Larsen steel sheet pile sinking method for avoiding obstacles in air

A Larsen steel sheet pile and steel sheet pile technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of difficult construction of steel sheet piles, inability to perform ground operations, affecting the construction efficiency and construction quality of steel sheet piles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

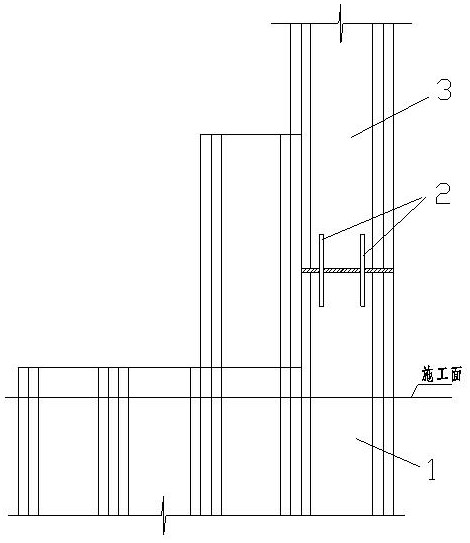

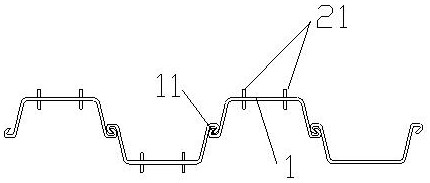

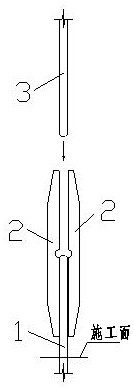

[0019] Example figure 1 , figure 2 and image 3 As shown, the Larsen steel sheet pile sinking method for avoiding obstacles in the air of the present invention comprises the following steps:

[0020] Step 1. Determine the height of the obstacle in the air. Set up the total station on the side with good visibility and about 30-40m away from the horizontal projection of the obstacle. Accurately measure the horizontal distance from the total station to the horizontal projection of the obstacle. The angle between the line of sight of the station instrument and the obstacle in the air and the horizontal line, according to the measured angle and horizontal distance, calculate the height of the obstacle in the air to the construction ground, and determine the airspace for safe operation of construction machinery in the air;

[0021] Step 2: Grinding the groove on both sides of the welded end of the steel sheet pile 1, the groove must avoid the bite of the steel sheet pile 1;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com