Cofferdam structure for water taking head structure construction in river and construction method thereof

A construction method and technology of water intake head, applied in the direction of basic structure engineering, construction, etc., can solve the problems of large adverse impact on the front end of the cofferdam, insignificant pumping effect, impact, etc., and achieve the effect of ensuring the quality of structural construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

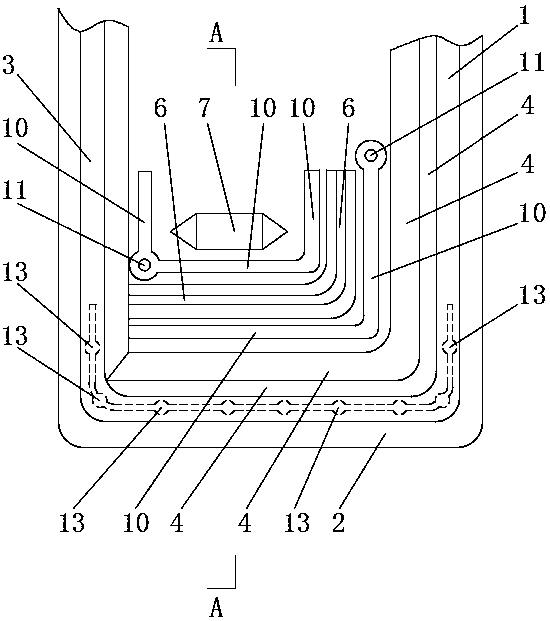

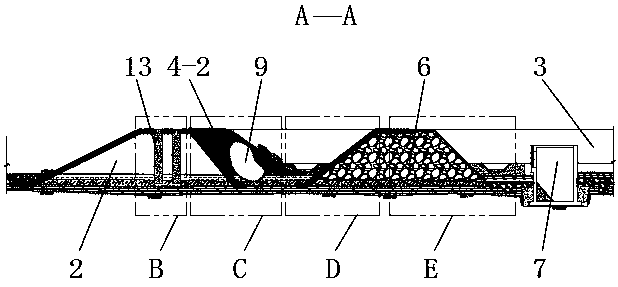

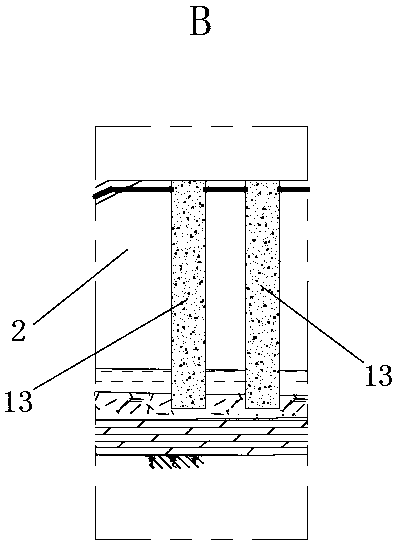

[0027] Such as Figures 1 to 6 As shown, the cofferdam structure used for the construction of the water intake head structure in the river includes the peripheral weir. The peripheral weir includes the upper cofferdam 1, the end cofferdam 2 and the lower cofferdam 3 connected in sequence. The inner side of the end cofferdam 2 Widening cofferdam 4 is provided on the inner side of the front end of upper cofferdam and upper cofferdam 1, composite geomembrane 5 is laid between widening cofferdam 4 and end cofferdam 2 and upper cofferdam 1, widening cofferdam 4 and lower cofferdam 3 is built with an inner cofferdam 6, and the construction area of the water intake head structure 7 is located in the area between the lower cofferdam 3 and the inner cofferdam 6, and the inner cofferdam 6 blocks the front end and the upstream end of the water intake head structure 7, One end of the inner cofferdam 6 is connected with the construction of the lower cofferdam 3, and the slope ratio range...

Embodiment 2

[0030] Such as figure 1 , 2 , 5 to 7, on the basis of Embodiment 1, an open drainage ditch 10 is arranged between the inner cofferdam 6 and the widening cofferdam 4, and the track of the open drainage ditch 10 is parallel to the track of the widening cofferdam 4, and the open drainage ditch The trajectory of 10 blocks the construction trajectory of the inner cofferdam 6. One end of the open drainage ditch 10 is connected to a sump 11. The longitudinal gradient of water diversion of the open drainage ditch 10 is 1% to 3%. The sump 11 is lower than the open drainage ditch 10. The lowest point of the inner cofferdam 6 and the water intake head structure 7 is also provided with an open drainage ditch 10, the track of the open drainage ditch 10 is parallel to the track of the inner cofferdam 6, and the track of the open drainage ditch 10 blocks the front end of the water intake head structure 7, At the upstream end and the downstream end, the open drainage ditch 10 is also connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com