Ground construction robot

A robot and ground technology, applied in the direction of machine tools, manipulators, and manufacturing tools suitable for grinding workpiece planes, can solve the problem of uneven construction methods and equipment, difficulty in achieving consistent construction standards, seamless construction coordination, and Improve the precision and efficiency of ground construction, save labor and material costs, and ensure the safety of construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

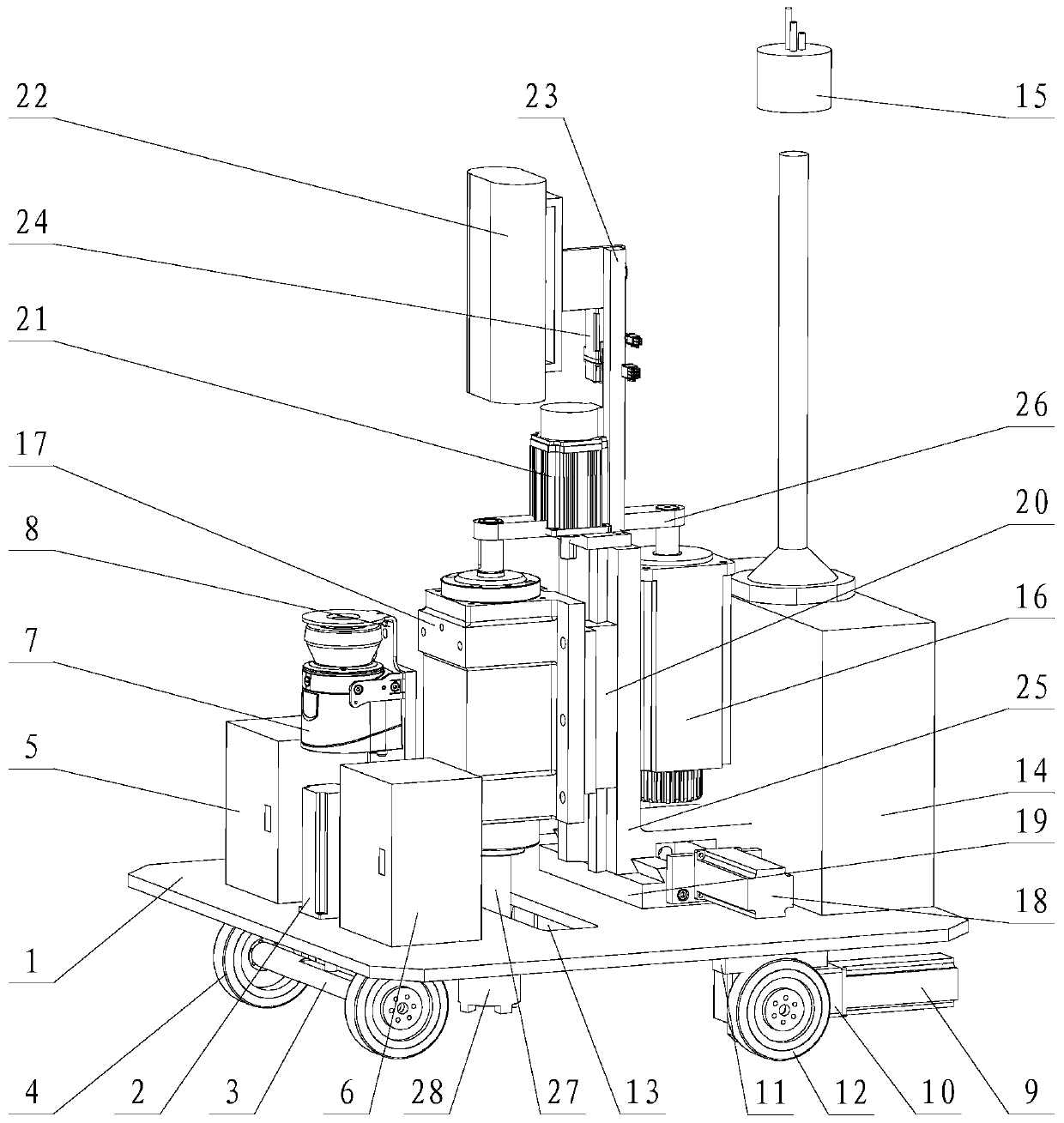

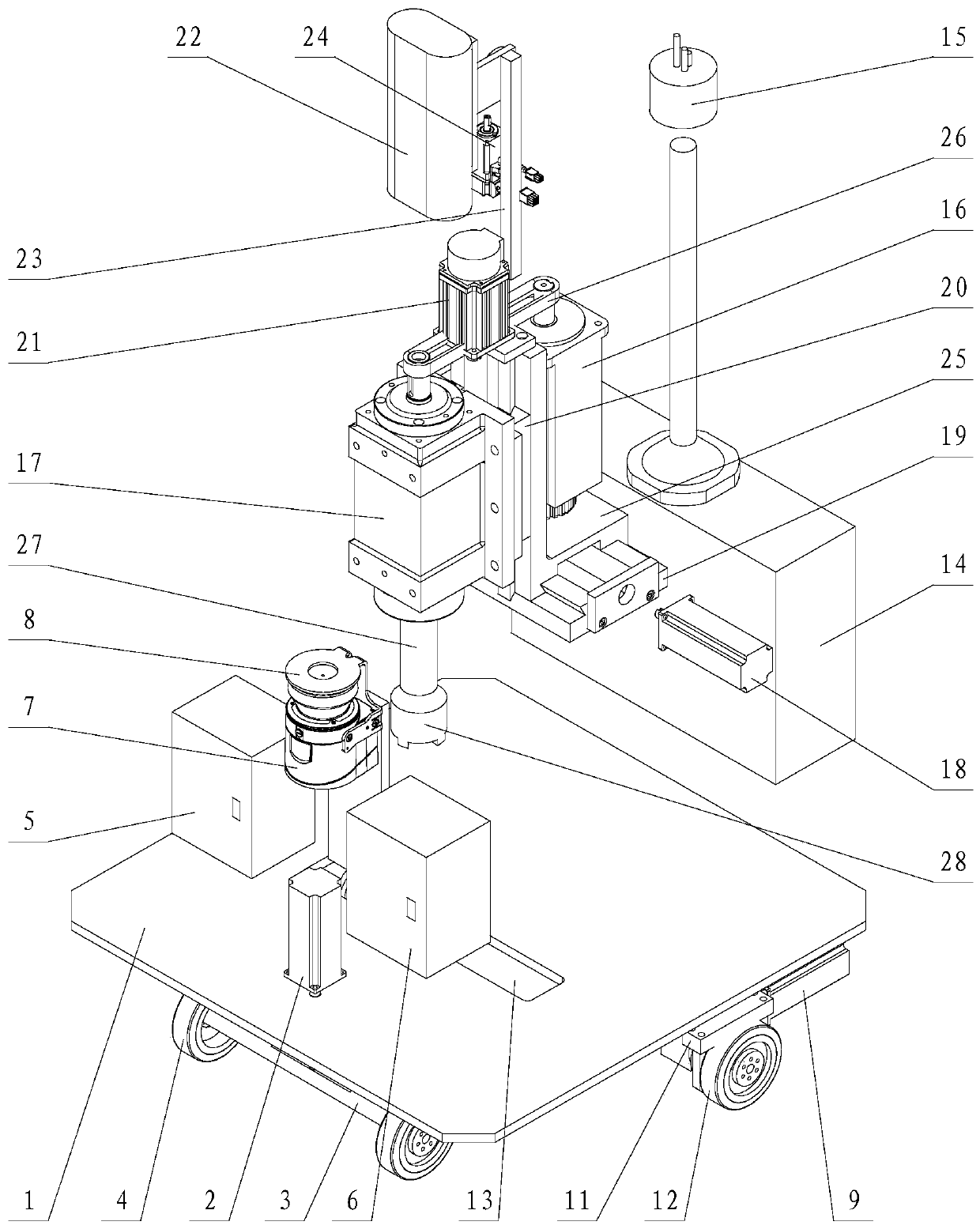

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , figure 2 As shown, the present invention includes a chassis 1, a steering wheel 4, a servo motor control box 5, a lower computer 6, a laser radar 7, a laser radar bracket 8, a driving wheel power source, a driving wheel 12, an electric box 14, a conductive slip ring 15, Spindle power motor 16, boring and milling head 17, slide plate transverse motor 18, slide table transverse base 19, Z-axis longitudinal slide plate 20, Z-axis longitudinal slide plate control motor 21, elevation data receiver 22, elevation data receiver bracket 23, angle control Device 24, sliding table longitudinal base 25, transmission mechanism 26, main shaft 27 and end effector 28, wherein servo motor control box 5, lower computer 6, driving wheel power source, electric box 14 and sliding table horizontal base 19 are respectively installed on the chassis 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com