A transfer and unloading method for the secondary lining steel bars of small-diameter tunnels

A small-diameter, steel-reinforced technology, used in tunnel linings, tunnels, shaft linings, etc., can solve the problems of low manual operation efficiency, large secondary handling volume, and high safety risks, and achieve low manual operation intensity and less manual use. , the effect of high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

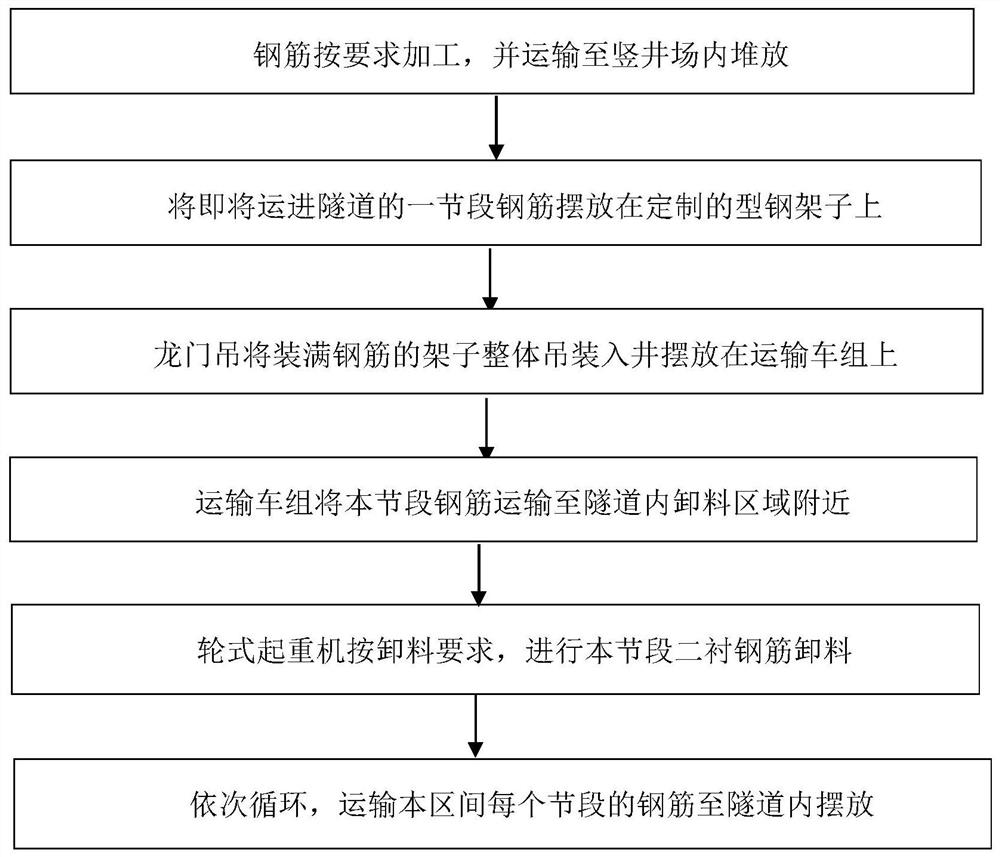

[0028] Such as figure 1 As shown, it is a schematic flow diagram of steel bar transfer and unloading method in a small-diameter tunnel of the present invention, which mainly includes the following construction steps:

[0029] Step 1: According to the design and binding requirements of the second-lined steel bars of the tunnel, all the second-lined steel bars in this project will be processed and unloaded in the steel bar processing plant by division, type, and size. Segment arc steel bar. After the steel bars are processed, they are bundled into small bundles according to the demand of a single segment. After each bundle is processed, they are marked with post-it notes and stacked in sections. After the tunnel is penetrated, the steel bars are transported to the shaft yard by a trailer for sorting and stacking.

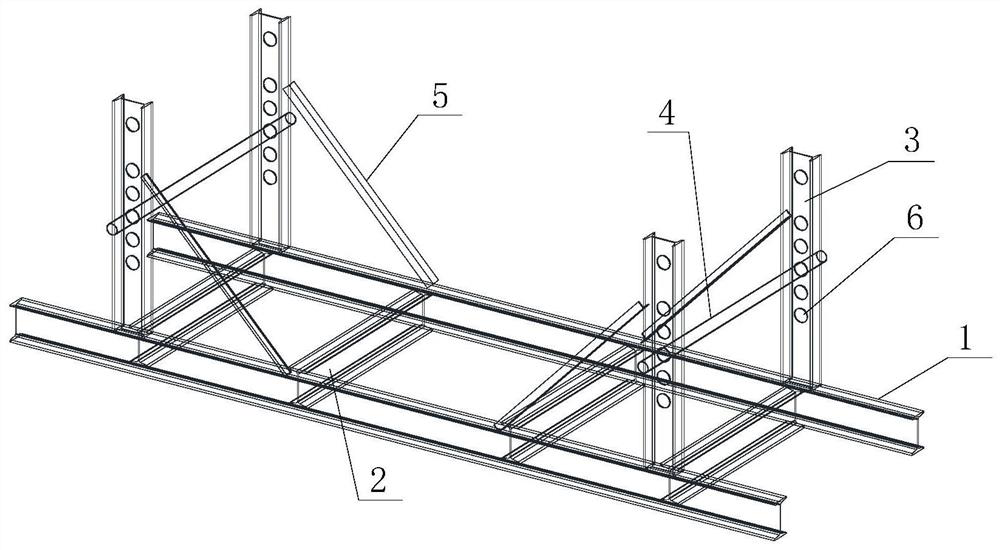

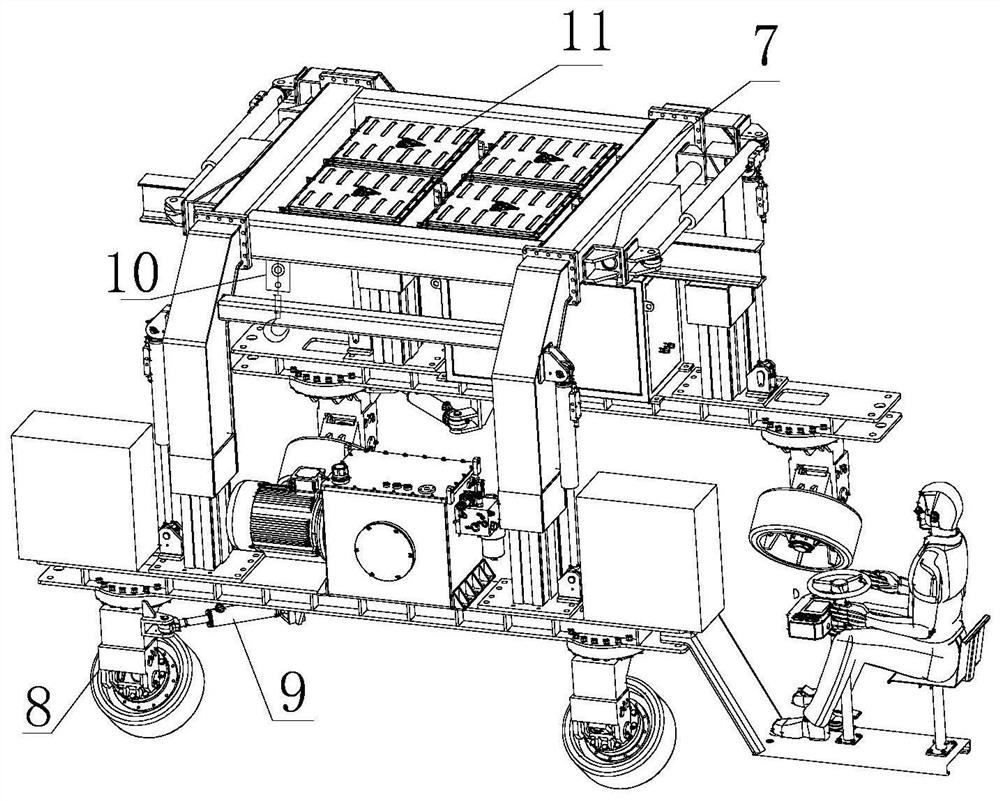

[0030] Step 2: Divide the tunnel section into a single section with a length of 43.2m, and transport steel bars in sequence according to the section division. Custo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com