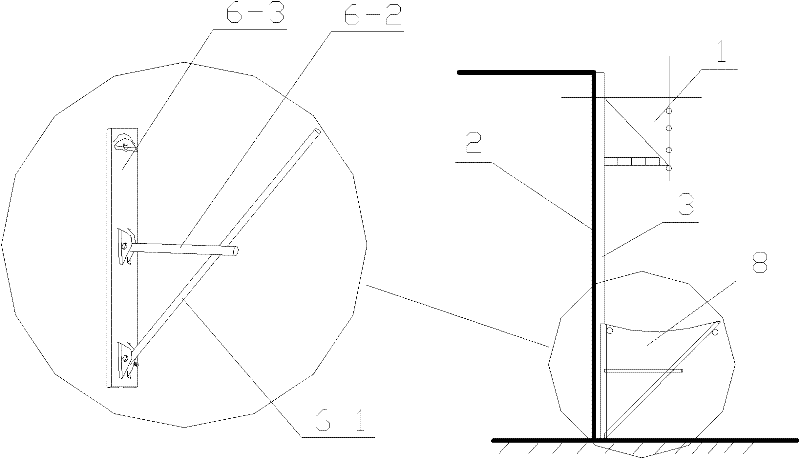

Construction method of safe flat net positioned on periphery of building

ActiveCN102061810BImprove ergonomicsReduce labor intensityBuilding material handlingArchitectural engineeringJoist

Owner:中建六局第一建设有限公司 +1

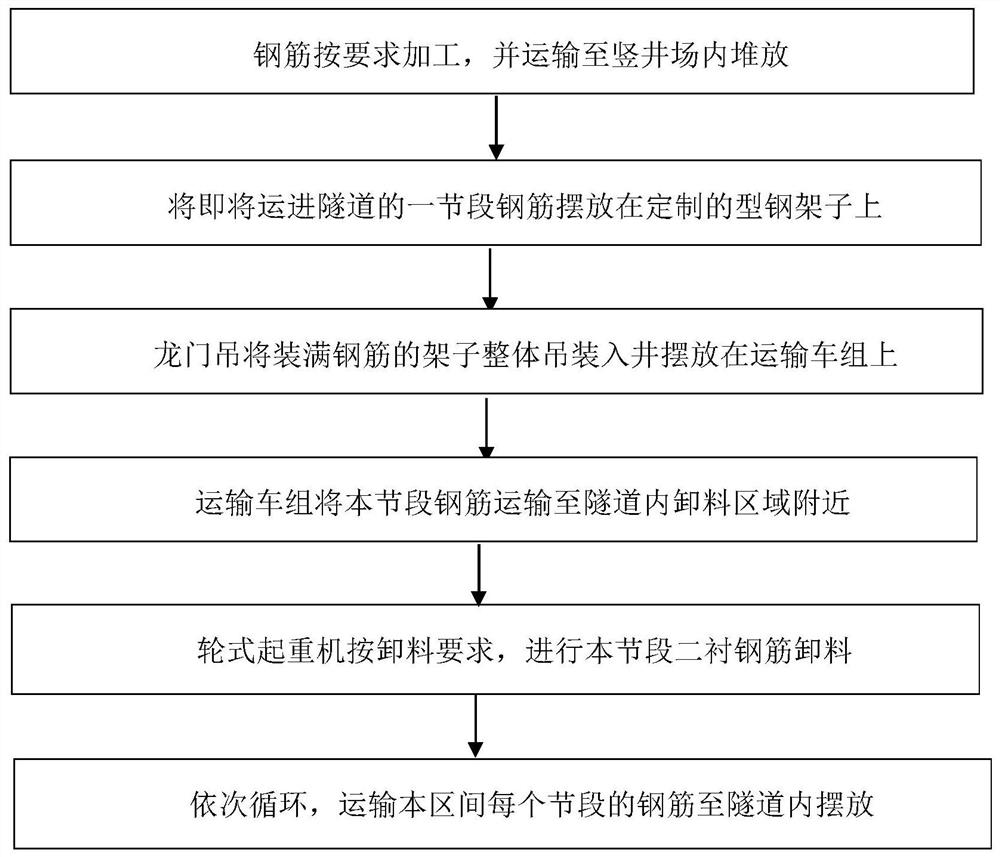

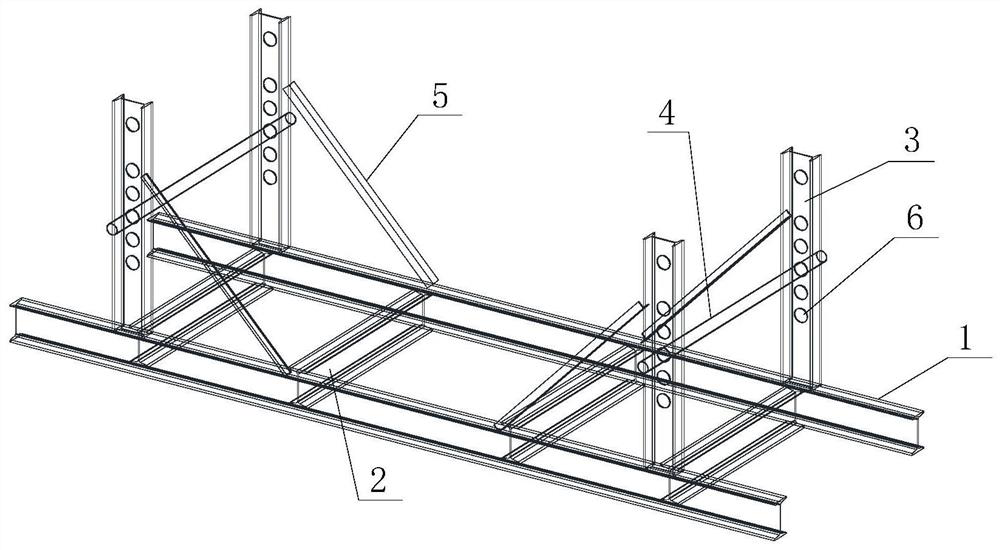

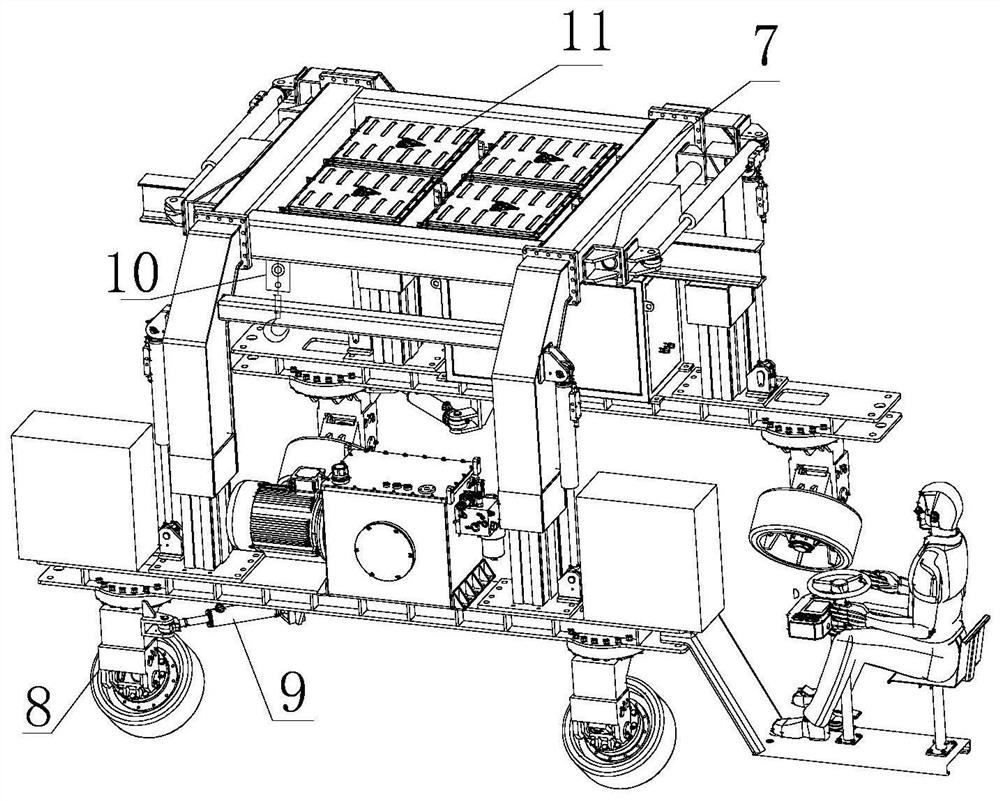

A transfer and unloading method for the secondary lining steel bars of small-diameter tunnels

ActiveCN111119954BReduce the difficulty of operationSolving steel transport problemsUnderground chambersTunnel liningSteel frameRebar

The invention discloses a method for transferring and discharging steel bars for secondary linings of small-diameter tunnels. Place them on the customized profiled steel racks in sequence, then hoist the aforementioned profiled steel racks to the flatbed truck of the transport vehicle group at the bottom of the shaft, and transport the steel bars of this segment to the unloading area of the corresponding segment in the tunnel by the transport vehicle group. Use a custom-made wheeled crane to lift the steel bars of this section from the steel frame on the transport vehicle to the unloading area in turn according to the requirements of the steel bar binding sequence, and repeat the above steps to complete the transportation and stacking of the secondary lining steel bars in the tunnel area. Aiming at the situation where the space of small-diameter tunnels is limited and the conventional unloading equipment cannot be used, the invention realizes the rapid transfer and unloading of steel bars, greatly improves the transportation efficiency of steel bars, has simple operation and high degree of mechanization, and effectively reduces the labor intensity of operators. .

Owner:CCTEB INFRASTRUCTURE CONSTR CO LTD +1

Cable erecting device and erecting method thereof

PendingCN112436437AReduce frictional resistanceReduce wearApparatus for overhead lines/cablesEngineeringElectric cables

A cable erecting device and an erecting method thereof belong to the technical field of buildings, and the device comprises: a mounting assembly used for being mounted on a wall body, wherein the mounting assembly is arranged on the wall body; an adjusting assembly which is used for adjusting the position of the mounting assembly on the wall body, wherein the adjusting assembly is arranged on themounting assembly and abuts against the wall body; a supporting assembly which is used for supporting the cable, wherein the supporting assembly is arranged on the mounting assembly; and a rotating assembly which is used for winding the cable on the supporting assembly, wherein the rotating assembly is arranged on the supporting assembly in a rotatable mode. The cable erecting device and the erecting method thereof provided by the invention have the following beneficial effects: (1) a plurality of brackets can be mounted, and a plurality of cables can be erected at the same time; and (2) the supporting rod can rotate in the sleeve, so that the frictional resistance between the supporting rod and the cable is greatly reduced, and the abrasion of the surface of the cable is reduced.

Owner:MCC TIANGONG GROUP

Gas and sand mixing high-voltage electrified cleaning system

PendingCN110666699ASand content is stableGood cleaning effectBlast gunsAbrasive feedersSprayerHigh pressure gas

The invention relates to a gas and sand mixing high-voltage electrified cleaning system. A gas and sand mixing device, an insulating gas and sand conveying pipe and an insulating sprayer are included.An air inlet hole of the gas and sand mixing device communicates with compressed air equipment. A gas and sand outlet of the gas and sand mixing device communicates with the insulating gas and sand conveying pipe. The insulating gas and sand conveying pipe communicates with the insulating sprayer. The insulating gas and sand conveying pipe and the insulating sprayer are made of insulating materials. Under the action of high-pressure gas, cleaning sand enters a gas and sand mixing part through a sand outlet hole, acceleration is conducted in the gas and sand mixing part, the cleaning sand is injected to the equipment surface with the high speed, dirt on the surface is cleaned, and the function of cleaning is achieved. The sand content of a sprayer outlet is stable, the cleaning effect is good, and particularly for electrical equipment with serious air drying dust pollution but without serious oil dirt, a good cleaning effect is achieved.

Owner:HENAN HENGAN ELECTRIC POWER

Self-adaptive plate mounting robot

ActiveCN113977601AWide range of performance applicationsSeven degrees of freedomManipulatorControl engineeringActuator

The invention discloses a self-adaptive plate mounting robot. The self-adaptive plate mounting robot comprises a movable base, a lifting device, a mechanical arm and an end effector; the movable base is used for driving the robot to move in any direction; the lifting device is arranged on the movable base and used for achieving lifting of the mechanical arm in the height direction; the mechanical arm can provide telescopic and rotary motion; and the end effector rotates in the horizontal and vertical directions to adjust the mounting position of a plate, so that the mounting error is reduced, and the precision of the mounting operation is ensured. According to the self-adaptive plate mounting robot, through cooperative movement of all the components, the requirement for mounting operation in various indoor environments of different directions, angles and heights can be met; and meanwhile, the robot has seven degrees of freedom, and the application range of the degree-of-freedom redundancy performance of the robot is wider.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com