Underground construction blind shaft drainage system and construction method

A technology for drainage system and underground construction, applied in infrastructure engineering, construction and other directions, can solve the problems of waterproof construction raft reinforcement binding interference, raft concrete pouring construction quality hidden danger, drainage can not be quickly blocked and other problems, to solve the foundation pit Difficulty in drainage, good pumping effect, stability and strong anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

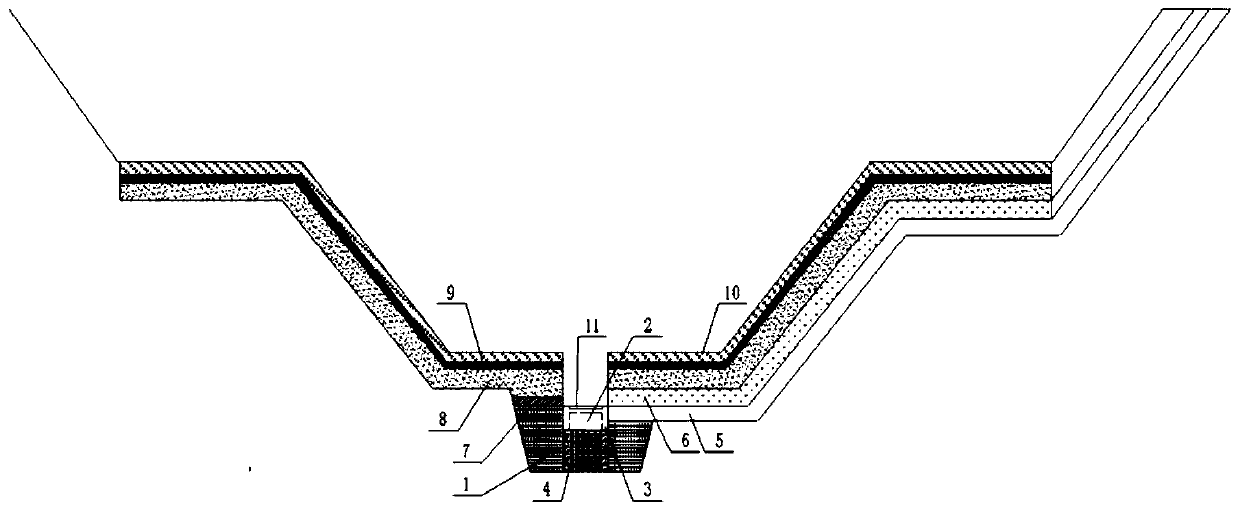

[0026] like figure 1 Shown, a kind of underground construction blind well drainage system comprises the sump 1 dug in the deep foundation pit, the pumping system arranged in the sump 1 and the drainage ditch dug on the top of the deep foundation pit; The water pumping system includes a submersible pump 2, and the submersible pump 2 is covered with a submersible pump protective case 3. The height of the submersible pump protective case is 100mm from the top surface of the sump, and the submersible pump protective case 3 is located on the side of the sump 1. The lower part is provided with water inlet holes 4 at a certain distance, and the upper part of the side of the submersible pump protective shell 3 is provided with outlets for the drainage pipe 5 of the submersible pump to discharge, and the retaining wall around the deep foundation pit is dug to provide a storage tank for drainage The pipe 5 is laid along the retaining wall to the drainage ditch on the top of the deep fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com